I N D E X

2

.....................................................................................page 3

...............................................................................page 3

.................................................................................page 3

......................................................................page 4

.........................................................................page 6

....................................page 7

...................................................................page 8

.................................................................................page 9

...............................................................................page 9

......................................................................page 9

...........................................................page 10

..........................................................page 12

................................................page 13

.................page 13

.............................................................page 15

.................................................................................page 15

...........................................................................................page 16

...................................................................................page 16

.............................................................................page 17

........................page 17

.................................................................page 18

................................................................................page 18

...............................................................................page 19

.....................................................................page 19

....................................page 21

...................................................................................................page 22

........................................................................page 22

.......................page 23

........................................................................page 24

................................................page 24

..................................................page 24

................................................................................page 25

..............................................................................page 27

...................................................................page 27

....................................................................page 28

...........................................................................................page 29

System requirements

How to install outer discs

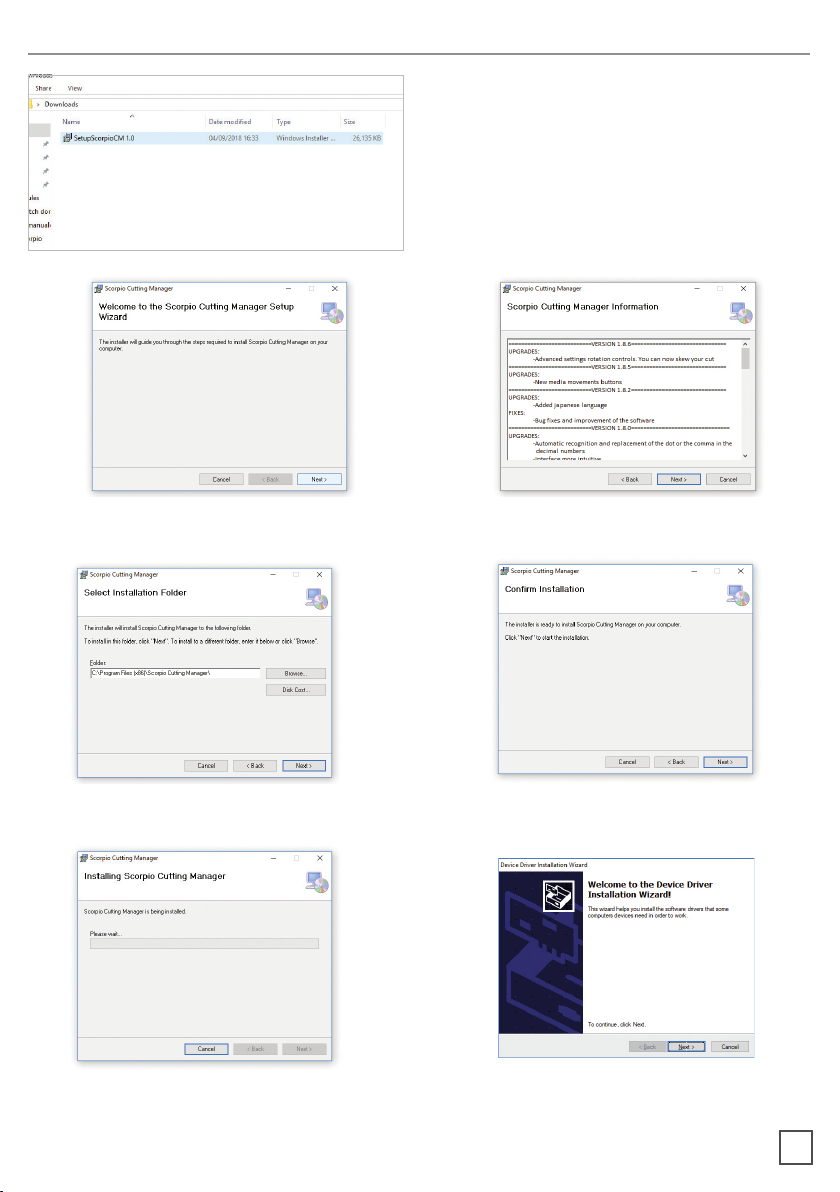

How to install the plotter

How to install the cutting plotter

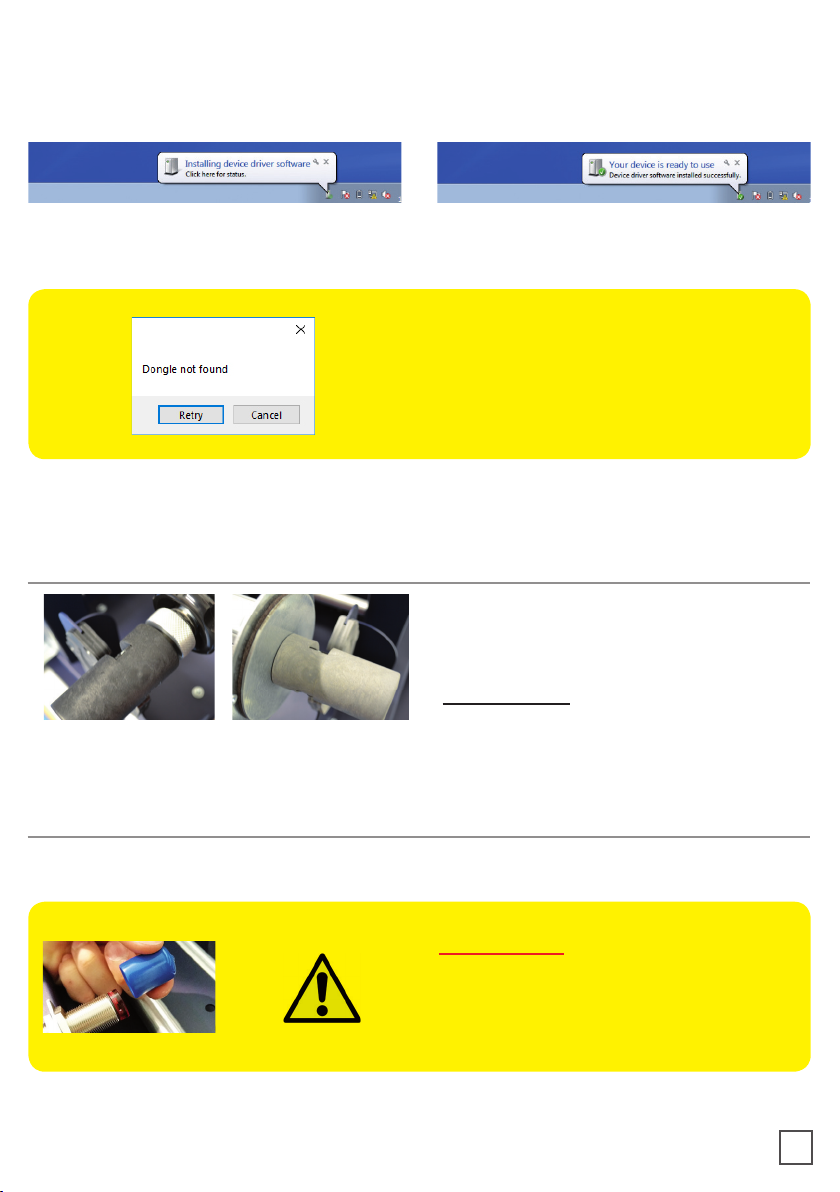

How to install the core holder

How to load and operate with the lamination module

How to set the lamination sensor

How to adjust the clutch

When to adjust the clutch

Load the media into the plotter

How to run the cut test and start a job

How load the matrix remover & slitter

How to load the matrix remover core holder

How to load the rewinder core holder and set the slitter module

How to add or remove blade holder

Metal guide alignment

Error Messages

Black-mark detection

Black-mark position in the media

How to cut blank labels

How to update software

How to restore plotter settings

How and when to reduce the plotter feeding speed

Media path

Ultrasonic sensor calibration

Lamination / matrix remover&slitter modules speed rotation

How to install pressing roller

Adaptor for the Scorpio SCR35 / SCR35PL

How to used the o-ring on the matrix roller

Graphtech mantenaice

How to replace the knife

How to replace the slitter blade

How to replace the cutting mat

Troubleshooting