Dnepr MT9 Operating instructions

MOTORCYCLES "DNEPR"

MT9

and

MTIO

REPAIR

MANUAL

V/0 AVTOEXPORT •

USSR

•

MOSCOW

CONTENTS

Pag

''

I.

Preparing the Mota·C)cie for Repairs

I

I.

Checking the Motorcycie for Technical

Co

nditi

on

Ill. N\ounting and Dismanllmg Operations

JV.

Engine Reconditioning

·~

L<0

v.

Repairing the Gear

Box

7'

• j

V

I.

Repairing the J\la

in

Drive

~2

VII. Repairing the Whe

el

r.s

r-

VIII. Repairing lhe r ront

fo,··k

:

·

~

I

X.

1\epairing the ,Frame

~

F

'

X.

Rep

ai

ring the Rear Suspension

!ILi

XI.

REpairing the Ha-ndlebar and Control Cables .n

XII. Repairing

!li

e rue! Supply

Syst

em I

JG

XIII.

Repairing the Intake and Exhaust Systems l•

ll

X

IV

. Repairing the Sideca,, 1

02

XV.

ElectricaI System

De

v1ces

l!'l

I. PREPARING

THE

MOTORCYCLE

FOR

REPAIRS

Regardless

of the

type

of

repairs

to be

carried

out,

one

must

do

·

the

following:

wash

the

motorcycle;

check it for

technical

condition;

draw

up an inspection report.

Prior

to

washing

the

motorcycle,

take

out

the

iouls; remove

the

seat

cus

hion

and

back,

take

off the cov

er

as

the3e should be

washed

separately

.

Fig

. !. Motorcycle "Dnepr"' MT9

When

washing,

take

care

to keep

water

out

of

the

ele

ctrical

de-

vices,

carburettors,

air

filter,

air

passages

and

petrol

tank.

The

techni

ca

l condit

io

n of

the

motorcycle

should

be checked

by

inspection

as

well

as

by

testing

the

appropriate

units

or

asse

mblies

du-Fing

riding.

r 3

.. .

Before

doing

this, it is

necessary

to

adjust:

spark

plug

gaps;

contact

breaker

gaps;

clearances

in the

va

lve

gear

drive;

carburettors

fo

r idling,

average

speed

and

for the

synchronous

operation

of

the

cylind

ers;

brakes

contro

ls;

c

lut

ch

release

drive;

tyre

pressure.

Fig. 2.

Motorcycle

"Dn

epr"

MTIO

At

the

same

time, check

the

amo

unt

of oil

in

the

crankcase

and

in

the

gear

box and

main

drive

cas

in

gs

.

Adju

st

the

clea

ranc

es in accor

danc

e with lhe Ope

ratin

g

In

s

tru

c-

tions.

II.

CHECKING THE MOTORCYCLE FOR TECHNICAL

CONDITION

The

technical

co

ndition

of the motorcycle, of its

units

and

assem-

blies

deteriorates

in

the

process of co

ntinuou

s service. As

th

e compo-

nents

become

worn,

the

eng

ine power diminishes, fuel

an

d oil con-

s

umption

incr

eases

,

operation

of

some

of

the

units

becomes

noisy

and

failures

occur

mor

e fre

qu

ently due to

fatigue

and

corrosion.

The

wear

of com

ponent

s leads to

increas

ed

clearances

in the

joi

nts, and

ca

uses

the

dynamic,

economical

and

operating

ch

arac

teri

stic

s

of

the

motorcycle

to

deteriorate.

Therefore,

periodic checks of the

motorc

ycle for tec

hnical

condi-

tion a

nd

elimination

of detected

faults

in due

tim

e are

mo

st impor-

tant

to

prolong

its

service

life. In

order

to

determine

whether

the

motorcycle

and

its

units

are

in good

conditio

n, it is

necessary

to

:

1.

Check

tha

t

ihe

motorcycle

is complete with all

necessa

ry

units;

parts

and

accessor

ies.

2.

Check

the

general

condition

of

the

motorcycle,

including:

free

rolling

path;

ma

ximum speed;

braking

di

stance;

trial

petrol

consumptio

n.

3. Check

the

engi

ne co

ndition

:

oil

consumption;

compression in the

cylinders;

make

sure

that:

no

extra

neous noises

are

produced

during

operation;

no loca l

heating

is ob

served;

there

are

no oil lea

kage

s;

check the

engine

operation

under

l

oad

at

various

rotational

speeds.

4.

Check

the

clutch

mechanism

condition,

including:

disengagement

of disks

during

declutching;

smoo

thn

ess

of

engagement;

absence

of

s

lipping

;

absence

of

extraneous

noise

with

the clutch released.

5.

Check

the

gear

box co

ndition

:

return

of

the

st

ar

ting

mechanism

pedal;

easy

and

faultless

gea

rs

hiftin

g;

mak

e

sure

that:

the

gears

do

not

di

se

ngag

e by

themselves;

there

are no o

il

l

eakages;

no local

overheati

ng

is observed;

no

extra

neous

noises

are

heard.

6.

Check the

propeller

sh

aft

and

the

main

drive

for:

the

absence

of

increased

cl

eara

nces in

th

e

joint

s

of

elas

tic

coup

l-

ing, in the uni

versa

l

joint

,

geari

ng

a

nd

at

the

wheel

hub

junction;

absence

of oil l

eakage;

absence

of local

overheating

and inc

rea

sed

run-out

of

the

pro-

peller shaft;

check

ihe

el

astic

coupling

for good

condit

ion.

7.

Check the

wheels

for:

wear

of the

tyres

and

possible

damag

e;

wear

of

ih

e shoes

and

of

intern

al

surfaces

of

the

brake

drum

s;

wear

of the

bearing

s;

radial

a

nd

axial

run-out

of

the

rim

and

tyre;

make

sure

that

th

e spokes

are

all

available

and

uniformly

ten-

sione

d;

check the condition of

the

toothed

coupling

with

the

wheel hub.

8.

Check

th

e front fork for:

clearances

in

the

stee

ring

column,

lower

end

piec

es

of

the

fork,

.as well

as

at

the

bridg

e

and

traverse

joints;

1

I

I

\

smoothness

of

operation

during

riding,

the

condition

of

the

cas-

ings

and

fender;

tightening

of

fastenings

;

absence

of h

eavy

shocks

during

ope

ration;

co

ndition

of

the

springs;

abse

nce

of d

amp

ing

f

luid

leakage

.

9.

Check

th

e

motorcycle

frame

for:

tightening

of

fastenings;

abse

nc

e of cr

acks

at

weld

sea

ms;

ab

se

nce of exte

rn

al s

ign

s of

damage;

proper

cond

ition of fenders.

10.

Check

the con

dition

of the hy

drauli

c shock

abso

rbers,

including:

s

moothne

ss

of their

operation

during

riding;

co

ndition

of

the

casings

and

silent-blocks;

absence

of

heavy

s

hock

s

during

operation;

absence

of da

mping

fluid l

eakage;

clea

ranc

es in the

joints.

11.

