Draper FlexShade Tension ZIP Programming manual

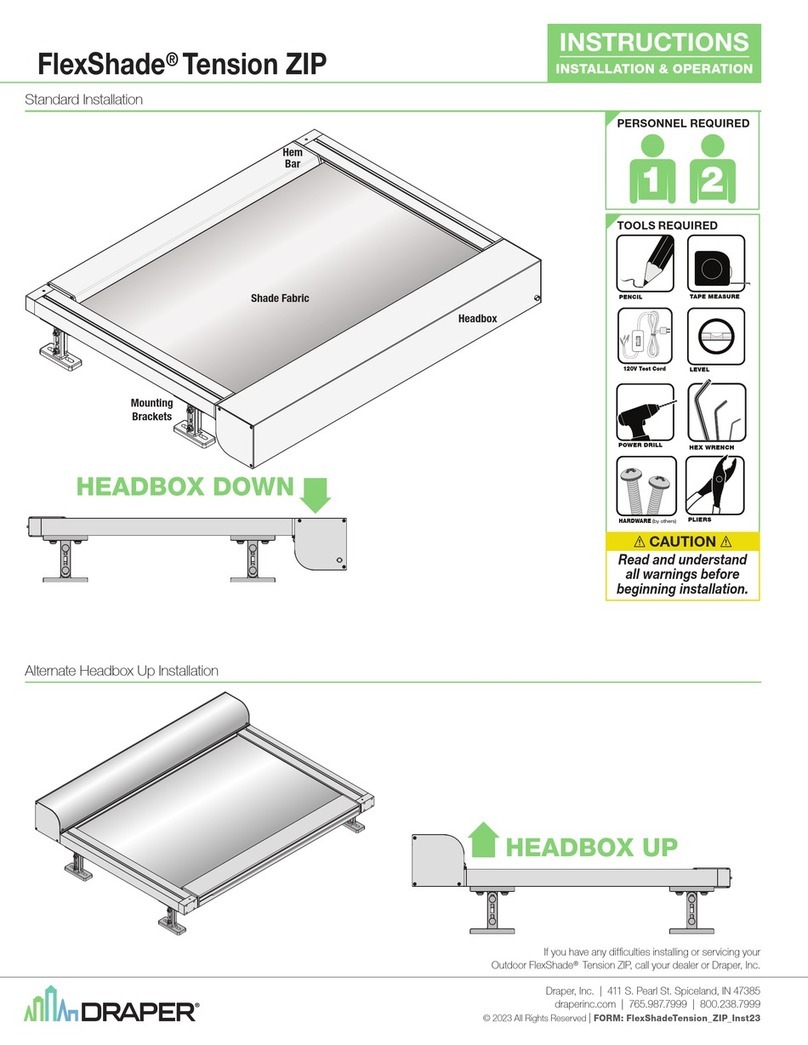

Standard Installation

Alternate Headbox Up Installation

Headbox

Mounting

Brackets

Hem

Bar

Shade Fabric

HEADBOX UP

HEADBOX DOWN

HEADBOX UP

Draper, Inc. | 411 S. Pearl St. Spiceland, IN 47385

draperinc.com | 765.987.7999 | 800.238.7999

© 2022 All Rights Reserved | FORM: OutdoorTension_ZIP_Inst22-R

Outdoor FlexShade® Tension ZIP

INSTRUCTIONS

INSTALLATION & OPERATION

If you have any difficulties installing or servicing your

Outdoor FlexShade® Tension ZIP, call your dealer or Draper, Inc.

21

PERSONNEL REQUIRED

POWER DRILL

PENCIL TAPEMEASURE

(by others)

HARDWARE

LEVEL

HEX WRENCH

120V Test Cord

TOOLS REQUIRED

CAUTION

Read and understand

all warnings before

beginning installation.

PLIERS

Caution:

1.

Inspect all boxes to make sure you have

received the proper shades and parts.

Controls may be shipped separately, or in

same carton as shades.

2.

Open cartons lengthwise, taking care not

to cut into cardboard shipping container.

3.

Before mounting shades, verify

measurements on label provided with shade,

and ensure unit is installed at correct width.

4.

All end caps, fascia, pocket headbox, and

other hardware must be installed level.

Shades must be level and square.

5.

Read the following installation guidelines

thoroughly and follow them carefully.

Failure to do so may cause product to fall or

otherwise fail, and invalidates warranty.

6.

Installer is responsible for selecting mounting

hardware appropriate for site conditions.

Section 1 - Mounting Tension Zip Side Channels

Caution: Before mounting shades, verify measurements on label provided with shade, and ensure unit is installed at correct width.

Section 1.1 - Mounting Considerations

Outdoor Tension ZIP is secured to the building structure by several mounting brackets

(number of brackets is size dependent)

that attach to BOTH Side Channels.

A.

It is recommended shade be mounted with headbox DOWN.

B.

Side rails are universal and can be placed on either side.

C.

Mounting brackets can slide along the entire length side channel

and MUST be secured to the building structure.

D.

Mounting brackets are to be spaced no more than 48"

(1219mm)

apart, and brackets

must be within 6"

(152mm)

of headbox and endcaps.

E.

Channel openings MUST face each other.

F.

Side channels must be parallel, square, in plane, and level with each other.

