4.3 Enclosure of replace inserts

Special expertise is required for building the replace insert into the replace.

The installation must comply with current Building Regulations, National and European

Standards and any Local Authority byelaws.

2. After installing the whole replace, the inlet and outlet of conventional air through any

construction parts must not be limited. The cross section of the inlet and outlet of air grilles is

listed in the technical sheet.

3. To augment the nal appearance of the replace, the dimensions of the door frames

exactly match the ceramic facing produced by Romotop spol. s.r.o.

4. The enclosure must be made of suitable, designated materials.

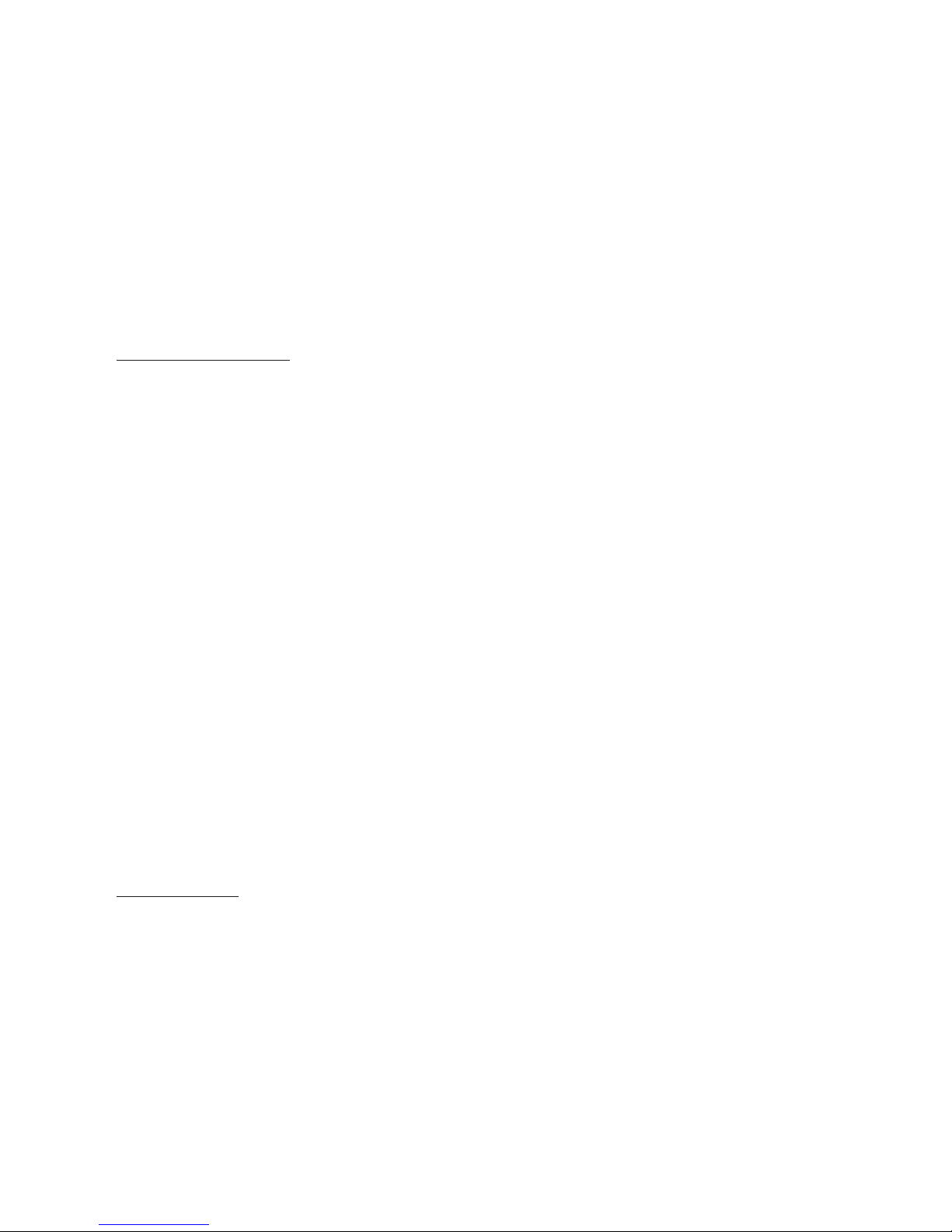

5. The warm conventional air outlet must be at least 30cm below the ceiling (gure 2).

6. An inammable ceiling construction must be present above the conventional warm air

outlet. Its temperature must not exceed 85deg C. Thus, the lower ceiling must be insulated

from the eects of heat coming from the replace by a barrier and at least one not fully

closeable grated opening (gure 2)

7. The same requirements also hold for the walls next to the replace and for the oor. A

ventilated air space must remain between the heat insulation and the wall.

8. The wall of the replace must not contain electric wiring and water or gas distribution

pipes. The wall nor its surface may contain ammable materials or materials which may

release harmful substances when heated.

9. Minimal free distances must be kept between the replace insert and the cover (see

technical sheet) for the whole height and width of the replace insert, so that convected air

can freely circulate and prevent the overheating of the replace set.

10. Eventual air conditioning piping must be located at least 40 cm from ammable building

constructions, or it must be documented that the heat from the piping cannot cause the

construction to catch on re. Convected air can reach temperatures of up to 300°C near the

insert!

11. Do not forget that replace inserts also spread heat in the direction of the oor. The oor

under the replace and at a distance of at least 80cm in front of the furnace and 40cm to the

sides of the furnace must be made of an inammable material. The distance is measured

from the closer edge of the furnace. The surface for the replace must have an appropriate

load capacity.

12. Do not forget that when considering the use of wooden decorative ledges, these must be

made of quality wood with a humidity of at most 15% and that convected cooling air must

ow around it with a gap of at least 1cm or they must be heat-insulated from the replace, so

that their surface temperature does not exceed 85 deg C.

13. When distributing hot air via natural air circulation, it is recommended to use horizontal

pipes at most 4m long. When distributing hot air via forced air circulation, the length of pipes

is not limited.

14. The pipes for distributing hot air must be tight and made of a material resistant to

operating temperatures. We recommend insulating them at the whole length, especially

where they traverse walls, ceilings or around ammable materials.

15. Hot air outlets must not be located at areas with materials susceptible to structural

changes caused by temperature uctuations (e.g. polyester lining, certain types of wallpapers

etc.)

16. No construction changes or adjustments may be performed on the replace insert!!!

01 – chimney vent

02 – wall

03 – insulation area above the chamber

04 – hot air chamber ceiling

05 – ventilated air gap

Vertical cross section of single-coating replace with closable furnace

06 – heat insulating layer

07 – hot air chamber area

08 – replace insert ue pipe

09 – replace insert smoke chamber

10 – closed replace furnace