Check

th

e

condition

of

the

petrol

tank

by

making

sure

that

:

petrol

does

not

leak

through

weld

seams

and

joint

s;

the

petrol

cock

and

hos

es

are

in

good

c

ondition;

the

petrol

tank

is

free

of

dents

and

other

injuri

es.

12

.

Check

th

e

exhaust

system

for:

tight

co

nn

ections;

absence

of

dents

and

other

signs

of

damage

on

th

e

lubes

and

silencers

.

13.

Check

the

condition

of

the

contro

ls,

including

:

condition

of

the

handl

e

bar

and

of

the

levers

and

other

mecha-

nisms

dispo

sed

on it;

co

ndition

of

cables

and

cable

sh

eaths;

foot

brake

pedal

and

brake

controls;

braking

effect,

when

using

the

both

brakes.

14.

Check

the

condition

of

lhe

sidecar,

including:

condition

of

the

shock

absorber;

absence

of

clearances

in

lhe

sidecar

-to-motor

cycle

attachment

hinges;

condition

of

the

wheel

fender, body,

sidecar

frame,

seat

cushion

and

back, cover.

15.

Ch

eck

the

condition

of

the

el

ectric

devices:

operation

of

the

ignition

lock;

operation

of

the

light

switch;

condition

of the

lighting

devices

;

operation

of

the

ignition

system;

operation

of

the

horn;

co

ndition

of

the

pilot

lamps;

condition

of the

wiring;

condit

ion of

the

speedome

t

er;

operation

of

the

emergency

oil

pressure

transmitter,

stop

light,

neutral

position

indicator

and

turn

indicator

switch.

6

.

~

' .

. ..

METHODS FOR

CHECKING

THE

MOTORCYCLE'S PARAMETERS

The

free rolling

path

of

the

motorcycle

is

measured

by

riding

a

fully

loaded

motorcycle on a

st

r

aight-line

section

of

the

hard-surface

road, in

dr

y

weather,

at

a

wind

speed

not

exceedin

g·

3

m/s.

The

mo-

torcycle is acce

lerat

ed up to 50

km/hr,

following

which

the

clutch

is

withdrawn,

the

gea

r

sh

ift

lever

is

set

to

the

ne

utral

position

and

th

e

motorcycle

is

allowed

to

move

until

it

comes

to a full

stop.

Measure-

ments

arc

made

by

riding

the

motorcycle

in

both

di r

ect

ions.

Th

e

l

engt

h of the

rolling

path

is

measured

from

the

point

of

clutch

with-

drawa

l to the ful l

stop

of

the

motorcyc

le.

The free

rolling

path

is

determined

as

the

arithmet

ic

mean

of

two

rides

in

both

directions

and,

·with

the

motorc

ycle in

good

repairs,

must

be

not

le

ss

than

250 m.

The

maximum

speed

is

determined

by

riding

on a

measured

(1

km

lo

ng)

stretc

h of

the

road

,

the

time

being

mea

s

ur

ed

with

a

stop-

watch.

The

maximum

speed

is

determi

n

ed

as

the

arit

hm

et

ic

mean

of

the

speeds

deve

l

oped

during

two

rid

es

in

the

opposite

directions

and

must

be

not

less

than

100

km/hr

for

the

MT9

motorcycle,

and

105 km/

hr

for

the

MTIO

model.

The

acceleration

must

be

sufficient

to a

llow

the

motorcycle

to

develop

th

e

maximum

steady

speed

before

reaching

the

measured

s

tretch

of

the

road,

the

road

cond

iti

ons

being

the

sa

me

as

when

measuring

a free

rolling

pat

h.

If

the

maximum

speed is

below

th

e

specified

figure

,

with

the

l

ength

of

the

free

rolling

path

being

nor-

mal,

this

means

that

the

engine

power

.is

insuffici

e

nt

and

the

engine

h

as

to be

repaired.

The

trial

petrol

consumption

mu

st

be de

termin

ed by

riding

the

se

rvi

ceab

le

motor

cycle

under

full

load

in

two

opposite

directions,

on

a m

easu

red (

10

km

long)

s

tr

etch of

the

dry,

hard-surface

road

hav-

ing

no

steep

upgrades

and

descents,

with

the

motorcycle

running

in

a

high

gea

r

at

75

km

/

hr

speed.

The

petrol

consumption

must

not

exceed

7.2 1

per

100

km

(to

be

mea

s

ur

ed

by

adding

petrol

into

the

tank

from a

measuring

vessel).

Simultaneously

with

measuring

petrol

consumption,

oil

consumption

is checked, which

must

not

excee

d 0.15 I per 100

l<m.

The

engine

condition

to

be

diagnosed

by

extraneous

noises

pro-

duced

during

the

engi

ne

operation,

as

we

ll

as

the

compression

in

the

cylinders

are

checked

emp

irically

by a

skilled

mechanic

of a

se

rvice

station

or

maintenance

shop

(Table

1).

Local

heating

and

general

overheating

can

be

detected

to

the

touch.

The

clutch

me

c

hani

sm

is

checked

for

condit

ion in

the

follow-

ing

manner:

when

the

e

ngine

is

inop

e

rativ

e,

release

the

clutch

and

turn

the

kick lever, in

this

case

the

engine

crankshaft

must

not

turn;

when

the

engine

is

running,

with

the

first

speed

gear

engaged

and

the

clutch

released,

the

motorcycle

must

not

move.

When

gradu-

:ally

engaging

the

clutch

release

l

eve

r,

the

motorc

ycle

must

start

moving

smoothly,

without

jerks.

With

the

gear

and

clutch

engaged,

7

..

JJ

I

I

a

sudden

ope

nin

g of

the

throttles

must

cause

the

motorcycle

to ra-

pidly

increa

se

its

sp

eed

w

ithout

any

noticeable

clutch

slip.

Th

e

gear

box,

propeller

shaft

and

main

drive

shou

ld be checked for

good

con-

clition by

testing

the

operation

of

these

mec

hani

sms

with

the

motor-

cycle

at

r

est

and

on

the go.

The

backla

sh in the

main

drive

gearing

must

be

wit

hin

0.1

and

0.3 mm,

the

permissible

run-out

of

th

e

propeller

s

haft

not

exceed-

ing

1.5

mm.

The

wheels

are

checked for condition by succ

essive

ly

in

specting

each

of

them

(by r

ais

in g, r

otating

th

e

whee

l

and

rocking

it

from

side

to

side)

. The

whee

ls must

rotat

e freely,

wit

h

out

play,

snaps

and

se

izur

es.

The

permissible

(lateral

and radial)

run-

out

of the

rim

s

hould

be

1.

5

mm.

The

spokes

are

checked

for

uni

form

tens

ioni

ng

by

li

stening to the sou.

nd

produc

ed when

tapping

the

spokes.

Th

e

front

fo

rk

, hy

draulic

shock

absorb

ers, s

teering

contro

ls

and

br

akes

are

checked for

condition

by

inspecting

them w

ith

th

e

motor-

cycle

at

rest or by t

est

ing their

operation

on the go. The

fork

must

be free

to

rotate

in the steerin g

column,

without

pla

ys

and

sto

pping

in ce

rt

ain

positions

.

