Content

Table of Content

1 Introduction .............................................................................................. 4

1.1 Quality Policy .................................................................................... 4

2 Technical Data........................................................................................... 5

2.1 Dimensions........................................................................................ 5

2.2 Power Consumption.......................................................................... 6

2.3 Precision............................................................................................ 6

2.4 Required Tools for Assembly ............................................................ 6

3 Lens preparation ....................................................................................... 7

3.1 Lens selection.................................................................................... 7

3.1.1 Diameter limitation................................................................... 7

3.1.2 Distance limitation .................................................................... 7

3.1.3 Lens Dimensions ....................................................................... 7

3.1.4 Environmental Conditions......................................................... 7

3.2 Lens gear assembly ........................................................................... 8

4 Setting up the Motor Drive ....................................................................... 9

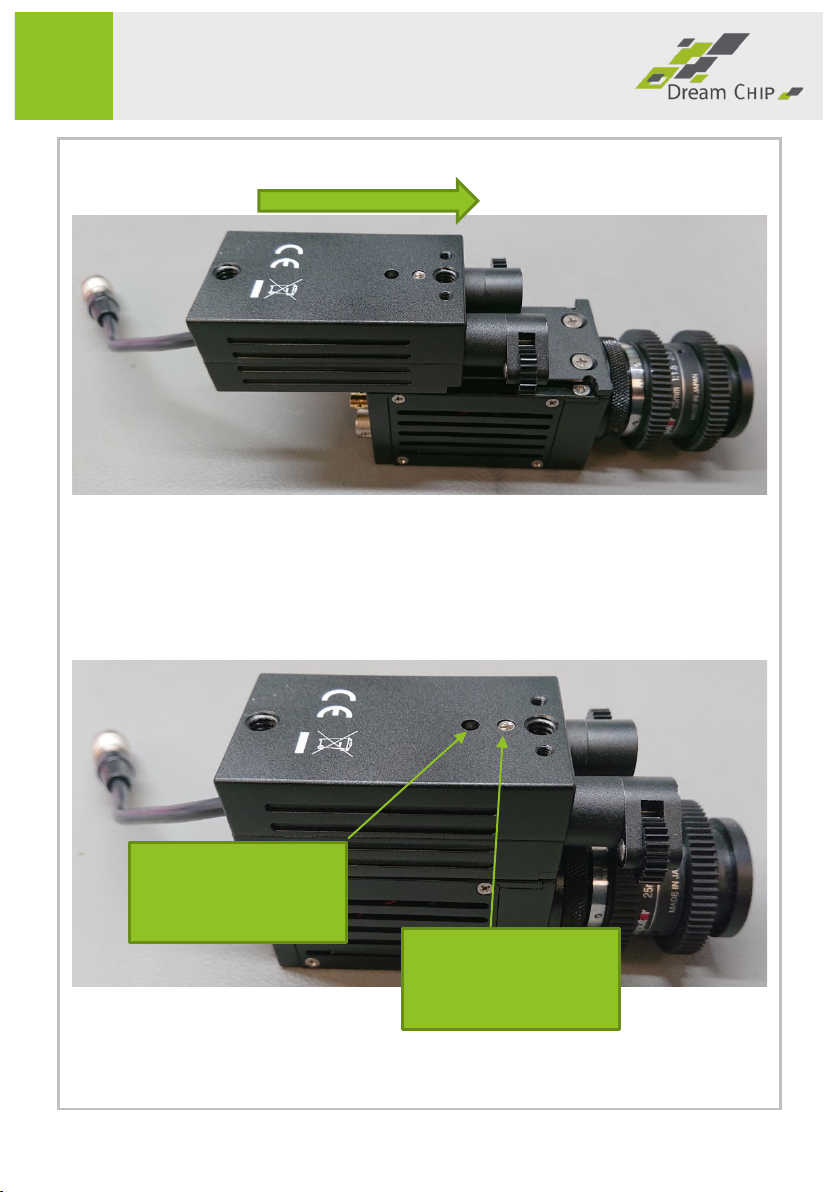

4.1 Mount the motor drive on the camera............................................. 9

4.2 Optimize the motor parameters..................................................... 12

4.2.1 Optimize the Torque Parameter ............................................. 12

4.2.2 Set the Iris F-Stop Table .......................................................... 12

5 Motor Operation..................................................................................... 14

5.1 RCP Remote Control........................................................................ 14

5.2 ProVideo Control Software ............................................................. 14

6 FAQ.......................................................................................................... 16

6.1 Q: The motor does not initialize proper ......................................... 16