DIVERSITECH DD-3X4 Manual

Operation & Maintenance Manual

Industrial Downdraft Tables

DD-3X4, DD-3X6, DD-3X8

Single Workstation Tables

DD-4X4, DD-4X6, DD-4X8, DD-5X10

Multi Workstation Tables

READ AND SAVE THESE INSTRUCTIONS

Visit our Website for more information on this product

www.diversitech.ca

2500 Alphonse Gariepy, Montreal, Quebec H8T 3M2

OMM-DD-Industrial-Series-104[E N]

Table of Contents

SECTION 1 –SAFETY PRECAUTIONS OF FUME & DUST EXTRACTION/COLLECTION.................................................................................. 1

1.1 Symbols ................................................................................................................................................................................................. 1

1.2 User Responsibility................................................................................................................................................................................ 1

1.2 Fume Extraction Hazards ................................................................................................................................................................... 1

1.3 Dust Collection Hazards..................................................................................................................................................................... 1

SECTION 2 –SPECIFICATIONS .......................................................................................................................................................................... 2

2.1 Model Configurations & Description ............................................................................................................................................... 2

2.2 Product Specifications ....................................................................................................................................................................... 3

2.3 Filter Specifications ............................................................................................................................................................................. 3

2.4 Dimensions............................................................................................................................................................................................ 4

SECTION 3 –SETUP / INSTALLATION................................................................................................................................................................. 5

3.1 To Setup or Install Safely..................................................................................................................................................................... 5

3.2 Un-Packaging ...................................................................................................................................................................................... 5

3.3 Selecting a Location .......................................................................................................................................................................... 5

3.4 Installation............................................................................................................................................................................................. 5

3.5 Preparing Unit for Operation............................................................................................................................................................. 5

SECTION 4 –OPERATION .................................................................................................................................................................................. 6

4.1 To Operate Safely ............................................................................................................................................................................... 6

4.2 Controls................................................................................................................................................................................................. 6

4.3 Pre-Use Checklist ................................................................................................................................................................................. 6

4.4 Principles of Operation....................................................................................................................................................................... 6

4.5 Reverse Pulse Filter Cleaning System............................................................................................................................................... 7

SECTION 5 –MAINTENANCE & TROUBLESHOOTING .................................................................................................................................... 8

5.1 To Maintain this Product Safely......................................................................................................................................................... 8

5.2 Tools Required...................................................................................................................................................................................... 8

5.3 Routine Maintenance Schedule ...................................................................................................................................................... 9

5.4 Filter Replacement.............................................................................................................................................................................. 9

5.5 Troubleshooting Procedure ............................................................................................................................................................. 11

APPENDIX 1A –ELECTRICAL DIAGRAM [230/460/575v] 3-Phase Power ................................................................................................ 12

APPENDIX 2 –MAINTENANCE RECORD ....................................................................................................................................................... 13

APPENDIX 3 –REPLACEMENT PARTS............................................................................................................................................................. 14

APPENDIX 4 –TABLE OPTIONS ....................................................................................................................................................................... 15

Limited Equipment Warranty ....................................................................................................................................................... back cover

Freight Claims ............................................................................................................................................................................. back cover

Return Material Policy ............................................................................................................................................................... back cover

Page 1 of 17

SECTION 1 –SAFETY PRECAUTIONS OF FUME & DUST EXTRACTION/COLLECTION

READ

BEFORE

USE

This manual contains specific cautionary statements related to worker safety. To

protect yourself and others, read this manual thoroughly and follow as directed

before use. Not all hazards of fume & dust control are listed in this manual, and no

hazards related to welding, cutting, grinding, painting, deburring or other

applications are listed. Consult a qualified safety professional

DO

NOT

USE

Do not use this equipment:

To extract smoke or fumes above 180°F / 82°C.

To extract combustible dusts, liquid vapors, aggressive fumes such as acids.

If the power cord has been damaged or ground (third prong) removed.

Without a filter.

1.1 Symbols

This manual uses

several symbols to

highlight specific

hazards. Be familiar

with these symbols

and when you see

them in this manual,

read adjoining

warning text to avoid

the hazard.

WARNING!

DANGER!

ELECTRIC

SHOCK

MOVING

PARTS

HOT

PARTS

1.2 User Responsibility

Improper use can be hazardous.

It is your responsibility to follow all applicable ANSI, OSHA, UL, CSA, National & Local Fire Codes, and other

regulatory guidelines covering the safe use of equipment that extracts fumes, collects dusts, and exhausts filtered

air either indoors or outdoors.

Before use, inspect the unit for damage and verify it is working properly.

Only qualified persons should install, operate, maintain, or repair this unit.

Do not modify or repair the unit with parts or accessories not supplied by the manufacturer.

Consult filter manufacturer’s instructions for filter use and reuse, including instructions for cleaning.

1.2 Fume Extraction Hazards

Breathing smoke, fumes, or dusts produced in applications such as welding, cutting, grinding, painting, deburring

are hazardous to user’s health. Proper ventilation or use of well maintained fume extraction and/or dust collection

equipment helps the user avoid these hazards.

Breathable contaminants may not be visible or have an odor.

Stop operation and leave the area immediately if 1) breathing becomes difficult, 2) experience dizziness, 3)

impaired vision, 4) or eye/nose/mouth irritation.

1.3 Dust Collection Hazards

Dusts from many welding, cutting, grinding, painting, or deburring applications can be combustible.

Do not use or install equipment where any potential for combustible fumes or dusts are present, until a qualified

person has indicated it is safe to do so.

Never use or install equipment where the potential for combustible fumes or dusts are present without a

fire/explosion protection system.

If you are unsure if the product you purchased is correct for your application, call Diversi-Tech at 1-800-361-3733.

