GF-8XtenCraneSystem Instruction Manual

Contents:

SAFETYGUIDELINES................................................................................................2

GeneralAssembly Procedure – GF–8........................................................................3

Forall GF-8Standard-Versions:...................................................................................3

Forall GF-8Xten-Versions:..........................................................................................6

Assembly &TechnicalSpecification Version1to 16...................................................7

Version1......................................................................................................................7

Version2......................................................................................................................8

Version3......................................................................................................................9

Version4....................................................................................................................10

Version5....................................................................................................................11

Version6....................................................................................................................12

Version7....................................................................................................................13

Version8....................................................................................................................14

Version9....................................................................................................................15

Version10..................................................................................................................15

Version11..................................................................................................................16

Version12..................................................................................................................16

Version13..................................................................................................................17

Version14..................................................................................................................17

Version15..................................................................................................................18

Version16..................................................................................................................18

Version17..................................................................................................................19

Version18..................................................................................................................20

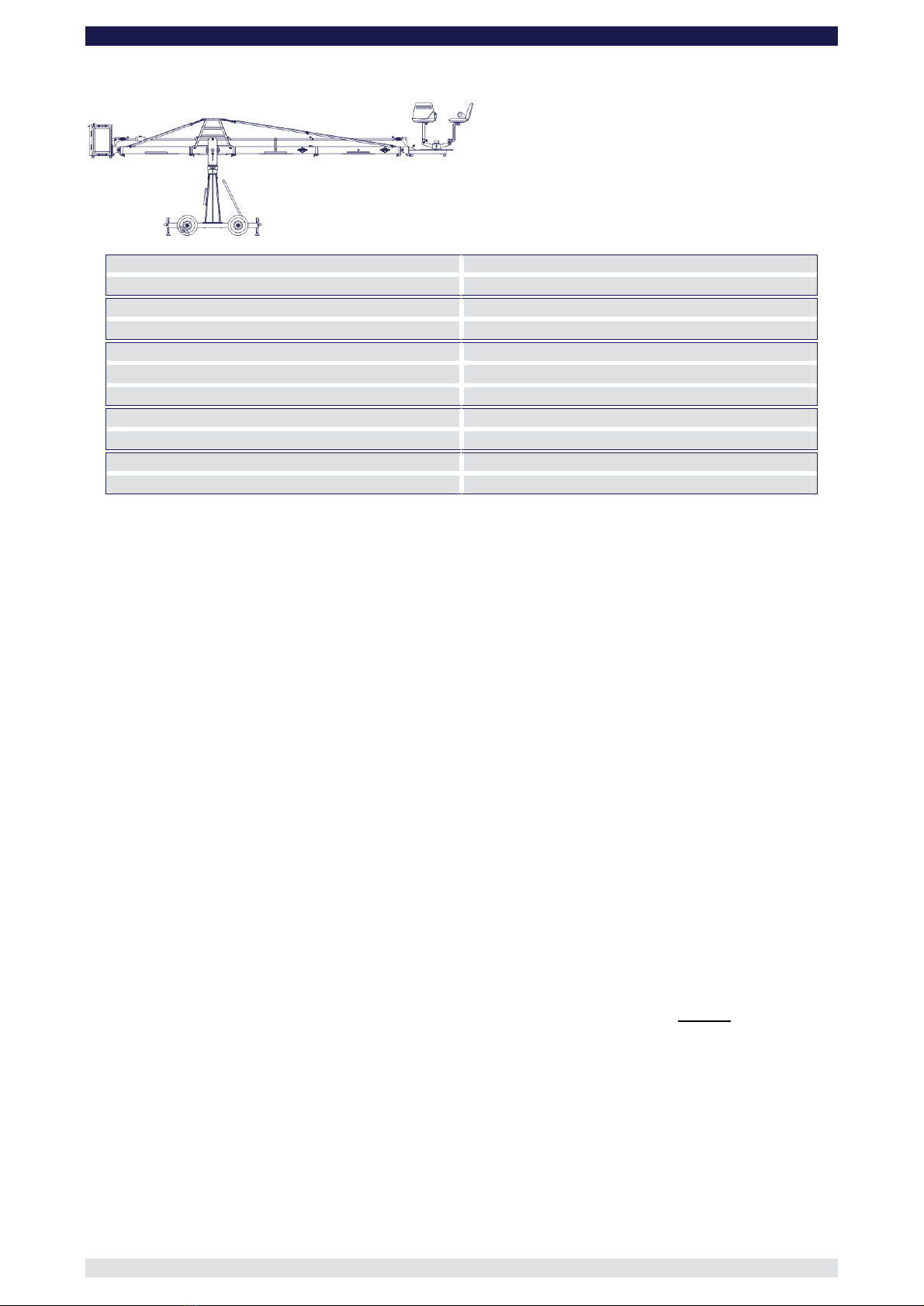

Assembly &TechnicalSpecifications forthe Xten Versions......................................22