When

inspecting

and

checking lhe

motorc

ycle

units,

m

ake

sure

that

the

<lnti

ru

st

co<1ting and p<linting of

the

component

p

ar

ts are in

good

co

nditi

on.

The

cau

ses

of

faults

and

troubl

es

hootin

g

procedure

s

are

gi

ve

n in

Table

2.

On

completing

the inspection

and

checking,

draw

up a

technical

co

ndition

r

eport,

on

th

e

basis

of

which

th

e

motorc

ycle _

ma

y be

sub-

jected

to

adjust

ment,

partial

or

total

di

sm

an

tling

and

r

eq

uir

ed re-

pairs.

III. MOUNTING AND DISMANTLING OPERATIONS

If, as·

lhe

result

of

checking

for

technical

condition,

it

is found

necessary

to

pe

rform

a

partial

or

total

dis

mantling

of

some

of

th

e

units,

asse

mblies

or

the

entire

motorc

yc

le for

th

e

purpose

of

repair-

ing

or

re

placing

the

component

parts,

the

dism

a

ntling

should

be

carried

out

to

the

ex

tent

not

greater

than

required.

Subj

e

ct

ed to

partial

dism

a

ntling

ma

y

be

the

assemblies

that

are

removed

or

not

removed

from

the

motorcycle.

Prio1

to

dismant

l

ing,

clean

and

wash

the

e

ntire

assembly

to

remove

oil,

dirt

and

du

st

that

may

foul

the

friction

parts

of

the

jointed

membe

rs

during

dismantling

.

After

disassembling,

clean

off

dirt

,

carbon

deposits

and

remnants

of

bak

elite

lacquer

from

th

e

co

mponent

part

s,

wash

and

examine

them

for

good

condi.tion,

mak

e

appropriate

mea

s

urements

to

determine

the

degree

of

wear.

The

maintenance

shop

or

service

station

must

have

at

its

disposal

a com-

plete

set

of

tools

necessar

y for

dismantling

or

assembling

th

e

motor

-

cycle

units.

In

case

the

unil

s or

assemblies

have

to

be

dismantled

without

re

moving

them

from

the

motorcycle

or

when

their

removal

is requ-ired,

it

is

advisable

to

detach

the

sidecar

to

ensure

a

better

access

and

thus

facilitate

the

re

pair

operations.

8

l ...