Page 2 of 17

SECTION 2 –SPECIFICATIONS

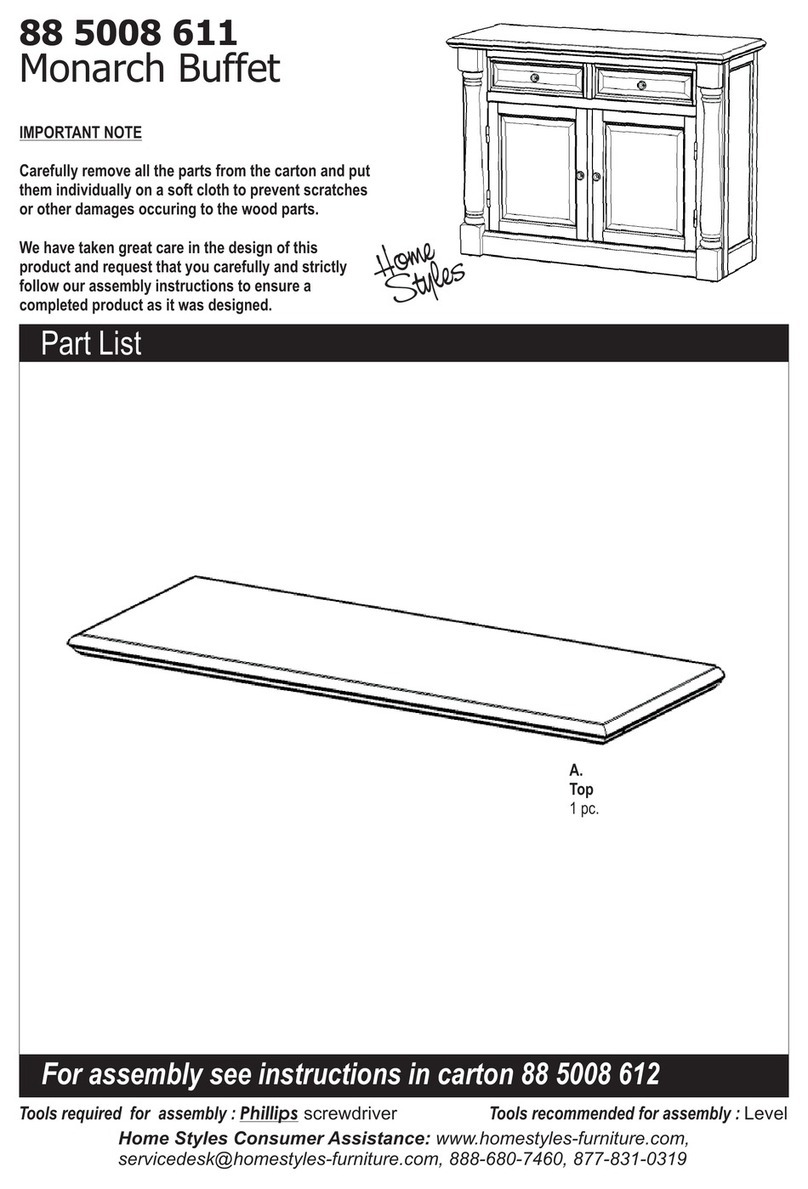

2.1 Model Configurations & Description

Open Works surface

Side/Back Walls

Clean Air Workstation

DD-3X4

DD-3X6

DD-3X8

DD-4X4

DD-4X6

DD-4X8

DD-5X10

Page 3 of 17

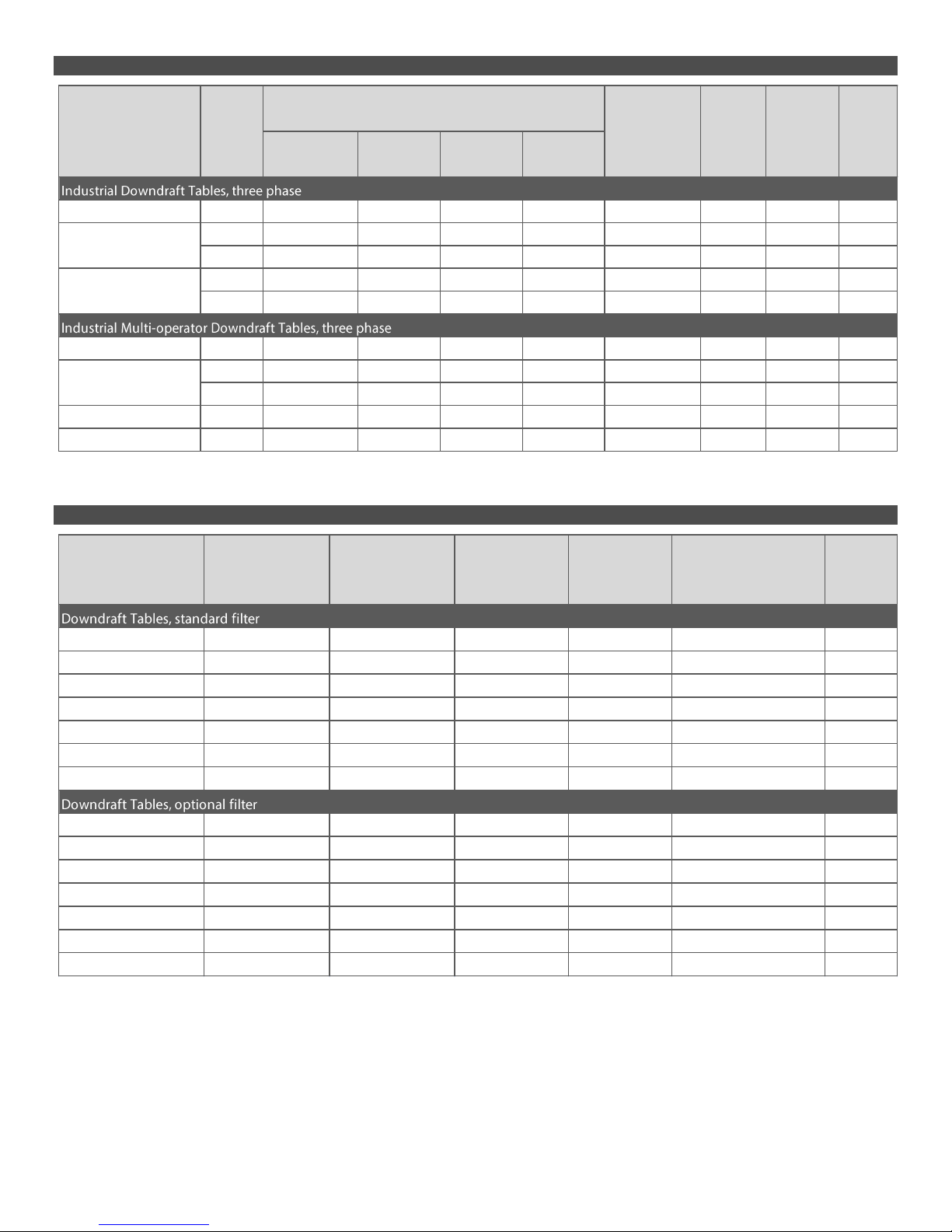

2.2 Product Specifications

2.3 Filter Specifications

For information on inspecting and cleaning filter, or purchasing replacement filters, contact DiversiTech at 1-800-361-3733.

Avg.

Avg. Airflow Static Face Noise

Motor Phase @230V @460V @575V Pressure Pressure Velocity @5ft.

(H.P.) (hz) (amps) (amps) (amps) (CFM) (in.) (FPM) (dB)

DD-3X4 5.0 3P / 60Hz 12.0 5.8 4.6 4300 4.0 450 79

5.0 3P / 60Hz 12.0 5.8 4.6 4300 4.0 325 79

7.5 3P / 60Hz 17.2 8.6 7.0 4800 4.0 375 81

7.5 3P / 60Hz 17.2 8.6 7.0 4800 4.0 330 81

10.0 3P / 60Hz 24.0 12.0 9.6 5050 4.0 380 83

DD-4X4 5.0 3P / 60Hz 22.0 11.0 9.0 4300 4.0 425 79

7.5 3P / 60Hz 15.2 7.6 6.1 4800 4.0 325 79

10.0 3P / 60Hz 24.0 12.0 9.6 5050 4.0 375 85

DD-4X8 10.0 3P / 60Hz 24.0 12.0 9.6 5050 4.0 300 81

DD-5X10 15.0 3P / 60Hz 42.0 21.0 17.0 8600 4.0 330 81

Model

Power

DD-3X8

DD-3X6

DD-4X6

Filter Part Filter Filter Filter Qty.

Type Number Size Area Efficiency Filters

(sq. ft.) Required

DD-3X4 Nanofiber S-3X4-0024 16" w/flange 140 99.99% @ 0.5 micron 2

DD-3X6 Nanofiber S-3X6-0024 16" w/flange 140 99.99% @ 0.5 micron 2

DD-3X8 Nanofiber S-3X8-0024 16" w/flange 140 99.99% @ 0.5 micron 4

DD-4X4 Nanofiber S-4X4-0024 16" w/flange 140 99.99% @ 0.5 micron 2

DD-4X6 Nanofiber S-4X6-0024 16" w/flange 140 99.99% @ 0.5 micron 2

DD-4X8 Nanofiber S-4X8-0024 16" w/flange 140 99.99% @ 0.5 micron 4

DD-5X10 Nanofiber S-5X10-0024 16" w/flange 140 99.99% @ 0.5 micron 6

DD-3X4 Spunbond Poly S-3X4-0002 16" w/flange 55 99.7% @ 0.5 micron 2

DD-3X6 Spunbond Poly S-3X6-0002 16" w/flange 55 99.7% @ 0.5 micron 2

DD-3X8 Spunbond Poly S-3X8-0002 16" w/flange 55 99.7% @ 0.5 micron 4

DD-4X4 Spunbond Poly S-4X4-0002 16" w/flange 55 99.7% @ 0.5 micron 2

DD-4X6 Spunbond Poly S-4X6-0002 16" w/flange 55 99.7% @ 0.5 micron 2

DD-4X8 Spunbond Poly S-4X8-0002 16" w/flange 55 99.7% @ 0.5 micron 4

DD-5X10 Spunbond Poly S-5X10-0002 16" w/flange 55 99.7% @ 0.5 micron 6

Model

Page 4 of 17

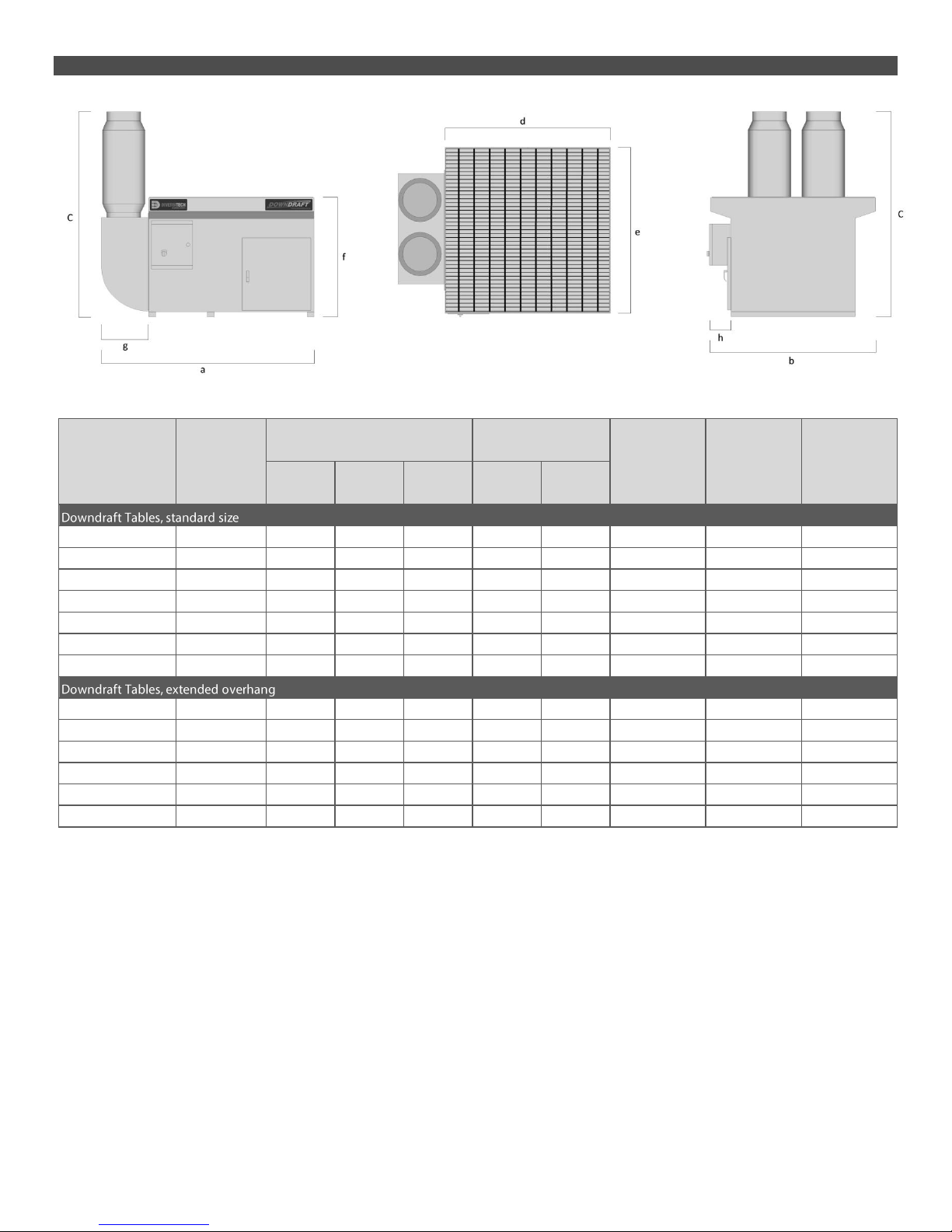

2.4 Dimensions

Exhaust Table

Diameter Width Height Length Width Length Height Exhaust

(in.) [a] [C ] [b] [d] [e] [f] [g] [h]