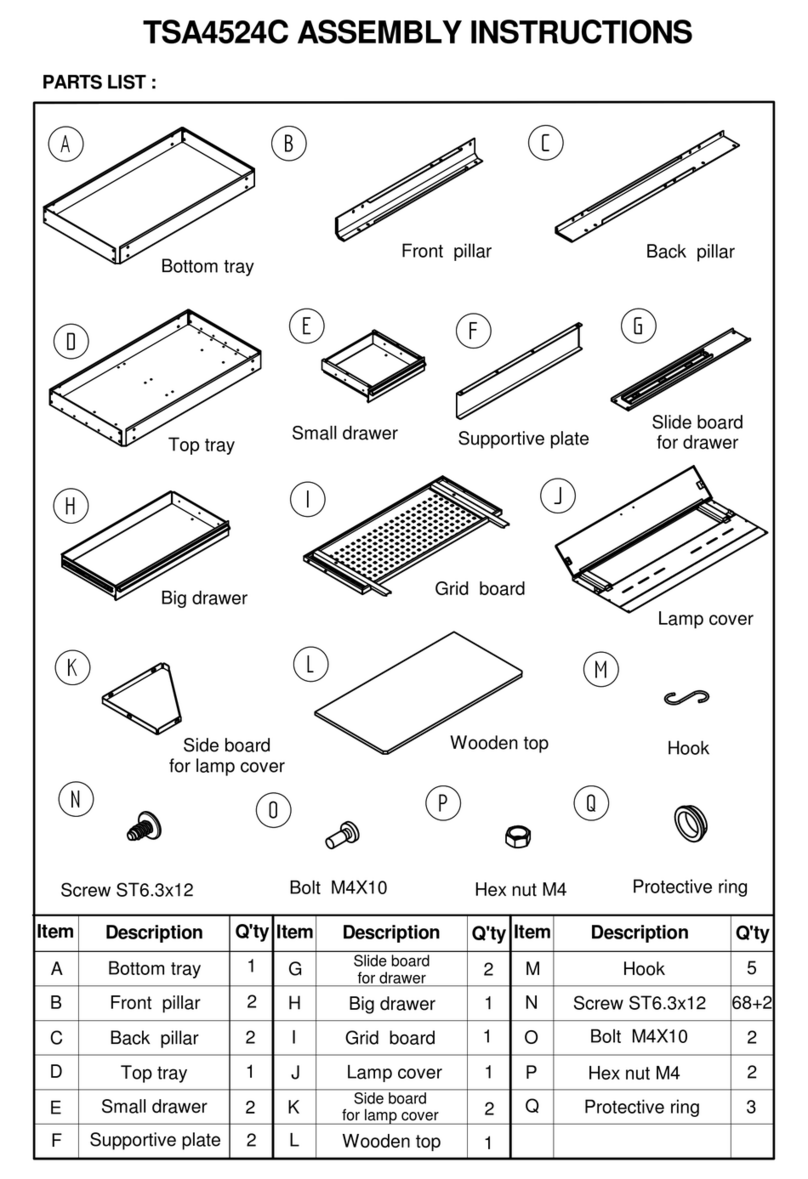

5/8" Square Nut

(2 per Bracket)

Slides into Side Channel

ADJUSTABLE

BASE BRACKET

4" (100mm) to

6.5" (168mm)

LOOSEN HEX

NUTS to ADJUST

HEIGHT

(2 per Bracket)

4 ½"

(114mm)

2 ½"

(63.5mm)

MAX

HEIGHT

6

5

/

8

"

(168mm)

1 ¾"

(44mm)

PLEASE READ - Field Adjustments

Each Draper Solar Control Shade is tested to

ensure proper operation. Even with this testing,

some field adjustments may be needed for

telescoping.

If the shade is telescoping, place a piece of

shimming fabric into the fabric roll when the shade

is deployed on the side that the fabric will be drawn

toward. For example: if the fabric is tracking to the

left, place the shimming fabric on the right side.

PLEASE READ - Cleaning and Maintenance

Cable and product will settle over first few months and re-adjusting of limits is

required. Failure to do so will result in product possible product damage.

Window covering products manufactured by Draper, when properly installed, should require no operational

maintenance or lubrication.

Most standard Draper fabrics may be cleaned at the window by vacuuming with a soft brush attachment.

They also may be cleaned by using a sponge or soft cloth and mild solution of warm soapy water. A mild

dish-washing liquid is recommended. A clean dry cloth is recommended for the metal finish.

Please Note: Exceptions are GreenScreen Evolve, GreenScreen Revive, Flocké, and Phifer

SW7000 fabrics, which must be cleaned with a dry art sponge.

Section 1.2 - Attaching Brackets to Side Channels

1.

Remove the four

(4)

screws and endcap from each side channel

(fig.1)

.

2.

Slide the

5/8

" Square Nuts

(2 per mounting bracket)

into both side channels

(see fig. 2.)

Note: If using Spreader Bar

(See Section 11)

, you will need to insert the Square Nuts to attach it now.

3.

Attach the mounting brackets

(2 fasteners per bracket)

to the side channels

(see fig. 3)

.

4.

Place side channels in desired position

(See fig. 4)

and mark the location of the bracket mounting slots.

5.

Secure mounting brackets and side channel assembly to building structure

(see fig. 4 DETAIL)

.

Please Note: Installer is responsible for selecting mounting hardware appropriate for site conditions.

