Magnehelic®and Photohelic®are registered trademarks of Dwyer Instruments, Inc.

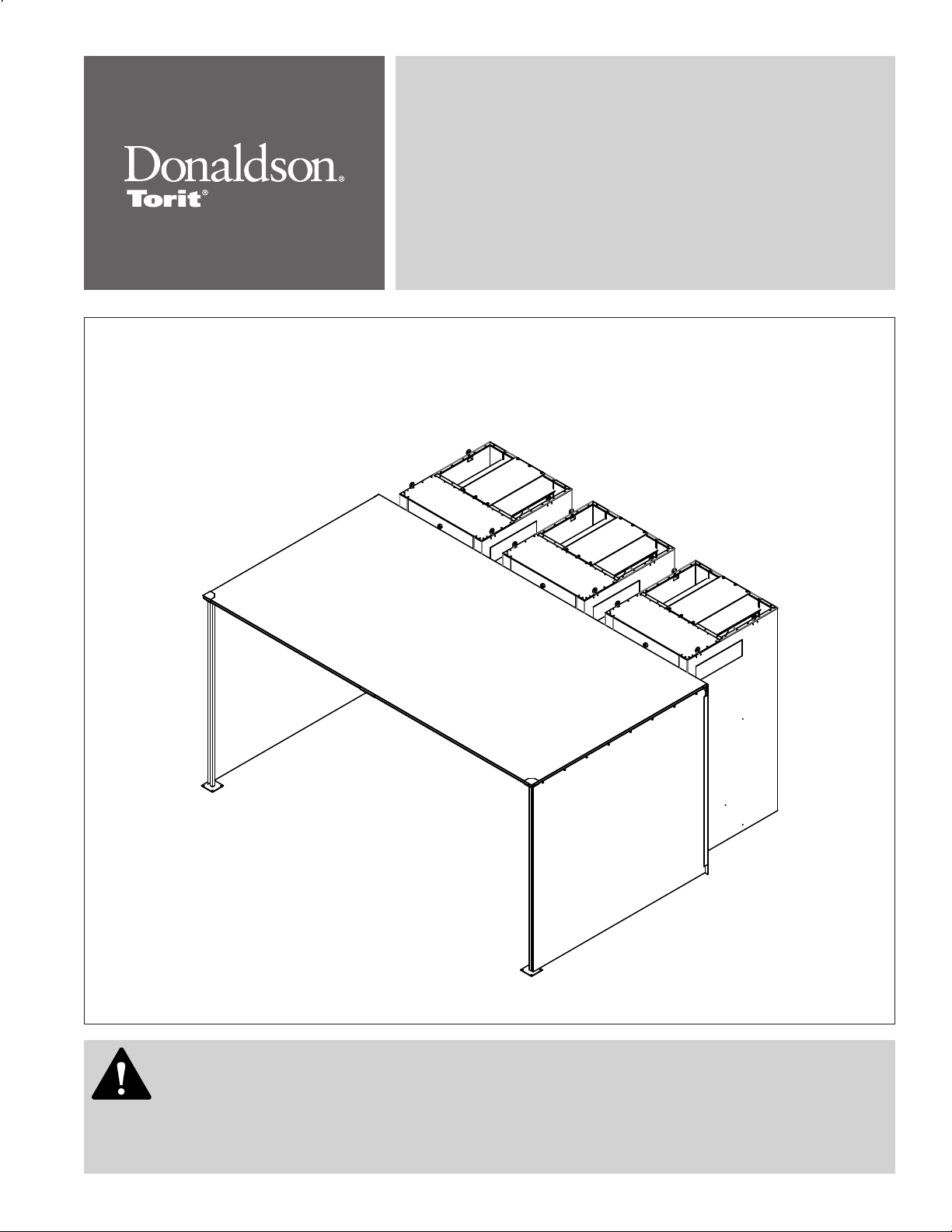

Downo Workstation, DWST 4-1 to 6-4

ii

Contents

IMPORTANT NOTES ............................................................................................................................................................................i

2 Product Description...................................................................................................................................................................3

3 Operation...................................................................................................................................................................................4

4 Product Service.........................................................................................................................................................................5

Operational Checklist .........................................................................................................................................................5

Dust Drawer........................................................................................................................................................................6

Filter Replacement .............................................................................................................................................................6

Light Bulb Replacement .....................................................................................................................................................7

Optional Afterlter Replacement.........................................................................................................................................7

Troubleshooting..................................................................................................................................................................8

Appendix A - Collector Installation................................................................................................................................................. A1

Collector Installation ........................................................................................................................................................ A2

Collector Location and Site Selection....................................................................................................................... A2

Provisional Anchor Bolt Recommendations ............................................................................................................. A2

Delivery and Inspection............................................................................................................................................ A3

DWST 4-1 and 6-1 Single Power Module Installation .............................................................................................. A4

DWST 4-2 to 4-4 and 6-2 to 6-4 Multiple Power Module Installation........................................................................ A5

Acoustic Hard Sided Booth Assembly ...................................................................................................................... A6

Soft Sided Acoustical Booth Assembly..................................................................................................................... A8

Compressed Air Installation...................................................................................................................................... A9

Electrical Wiring........................................................................................................................................................ A9

Solid-State Timer Installation..........................................................................................................................................A11

Optional Equipment....................................................................................................................................................... A15

Magnehelic®Gauge ............................................................................................................................................... A15

Photohelic®Gauge ................................................................................................................................................ A16

Delta P Control ...................................................................................................................................................... A18

Delta P Plus Control............................................................................................................................................... A18

Light Fixture ........................................................................................................................................................... A18

Afterlters ............................................................................................................................................................... A18

Acoustic Curtain for Power Module ........................................................................................................................ A19

Chamber Silencer................................................................................................................................................... A19

IEC Control Panel with Programmable Logic Control ............................................................................................ A20

IEC Control Panel Installation ................................................................................................................................ A22

Sprinkler ................................................................................................................................................................. A23

Start-Up/Commissioning Collector ................................................................................................................................ A24

Decommissioning Collector........................................................................................................................................... A26

Product Information ....................................................................................................................................................... A27

Service Notes ................................................................................................................................................................ A28

Donaldson Industrial Air Filtration Warranty................................................................................................................................ A30