DD-3X4 10" x 2 49 68.5 43 48 42 36 14 6"

DD-3X6 10" x 2 73 68.5 43 72 42 36 14 6"

DD-3X8 10" x 2 97 68.5 43 96 42 36 14 6"

DD-4X4 10" x 2 49 68.5 49 48 48 36 14 6" x 2

DD-4X6 10" x 2 73 68.5 49 72 48 36 14 6" x 2

DD-4X8 10" x 2 97 68.5 49 96 48 36 14 6" x 2

DD-5X10 10" x 2 121 68.5 31 120 30 36 34 12" x 2

DD-3X4-EO 10" x 2 49 68.5 49 48 48 36 14 12"

DD-3X6-EO 10" x 2 73 68.5 49 72 48 36 14 12"

DD-3X8-EO 10" x 2 97 68.5 49 96 48 36 14 12"

DD-4X4-EO 10" x 2 49 68.5 61 48 60 36 14 12" x 2

DD-4X6-EO 10" x 2 73 68.5 61 72 60 36 14 12" x 2

DD-4X8-EO 10" x 2 97 68.5 61 96 60 36 14 12" x 2

Model

Overhang

Footprint (in.)

Worksurface (in.)

Page 5 of 17

SECTION 3 –SETUP / INSTALLATION

3.1 To Setup or Install Safely

Do not place unit near flammables or combustible surfaces.

Refer to SECTION 2: Specifications, to know the electrical requirements of the unit you are

installing and ensure adequate input power that is properly sized, rated, and protected.

This unit must be grounded for safe operation.

3.2 Un-Packaging

1. Immediately upon receiving the unit, carefully examine the carton for damage during transit.

2. Remove packing material.

3. Avoid tipping or inverting during handling.

4. The item serial number, model, and electrical ratings are listed on the nameplate. Record this information in the

Maintenance Record provided on page 10, or your own preventative maintenance system.

3.3 Selecting a Location

Choose a location where the unit will be used, near the operator.

Choose a location sufficiently close to a grounded power source.

3.4 Installation

Electrical Connection:

oThis unit requires 3-phase (230/460/575V) direct connection.

oSee APPENDIX 1: Electrical Diagram for wiring instructions.

oHave a certified electrician install electrical connection according to local regulations.

oAll three power leads must be connected to L1, L2 and L3 on the contactor.

oThis unit must be grounded for safe operation.

oIf on start-up the downdraft table seems to be lacking performance or the table sounds very loud, the

motor is most likely running in the reverse direction. Reversing leads L1 and L3 will reverse motor rotation in

the right direction.

oCorrect direction of BLOWER WHEEL ROTATION = CLOCKWISE

Compressed Air:

oSupply 80-90 PSI of CLEAN, DRY, compressed air to the bulkhead bushing on the side of the unit.

oThe air tank in the downdraft table is fabricated to allow a maximum of 90 PSI, DO NOT attempt supplying

air pressure greater than 90 PSI without a properly installed pressure regulator.

oMoisture in airline can damage filter(s); use an air dryer if required.

Special Installation steps for table options:

oPlasma Cutting Packages & Kits

oSpray Painting Packages & Kits

3.5 Preparing Unit for Operation

Remove all packaging and shipping protection before use, in accordance with SECTION 3.2: Un-Packaging

Select a location appropriate for use that complies with all safety instructions contained herein, and SECTION 3.3:

Selecting a Location.

Confirm installation of correct input power source, compressed air, and any special installation requirements, in

accordance with SECTION 3.3: Installation. Look at the manufacturer’s label located on the exterior of the unit and

ensure the source is correctly sized in terms of Voltage and Amperes.

Prior to use in your application, turn the unit ON, and perform a function test. To do so:

oTurn switch to ON position

oLOOK: Is the unit level, stable, and that nothing is obstructing the extraction path.

oLISTEN: Does the motor and suction sound smooth and within expected volumes.

oFEEL: Place your hand on top of the unit and sense for unexpected vibration. Place you hand in front of

the intake surface and sense for expected level(s) of suction.

Inform all potential users of this equipment where they may find and review this manual.

Page 6 of 17

SECTION 4 –OPERATION

4.1 To Operate Safely

Read and understand SECTION 1: Safety Precautions and SECTION 4: Operation before use

Read and understand all Material Safety Data Sheets and Manufacturer’s instructions of all

process materials, consumables, and equipment used in conjunction with this equipment.

Keep away from all mechanical moving parts including motor, gears, and other pinch points.

Do not use product without first confirming if a Spark Arrestor is required and installed for the type

of dust, or fumes you are extracting and/or collection. If you are unsure, call a DiversiTech

representative at 1-800-361-3733.

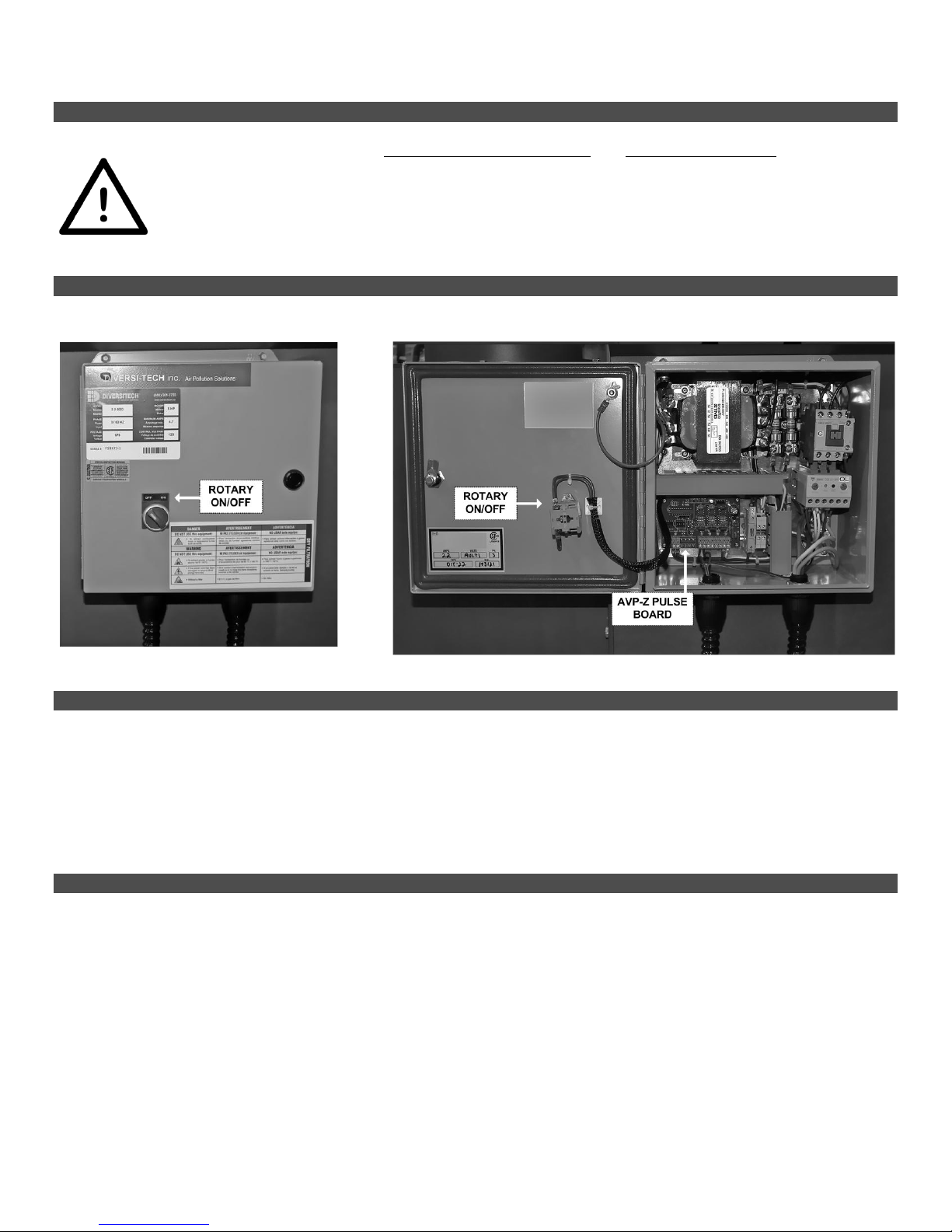

4.2 Controls

4.3 Pre-Use Checklist

Prior to use in your application, turn the unit ON, and perform a function test. To do so:

oTurn switch to ON position

oLOOK: Is the unit level, stable, and that nothing is obstructing the extraction path.

oLISTEN: Does the motor and suction sound smooth and within expected volumes.

oFEEL: Place your hand on top of the unit and sense for unexpected vibration. Place you hand in front of

the intake surface and sense for expected level(s) of suction.

Inform all potential users of this equipment where they may find and review this manual.