~

• •

~

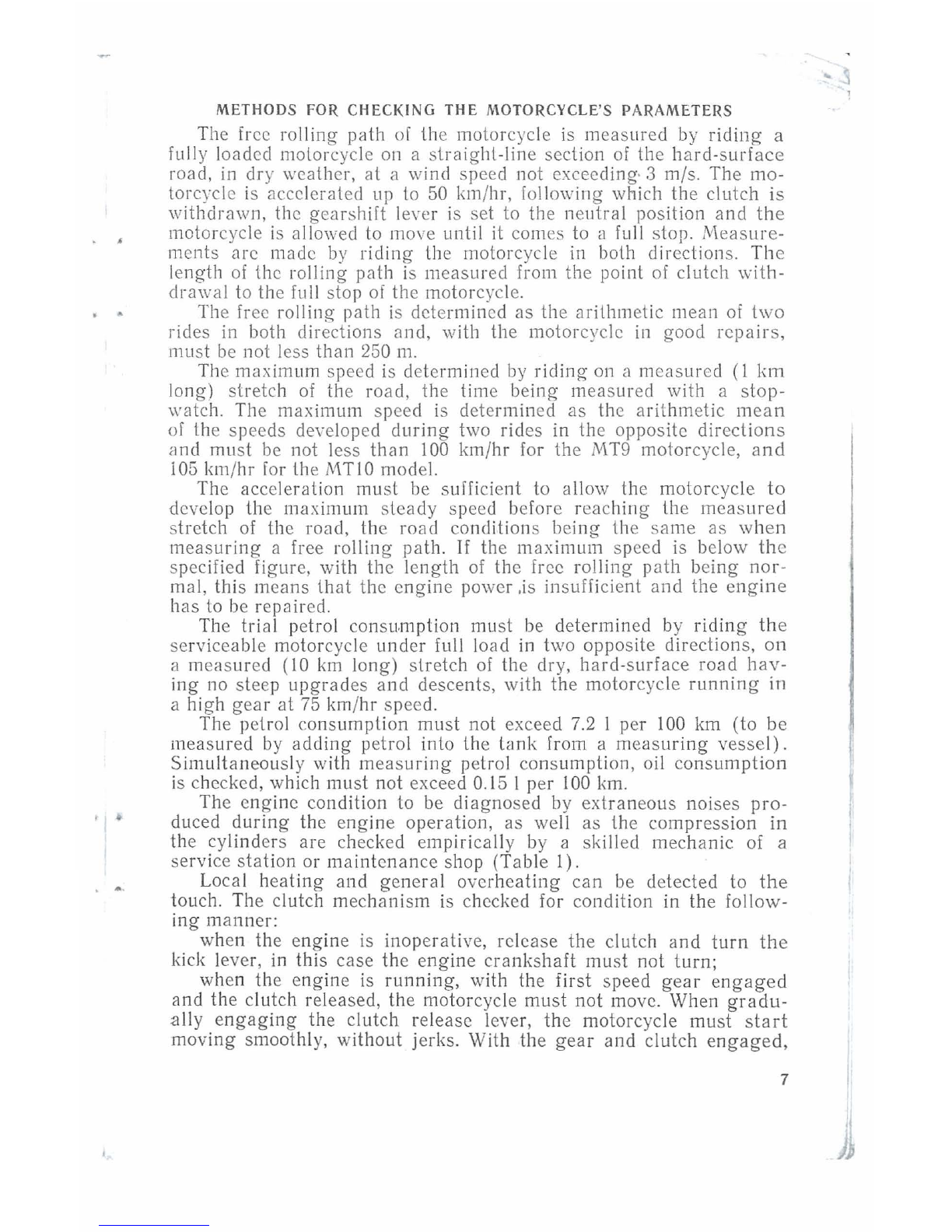

Table

1

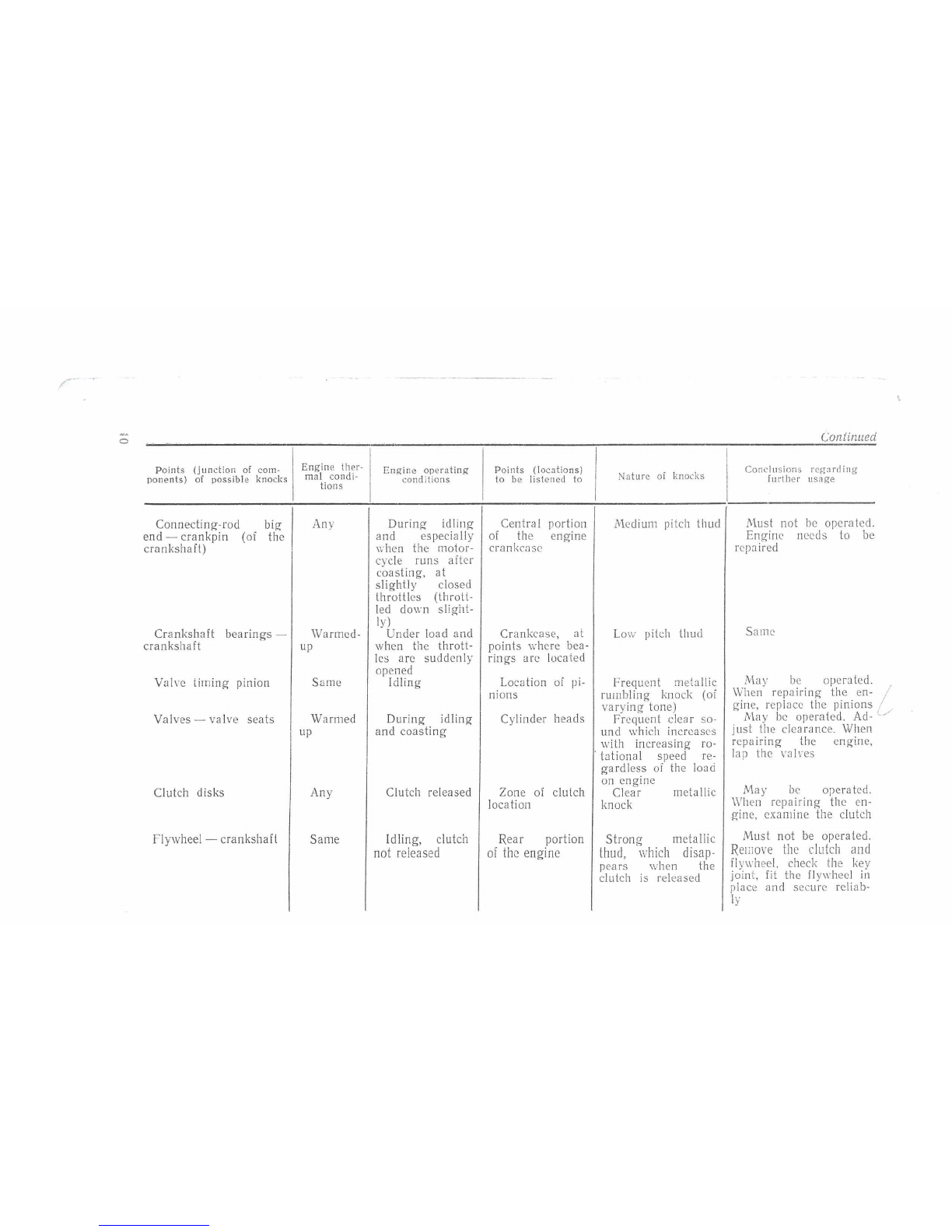

Checking the Motorcycle Engine lor Technical Condition by Noises and Knocks

Point

s

(junction

of

com-En

gine

!her-

Engine

operating

Poin

ts (l

ocatio

n

s)

Cone!usions

regarding

pone

nt

s)

of

possible

kn

ocks mal condi· conditions

to

be

Iistened

to

~aturc

ol knocks

further

usage

tions

Piston

pin -

conn

ect

-~

Warmed

U

nd

er load,

Cylinder

loca-

Clear

shrill

me

tal-

I

Must

not

he

opera

ted.

ing

-rod

small

e

nd

up followed by a lion lie knock

Cl

e

an

the

combu

stion

s

udd

en incr

ease

chamb

er

to

r

emove

car-

in ro

tati

ona

l bon de

posits;

if

neccs-

speed

sary,

replace

the

piston

pin en

sur

ing

that

i

ts

co-

louring

corresponds

to

that

of

con

n

ect

ing

rod

sma

ll end

Same

Pi

ston

pin -

piston

Sa

me

Same

Same

Knocks

no

t

so

boss

clea r

but

be

come

more

distinct

as

the

engine

warms

to

a

higher

tc

n1p

c

rature

Pi

ston -

cylinder

Cold

Idling

Cylinder

Joca -

Dry

metallic

knock

May be

operated

in

lion

\\"hich

becomes

mo- case the !mock

disap-

re

apparent

as

the

peMs

as

the

engi

ne

rota

tiona I

spe

ed

warms

up.

When

r

epai

r-

changes;

the

knock

ing

, repl

ace

the

piston

be

comes

l

ess

audible

as

the e

ngine

war

ms

up

<0

I

Simi

la r

kno

ck

due

Must

not

be

operate

d.

· to

the

pin being

Replace

the

piston

and

I

se

ized in

the

con

-

p:

n

necting-rod

sma

ll

end

i ,

' "

0

Points

(junction

of com-

ponents)

of

poss

ibl

e

kno

cks

Engine

ther-

mal

cond

i-

tions

Connecting-rod

big

I Any

end-

crankp

in

(of the

cranksha

ft)

Crankshaft

bearings

-

~

Warmed-

crankshaft

up

Va!Yc lilfli

ng-

pi

ni

on I Snrnc

Va l

ves-

val

ve

seats

I Warmed

up

Clutch disks Any

flywheel-

cr

an

ksha

ft

S

ame

Engine

operating

Points

(locations)

Nature

ol

knocks

conditions to be listened to

During

idling

and

especially

when the motor-

cycle runs after

coasting,

at

s

li

ghtly closed

throttles (thrott-

led down sl

ig-ht-

ly)

Under loa d

and

when the thrott-

les arc suddenly

opened

Idling

During

id

li

n

g-

and coast

in

g

Central portion I ,\tedium pitch thud

of

the engine

crankc:1sc

Crankcase,

at

I

Lo

w pitch thud

points where bea-

rings

ar

c located

Location

of

pi- Frequent metallic

nions

ru111bling

knock (of

varying

tone)

Cylinder heads Frcqucnl clear so-

und w

hi

ch

increases

with increasing- ro-

. tationaI speed re-

gard

less oi

th

e load

Continued

Conclusions

regarding

further

usag-e

Must not

be

operated.

Engine needs

to

be

repaired

Same

lv\ay be operated.

\Vhen rep2iring the en-/

gine, repla

ce

the pinions

..

May

be

operated. Ad-

l/

ju

st

the clea rance. When

repairing the

eng

ine.

lap the \'aJI·es

C

lu

tch released Zone of

cl

utch

location

on

engine

Clear

knock metallic I Nlay

be

operated.

Idling, clutch

not released Rear

po

rtion

of

the e

ng

ine

Strong

metallic

thud, which disap-

pears when the

clutch is released

\Vhen repairi

ng

the

c

n-

gine, examine the clutch

Must

not

be

operated.