WINDOW

OPENING

MOUNTING POINTS

Headbox Width - 2½” (63.5mm)

MOUNTING

BRACKETS

Figure 4

SIDE

CHANNEL

Button-head Screw

5/8" Square Nut

ENGAGED IN

SIDE CHANNEL

5/8" Split Lock Washer

STANDOFF

Mounting Bracket

CABLE

Figure 3

SIDE

CHANNEL

ENDCAP

SCREWS

ENDCAP

x4

Figure 1

SIDE

CHANNEL

5/8” Square Nuts

2 per bracket

Figure 2

Figure 4

DETAIL

page 3 of 20

Outdoor FlexShade® Tension ZIP

page 2 of 20

Outdoor FlexShade® Tension ZIP

WARNING

Improper installation and use of the Outdoor FlexShade Tension Zip can result in serious injury or death. Primarily, injuries can occur if the unit

falls due to imprecise installation, mishandling of the unit during installation, or installation on an insufficient wall or ceiling structure. Please

use extreme care.

1.

Please read the following installation guidelines thoroughly and follow them

carefully. Failure to do so may cause product to fall or otherwise fail, and

could result in serious injury or death.

2.

Installation and calibration of the unit should only be performed by an

authorized, qualified, and experienced professional. In particular, electrical

work and wiring [indicated in diagram by dashed lines] must be completed

only by a qualified professional electrician who has read this manual

completely and is familiar with the construction and operation of this

equipment and the hazards involved.

3.

Do not affix the unit to wall or ceilings that have inadequate strength to

permanently hold the unit during use. It is the owner’s and installer’s

responsibility to confirm the wall or ceiling to which the unit attaches is

sufficient to permanently hold the weight and stress loads of the unit at all

times. Draper®, Inc., is not responsible for improper installation, application,

testing, or workmanship related to the product at place of installation.

4.

It is the installer’s responsibility to make sure appropriate fasteners are used

for mounting.

5.

Never leave the area while operating the unit during installation,

maintenance, or normal operation, unless it is secure and safe.

6.

Before testing or operation, carefully inspect the entire area and path of the

shade and areas underneath the shade to be sure no persons or objects are

in the area.

7.

Turn off power and any nearby equipment or cables carrying electricity

before connecting switches, wires, controls, or electrical components.

8.

Make sure the limit switches are pointed down or accessible when placing

the motor in brackets/end caps.

9.

All motors should be tested and limits set using test cord prior to the final

connection of the shade to building power.

10.

Do not wire motors in parallel without written permission from Draper, Inc.

11.

During testing or operation, carefully watch the surrounding area for any

potential safety concerns including nearby persons or objects.

12.

After installation, the entire system, including all sensors, should be carefully

tested to ensure safe and normal operation. Extreme care should be taken

during testing to remain clear of moving parts to avoid possible injury.

13.

Operation of unit should be performed only by authorized and qualified

personnel, who have been trained in the safe and effective operation of the

unit and understand its safety features.

14.

The safety features of the unit, including sensors, should never be disabled,

bypassed, or overridden. The system should not be operated until all safety

features, including the sensors, are properly and completely installed,

calibrated, and tested.

15.

Unit may need to comply with local, state, or district rules and regulations,

in particular when installed in schools. All applicable rules and regulations

should be reviewed before installation and use.

16.

Failure to precisely follow installation guidelines invalidates all warranties.

17.

Systems is intended for sun shading only. Unit must not be deployed or

operated in any type of precipitation event. Retract the shade to prevent the

accumulation of rain, ice or snow. Product should be installed on a 15 degree

angle to drain water if left deployed. Failure to do so may cause product to

fail, and could result in serious injury or death.

18.

Custom products/installations may not be reflected in this manual. Call

Draper, Inc., if you have questions about the installation of custom products

or any questions about your installation.

Before Beginning Installation

1.

Look for any job site conditions that could interfere with installation or

operation of the system.

2.

Read carefully and be sure to understand all installation instructions and

all related operations manuals. These instructions are intended to serve

as a guide for the installer and owner. They should be followed closely and

combined with the expertise of experienced qualified installers. Draper,

Inc., is not responsible for improper installation, application, testing, or

workmanship related to the product at place of installation. Please retain all

instructions for future use.

3.

Open cartons lengthwise.

4.

Locate and lay out all pieces.

5.

Inspect all boxes to make sure you have received the proper shade and

parts. Controls may be shipped separately, or in same carton as shade.

6.

If you have any difficulties with installing, servicing, or operating your shade,

call your dealer or Draper, Inc., 765-987-7999.

Important Safety Information Important Safety Information

PLEASE READ - Important Installation Information

PLEASE READ - Safety Information

WARNING! - DO NOT DRILL THROUGH OR MODIFY SIDE CHANNELS DURING INSTALLATION.

Modification of Side Channels could cause product to be damaged or otherwise fail.

Please Note: Installer is responsible

for selecting mounting hardware

appropriate for site conditions.

Section 2 - Mounting Headbox to Side Channels

Section 2.1 - Attaching Headbox and Fabric Assembly to Side Channels

1.

Remove the Headbox Cover screws

(one per side)

and then carefully remove the Headbox Cover

(see fig. 4)

.

2.

Remove the four

(4)

screws from side channel attachment tangs

W

(2 per tang)

on each side of the headbox.

3.

Connect the unit to building power using a test cord.

Deploy the shade approximately 15"

(38cm)

.

4.

Insert the Hem Bar into the side-channels.

5.

Slide the tangs on each end of headbox into the side-channels.

6.

With the zipper secured in the retainer strip, slide the hem bar,

fabric assembly and headbox into place.

ZIP HEM BAR

HEADBOX COVER

1A

ZIP HEM BAR

HEADBOX COVER

1B

Figure 4

Insert Headbox

into Side Channel

Fabric Channel

BACK of HEADBOX

SIDE CHANNEL

Fabric Bundle

Fabric

Panel

REVERSE

VIEW

Side Channel

Hem

Bar

Fabric

Headbox

4

Side Channel

Headbox

Hem

Bar

5

Headbox

Hem

Bar

Side Channel

6

The tabs on each endcap will slide

into RECEIVER SLOT the side

channel.