4.4 Principles of Operation

This product is designed to capture and clean smoke and dust from medium & heavy duty welding, soldering, and grinding

applications. When operating, air is drawn in through the table surface grating, passes through spark-arrestor baffling, then

through the table’s filtration system, and exhausted through the side stack exhaust.

This product consists of basic components:

1. Protective table surface grating(s)

2. Multi-stage spark-Arrestance baffling

3. Table cabinet/module(s)

4. Cartridge Filter(s)

5. Motor/Blower Assembly

6. Reverse pulse filter cleaning system

7. Dust Drawer

Page 7 of 17

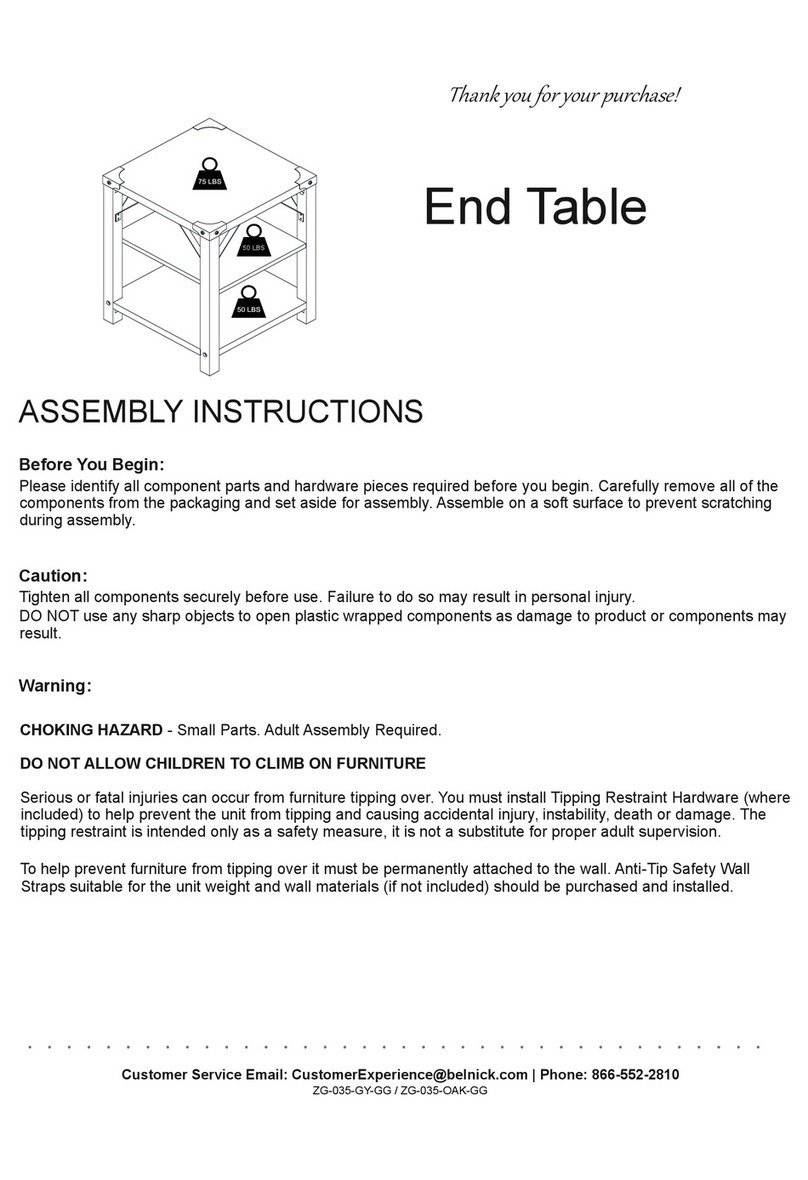

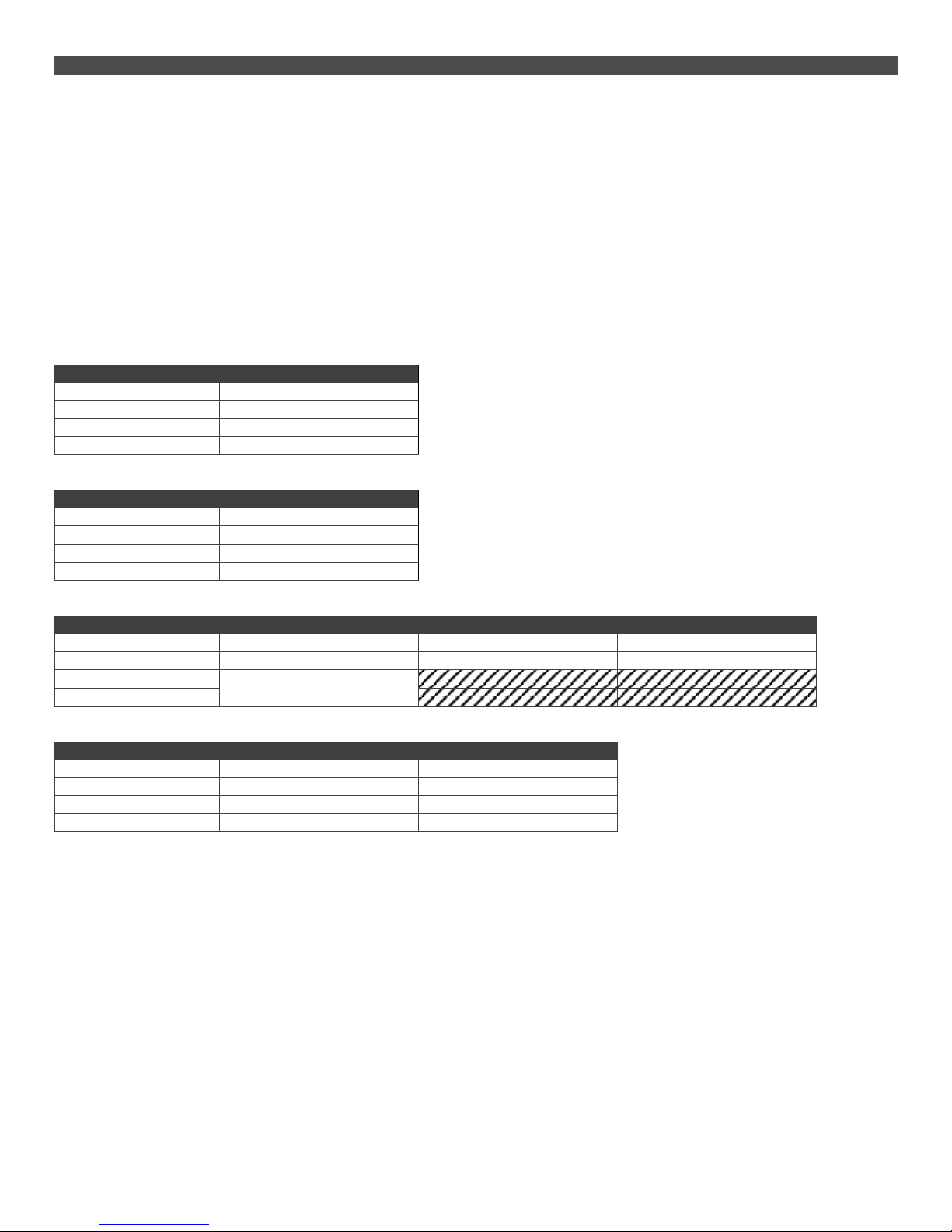

4.5 Reverse Pulse Filter Cleaning System

The downdraft table is equipped with a reverse pulse automatic filter cleaning system. This system is controlled by a PC

board inside the control box (Labelled “AVP-Z”). Changing the dip switch settings on the AVP-Z board, allows you to

control:

1. Pulsing online or offline

2. Number of pulses

3. Pulse duration

Solenoid operated air valves discharge large blasts of air through the filter cartridges thus dislodging particles embedded in

the filter media. The particles fall into a dust drawer located below the cartridge. The angled v-shaped baffles above the

drawer prevent the dust from re-entering the cabinet when the machine is turned on.

Neglecting to pulse the filter regularly will reduce filter life.

Factory Setting

DIP SWITCH #

FACTORY SETTING

This factory setting allows for online & offline

pulsing. 1 x 0.5 second air blast every 45 seconds,

while online, and 20 x 0.5 second air blast when

offline.

1

ON

2

OFF

3

ON

4

OFF

Recommended for Aluminum Dust

DIP SWITCH #

FACTORY SETTING

This factory setting allows for only offline pulsing,

20 x 0.5 second air blast each time the machine is

switched off.