ReiiJove the clutch

and

fly11'heel,

check the key

joint, fit the flywheel

in

place and secure reliab-

ly

Points (junction of com-

ponents)

of possible

knocks

Generator

i:ear-

cam-

shaft

gear

Breather-

front

cover

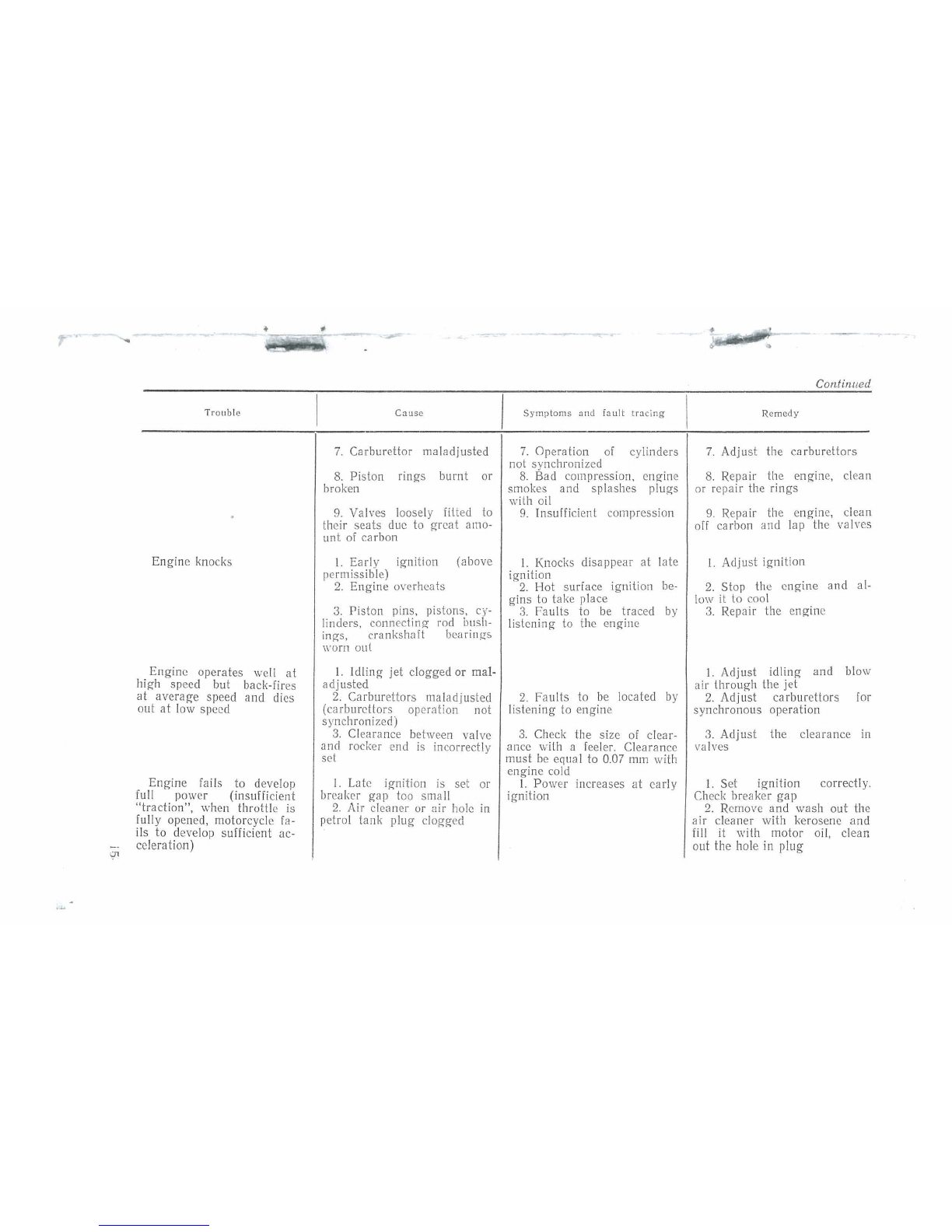

Trouble

Engine

will

not

start

~-

-

' .

!>._

-

Continued

Engine

thcr-

Engin

e operating

Point

s

(locations)

Cone! usions

reg~

rd

i

ng

mal

condi-

con

ditions

to

be

list

ened

to

Nature

of knocks

furth

~

r

usage

tions

Any

Variable

du

ty

Front

upper

Frequent

rumblini:

May

be

operated

af-

portion

of

the

metallic

knock, tcr

adjusting

the clear-

engine

"howl"

ance

in the

gearing

(by

turning

the

generator

body)

Warmed

Idling

Front

portion

Frequent

metall

ic

May

be

operated.

At

up of the

engine

knocks

.Troubleshooting

of

the Motorcycle Units

Cause

Symptoms

and

fault

tracing

Engine

I.

Petrol

not

supp

lied to

carburettor

2.

Excess

of

petrol

in cy-

linders

(especially

when

en-

gine

is

hot)

I.

Press

down

on

carburet-

tor

depressor

with

your

fing-

er;

if

petrol

docs

not

flow

out

of it,

this

means

that

fuel

is

not

supp

lied to

carburettor

2.

Sporadic

flashes

with

backfire

the first

opportunity

examine

the

breather

af

-

ter

first r

emoving

th

e

distributo

r

cover

Table 2

Remedy

I.

Open

the petrol cock

2.

Close

the

petrol

cock. ful-

ly

open

the

thr

o

ttle

,

press

down

the

kick lever 5

to

l0

times,

start

the

engine

""

Tr

oub

le

-~

Cause

3.

Filter

and

petrol cock

dirty

or

clogged

4. No

spark

produced

by

plug

:

a)

no

gap

between

plug

electrodes,

dirt

and carbon

deposits in

plugs,

insulator

punctured;

b) no

gap

between breaker

(contact)

points,

breaker

po-

ints

oi

led or

burnt;

c)

ignition

co

il

faulty;

d)

low-tension

wires

bro-

ken

Symptoms and

fault

tracing

3.

Di

sconnect

petrol

supply

pipes from

carburettors

and

check to

see

whether

petrol

runs

if cock is opened for re-

serve

fuel consumption

a)

screw

out

the p

lu

g, con-

nect

its

body to

"earth"

and

check

whet

h

er

spa

rk is pro-

duced

at

pl

ug

electrodes;

b)

remove

wire tip

and

check wh

ether

spark

appears

at tip

by

connecting

it

to

"e

arth

",

with

a

small

air gap_

If

spark

is produced, this

means

that

plug

is f

aulty.

Ab-

sence

of

spark

i

ndicates

that

there is no

gap

between bre-

ak

er

points;

c)

if

, duri

ng

checking

by

method specifi ed in step

"b",

spark

does

not

appear,

this

indicates

that

ignition coil is

probably

at

fault;

d)

remove

front

cover,

switc

h on ignition. Check por-

tab

le l

amp

circuit. for which

Continued

Remedy

3.

Disconnect

the

ends

of

petrol

supply

pipes from

car-

burettors

and

blow

them

Lhr

ough

(one

after

another,

by

clutching

the

ot

her pipe).

If

this fails to

make

petrol

fl

ow

in a full jet, remove set-

tler, cock filter a

nd

wash

them

with petrol

a)

replace

plugs

or, ii their

condition permits,

sel

the re-

quired

gap

between electrodes,

clean the p

lu

gs;

b)

after

removing

crank-

case

outer

cover, set

breaker

point

gap

within

0.4

and

O.G

mm.

Clean

an

d,

if

nec

essa-

ry, trim

the

contact

points

with

needle f

il

e;

c)

replace

ignition coil

I

I

I

1_/

e

Trouble

w

Caust.!

5.

