S SERIES TRIPLE SCREW PUMPS 8

SECTION 5

INSTALLATION

PIPING SYSTEM

Since the pump’s basic operating parts are designed to be axed

on screws, extremely close running clearances exist between the

screws and the body; therefore, it is very important to have the

piping (especially the suction-side piping) cleaned thoroughly

before connecting the piping to the pump anges.

After the pump unit has been installed and secured on its

foundation, pipe connections may be installed.

NOTE: Please see pump outline drawing for location of all pipe

connections, ange sizes and other notes pertinent to piping.

Pipes should be as short and direct as possible. Use long radius

elbows to change direction when needed.

Suction piping must be at least the same size of the inlet diameter;

it is acceptable if the suction pipes are one class larger than the

inlet. For example, if the size of the inlet is 150 mm (6 in), the

suction pipes could be 200 mm (8 in). The pipe diameter (length of

pipe should be four [4x] times that of the pipe’s diameter) is used

to connect the suction pips and the inlet. Discharge piping should

be the same size as the diameter of the outlet.

All major piping parts, including suction pipes, discharge pipes,

valves and strainers, should be supported independently and

installed properly to avoid any unnecessary strain on the pump.

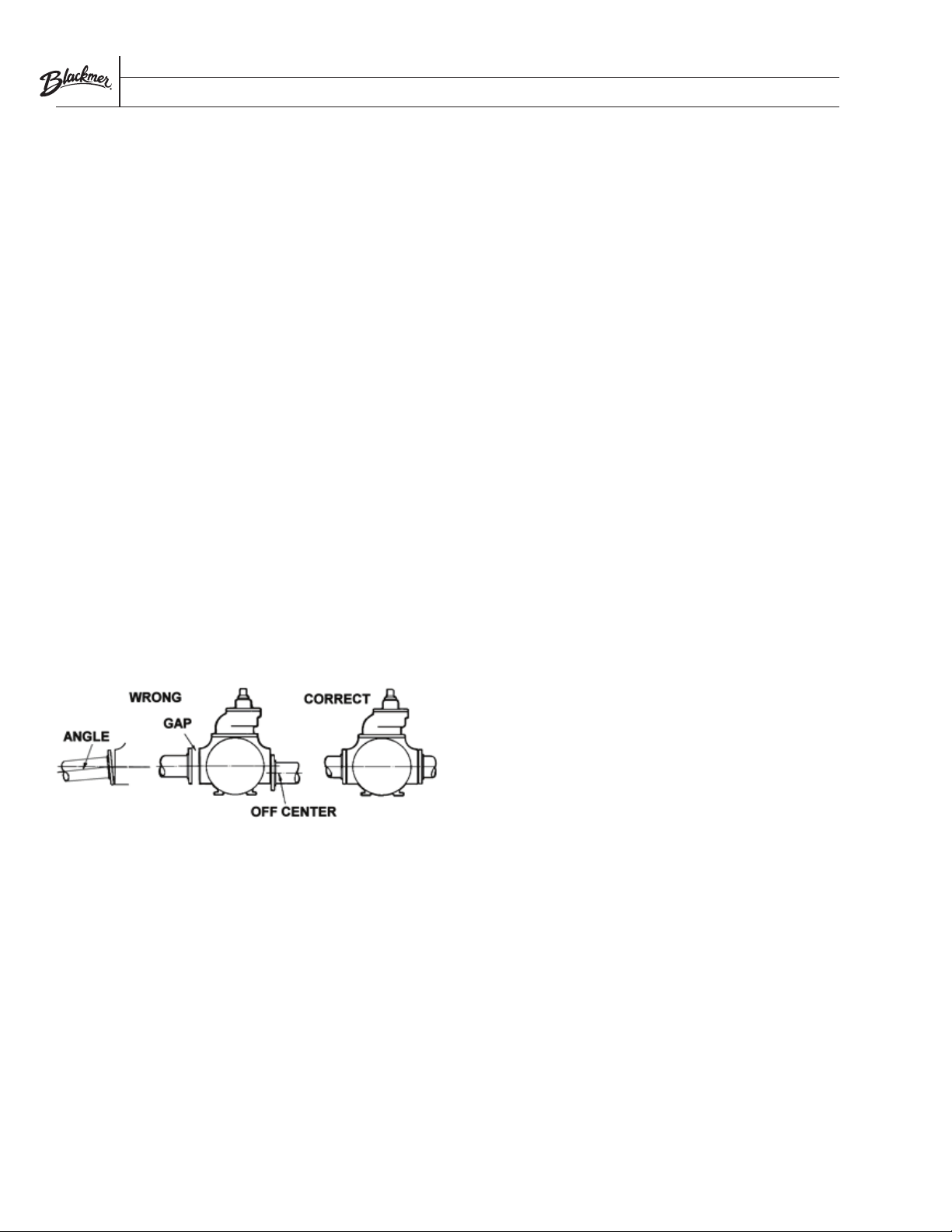

The piping anges must be properly aligned with the pump

anges. To check alignment, insert ange bolts through the pipe

and pump ange. If the bolts are easily moved within the bolt

holes and if the ange faces are parallel with each other, the

piping is properly aligned.

All the valves and lters on the suction pipes and discharge

pipes shall be supported independently and secured to avoid

transmitting the stress to the pump body. The ange of the pipes

shall be straightly facing the anges on the pump. Check the

alignment between the pipes and ports by looking at the through

holes on the pipe anges and port anges. If the bolts can move

freely through the holes and the anges are parallel to each other,

then it is deemed that the pipes are aligned.

