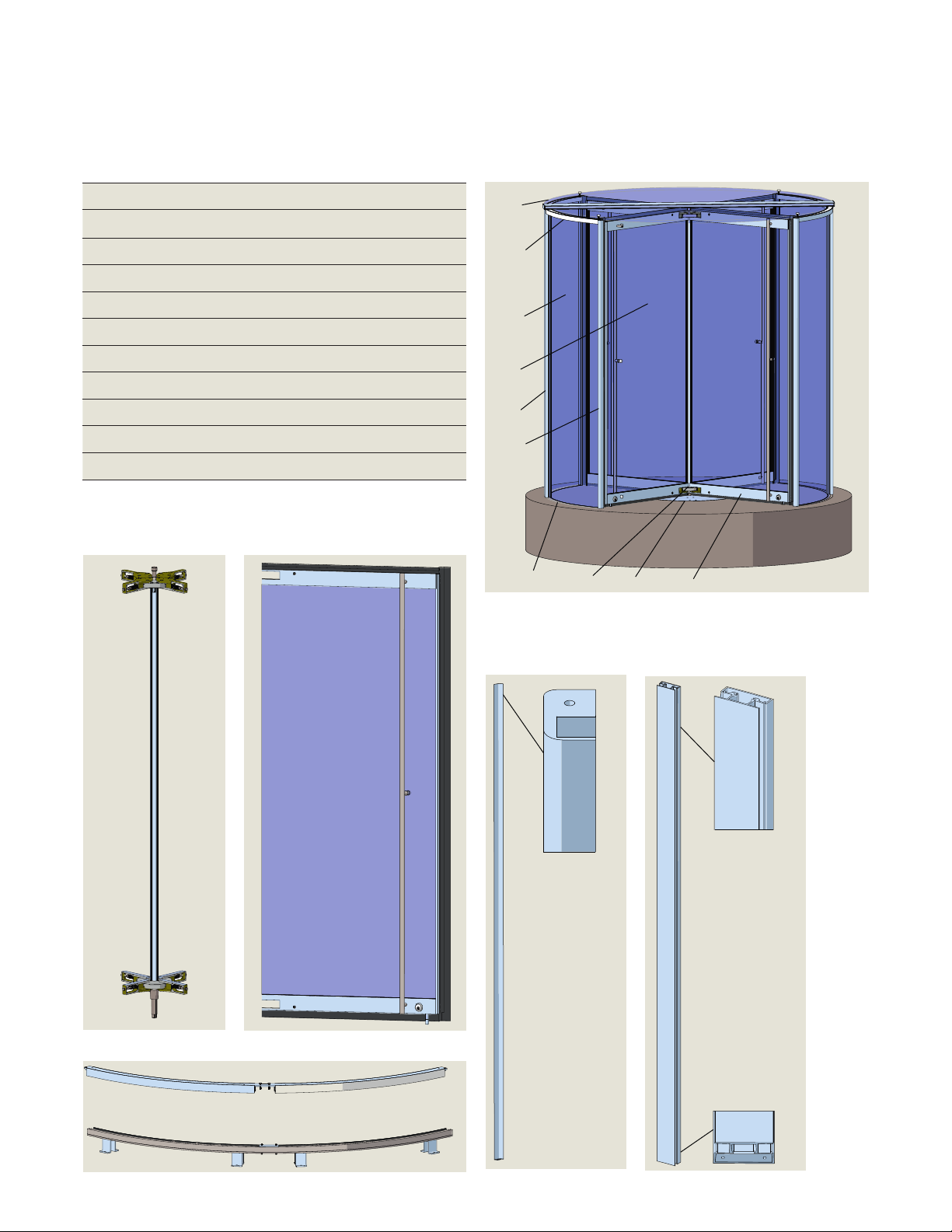

3Crane 4000LE 07-2022RL6002-002

Crane 4000LE Owner's Manual

In-ground Motion Assist 360 drive and speed control

Remote control enclosure

Chapters 1,2 and 3

. Owner's Manual

This Owner's manual applies to Crane LE manual

revolving doors with:

• In-ground (low profile) Motion Assist drive with

remote control enclosure.

• In-ground speed control.

. Manual storage.

This document must be kept in a secure place, and

accessible for reference as required.

. dormakaba.us website.

Manuals are available for review, download, and printing

on dormakaba.us website.

. Dimensions

Unless otherwise specified, all dimensions are given in

inches (“).

General information

To our customers

We are pleased that a Crane LE (low energy)

manual revolving door has been selected for this

installation. Crane designed, tested and built the system

to provide many years of service.

The purpose of this manual is to provide you information

regarding your Crane LE revolving door. This

includes safety and maintenance information.

It is essential that you recognize the importance of

maintaining your door.

What you should know

.. dormakaba USA, Inc. distributor information.

Be sure that the dormakaba USA, Inc. distributor has

provided the following information for this revolving

door installation:

. Crane Owner's Manual RL-.

. Discussion of problems that could result from door

operation after a malfunction observed.

. Number to call for service or questions about your

revolving door if you are uncertain of any condition or

situation.

. Location of job number tag on door steel center

shaft assembly.

• Reference Chapter ..

. Distributor information

. Location of Vac circuit breaker for

Motion Assist power supply.

• Reference Paragraph ., remote control enclosure.

. Exit location of in-ground container drain tube or

pipe.

• Reference Chapter , Maintenance information.

WARNING

If there are any problems, discontinue door

operation immediately and secure the door in

a safe manner.

Call your local dormakaba USA, Inc.

distributor for repair.

It is your responsibility as owner and caretaker of the

equipment, to inspect the operation of your door system

to insure that it is safe for use by your customers and

employees.

Call your local dormakaba distributor for repair. The

distributor is trained to service the revolving door using

the applicable dormakaba USA, Inc. Installation Manual.

. Service availability.

dormakaba USA, Inc. has a nationwide network of

authorized distributors for sales, installation and service

of its products.

. Symbols used in this manual.

WARNING

This symbol warns of hazards which could result

in personal injury or threat to health.

NOTICE

Draws attention to important information

presented in this document.

CAUTION

Warns of a potentially unsafe procedure or

situation.