Tab Inside

Side Channel

HEADBOX

7.

Pull the retainer strip out approximately 3"

(76mm)

.

8.

Temporarily press the fabric out of the side channel near the headbox and re-install the screw removed in step 1.

9.

Push retainer strip back into side channels. Leave the end caps unattached for now.

8

2

SIDE CHANNEL

ATTACHMENT TANG

REMOVE

SCREWS

page 5 of 20

Outdoor FlexShade® Tension ZIP

page 4 of 20

Outdoor FlexShade® Tension ZIP

3

Side Channel

Hem

Bar

Fabric

Headbox

120V Test Cord

HEX WRENCH

4mm

SIDE

CHANNEL

PULL OUT

RETAINER

STRIP

3"

(76mm)

7

PLIERS

FABRIC

ROLL

FABRIC

ROLL

Fabric From Bottom of Roller

THROUGH HOLE

IN SPOOL

FABRIC from

Bottom of Roller

CABLE FROM

PULLEY A

THROUGH HOLE

IN SPOOL

SIDE VIEW

SIDE VIEW

Cable Over Top of Roller and

Around Motor Spool

At Least 3 Wraps

M

O

T

O

R

S

P

O

O

L

M

O

T

O

R

S

P

O

O

L

FABRIC

ROLL

Please Note: 2-3 wraps of cable should always remain on the spool.

Figure 5C

DETAIL

BACK of HEADBOX

Fabric Bundle

A

From

Under

Pulley

REVERSE

VIEW

SIDE CHANNEL

B

To Pulley Wrap Cable

over and

around spool

on motor

1

Figure 5A

DETAIL

SHADE FABRIC

1 - 2 - 3

A

1. From

Under

Pulley

2. Wrap Cable

over and around

spool on motor

AT LEAST 3 WRAPS

3. Through Hole in Spool

4. Tie with

Double

Square

Knot

5. Pull the other

end of cable

to remove slack.

5. Pull the other

end of cable

to remove slack.

Figure 5B

DETAIL Cable MUST wrap

in the OPPOSITE

DIRECTION of

Shade Material

Section 2.2 - Attaching Cables to Motor Spools

1.

Feed the cable from under Pulley A

(on end of side channel)

and wrap cable over and around the cable spool AT LEAST 3 WRAPS on each end of the

fabric assembly. If cable is routed OVER pulley, re-route under in accordance with Fig 5 below.

Section 2.3 - Re-attaching Side Channel Endcaps

1.

Thread cable around PULLEY B located within each side channel end cap.

2.

Re-install the endcaps to side channels.

Figure 8

PULLEY B

PULLEY B

CABLE

from Side Channel

END CAP CABLE ROUTING DETAIL

Figure 8

DETAIL A

1

Replace the four (4)

screws and Side

Channel Endcap

Figure 8

DETAIL B

2

Section 3 - Routing Cables

Section 3.1 - Removing Hem Bar Cover

1.

Separate the snap-on Hem Bar Cover from the Hem Bar

(See Fig. 9)

. This will expose the location where

the pulleys and tie-off cleats that will be used to set the cable tension.

WARNING: Hem bar cover is attached to the hem bar by two

(2)

safety tethers.

In some instances, these safety tethers may need to be removed to aid in cable routing.

SAFETY TETHERS MUST BE REATTACHED PRIOR TO HEM BAR COVER BEING REATTACHED.

PRODUCT IS NOT PROPERLY INSTALLED IF SAFETY FEATURES HAVE BEEN DISABLED.

Attach Spring to Hem Bar

Section 3.2 - Installing Tensioning Springs within Hem Bar

1.

Locate both tensioning springs and pulleys

(packed with shade)

.

2.

Attach one pulley to one end of each spring, and attach the other end to provided hooks within Hem Bar

(See Fig. 10)

.

3.

Route cable from PULLEY B at the end of the side channel, the cable will then go on the outside

of the side rail to PULLEY C on the hem bar

(See Fig. 11 on next page)

.

TENSIONING SPRING

Figure 10

Figure 9

page 7 of 20

Outdoor FlexShade® Tension ZIP

page 6 of 20

Outdoor FlexShade® Tension ZIP

CABLE ROUTING DETAIL A Figure 11

DETAIL A

TIE END OF CABLE INTO A LOOP

and PULL UNTIL SPRING

EXTENDS AT LEAST 1” (25mm)

and ATTACH TO CLEAT

HEM BAR

(Cover Removed)

ED

CDEC

F

F

TIE END OF CABLE INTO A LOOP

and PULL UNTIL SPRING

EXTENDS AT LEAST 1” (25mm)

and ATTACH TO CLEAT

From RIGHT

Side Channel Pulley

From LEFT

Side Channel Pulley

FABRIC PANEL

(Engaged in Zippers)

Roller Assembly

B

A

B

A

Figure 11

Section 3.3 - Routing Cables within Hem Bar -

For smaller sizes up to 84"

(213cm)

Wide - Cable Routing A

1.

Refer to CABLE ROUTING DETAIL A below

(Fig. 12 Detail A)

.

2.

Route cables from PULLEY C to PULLEY D to PULLEY E and then to CLEAT F.

PLEASE NOTE: Tying a loop in the end of the cable will aid in pulling the cable taught.