No

compression

or

insuf-

fici

ent

compression

in

engi-

ne:

a)

no

cl

earances

in

valve

gear;

b)

valves

loosely fitted due

to

lhc

presence

of

carbon

de-

posits

or

valve

retainers

be-

ing

burnt

through;

c)

piston

rings

are

burnt

or

broken

SYllliJtoms

and

iault

tracing

l

amp

wi re

to

"earth",

and

the

other

end

-

to

low-t

ension

terminals

of

ignition

co

il

,

and

th

en -

to

termina

l of

breaker

wire.

Lamp

will

not

light

up:

if

connected

to

input

termi-

nal of

ignition

coil,

in

case

headlamp-to-ignition

coil

wire

is

broken;

if

connected

to

output

ter-

minal

of

ignition

coil, in

case

primary

circuit of

ignition

coil

itself is broken;

if

connected

to

terminal

of

breaker

wire, in

case

ignition

coil-

to

-break

er

wire

is

broken;

in

this

case

breaker

points

must

be in a

disconnected

state

a)

when

depressing

starting

pedal,

engine

crankshaft

\\·ill

turn

with

out

compression;

b)

same

c)

smoke

escaping

from

breather

•

Continued

Remedy

a)

ad

ju

st

clearances;

b)

repair

the

eng

ine,

lap

or

repair

lhe

valves

;

c) repair

the

engine,

cl

ean

the

piston

rings

an

d

grooves

to

remove

carbon

deposits,

re-

place

rings

""

Trouble

Irregular,

erratic

opera-

tion of

engine;

only

one

cy-

lind

er

functioning

.

--

Cause I

Symptoms

and

fault

tracing

6.

Clutch s

li

pping

I

6.

Engine

c

rank

sh

aft

will

not

rotate

when

pressing

down

starting

pedal

I.

Mixture

too lean: I

I.

Engine

back-fires

a)

petro

l

supply

to

carbu-

rettor

is insufficient

and

ir-

regular;

b)

carb

urett

or

jets

dirty;

c)

water

in

petrol

2.

Plugs

faulty

3.

Poor

contact

at

sto

r

age

ba tlery

term

ina Is

4.

Bad

condition of

breaker

points

5.

Capacitor

faulty

or

bad-

ly

connected

6.

Mixture

enrichment

due

to

float

chamber

being

over

-

filled with petrol:

a)

float needle

valve

dirty

and

leaky (lets petrol

out);

b) leaky float

c)

carburettor

jet

came

un-

c:rrPH'Prl

2.

Same

as

in

step

4 a of

the first failure of

engine

3.

Pilot

l

amp

blinks

4.

Spark

occurs

irr

egular

ly

between wire

tips

and

"earth"

5.

Bangs

heard

from silen-

cer,

bad

spa

rk

a)

engine

smokes

badly,

bangs

heard

from

silencer,

petrol

leaking thr

ough

carbu-

rctlor

--

Continued

Remedy

6.

Adjust

the

driv

e;

if

clutch

continues

to slip, r

epair

the

clutch

(dismantle

and

exam

ine

it)

I.

Same

as

in

step

3 of

the

first failure of e

ngin

e;

c)

change

petrol

2.

Same

as

in

step

4 a

of

the

fi

r

st

failure

of

e

ngine

3.

Ensure

good

contact

at

storage

battery

te

rminals.

Clean

;'

the

contacts,

light

en

screws

faste

ning

the

wires

1

--'

4.

Examine

co

ntact

points.

trim

or

file them off,

adjust

the

gap

5.

Ensure

good

contact

or

repla ce

capac

itor

a)

clean

the

needle

valve;

b) repair the

carb

ur

ettor,

re-

place

or

repair the

float;

fit

the

jet

properly

......

<.!'

+

Tro uble

Engine

knocks

Engine ope

rat

es well

at

high speed but

ba

c

k-

fi

res

at

averaJ:!e speed and dies

out

at

low speed

Engine

fa

il

s to develop

full power (insuffici

ent

"traction", when

thr

ottle

is

fu

ll

y opened, motorcycle fa-

ils to devel

op

sufficient ac-

ce

leration)

..

Cause

7.

Carburettor maladjusted

8.

Piston rings burnt or

broken

9.

Valves loosely filled to

their

seats

due to

great

anw-

unt

of

ca

rb

on

l.

Ear

ly ignition (above

permiss

ibl

e)

2.

Eng

in

e overheats

3.

Piston

pins, piston

s,

cy-

linders, connecting rod bush-

ings, crankshaft bearings

worn oul

I. Idl

ing

jet clogged or mal-

adjusted

2. Carburettors maladjusted

(carburcllors operation not

synch ronized)

3.

Clearance betw

ee

n valve

and

rocker end is incorrectly

sel

l.

Late ignition

is

set

or

breaker

gap

too sma

ll

2.

Air cl

ea

ner or a

ir

hole

in

petrol

tank

p

lu

g

clogg

ed

Symptoms and

fault

t

racing

7.

Operalion of cylinders

not synchronized

8. Bad compression,

eng

in

e

smokes and splashes p

lu

gs

wi

th

oil

9.

Insufficient

co

mpression

I.

Knocks disappear

at

l

ate

ignition

2.

Hot

sur

fa

ce

ignition

be-

gins to take place

3.

Faults to be traced by

li

steni

ng

lo the engine

2.

Faults to be located by

l

is

t

en

ing to eng

in

e

3. Check the size of clear-

ance wilh a feeler. Cl

eara

n

ce

must be equa l to 0

.07

mm

wi

tl

1

engine

co

ld

I.

Po

wer increases

at

early

ignition

•

6

Continued

Remedy

7.

Adjust

the ca rbur

ettors

8. Repair

th

e

eng

ine,

cl

ea

n

or repair the rings

9.

Repai1·

the engine, clean

off

ca

r

bo

n

and

lap the valves

I. Adjust ignition

2. Stop

th

e engine

and

al-

low

it

to cool

3. Repair the engine

1.

Adjust idling

and

blow

air through the jet

2.

Adju

st

ca

rburettors for

sync

hr

onous operation

3.

Adjust

the clearance

in

valves

I.

Set ignition correctl

y.

Check breaker

gap

2.

Remove

and

wash out the

air cleaner with kerosene

an

d

fill it wilh motor oil, clean

out

th

e hole in plug

a>

Troubl

e

Engine

overheats

Cnusc

3.

Va

lves do

not

fit close-

ly to th

eir

scats

due

to accu-

mulatio

n of

ca

rbon

deposits

4.

Gases

burst

fo

rth

from

under

cy

lind

er

head

5.

Pi

ston

ri

ng

s

burnt

·

or

broken

6. Cylind

ers

and

pi

sto

ns cx-

cess

iY

ely

worn

l.

No

oil or

insufficient

amount

of

it

in

the

c

rankca

se

2.

Enri

c

hed

mixture:

a)

ca

rbur

ettor

overfi

lled

du

e

to

float

needle Ya l

ve

be-

ing

badl

y

seated

;

b)

air

clean

er

dirt

y;

c)

carburettor

thro

tt

le need-

le

wrongly

set

3.

Diluted

mix

tur

e:

a)

th

rottle

n

ee

dle inco

rr

ect-

ly

set;

b) air inle

akage

at

carbu-

r

ettor

-t

o-head

junctio

ns

4.