XtenVersion1............................................................................................................22

XtenVersion2............................................................................................................23

XtenVersion3............................................................................................................24

XtenVersion4............................................................................................................26

XtenVersion5............................................................................................................27

XtenVersion6............................................................................................................29

XtenVersion7............................................................................................................30

XtenVersion8............................................................................................................32

ParallelogramRod Support.......................................................................................34

Riggingsystem..........................................................................................................35

Double Rigging System.............................................................................................36

Lower, front rigging.....................................................................................................36

Top, front rigging........................................................................................................36

Mountingthe Extra, MiniCounterweight BucketforXtenVersions..............................38

Balancingthe crane arm...........................................................................................38

GeneralSafety..........................................................................................................39

Accessories forGF- 8 crane......................................................................................40

Mountingthe accessories...........................................................................................40

Use with GFMTrack(GF-Track)...............................................................................41

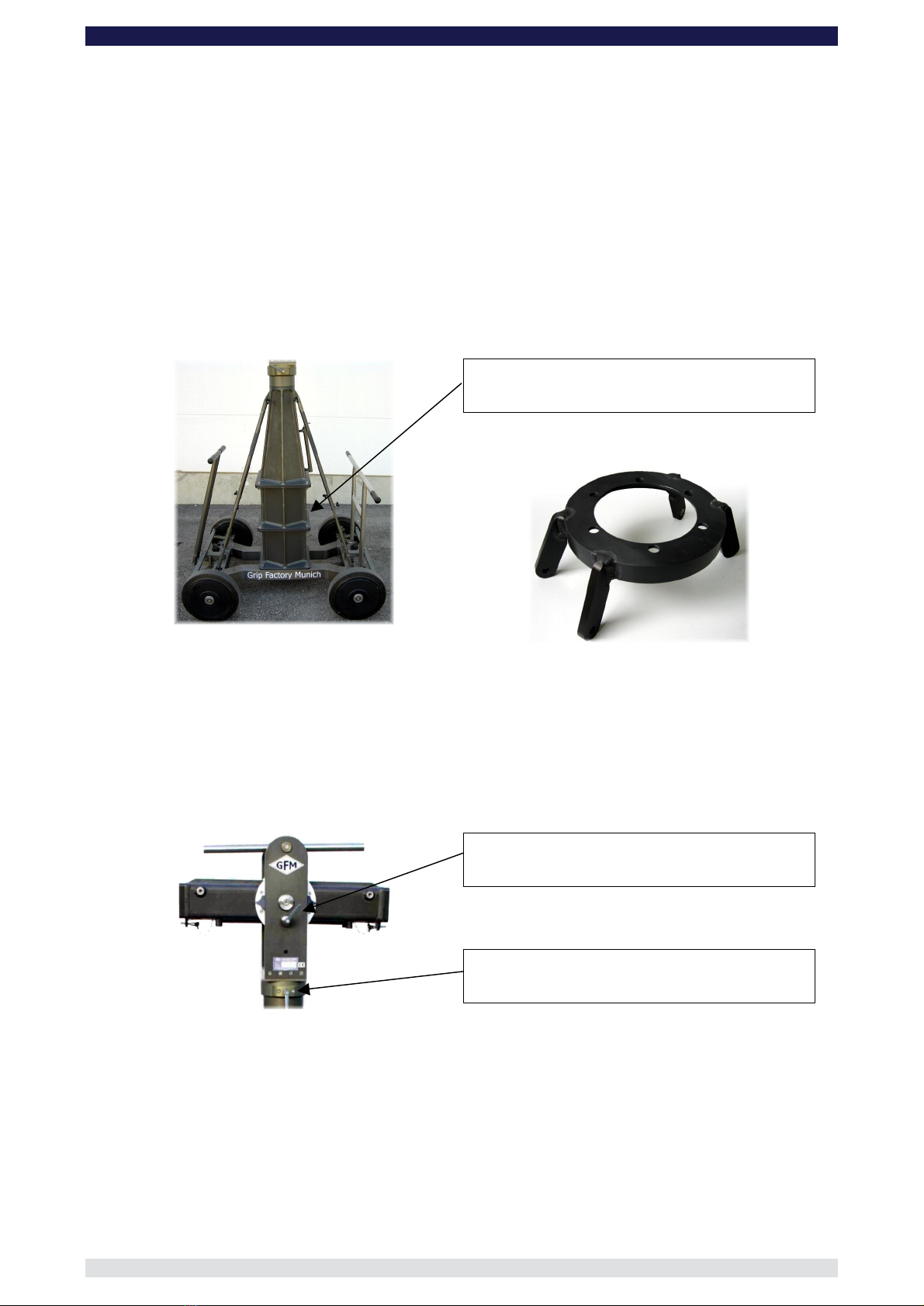

Transport trolley forthe GF-8Crane.........................................................................42

GF-8 Crane Dollies...................................................................................................43

The GF-8DoubleEndedConnectedSteeringBase....................................................44