Be sure cable is properly engaged in ALL pulleys prior to operating shade.

Improper cable routing can cause product to be damaged or otherwise fail.

PLEASE NOTE: Do not put the cover on at this time.

TIE END OF CABLE INTO A LOOP

and PULL UNTIL SPRING

EXTENDS AT LEAST 1” (25mm)

and ATTACH TO CLEAT

HEM BAR

(Cover Removed)

ED

CDEC

F

F

TIE END OF CABLE INTO A LOOP

and PULL UNTIL SPRING

EXTENDS AT LEAST 1” (25mm)

and ATTACH TO CLEAT

From RIGHT

Side Channel Pulley

From LEFT

Side Channel Pulley

FABRIC PANEL

(Engaged in Zippers)

Roller Assembly

B

A

B

A

WIDTH

LENGTH

40" 48" 60" 72"

102cm 123cm 153cm 183cm

12" 30cm

24" 61cm

36" 91cm

48" 122cm

60" 152cm

72" 183cm

84" 213cm

96" 244cm

108" 274cm

120" 305cm

132" 335cm 50"

144" 366cm 50"

156" 396cm 50"

168" 427cm 50"

CABLE

ROUTING A

SMALL 17" SPRING

CABLE

ROUTING A

LARGE 21" SPRING

page 9 of 20

Outdoor FlexShade® Tension ZIP

page 8 of 20

Outdoor FlexShade® Tension ZIP

Section 3.4 - Routing Cables within Hem Bar - For larger sizes wider than 84"

(213cm)

1.

Refer to CABLE ROUTING DETAIL B below

(Fig. 12 Detail)

.

2.

Route cables from PULLEY C to PULLEY D to PULLEY E to PULLEY F to

PULLEY G and then to CLEAT H.

PLEASE NOTE: Tying a loop in the end of the cable will aid in pulling the cable taught.

Be sure cable is properly engaged in ALL pulleys prior to operating shade.

Improper cable routing can cause product to be damaged or otherwise fail.

PLEASE NOTE: Do not put the cover on at this time.

HEM BAR

(Cover Removed)

HEM BAR

(Cover Removed)

FABRIC PANEL

(Engaged in Zippers)

Roller Assembly

Center

Line

Tensioning SpringTensioning Spring

Tensioning Spring

Tensioning Spring

D

F

H

E

G

C

TIE END OF CABLE INTO A LOOP

and PULL CABLE UNTIL SPRING

EXTENDS AT LEAST 1” (25mm)

and ATTACH TO CLEAT at “

H

”

B

GF

ED

C

B

LEFT SIDE CLEAT

H

From LEFT

Side Channel Pulley

LEFT SIDE CABLE ROUTING DETAIL B

Figure 12

DETAIL

HEM BAR

(Cover Removed) HEM BAR

(Cover Removed)

FABRIC PANEL

(Engaged in Zippers)

Roller Assembly

Center

Line

Tensioning SpringTensioning Spring

Tensioning Spring

Tensioning Spring

D

F

H

E

G

C

TIE END OF CABLE INTO A LOOP

and PULL CABLE UNTIL SPRING

EXTENDS AT LEAST 1” (25mm)

and ATTACH TO CLEAT at “

H

”

B

GF

ED

C

B

LEFT SIDE CLEAT

H

From LEFT

Side Channel Pulley

From RIGHT

Side Channel Pulley

G

F

D

B

H

TIE END OF CABLE INTO A LOOP

and PULL CABLE UNTIL SPRING

EXTENDS AT LEAST 1” (25mm)

and ATTACH TO CLEAT at “

H

”

C

E

RIGHT SIDE CLEAT

HEM BAR

(Cover Removed)

HEM BAR

(Cover Removed)

FABRIC PANEL

(Engaged in Zippers)

Roller Assembly

Center

Line

Tensioning SpringTensioning Spring

Tensioning Spring

Tensioning Spring

From RIGHT

Side Channel Pulley

G

F

D

B

H

TIE END OF CABLE INTO A LOOP

and PULL CABLE UNTIL SPRING

EXTENDS AT LEAST 1” (25mm)

and ATTACH TO CLEAT at “

H

”

C

E

RIGHT SIDE CLEAT

RIGHT SIDE CABLE ROUTING DETAIL B

Figure 12

WIDTH

LENGTH

84" 96" 108" 120" 132" 144" 156" 168" 180" 192"

213cm 244cm 2 74 cm 305cm 335cm 366cm 396cm 427cm 4 57cm 488cm

12"

30cm

24"

61cm

36"

91cm

48"

122cm

60"

152cm

72"

183cm

84"

213cm

96"

244cm

108"

274cm

120"

305cm

132"

335cm

144"

366cm

156"

396cm

168"

427cm

180"

457cm

192"

488cm

204"

518cm

216"

549cm

228"

579cm

240"

610cm

CABLE

ROUTING B

LARGE 21" SPRING

page 11 of 20

Outdoor FlexShade® Tension ZIP

page 10 of 20

Outdoor FlexShade® Tension ZIP

Minimum Tension with Hem Bar in Center

When springs sag, stop motor and remove slack in cable.

Section 4 - Removing Excess Slack from Tensioning Cables

Section 4.1 - Deploying shade to remove excess slack in cables:

All steps in Sections 3.4 and 3.5 are to be done uniformly to BOTH CABLES and BOTH TENSIONING SPRINGS.

1.

Once tensioning springs are installed and attached to cables, use a test cord to deploy shade.

Refer to Figure 13 below.

2.