Lat

e

ignition

advance

Symptoms and iJ

ul

t lracillR

3. L

ow

compression

is ob-

served

4.

Bangs

arc

heard

an

d lo\\.

compression

is

obsen·ed

5. L

ow

compression,

eng

ine

smokes a

nd

splashes

the

plugs

with oil

6.

To

be

checked at

main-

te

nan

ce

shop

l.

Ch

ec

k o

il

level

2.

Engine

fai ls to

de\·elop

sufiicient

speed:

a)

check

whether

pe

trol

flows

fr

om

fl

oat

chamb

2r

(chamber

overfilled)

a)

eng

ine, if

und

er

l

oad

,

fails

to

de

velop

the

proper

speed;

b)

bangs

in

the

ca

rbur

et

l

or

Continu

ed

Remedy

3.

R

epair

the e

ngine.

Clean

off

carbo

n

and

l

ap

th

e val

ves

tl.

Tight

en the

nuts

sec

ur

i

ng

the

h

ea

ds

lo

cy

l

inder

5.

Repair

the

en

gin

e.

Clean

or

r

eplace

the

rings

6.

Repair

th

e e

ngin

e.

Repla

-

ce

or

r

epai

r

the

cy

linders

and

pist

ons

at

maintenanc

e shop

I. Fill up w

ith

o

il

2.

Clean

dirt

from

the

float

c

hamb

er:

a)

repair

the

carburetlor

1.

and

Ia

p

the

needle

va

lve; ..

l./

b) r

emove

the

air

c

lean

er

and

was

h it;

c)

adj

ust

the

ca

rbur

et

tor

a)

a

dju

st

th

e

carb

ur

e

tt

or;

b)

tighte

n

the

nuts

secu

ring

the

car

bur

e

tt

or

to the

head.

If

in

l

eakage

continues

to

take

place, re

place

the

gasket.

Check

the

breaker

gap

.

Set

the

igniti

on

.

"'

§

!"'

'l

~

•

Trouh

lc

Excessive oil consumption

Emergency oil pressure

transmitter lamp is

on

Clutch slipping

Clutch

wi

ll not disenga-

ge completely

Cause

a) piston rings burnt or

broken;

b)

cylinder face or piston

worn;

c)

fitting place for breather

in

the cover

of

distribution

box worn out;

d)

drain holes for discharg-

ing oil from cylinder heads

clogged

I. Faulty

transmittN

2.

Engine out of order

~

~~

--

·~

~

-

::.....

":'

-

--

~~

-

.

Syrnptorns

ami

r.:~ult

tracing

I. Check with

pressure

gauge

2.

Sarne

reference I

Continued

Remedy

a) repair the engine. Repla-

ce the piston rings;

b)

repair the engine. Bore

th

e cylinders or replace with

n

ew

ones (at the same time

t·eplace the piston and

rings);

c)

repair the engine;

d)

clean out the drain holes

I. Replace the tratlsrnilter

2. Repair tltc engine

Power

Transmi

ssion

I. Incomplete engagement

due to maladjustment

of

con-

trol drive

2.

Driven disk facings grea-

sy

3.

Driven disk facings ,,·orn

or burnt

I. Clutch drive maladjusted

(free travel of lever too

great)

I. Check the clutch control

lever for proper

fre

e travel

2.

Check during dismantling

and exami

ne

3.

Same

I. Check

th

e clutch lever on

handlebar for free travel

I. Adjust the control drive

by

turning the

adjusting

screw

until a

fr

ee travel of 5 to

8 rnrn

is

ensured

at

the end

of clutch lever

2. Dismantle the

cl

utch.

Wash the facings wi

th

petrol

3. Repa ir the clutch. Repla-

ce

the facings or disk assem-

bly

l.

Adjust the clutch drive by

turning the

adjusting

screw so

as to ensure complete disen-

gagement of the clutch and to

provide a 5 to 8

mm

free tra-

vel

nl

lhc

end

of

clutch

lever

cc

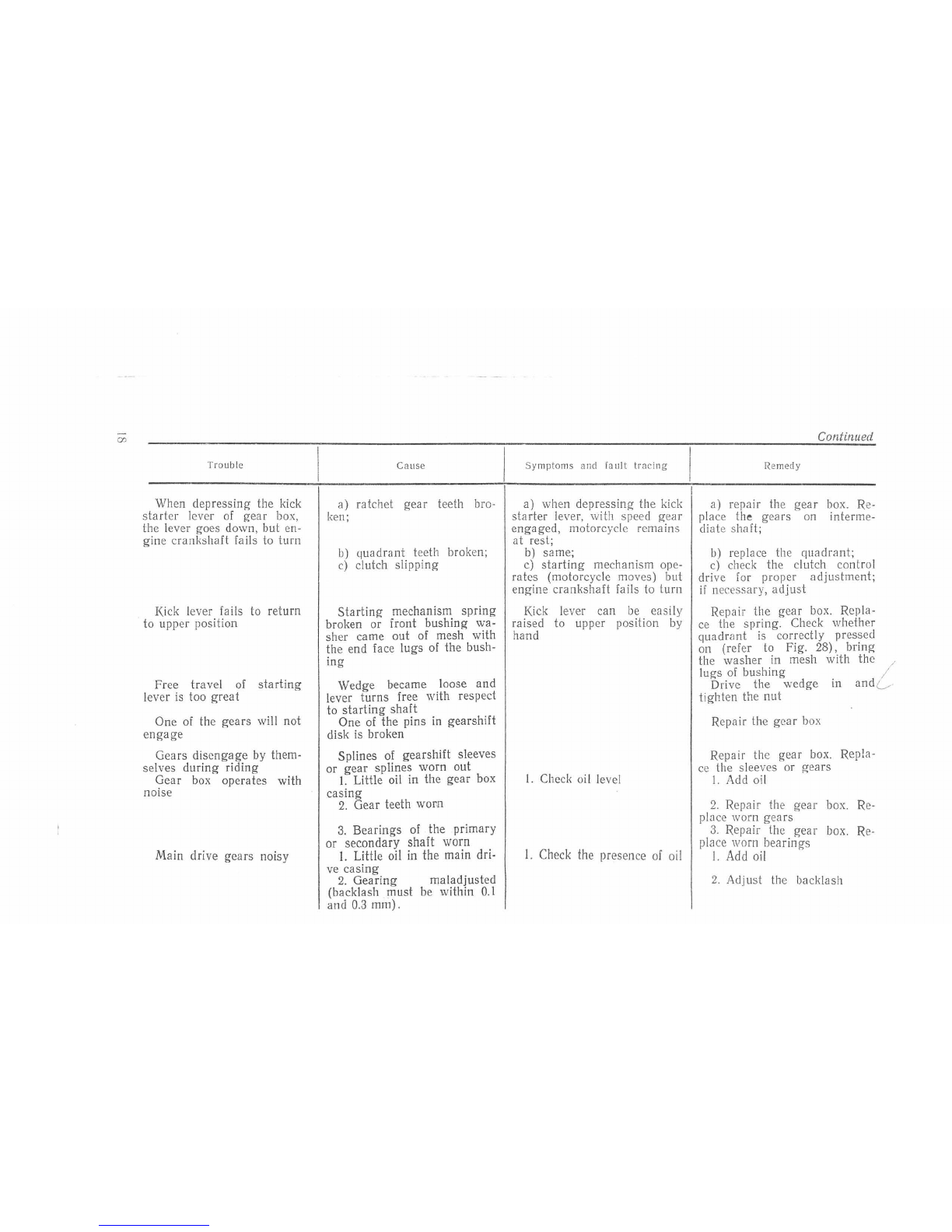

Tro

uble

When

depre

ss

ing

the kick

sta

rt

er

l

eve

r of

gear

box,

the l

ever

goes

do

wn

, bu t

en

-

gin

e c

rank

sha

ft fails to

turn

Kick l

ever

fails to

return

to

upp

er

pos

ition

Free

trav

el of

starting

lever is

too

gre

at

One

of the

gears

will

not

engage

Gears

disengage

by

them-

selves

during

riding

Gear

box

operates

with

nois

e

Main

drive

gear

s noisy

Cause

a)

