2 Crane 4000LE 07-2022RL6002-001

Crane 4000LE Installation Manual

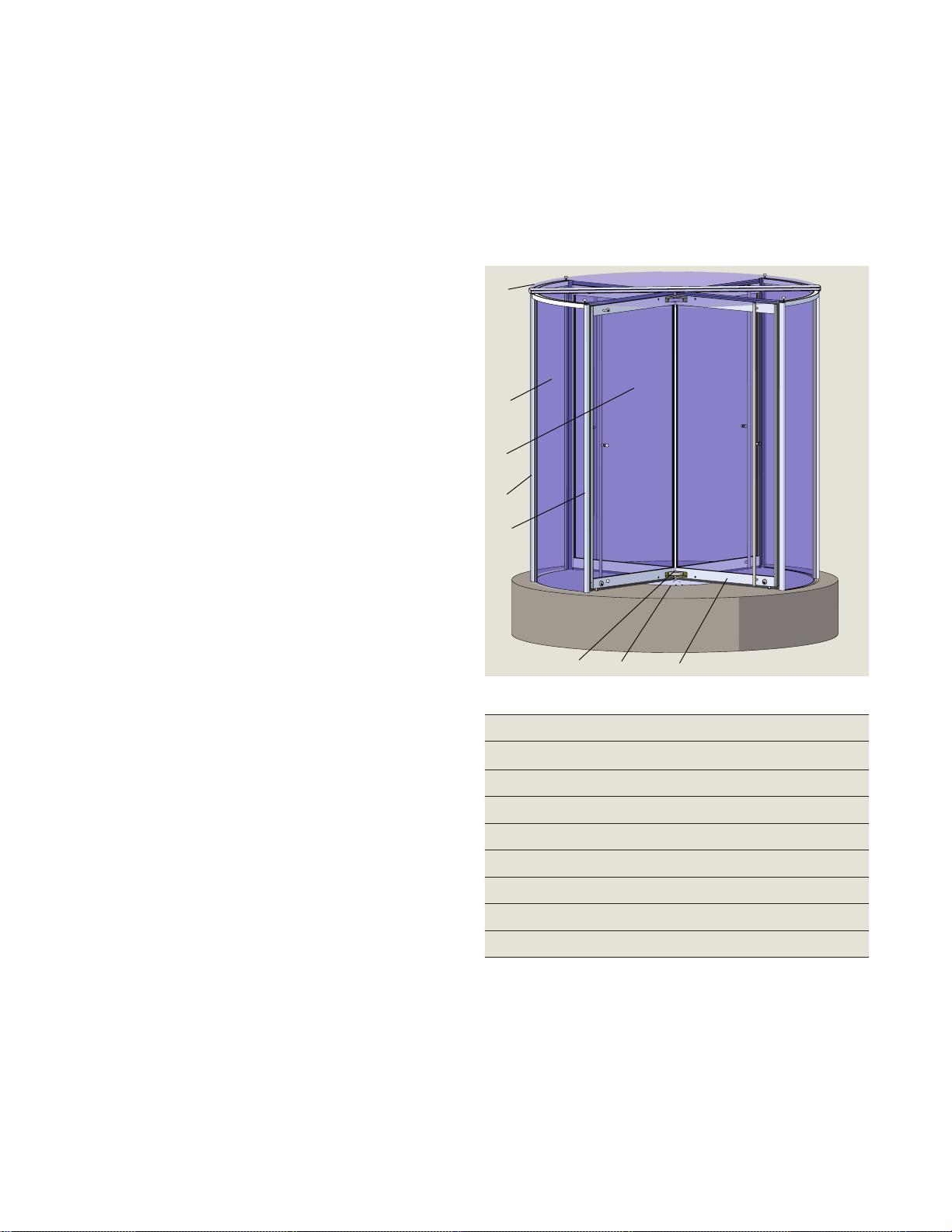

In-ground Motion Assist 360 drive and speed control

Remote control enclosure

Table of Contents

Table of contents

General information

Product description and technical

information

. Crane LE series

. Available options

. Motion Assist technical information

. LE series model comparison

Safety information

. Safety Warnings

Operator components

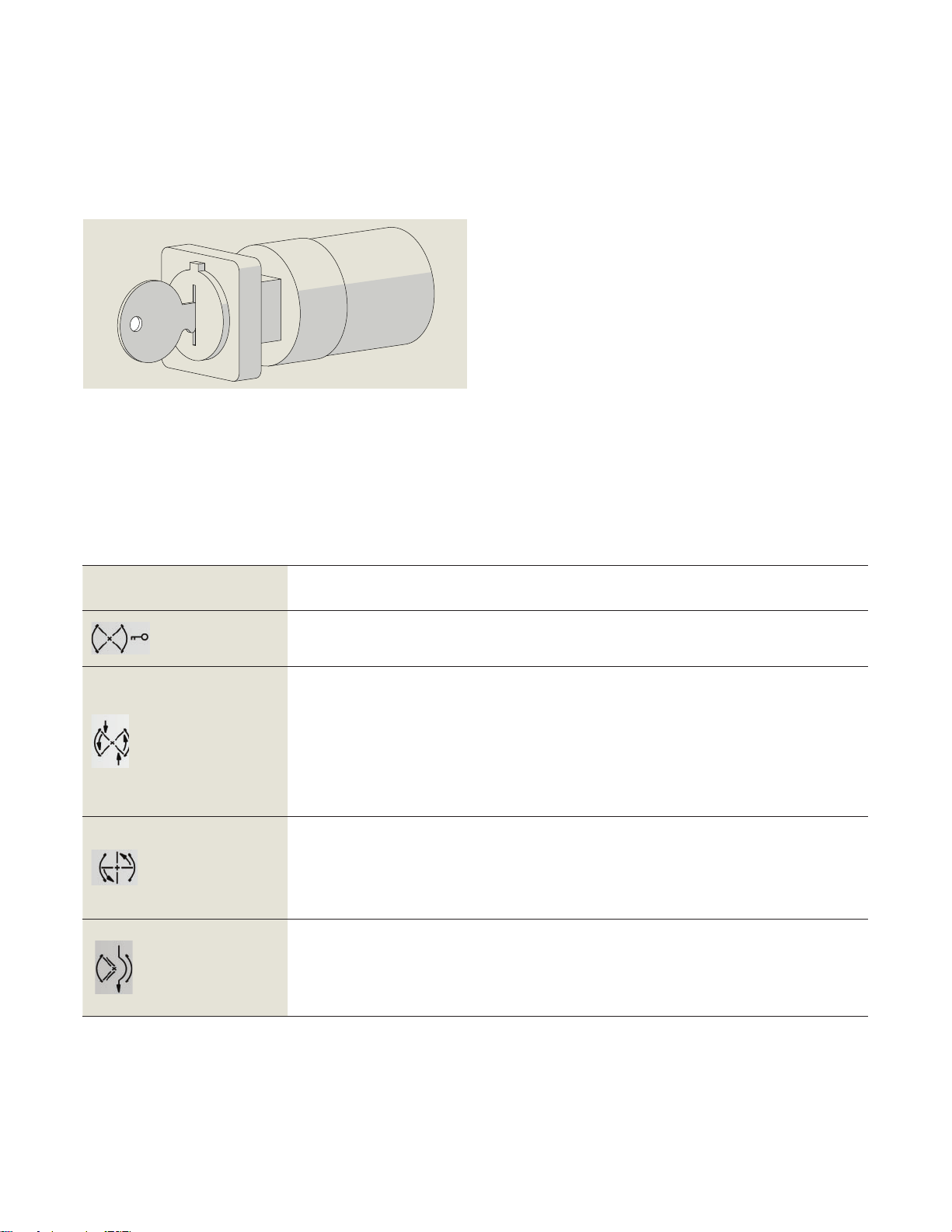

. Mode switch

. Emergency Stop pushbutton

.. Triggering an Emergency Stop

.. Start up after an Emergency Stop

. Service panel (option)

. Wave to Open, Push to Start plates (option)

. Fault LED

Revolving door assemblies

. Door configurations

In-ground Motion Assist drive and speed

control

. Glass canopy with muntin assembly

. Muntin and bearing assembly

. Glass canopy with bearing assembly

. wing steel shaft assembly, floor drive/speed

control RS-

. wing steel shaft assembly, floor

drive/speed control RS-

. Hanger assembly, steel shaft RS-X

. Bookfold mechanism

. Enclosure posts

. LE door wing assembly example

. Door wing types

. Header bar assembly

. Floor bar assembly and base clips

. Motion Assist in-ground drive

assembly RS

. In-ground speed control assembly

. Motion Assist drive bracket assembly

. Remote enclosure – Motion Assist

power supply and control unit

. Floor grill and pan assembly (option)

. Uninterruptible Power Supply (UPS)

(option)

In-ground container hardware

. In-ground container assembly

. Motion Assist extension cables to

remote enclosure

. Motion Assist earth grounding cable

. Service panel communication cable

. In-ground container assemblies with

fastener hardware

. Container lids and cover assemblies

Recommended Tools And Materials

. Recommended tools

. Recommended installation materials and

installation hardware

Assembly safety

. Assembly safety

. Cordon off work area

Prepare finished floor

. Assembly location

. Preparing finished floor for revolving door

assembly

Floor template

Mark revolving door location on

sub floor, install base rail assemblies

. Mark door centerpoint

. Mark door base rail locations, install base

rail assemblies

. Floor base clips and rail assembly –

mounting to sub floor

. Floor clip shimming

Install leveling plate in pit, install

container in pit

. Pit location and dimensions

. Crane Shop drawing, pit dimensions for

in-ground container

. Install leveling plate in pit

. Orientation of in-ground container in pit –

building interface

. Conduit in pit for building wiring – overview

. Determine in-ground container conduit

adapter position in pit

. Container drain: locate and drill hole for

through-wall pipe fitting

. Container drain hole location dimensions

using leveling plate

. Check hole alignment of container covers

on container flange

. Install cable ties

. Install in-ground container in pit