Observe shade as it travels. Ensure that both sides of the hem bar are traveling at the same speed

and that movement is uniform.

As shade deploys, cables will go slack and the tensioning springs will sag

(see Fig. 15 on page 11)

.

STOP MOTOR IMMEDIATELY if hem bar becomes misaligned, stuck or stops traveling uniformly.

3.

With motor stopped, remove slack in fabric by moving hem bar evenly by hand through side

channels. Ensure the hem bar is properly aligned within the side channels.

4.

Remove cable slack

(See Fig. 14)

.

A.

Remove cable loop from cleat and tie new knot in cable.

B.

Pull cable loop until spring extends and reattach to cleat.

TIP: Tying a new loop in the cable closer to the cleat will allow for better leverage and will

require less stopping to remove slack.

6.

Continue deploying the shade, stopping motor IMMEDIATELY if hem bar becomes misaligned,

stuck or stops traveling uniformly. Removing cable slack in accordance with step 4.

7.

Stop when the shade is 90% deployed.

Pull cable, adding tension until spring extends 1"

(25mm)

and reattach each cable to its cleat.

Use guide below to for proper spring lengths to be achieved in Step 7 above.

Measure the length of BOTH tensioning springs to ensure they are of equal length and under equal tension.

Size of springs provided is determined by size of shade.

Both springs provided with each shade will be identical in length.

MAX. Spring Deflection: 23 ½"

(597mm)

RELAXED SPRING: 17"

(432mm)

MAX. Length when Extended: 32"

(813mm)

RELAXED SPRING: 21"

(533mm)

Maximum Spring Deflection for spring sizes:

Springs size is configured based on the size of the shade ordered. Springs provided with configured shade will be identical.

Measure springs relaxed with zero tension, then compare their length while extended under tension.

DO NOT STRETCH or EXTENDED SPRINGS BEYOND MAX LENGTHS SHOWN BELOW (Fig. 16).

WARNING:

DO NOT STRETCH OR

EXTENDED SPRINGS

BEYOND MAX LENGTH

Section 4.2 - Retract shade to remove remaining excess slack

(adding tension)

in cabled system:

The Outdoor tensioned Zip will need to be retracted and deployed several times to remove all slack from cables.

The cables in the system will settle over time.

All steps in Sections 3.4 and 3.5 are to be done uniformly to BOTH CABLES and BOTH TENSIONING SPRINGS.

1.

Retract the shade. Observe to ensure that both sides of the hem bar are still moving uniformly through side channels.

2. STOP MOTOR IMMEDIATELY if hem bar becomes misaligned, stuck or stops traveling uniformly.

Please note: While retracting, system will lose tension as hem bar approaches the center of the shade

(50% retracted)

,

and will begin adding tension as the hem bar approaches the head box

(100% retracted)

.

3.

Measure the length of tensioning springs to ensure they are equally stretched and not hyper-extended.

Refer to max spring deflection chart BELOW.

4.

If more tension is required, deploy shade to 90%. Add tension by pulling cables until taut and reattaching each to its C L E AT.

5.

Repeat sections 3.4 and 3.5 until shade operates smoothly.

6.

Set motor limits

(see Section 5)

.

PLEASE NOTE: Cable and product will settle over first few months and re-adjusting of limits is required.

Failure to do so will result in product possible product damage.

IF SPRINGS ARE HYPER EXTENDED:

1. Move shade to 50% deployed

(Minimum system tension)

.

2. Carefully, unhook the cable at the Cleat

and reattach it with less tension.

3. Repeat with the other cable.

Minimum Cable Tension with Hem Bar in Center

Maximum Cable Tension When Retracted

Attach Cables to Springs Here and Adjust As Shade Deploys

Increased Cable Tension When Deployed

Roller Assembly

Figure 13

Please note:

System will lose

tension as hem bar

approaches the

center of shade.

PULL CABLE LOOP until spring

extends and reattach to Cleat

B

KNOT TIED IN CABLE TO PREVENT SLIPPAGE

Remove Cable Loop from Cleat

and tie a new knot in the CABLE

A

Figure 14

Figure 15

Length when Extended: 18"

(457mm)

RELAXED SPRING: 17"

(432mm)

SMALL SPRING - CABLE ROUTING A

Length when Extended: 22"

(559mm)

RELAXED SPRING: 21"

(533mm)

LARGE SPRING - CABLE ROUTING A or B

Figure 16

page 13 of 20

Outdoor FlexShade® Tension ZIP

page 12 of 20

Outdoor FlexShade® Tension ZIP

120V Test Cord

Section 5 - RF Remote Programming Instructions

Please Note: The motor ships with no programming. Follow these instructions to program unit to the desired transmitter.

Setting an Intermediate Stop -

Shade MUST BE in USER mode.

1.

Move shade to desired mid-point

location and hold MY/STOP button

until motor jogs.

2.

To test, press the MY/STOP button

when motor is standing still. The shade

will move to that intermediate location.

3.

To delete an intermediate stop, go to the

intermediate stop and hold the MY/STOP

button until motor jogs.

Add a Channel -

Shade MUST BE in USER mode.

1.

Select channel currently operating

motor, then hold programming button

until motor jogs.

2.

Select new channel to add to motor, then

hold programming button until motor jogs.

3.

The motor should now work on both the

old and new channel.

Delete a Channel -

Shade MUST BE in USER mode.

1.

Select channel operating motor desired,

then hold programming button until

motor jogs.

2.

Select channel to remove, then hold

programming button until motor jogs.

Motor should now only work

on channel kept from Step 1.

1.