r

atche

t

gear

teeth

bro-

ken;

b)

quad

r

ant

t

eeth

brok

en;

c) cl

utch

slipping

Starting

me

chanism

spring

broken

or

front

bushing

wa-

sher

came

out

of

mesh

with

the

end

fac

e

lugs

of

the

bush-

in

g

Wedge

became

l

oose

and

lever

turns

free

wi

th

respect

to

starting

shaft

One

of

the

pins

in

gearshift

disk

is

broken

Splines

of

gearshift

sleeves

or

gear

splines

worn

out

I.

Little

oil

in

the

gear

box

casi

ng

2.

Gear

teeth

worn

3.

Bearings

of

the

primary

or

seco

nd

ary

shaft

worn

I. Little oil in

th

e

main

dri-

ve

casing

2.

Gearing

maladjusted

(backlash

must

be

with

in

0.1

and

0.3

mm)

.

Symptoms and fault

tra

cing

a)

wh

en

depressing

the

kick

sta

rter

l

ever,

with

speed

gear

enga

ged,

motorcycle

r

emains

at

re

st

;

b)

same;

c)

starting

mechanism

ope-

rates

(mo

torcy

cle

moves)

bu

t

e

ngin

e

cra

nkshaft

fails to t

urn

Kick l

ever

ca

n be

easi

ly

raised

to

upp

er

position

by

hand

I. Check oil level

I.

Check

the

presence

of o

il

Continued

Remedy

a)

repair

the

gea

r box. Re-

plac

e

the

gea

rs on

int

e

rm

e-

diate

shaf

t;

b) r

eplace

the

quad

ra

nt;

c) check

th

e

clutch

control

drive

for pr

oper

ad

ju

stment;

if

necessary,

ad

ju

st

Repair

the

gear

box.

Repla-

ce

the

spring.

Check

whet

her

quadrant

is

cor

r

ect

ly

pr

essed

on

(refer

io

Fig.

28),

bring

the

washer

in

mes

h

wit

h

th

e

l

ugs

of bu

shing

1

Drive

the

wedge

in

and

L,..-

tig

ht

en

th

e

nut

Repair the

gear

box

Repair

the

gear

box.

Repla-

ce the s l

eeves

or

gears

I.

Add

oil

2.

Repair

the

gear

box. Re-

place

worn

gears

3.

Repair

the

g-e

ar

box. Re-

place

worn

bear

ing

s

I.

Add

oil

2.

Adju

st

the

backlash

""

*

-

'-='

•

Trouble

Main drive casing- over-

h

ea

ts

Front fork knocking

Cause

3.

Key

bolt loosened

L

No

oil or

oil

of

inade-

quate grade

2.

Component parts worn

or broken

Symptoms and

fault

tracing

I

I 3 Too great axial play

of

the universal jotnt

l.

Check the presence and

quality

of

oil

I 2 Dismantle the main drive

and check it for condition

at

i maintenan

ce

shop

I

Running

Gear

L Play

of

steering

col

umn

in

radial bearings

2.

Play

of

tapered end

pie-

ces

of

fork legs

in

traverse

du

e to clamp nuts

g-etting-

loose

3.

Fastenin.:

of

tlie front

fender or headlamp

is

dis-

turbed

4. Bushings

of

the fork leg

tubes are excessive

ly

worn,

lower bushing disconnected or

dropped

L Brake the front wheel

and, holding the motorcycle

by

the handlebar, push it

backward and forward to

de-

termine whether there

is

a

play

in

radial bearings

2. Check for the p

la

y by

pushing the motorcycle

for-

ward and backward with the

front wheel braked

3.

Examine and ·check the

nuts for proper lightening

by

using a wrench

4.

Place the motorcycle

on

a support and raise the front

whee

l.

Too great a play,

re-

vealed when shifting the legs

up

and down, indicates that

the front fork

is

faulty

Continued

Remedy

3.

Tighten

up

the nut

of

key

bolt

I.

Acid

oil

or replace it

2.

Repair the main drive.

Replace worn component parts

L Eliminate the play by

tightening the bearings

2.

Eliminate the play by

screwi

ng

in

the nuts

3.

Eliminate

th

e fault by

tightening the nuts

4.

Repair the front fork.

Check the component parts

for

condition, rep lace

t

h~

bush_-

ings

"-'

0

Troubl

e

Recurrent heavy shoc

ks

in the front fo

rk

(bad shock

absorption)

Cause

5.

End pieces came un-

screwed from the

spr

i

n~

I.

No

oil

in

the front fork

due to leakage

2.

Front fork

sprin~s

lost

e

la

sticity

Symptoms

and

faull

tra

dng

I. Take out the drain screw

of fork

l

e~

end piece (located

at

the bottom), c

he

ck the pre-

sence of

oi

l (130 cm3

of

oi

l is

r

eq

uired ior each fork leg).

Locale

oi

l leakage

by

inspec-

tion

2.

Dismantle

th

e fork, re-

move the

spr

in

~s

and check

Continued

Remedy

5.

After

unscrewin~

th

e

clamp nut, check and,

if

ne-

cessary, sere,,· up the end pie-

ces

I.

If

oil

is

leaking through

the drain screw, screw up

th

e

latter lightly

after

first clean-

in~

the

gasket

washer. Hal·-

in~

undone the clamp nul

of

fork leg tube, fill oil into the

fork and make

sure

the1·

e IS

no leakage.

If

o

il

leaks from under lllc

axl

e.

partially

di

smantle the

fork (remove lhe

whc~l,

screw

oif the ci;:Hilp nut on the tra-

\'l'I'Se, unscrew the gland hous-

ing

on

fork leg end piece, re-

mo,·e end pieces together with

sho

ck

absorbe

r}.

In

this case oil may leak

from under lhe s

ho

ck ahsorhcr

holtom.

Eliminate the l

eakage

by

lightening the bolt.

Pour

in

kerosene to check the tight-

ness. Assemble the fork and

fill it

wi

lh o

il

, make sure

th

ere

is

no

l

ea

ka

gc

2.

Repa ir the fork. Repla

ce

lite springs

This manual suits for next models

1

Table of contents

Other Dnepr Motorcycle manuals