If the pump is required to operate with suction lift, the suction piping

system must be properly made in relation to the original design.

NOTE: NPSHa of suction piping must be larger than pump’s NPSHr.

The pump cannot be expected to overcome deciencies in the

suction piping system, such as narrow/thin runs of suction piping,

numerous elbows, valves and excessively high points above pipe

suction, etc. In such cases, cavitation will invariably occur and the

pump may not operate at normal capacity.

Pump and pump accessories should be kept apart by valves to avoid

any force while pressure testing or washing the piping system.

PIPING SYSTEM ACCESSORIES

SUCTION STRAINERS

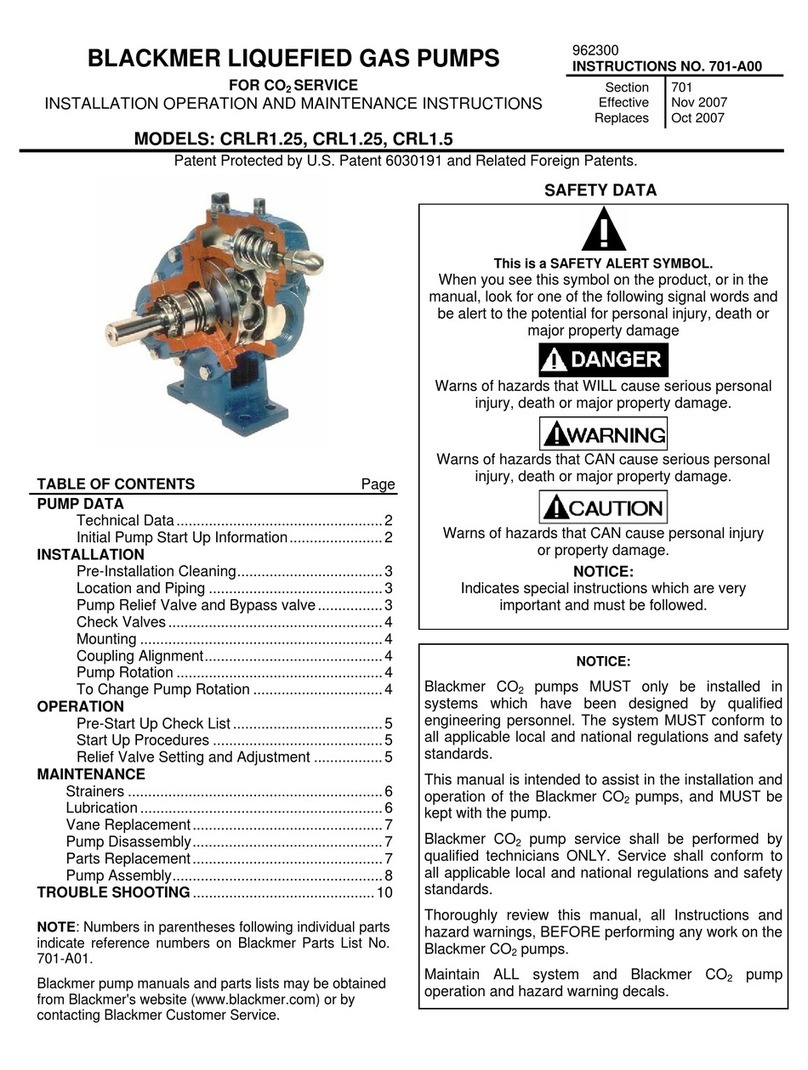

Blackmer suggests that suction strainers be installed on the

suction side of the pump at least temporarily until the new system

is deemed clean of solid residue. The screen area of the strainer

should be as large as possible. Generally, the strainer screen should

be constructed of 40 meshes, and 10 or 20 meshes for high-viscosity

applications. The net screen area should be approximately ve (5)

to eight (8) times the ow cross-sectional area of the suction pipe.

However, if the viscosity of the media is in excess of 200 mm2/s,

then approximately 10 to 20 times the pipe cross-sectional area

is suggested for the net screen area. The maximum dierential

pressure is 0.1 bar (1.5 psig). Install pressure gauges on either side

of the strainer to indicate when the strainer should be cleaned. The

installed strainer should be easy to maintain and clean.

Generally, strainers can be used on all liquids except for those of

an extremely high viscosity. In these cases, the strainer cannot be

installed; therefore, piping and accessory cleaning is mandatory.

CHECK VALVE

If the discharge piping system is subject to a high static head and if

the uid handled ows back into the pump cavity when stopping

the pump, a check valve should be installed. This valve will prevent

hydraulic shock acting upon the pump, and, most importantly, it

allows for separately starting the pump in a parallel connection

system.

PRESSURE RELIEF VALVE

An external pressure relief valve must be installed between the

pump discharge flange and the gate valve (on the discharge pipe

after the discharge port) to protect the pump and the piping

system. The pressure and flow rating should match the working

pressure and flow of the pump, and media through the valve must

return to the suction source.

NOTICE: The pump internal pressure-limiting valve is designed

to protect the pump from excessive pressure and must not be

used as a system pressure control valve.

GAUGES

Proper gauges must be installed to monitor and control the pump

while in operation. A pressure gauge and a vacuum gauge can be

separately installed on the inlet and outlet piping near the pump.