Select a transmitter channel to assign motor.

Hold UP and DOWN buttons

until motor jogs, then release.

2.

Check motor direction. To reverse motor

direction, hold MY/STOP button for

5 seconds until motor jogs. Check direction

again.

3.

Move motor to upper limit position. Hold MY/

STOP and DOWN buttons until motor moves

down, then release. Use UP and DOWN buttons

to move shade to correct lower limit and press

M Y/ S TO P.

4.

While motor is at lower limit, hold UP and MY/

STOP buttons until motor moves up, then

release. The shade should move to upper limit

and stop.

5.

Next, hold MY/STOP button until motor jogs.

6.

Put motor into USER MODE by holding small

programming button on the back of transmitter

and waiting for motor to jog.

Adjust Limits in User Mode

1.

Move motor to limit

(upper or lower)

to be

changed. Shade must move to previously

set limit and will stop automatically.

2.

Hold UP and DOWN buttons until motor

jogs.

3.

Move motor to its new limit location and

hold MY/STOP button until motor jogs.

Reset Motor

1.

Disconnect for 3 seconds, reconnect for

10 seconds, disconnect for 3 seconds.

Shade will roll.

2.

Hold program button on remote and wait

for 2 separate jogs.

Motor is now reset.

Channel

Selector

UP

STOP

DOWN

LED Lights

SHADE

SHADE

SHADE

BACK

Programming

Button

Pen

BACK

Programming

Button

Pen

BACK

Programming

Button

Pen

BACK

Programming

Button

Pen

SHADE

SHADE

upper

or

lower

limit

Section 6 - Limit Switch Adjustments

Standard and Quiet Motors

Caution: Unit ships without limits. Limits will need to be set

before the unit is operated. Always be prepared to shut off

manually when new adjustment is being tested.

Push Button Limits

1.

Fully depress both limit switch push buttons, then operate

wall switch to make sure system works properly.

2.

Raise shade to desired "UP" stop position.

3.

Set upper limit by depressing proper

(back)

push button.

4.

Lower shade to desired "DOWN" stop position.

5.

Set lower limit by depressing proper

(front)

push button.

Screw-Type Limits

6.

Determine which direction of fabric travel corresponds with

arrows on motor.

Caution:

- Be sure all switches are in

"off" position before adjusting

limit switches.

- Shade may be damaged by

running shade fabric up too

far and exposing roller.

- If using a group control

system, each limit switch

must be set prior to

connecting to system.

- Motor must be installed so

limit switches are pointed up

or accessible.

7.

Operate shade to desired "down" stop position.

Set limit by turning proper socket toward "+" to lower limit, and "-" to raise it.

8.

Operate shade to desired "up" stopping position.

Set limit by turning proper screw toward "-" to raise limit, and "+" to lower it.

Please Note: Each full rotation of the limit screw equals approximately

5/8

"

(16mm)

of shade travel, which may require rotating the limit screw several times.

Caution: DO NOT allow the hem bar to hit the upper roller or fascia. This will damage the unit.

Screws

+

+

Front

Back

Bottom View

Side View

GLASS SIDE

ROOM SIDE

GLASS SIDE

ROOM SIDE

Front

Back

Bottom View

Side View

GLASS SIDE

ROOM SIDE

Front

Back

Bottom View

Side View

PUSH BUTTON LIMITS Standard right-hand

motor configuration shown

Screws

+

+

Front

Back

Bottom View

Side View

GLASS SIDE

ROOM SIDE

Screws

+

+

Front

Back

Bottom View

Side View

GLASS SIDE

ROOM SIDE

SCREW-TYPE LIMITS Standard right-hand

motor configuration shown

Section 7 - Complete Electrical Connection

Operates on 110-120V, 60 Hz. current. Shade is shipped with internal wiring complete and control switch

(es)

fully boxed, and supplied with a 6'

(183 cm)

cable

lead

(standard)

. Longer lead can be substituted by removing two screws in motor end of roller, removing lead, plugging new lead in, and replacing screws. Wire to

connect shade to switch

(es)

and switch

(es)

to power supply should be furnished by installer. Connections should be made in accordance with attached wiring

diagram, and wiring should comply with national and local electrical codes.

DO NOT wire motors in parallel without written permission from Draper.

All operating switches should be “off” before power is connected.

Controls & System Overview

Sonesse®RTS 120VAC Motors

B WG

RTS

MOTOR

120V

110-120V Line

Decora RTS

Wireless Keypad

Patio

RF Remote

STOP

Dashed Wiring

by Electrician

NOTE: Test shade operation

If shade direction does not

correspond with the switch

orientation, turn power back

off and switch the red and black

wires from the motor to the switch.

Do not wire motors in parallel without

written permission from Draper.

Controls & System Overview

Sonesse®120VAC Motors

WB RG

B

Control

Switch

Single Gang

Box (by others)

120V

MOTOR

110-120V Line

Dashed Wiring

by Electrician

Sonesse®is a registered trademark of Somfy®Systems, Inc.

