52014+ XL Raider

NOTE: Refer to H-D service manual for detailed

instructions on the proper removal of OEM parts.

1. Place motorcycle on motorcycle lift. Make sure

bike is standing straight up and handlebars are

centered.

2. Raise motorcycle and properly support frame with

center stand. Verify frame is level.

3. Remove seat.

4. Remove side covers and disconnect battery.

NOTE: Always disconnect the negative battery ca-

ble first.

5. Remove side stand.

6. Remove LH passenger foot peg.

7. Disconnect rear wiring harness.

8. Remove and save rear turn signals from fender.

9. Remove rear fender assembly from motorcycle.

NOTE: Unplug oxygen sensors before removing

head pipes.

10. Remove mufflers, heat shields and head pipes

from motorcycle. Save exhaust hardware.

11. Remove chrome belt cover. Save cover and hard-

ware for reinstallation. Remove belt from motorcy-

cle. Mark belt orientation for reinstallation.

12. Remove rear brake line and remove caliper.

13. Remove shocks. Save LH mounting bolts.

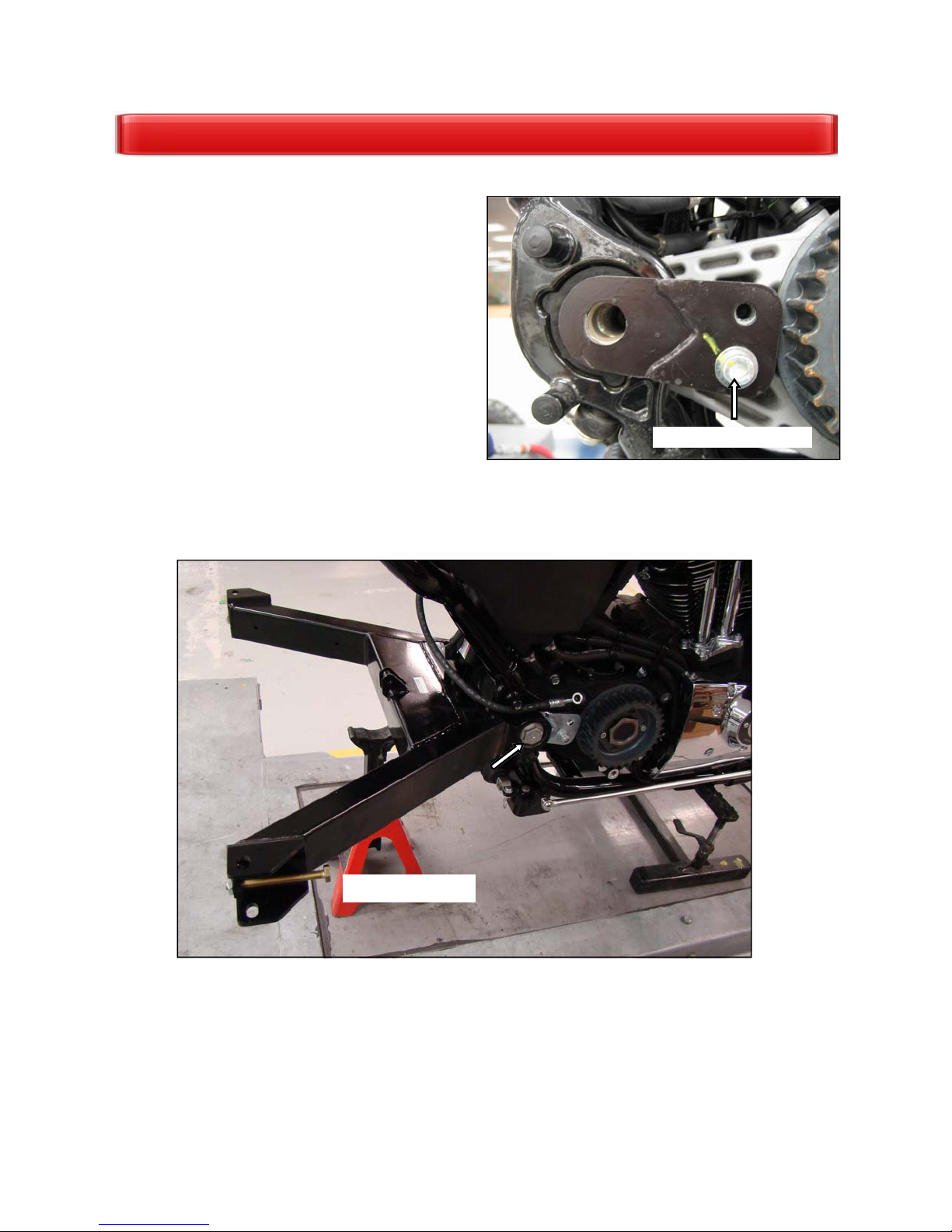

14. See Fig. 1. Remove rear master cylinder and RH

passenger foot peg assembly .

15. Remove rear wheel assembly.

NOTE: OEM swingarm pins will not be reused on

2014+ models.

17. Remove swingarm from H-D frame. Bearings

should be pressed out and reinstalled in trike swin-

garm, Replace bearings if they show signs of wear

or damage.

18. See Fig. 2. Remove rear brake line clamp and

plugs from rear frame.

PREPARING THE MOTORCYCLE

Master cylinder

Remove clamp

Fig. 1

Fig. 2

Remove plugs

RH foot peg