1

OFF

2

OFF

3

ON

4

OFF

Custom Application Settings

DIP SWITCH #

PURPOSE

LEFT

RIGHT

1

Mode

Online & Offline

Offline Only

2

Duration

0.5 second

1 second

3

Number of Pulses

4

# OF PULSES

DIP SWITCH #3

DIP SWITCH #4

5

OFF

OFF

10

OFF

ON

20

ON

OFF

30

ON

ON

Page 8 of 17

AVP-Z Board

SECTION 5 –MAINTENANCE & TROUBLESHOOTING

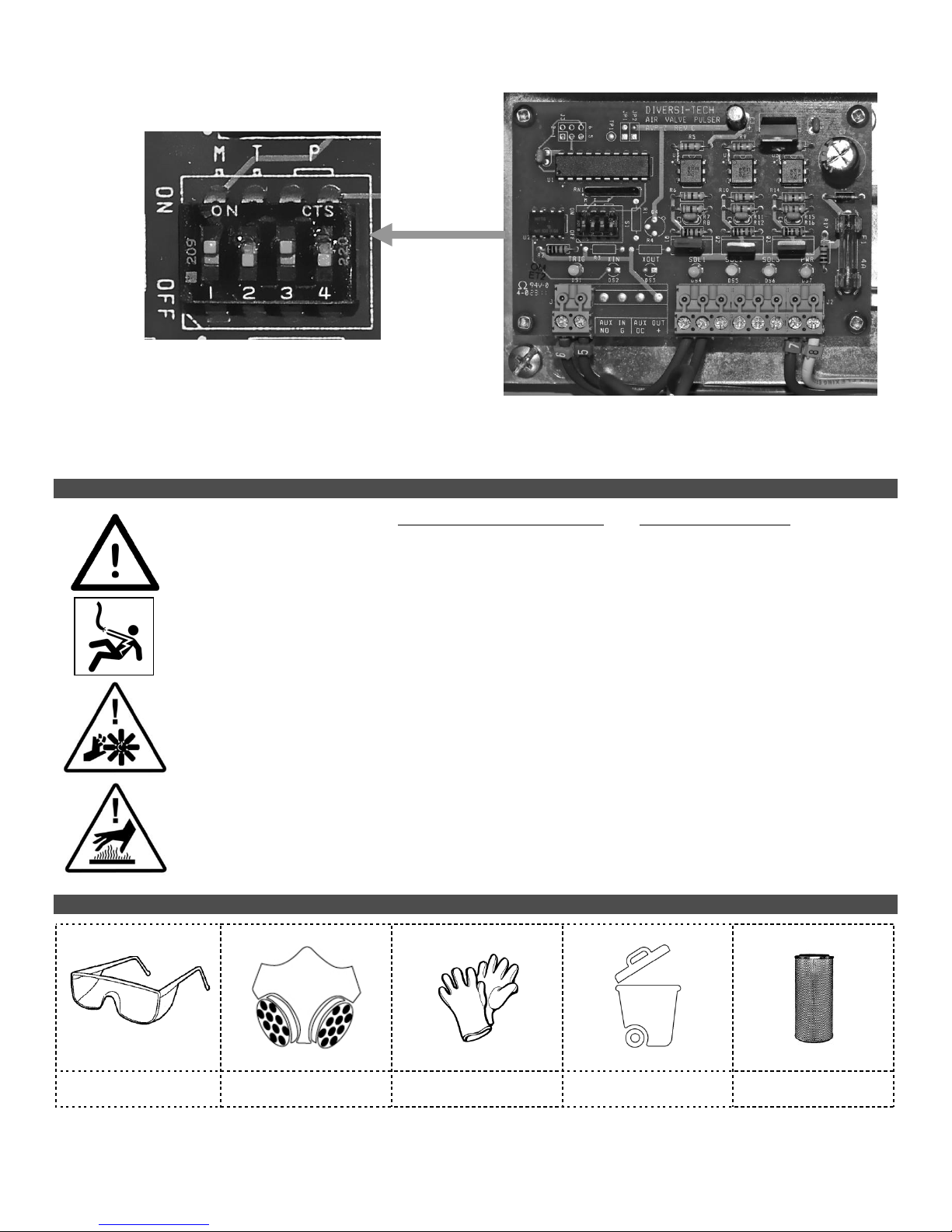

5.1 To Maintain this Product Safely

Read and understand SECTION 1: Safety Precautions and SECTION 4: Operation before

maintenance.

Do not breathe the dust collected from product while changing/cleaning filters or performing

maintenance on this product.

Disconnect power before performing any maintenance on unit, including filter inspection. The

input power to this unit is high voltage, and touching any live electrical parts can cause fatal

shocks or severe burns. Do not touch live electrical parts.

Keep away from all mechanical moving parts including motor, gears, and other pinch points

while operating.

Operating this unit causes some parts to heat to a point that will burn bare hands. Before

maintenance allow parts to cool, or use proper tools and personal protection equipment during

maintenance.

5.2 Tools Required

EYE

PROTECTION

RESPIRATOR

GLOVES

WASTE CONTAINER

REPLACEMENT FILTER

(if required)

Page 9 of 17

5.3 Routine Maintenance Schedule

The manufacturer recommends the following routine maintenance based on light-duty use in normal operating conditions.

Service more frequently if the unit is used in severe conditions.

Frequency

Manual Reference

Pre-Use

Perform pre-use inspection to ensure operating correctly.

If you application involves grinding, or any process that produces heat/sparks –lift the top

grate and visually confirm that metal-mesh pre-filters (spark arrestors) are correctly seated

on the baffle tray, and that no holes are present.

4.3

Every (1) Week or 20 Operating Hours - Empty Dust Drawer/Clean Surface

Remove and wipe clean surface matting (if used). Remove dust drawer and deposit

accumulated particulate in appropriate waste container. Refer to local regulations

regarding disposal procedures as some captured contaminants may be flammable,

explosive, or toxic.

Particles and stray material on the surface should be blown into the table towards the filter

using compressed air. If a cushion grid mat (option) is used, direct particles into the table

using a broom or brush.

Recommended frequency is one week, but may be less or more depending of application.

Every (4) Week or 80 Operating Hours –Inspect/Clean Cabinet

Remove and wipe down dust drawer, baffle trays, and metal mesh prefilters, depositing

accumulated particulate in appropriate waste container. Refer to local regulations

regarding disposal procedures as some captured contaminants may be flammable,

explosive, or toxic.

Inspect, and clean if necessary the cabinet interior and dust drawer slats.

As Required –Replace Filter

1. Replace Filter , see SECTION 5.4: Filter Replacement for instruction

Every (12) months Inspect Basic Components

1. Clean unreadable labels and exterior surfaces

2. Cabinet: Look for loose wiring.

5.4 Filter Replacement

Warning

Do not attempt to clean filters containing hazardous materials; refer to local regulations

regarding disposal procedures as some captured contaminants may be flammable, explosive,

or toxic.

Cleaning cartridge filters with compressed air, water, or solvents can damage/destroy the filter

media. Always check the manufacturer’s instructions and specifications prior to cleaning.

Nanofiber / Paper-pleated filters

Do not wet or clean the cartridge with any liquid, as it may cause the forming of unwanted

blockage on the filter media.

Spunbond-poly filters

Cleaning should be carried out on water-soluble materials only.

Hydrocarbons may not be removable.

The use of solvents may attack certain components of the filter. Consult the instructions and

specifications prior to cleaning.

Page 10 of 17

The table’s reverse-pulse filter system works to extend the life expectancy of your filter(s). The actual usable life of the filter

varies greatly on application,

density, particle size, humidity, oil, but the typical range when pulsed regularly is 6-18 months.

As part of routine maintenance, it is important to visually inspect the filter. Replace the filter if you see:

1.

Overloading or accumulation of particles

2.

Rips, tears, or warping of filter media

3.

Decreased table performance due to excessive static build up

To remove the filter, follow this 3-step procedure:

