– 6 –

4. Health and Safety Information

Repetitive Motion Hazards

• When operating a sander frequently or for extended

periods, the operator may experience discomfort in

the hands, arms, shoulders, neck and other parts of

the body.

• While using the sander, adopt a comfortable posture

while maintaining secure footing and avoiding

awkward or o-balance positions.

− Change posture and operating positions regularly

during extended use to help avoid discomfort

and fatigue.

• DO NOT ignore symptoms such as persistent or

recurring discomfort, pain, throbbing, aching,

tingling, numbness or burning sensations.

− If these symptoms occur, stop using the tool and

consult a qualied health professional.

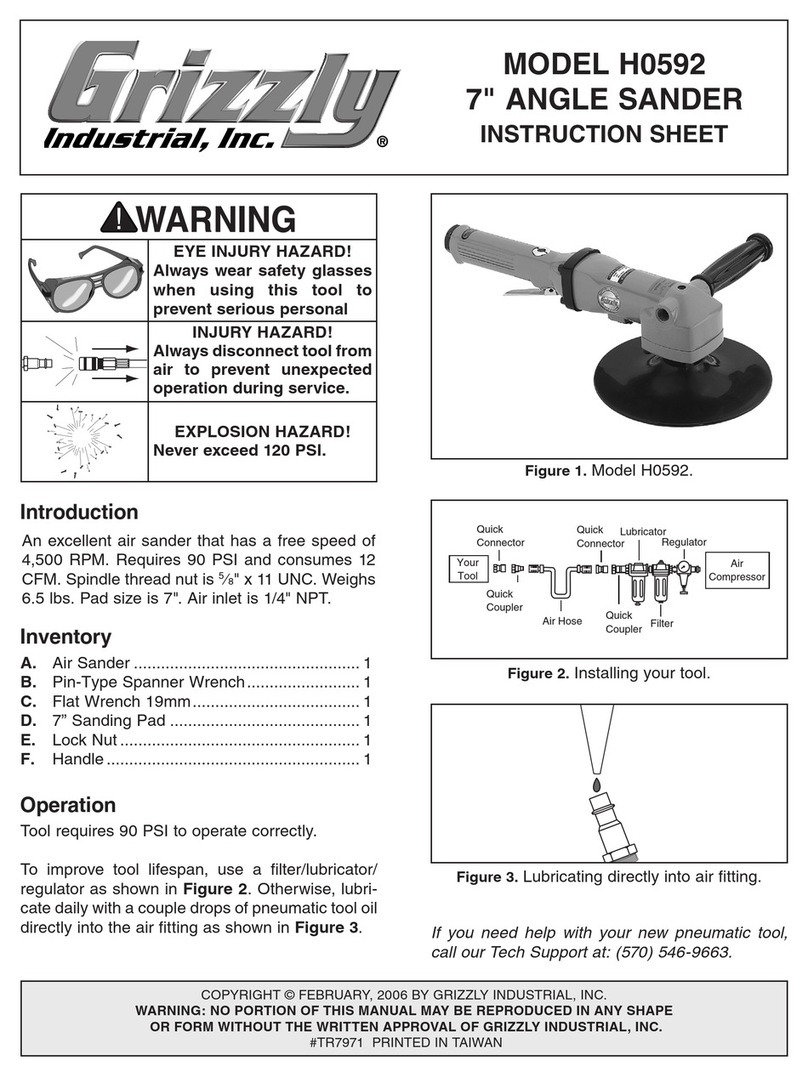

Accessory Hazards

• ALWAYS disconnect the sander from the air supply

before tting or changing accessories.

• Avoid direct contact with the sanding pad and

backing plate during and immediately after operation

as it may become hot during use.

• ONLY use accessory types and sizes recommended by

Draper Tools.

• DO NOT attach grinding wheels or cutting-o

accessories to this tool and do not use it for

these purposes.

• ALWAYS ensure that the maximum operating speed

of the backing pad is higher than the rated speed of

the sander.

• Self-xing sander discs must be placed concentrically

on the supporting pad.

Workplace Hazards

• Stay alert for surfaces that may become slippery as a

result of use of this tool and for trip hazards caused by

the air line.

• This sander is not suitable for use in potentially

explosive atmospheres and is not insulated against

contact with electric power.

• Ensure that there are no electrical cables, gas pipes,

etc. present in the workpiece that may cause a hazard

if damaged by the tool.

Dust and Fume Hazards

• Dust and fumes generated by sanding operations can

cause ill health (e.g., cancer, birth defects, asthma

and/or dermatitis).

− Perform a risk assessment and implement any

appropriate controls for identied hazards before

performing any operation.

− Any risk assessment performed must include dust

created by use of the tool and disturbance of any

existing dust.

• Operate and maintain the sander appropriately to

minimise the dust or fume emissions.

• Direct the exhaust so as to minimise disturbance of

existing dust in dusty environments.

• Where dust or fumes are created, priority must be

given to controlling them at the point of emission.

• All integral features and accessories for the collection,

extraction or suppression of airborne dust or fumes

must be correctly used and maintained in accordance

with the manufacturer’s instructions.

• Select, maintain and replace the backing plate and

sanding pads as recommended in the manual to

prevent any unnecessary increase in the emission of

dust or fumes.

• Use appropriate respiratory protection in accordance

with local occupational health and safety regulations.

Noise Hazards

• Exposure to high noise levels can cause permanent

hearing loss and other problems.

− Perform a risk assessment and implement any

appropriate controls for identied hazards before

performing any operation.

• Implement appropriate controls, such as dampening

materials, to prevent the workpiece from “ringing”

during operation.

• Use appropriate hearing protection in accordance

with local occupational health and safety regulations.

• Operate and maintain the sander appropriately to

prevent unnecessary increase in noise emissions.