5. HEALTH AND SAFETY INFORMATION

5.3 RESIDUAL RISK

Important: Although the safety instructions and operating manuals for our tools contain extensive

instructions of safe working with power tools, every power tool involves a certain residual risk which

can not be completely excluded by safety mechanisms. Power tools must therefore always be

operated with caution!

5.4 SAFETY INSTRUCTIONS FOR MAINS POWERED BATTERY PACKS AND

CHARGERS

Chargers

– The charger is for indoor use only.

– Prior to plugging the charger in to the supply, check that the plug and the cable are in good

repair. If either are damaged, have the defective item replaced immediately by a suitably

qualified person. If the casing of the battery charger is damaged, it is good policy to have the

charger checked over by a suitably qualified person.

– Only use a correctly rated mains outlet to provide power, do not plug into site generators, attach

to engine generators or D.C. sources. Do not use a mains socket outlet that is not switched.

– Use the correct Draper charger in conjunction with it’s corresponding battery pack (see the

table on page 19 for information).

– Do not charge any other batteries with Draper chargers. Any other application is considered

misuse.

– Do not attempt to charge battery packs that are too hot (over 30ºC) or too cold (under 5ºC); if

these conditions apply set the battery pack aside to “normalise” before proceeding with the

charging operation.

– Set up the charger and cable in a safe place where it won’t be knocked, tripped over, stepped

on, etc. and where it is well ventilated; make sure the ventilation slots in the charger case are

not obstructed, plug the charger into the socket outlet.

– Inspect the battery pack for damage; if it is undamaged, plug it into the charger, ensuring the

correct orientation. (Most chargers and batteries have ‘keys’ etc, to make sure the battery pack

is not inserted incorrectly, if you are having to ‘force’ the battery pack into the charger, the

chances are you have it the wrong way round, check and try again.)

– Switch the charger on and check that the correct indicators illuminate, allow the battery pack to

charge (see the specific instructions for your charger). Once charging is complete, switch the

charger off, remove the battery pack and store, repeat the procedure if you have more than one

battery pack to charge.

Caution: When the battery charger has been continuously used, the battery charger will be hot.

Once the charging has been completed, give 15 minutes rest until the next charge.

– After charging is complete, unplug the charger from the socket outlet by pulling on the plug. Do

not pull on the cable. Store the charger in a dry secure place.

– If, when the charger was switched on, the correct indications did not occur, leave for two or

three minutes to allow the charger to stabilise; if the correct indications occur, allow the

charging cycle to proceed as normal.

– If no indication appears at all, switch off, remove the battery pack, unplug the charger, check

that the charger contacts and the battery contacts are clean and repeat the process; if there is

still no indication, switch off, remove the battery pack, unplug the charger and check the fuse. If

the fuse is blown, replace and repeat the process; if the fuse blows again, or if the fuse was

intact, attempt no further action. Refer the charger to a suitably qualified person for repair.

- 8 -

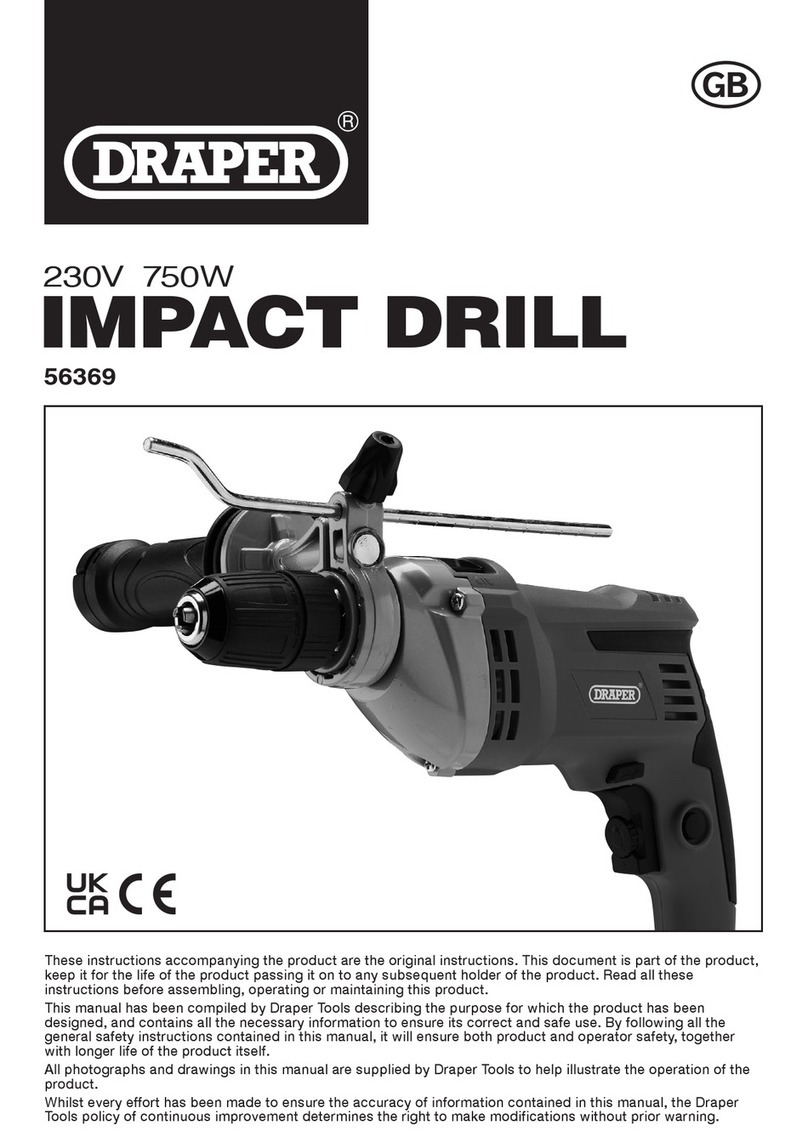

9. BASIC OPERATION

FIG.13

- 17 -

FIG.12

9.10 DRILLING WOOD AND PLASTIC –

FIG. 11

To prevent splitting around the drill holes on the

reverse side, clamp a piece of scrap timber

under the material to be drilled.

9.11 DRILLING METAL – FIG.12

Metals such as mild steel, aluminium and brass

may be drilled.

– Mark the point to be drilled with a centre

punch to help the drill bit tip to locate.

– A drop of oil on the drilled area will aid

cutting and help prolong the life of the bit.

Note: Although metal drilling is technically within

the capabilities of this drill, its rotational speed

is not always fast enough to achieve perfect

results every time. For this reason, extra

caution should always be taken when drilling

metal, as snagging of the drill may occur.

9.12 DRILLING MASONRY

Start drilling at a low speed to prevent the drill bit

from wandering. Once penetration is achieved, fully

depress the trigger to achieve maximum speed and

hammer power.

9.9 SCREWDRIVING

To prevent slip or damage to the screw head, match the screwdriver bit to the screw head size.

To remove screws:

– Move the direction switch to the reversing position and apply pressure to the screw head and

depress the trigger slowly).

Screwdriver bits are consumable items.

B

C

B

C

A

A