1. Open the cabinet door

2. Unhook barrel bolt latch

3. Slide filter cartridge(s) out

Page 11 of 17

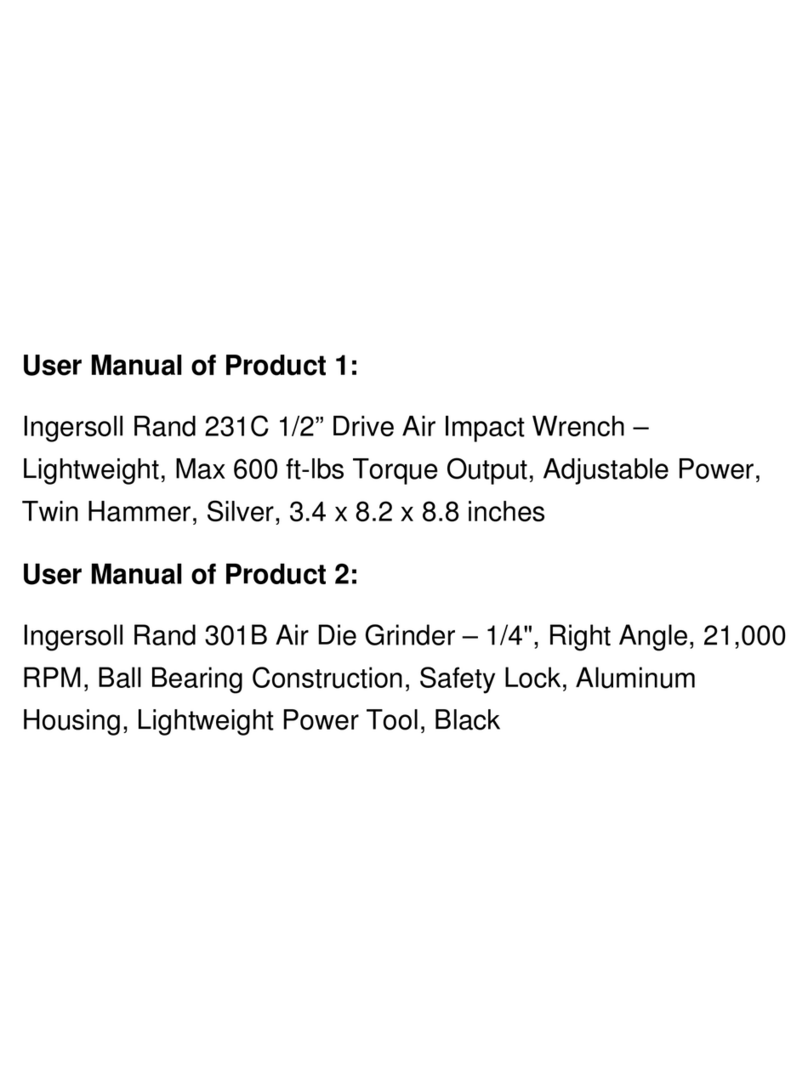

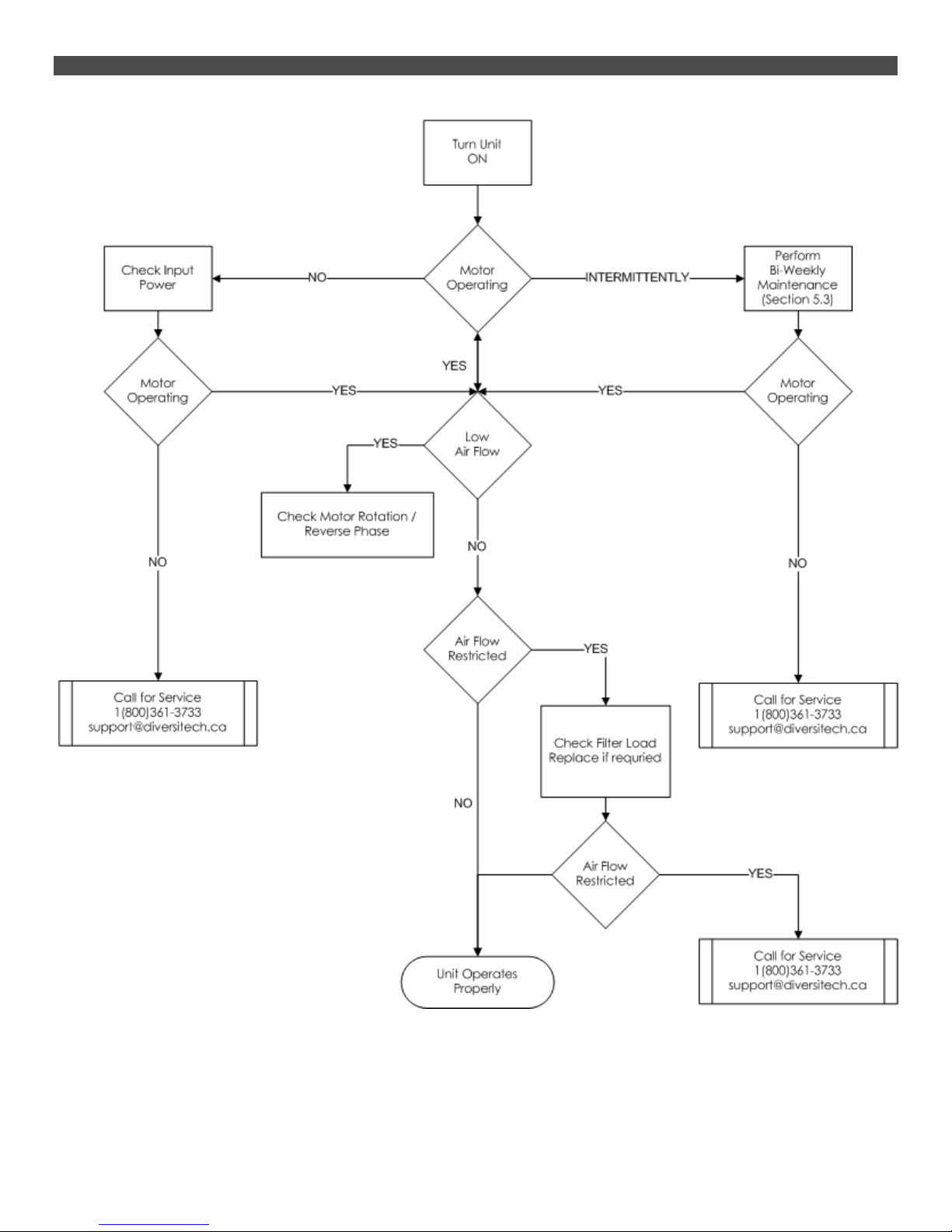

5.5 Troubleshooting Procedure

Page 12 of 17

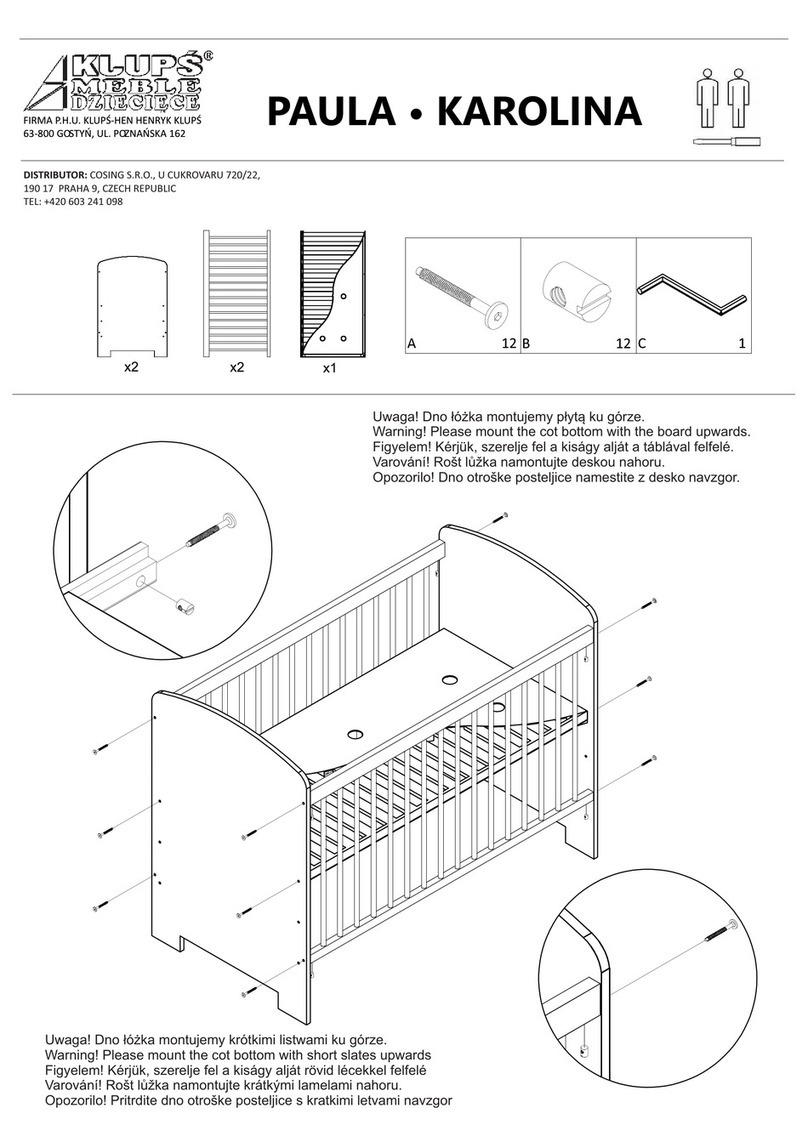

APPENDIX 1A –ELECTRICAL DIAGRAM [230/460/575v] 3-Phase Power

ELECTRIC

SHOCK

HAZARD

Disconnect power before performing any maintenance on unit, including filter

inspection. The input power to this unit is high voltage, and touching any live

electrical parts can cause fatal shocks or severe burns. Do not touch live electrical

parts.

Page 13 of 17

APPENDIX 2 –MAINTENANCE RECORD

DiversiTech Inc. authorizes this page to be photocopied or otherwise reproduced as needed for management of

maintenance records.

MANUFACTURER:

DIVERSITECH INC.

MODEL NO:

FRED

SERIAL NO:

SERVICE LOCATION:

CONTROL NO:

Date

Description of Service

Serviced By

Location

Comments

Only use manufacturer approved replacement parts on this unit.

Page 14 of 17

APPENDIX 3 –REPLACEMENT PARTS

Industrial Downdraft Tables (dry)

ITEM NUM B ER D ESC RIP TION

S-DXD-0907 3/4" Air Valve, DD ●●●●●●●

S-DXD-0808 12V SOLINOID VALVE ●●●●●●●

S-DXD-0106 AVP-Z pulse cleaning control board ●●●●●●●

S-C ONE-0074 5.0HP Motor C one, plastic ● ● ●

S-C ONE-0063 7.5/10HP Motor Cone, steel ● ● ● ●

S-C ONE-0064 #N/A ●

S-WHEL-0003 5.0HP C omposite Blower Wheel, backward inclined ● ● ●

S-WHEL-0010 7.5HP Aluminum Blower Wheel, backward inclined ● ● ●

S-WHEL-0011 10.0HP Aluminum Blower Wheel, backward inclined ● ● ●

S-WHEL-0012 15.0HP Aluminum Blower Wheel, backward inclined ●

S-184T-050T2 5.0HP TEFC MOTOR [230/3/60] ● ● ●

S-184T-050T4 5.0HP TEFC MOTOR [460/3/60] ● ● ●

S-184T-050T5 5.0HP TEFC MOTOR [575/3/60] ● ● ●

S-213T-075T2 7.5HP TEFC MOTOR [230/3/60] ● ● ●

S-213T-075T4 7.5HP TEFC MOTOR [460/3/60] ● ● ●

S-213T-075T5 7.5HP TEFC MOTOR [575/3/60] ● ● ●

S-215T-100T2 10.0HP TEFC Motor [230/3/60] ● ● ●

S-215T-100T4 10.0HP TEFC Motor [460/3/60] ● ● ●

S-215T-100T5 10.0HP TEFC Motor [575/3/60] ● ● ●

S-254T-150T2 15.0HP TEFC Motor [230/3/60] ●

S-254T-150T4 15.0HP TEFC Motor [460/3/60] ●

S-254T-150T5 15.0HP TEFC Motor [575/3/60] ●

DD-5X10

DD-3X4

DD-3X6

DD-3X8

DD-4X4

DD-4X6

DD-4X8

Page 15 of 17

APPENDIX 4 –TABLE OPTIONS

1. When ordering, please replace #X# with table size.

Part # Description

DD-3X4

DD-3X6

DD-3X8

DD-4X4

DD-4X6

DD-4X8

DD-5X10

A-#X#-SBW-01 Side & back walls, powder coated mild steel ● ● ● ●

A-#X#-SBW-02 Hinged right side & fixed back/left side walls, powder coated mild steel ● ● ●