Please Note: NEMA 3 prong

plugs provided by others.

page 15 of 20

Outdoor FlexShade® Tension ZIP

page 14 of 20

Outdoor FlexShade® Tension ZIP

Section 10 - Mounting Bracket Dimensions

5/8" Square Nut

(2 per Bracket)

Slides into Side Channel

ADJUSTABLE

BASE BRACKET

4" (100mm) to

6.5" (168mm)

LOOSEN HEX

NUTS to ADJUST

HEIGHT

(2 per Bracket)

4 ½"

(114mm)

2 ½"

(63.5mm)

MAX

HEIGHT

6

5

/

8

"

(168mm)

1 ¾"

(44mm)

5"

(127mm)

1"

(25mm)

13

/

16

"

(21mm)

11

/

16

"

(17mm)

1

1

/

2

"

(38mm)

2

7

/

8

"

(73mm)

2

7

/

8

"

(73mm)

3

7

/

8

"

(95mm)

Square Nut

(2 per Bracket)

Slides into Side Channel

MOUNTING

BRACKET

Side

View

To p V iew

Section 9 - Assembled Dimensions

"

(6.35mm)

5"

(133mm)

5"

(133mm)

5"

(133mm)

Hem Bar Thickness: 2"

(51mm)

1"

(44mm)

2"

(73mm)

1"

(44mm)

1"

(32mm)

Shade Width

Shade

Height

Side

Channel

Length

Hem Bar Width

4"

(102mm)

Fabric Width

ELEVATION

VIEW

SIDE

VIEW TOP

VIEW

Hem Bar

Thickness:

2"

(51mm)

1 ¼" (32mm)

Edge of Shade

to Mounting Point

Mounting Bracket

Channel

Mounting Bracket

Channel

MOUNTING POINTS:

Headbox Width - 2 ½” (63.5mm)

Section 8 - Cable Exit

The Outdoor FlexShade®Tension ZIP can be ordered with a cable exit pre-drilled in the side or back of the Headbox

(See Fig. 17)

.

If no cable exit is specified, the cable is routed down and out the fabric opening under the motor.

Please Note: Right hand motor is shown.

TOP

(19mm)

(17m m)

Cable Exit:

SIDE

BACK

(13mm)

SIDE

(Endcap)

Figure 17

(9.5mm)

(13mm)

1

(30mm)

Cable Exit:

BACK

BACK

(13mm)

TOP

SIDE

(Endcap)

Figure 19

page 17 of 20

Outdoor FlexShade® Tension ZIP

page 16 of 20

Outdoor FlexShade® Tension ZIP

Section 11 - Side Channel Spreader Bar

Section 11.1 - Spreader Bar Dimensions

Section 11.2 - Spreader Bar Installation

The Side Channel Spreader Bar is to be used when shade fabric

tension distorts the side channels, interfering with the operation

of the shade

(see Figure 15)

.

6"

(152mm)

2 7/16"

(62mm)

Shade Width -

7

/8"

(22mm)

3"

(76mm)

3/8" Square Nut

(2 per Bracket) Slides into Side Channel

SPREADER BARSPREADER BAR

Side

View

SIDE CHANNEL

SPREADER BAR

C126.392SA

Button-head Screw

5/8” Square Nut

ENGAGED IN

SIDE CHANNEL

Washer

Split Lock Washer

Spreader Bar

Figure 15

page 19 of 20

Outdoor FlexShade® Tension ZIP

page 18 of 20

Outdoor FlexShade® Tension ZIP

page 20 of 20

Outdoor FlexShade® Tension ZIP

Other manuals for FlexShade Tension ZIP

1

Table of contents

Other Draper Outdoor Furnishing manuals

Popular Outdoor Furnishing manuals by other brands

Safavieh

Safavieh PAT7015 Aassembly Instructions

Sojag

Sojag SUNSHELTER Assembly manual

Rutland County Garden Furniture

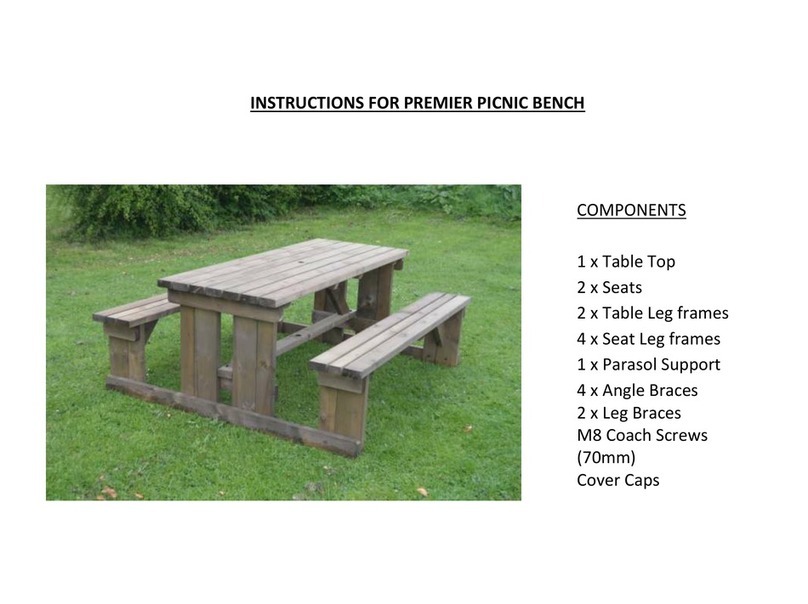

Rutland County Garden Furniture PREMIER instructions

Spear & Jackson

Spear & Jackson ZQ850 Assembly instructions

Costway

Costway HW57080 user manual

Nuu Garden

Nuu Garden DB150S instruction manual

TOPMAQ

TOPMAQ TSA4524C Assembly instructions

SUNS

SUNS Alvaro A Assembly instruction

Dunster House

Dunster House Atlas installation manual

Yardistry

Yardistry MERIDIAN YM11756 Installation and operating instructions

Royal garden

Royal garden GRLGZBGRY Assembly instructions

Weishaupl

Weishaupl Cross Assembly instructions