A-#X#-SBW-04 Hinged left/right side walls & fixed back wall, powder coated mild steel ● ● ●

A-#X#-SBW-11 Side & back walls, 4" steel frame with clear lexan insert ● ● ●

A-#X#-SBW-12 Hinged right wall & fixed back/left walls, 4" steel frame w/ clear lexan insert ● ● ●

A-#X#-SBW-14 Hinged left/right side walls & fixed back, 4" steel frame w/ clear lexan insert ● ● ●

A-#X#-SMW-01 Side walls & middle seperator, powder coated mild steel ● ● ● ●

A-#X#-SMW-11 Side walls & middle seperator, 4" steel frame with clear lexan insert ● ● ● ●

O-#X#-LK-24F 24" Dust & Vapor Proof Flourescent Light Kit ●●●

O-#X#-LK-48F 48" Dust & Vapor Proof Flourescent Light Kit ● ● ●● ●● ●●

O-#X#-BDH Backdraft hood w/sliding gates ● ● ●

O-#X#-XA Extractor Arm w/bracket, flexhose, and blast gate (6" x 10') ●●●●●●●

O-#X#-MH Minihelic gauge ●●●●●●●

O-#X#-SC 3" Swivel castors, set ●●●●●●●

O-#X#-MR Mirror table ●●●●●●●

AK-#X#-ODOR Odor Kit Adds: V-bank module w/ A40 activated carbon granules ● ● ● ● ● ●

AK-#X#-SSH Kit adds: Side stack silencer w/HEPA filter and frame ●●●●●●●

A-#X#-OPT Set of two Opti-flow grates for ●●●●●●●

A-#X#-CGM-B Blue cushion grid matting ●●●●●●●

A-#X#-GL Grounding lug ●●●●●●●

Page 16 of 17

NOTES

Page 17 of 17

NOTES

Limited Equipment Warranty

All Diversi-Tech units are warranted to be free from defects in material for a

period of two years from the date of purchase. Diversi-Tech Inc. will repair, at

our option, any defective parts returned to the manufacturer’s plant in

Montreal - Quebec freight prepaid- which fail during the warranty period.

This warranty is limited to replacement parts ONLY, subject to on site or in

house evaluation of defective materials and does not apply to any personal

liability or property loss that occurs due to the use or installation of this

equipment.

FREIGHT CLAIMS

All Diversi-Tech units are sold ex-plant, Montreal, Qc., Canada. Therefore, it is

the user’s responsibility to file any freight claims for obvious or concealed

damages which developed in transit from Montreal to your location or when

drop shipped.

RETURN MATERIAL POLICY

Prior to the return of material, for whatever reason, a return manufacturing

authorization number (RMA#) is required from the Diversi-Tech production

control department. This procedure is necessary for proper control and

handling of returned materials. Fax us or call to obtain the RMA.

All material must be returned prepaid. Credit will be given for returns for

warranty replacement. Freight collect shipments will not be accepted. It is

the shipper’s responsibility to insure that material being returned to Diversi-

Tech is adequately packaged for shipment to preclude damages.

2500 Alphonse Gariepy

Montreal, Quebec

H8T 3M2

Visit our Website for more information of this product

www.diversitech.ca

Tel: 1.800.361.3733

Fax: 1.514.631.9480

This manual suits for next models

6

Table of contents

Other DIVERSITECH Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Home Styles

Home Styles 88502395 C quick start guide

Simpli Home

Simpli Home WyndenHall Brooklyn+Max AXCRAMH20-HIC manual

m-Dimension

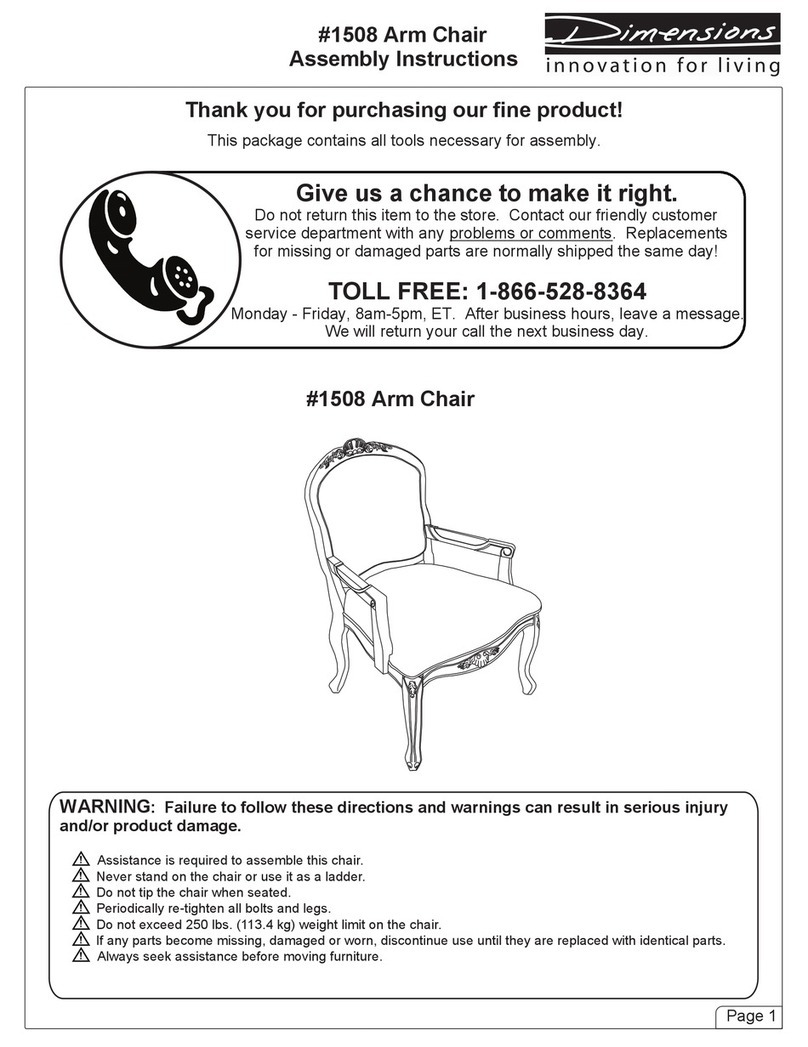

m-Dimension 1508 Assembly instructions

GFW

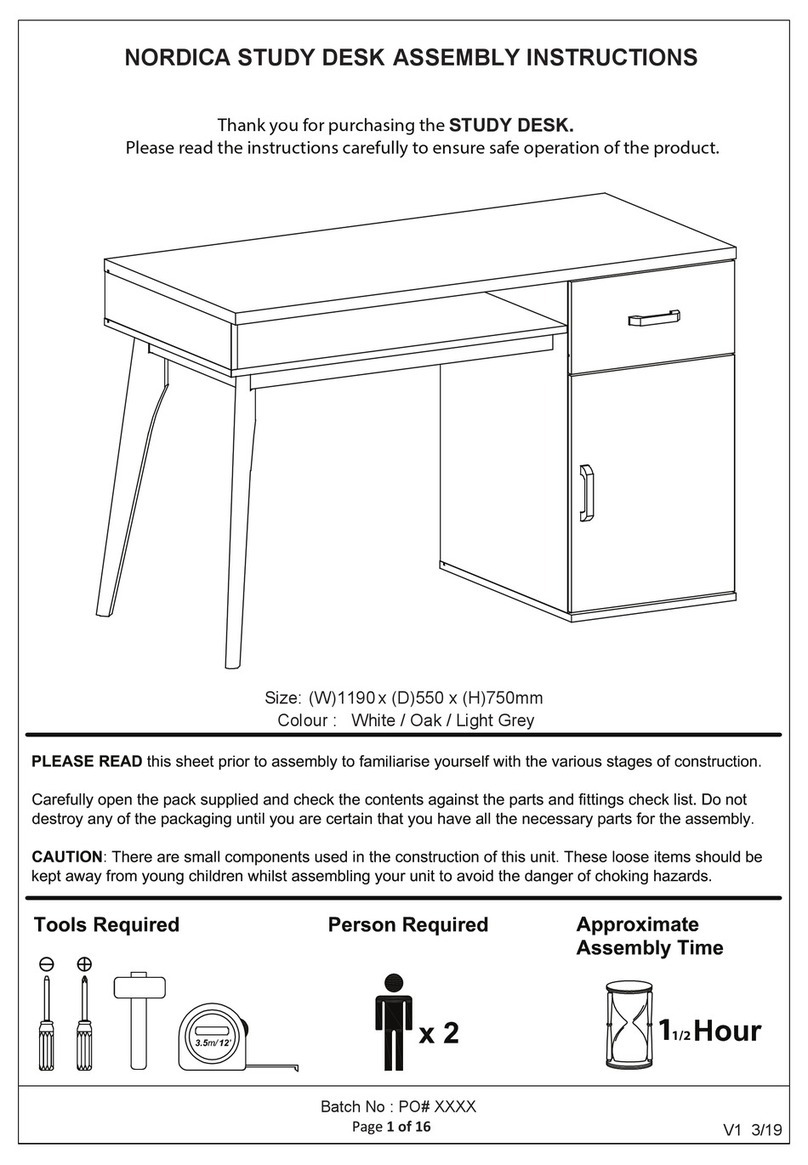

GFW NORDICA STUDY DESK Assembly instructions

home star

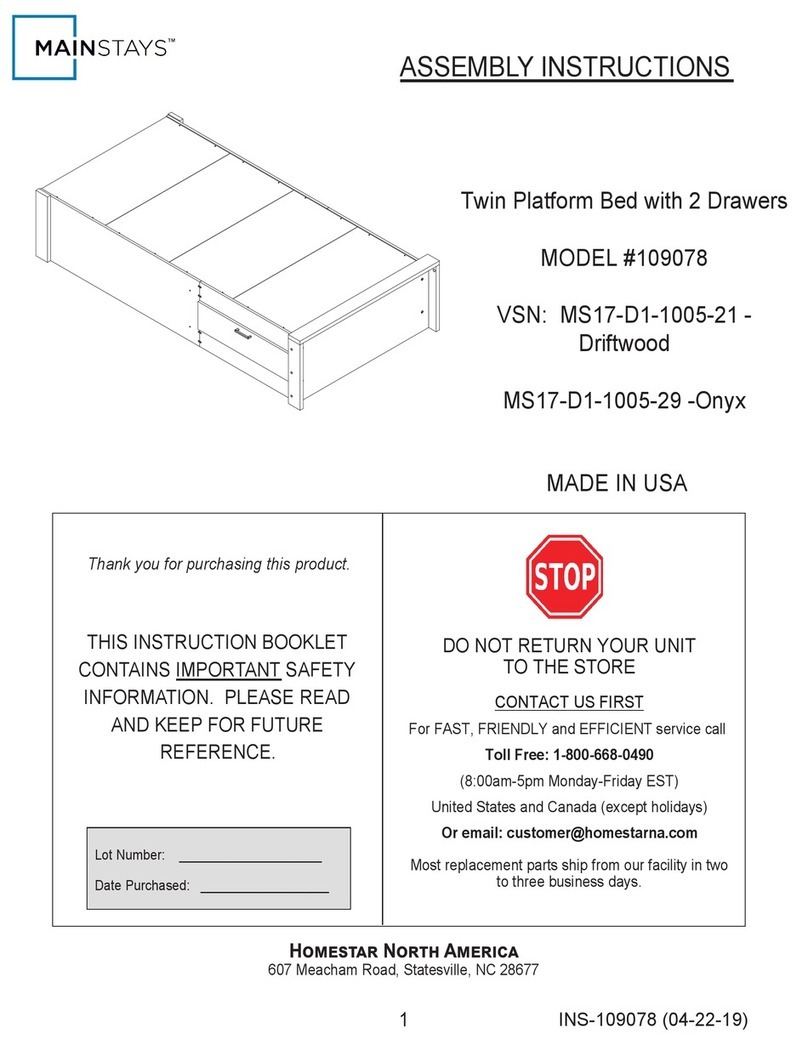

home star MAINSTAYS 109078 Assembly instructions

Seconique

Seconique Panama 1 Assembly instructions

Rauch

Rauch M2227 Assembly instructions

BUT

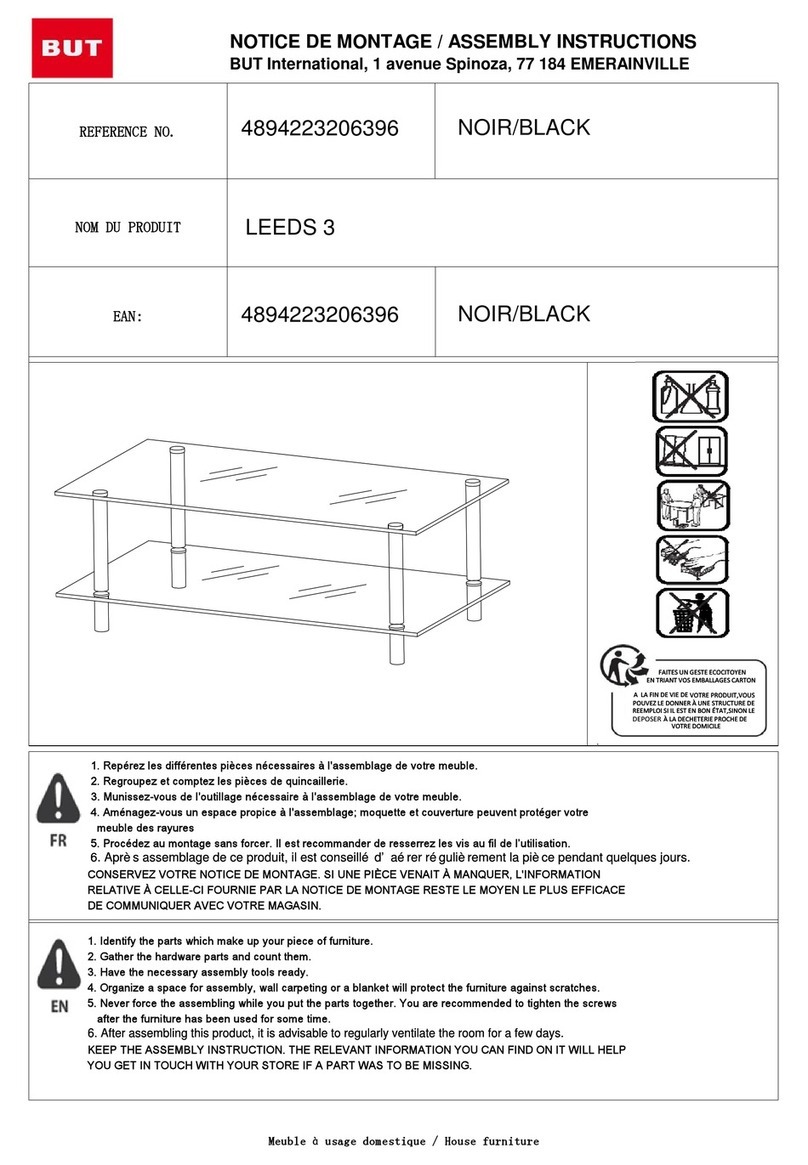

BUT LEEDS 3 4894223206396 Assembly instructions

Naterial

Naterial MOBIS TRAY 3276007268072 Assemby - Use - Maintenance Manual

ducduc

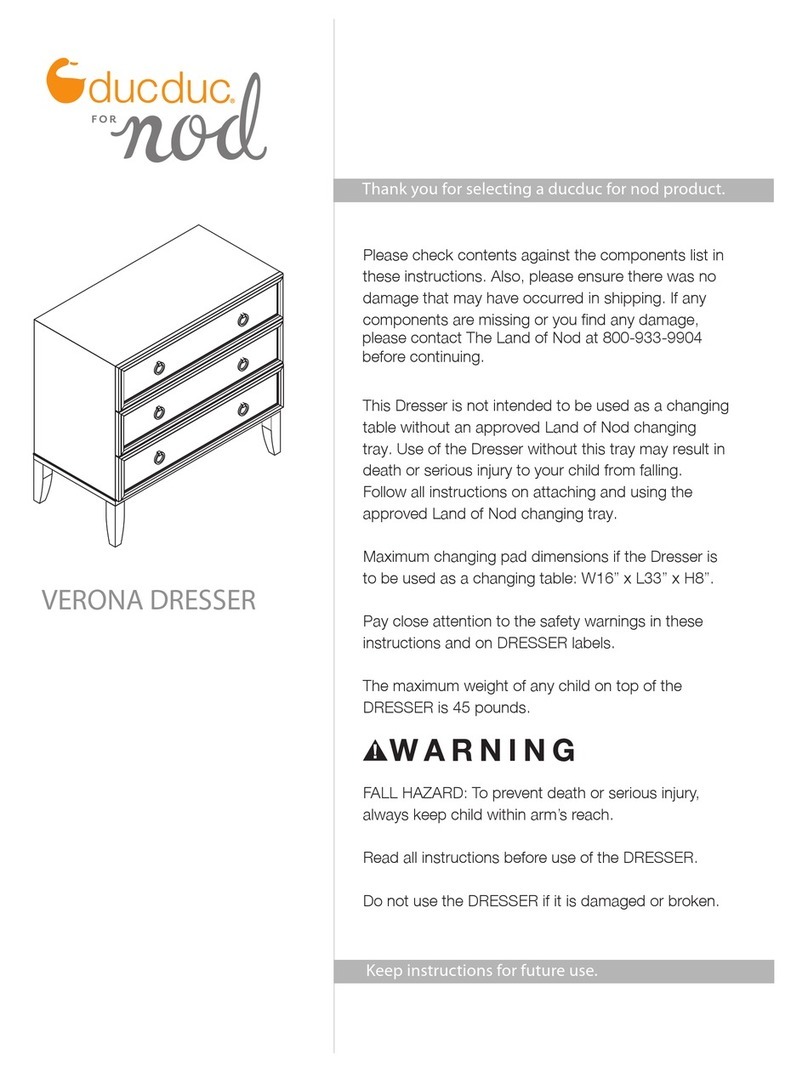

ducduc OSLO Assembly instructions

Vinsetto

Vinsetto 921-451 Assembly & instruction manual

Crate&Barrel

Crate&Barrel Alfresco II instructions