Discus Launch for Everyone!

There are few experiences in model aviation more satisfying to the soul than flying an efficient, slow-moving

glider that has been launched to soaring altitude by hand. The Libelle takes RC hand-launch glider flying to the

next level, building off of the global acceptance of the Alula. Until now, this type of experience had been out of

reach for many pilots for a variety of reasons. The Libelle is for everyone; it can be assembled, balanced, and

trimmed for flight by pilots of any experience level.

Modern RC Glider Design

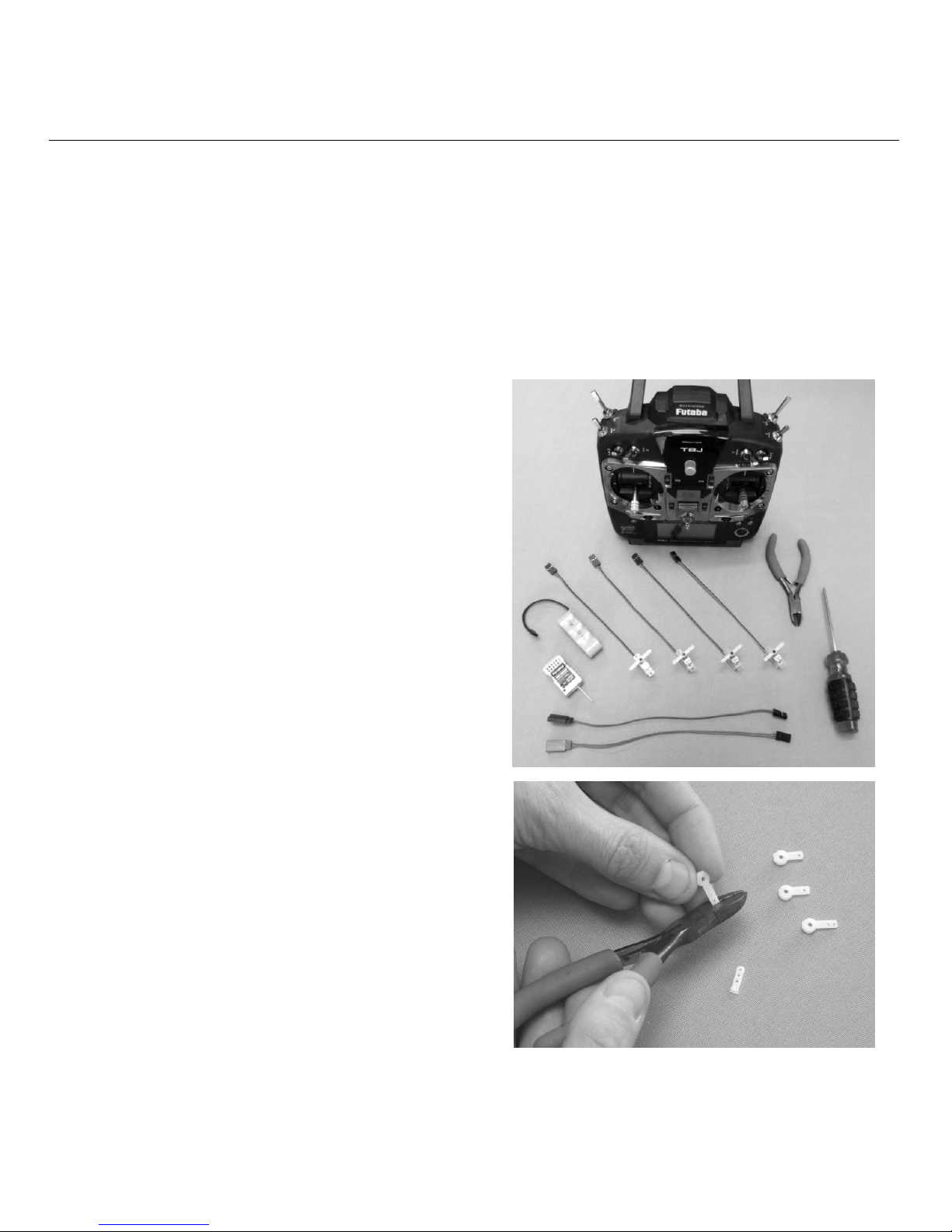

ARG - The Libelle is our first ARG design (Almost Ready to Glide). You'll get out and glide faster, as many time-

saving tasks have been expertly finished at our factory. Utilizing the most modern materials and foam molding

techniques, we have achieved a durable, lightweight, and super smooth airframe that is a huge improvement

from the past. The entire model is comprised of proprietary components purpose-designed for the Libelle. For

ease of assembly, all essential areas of the model are self-aligning and interlocking.

Launch! Launching the Libelle could not be easier or more accessible. Utilizing clever design by combining

injection molded wingtip launch plates and carbon fiber wing spars, the Libelle can be launched “discus style” by

both right and left handed pilots. Just slip the included launching peg into whichever wingtip suits your needs.

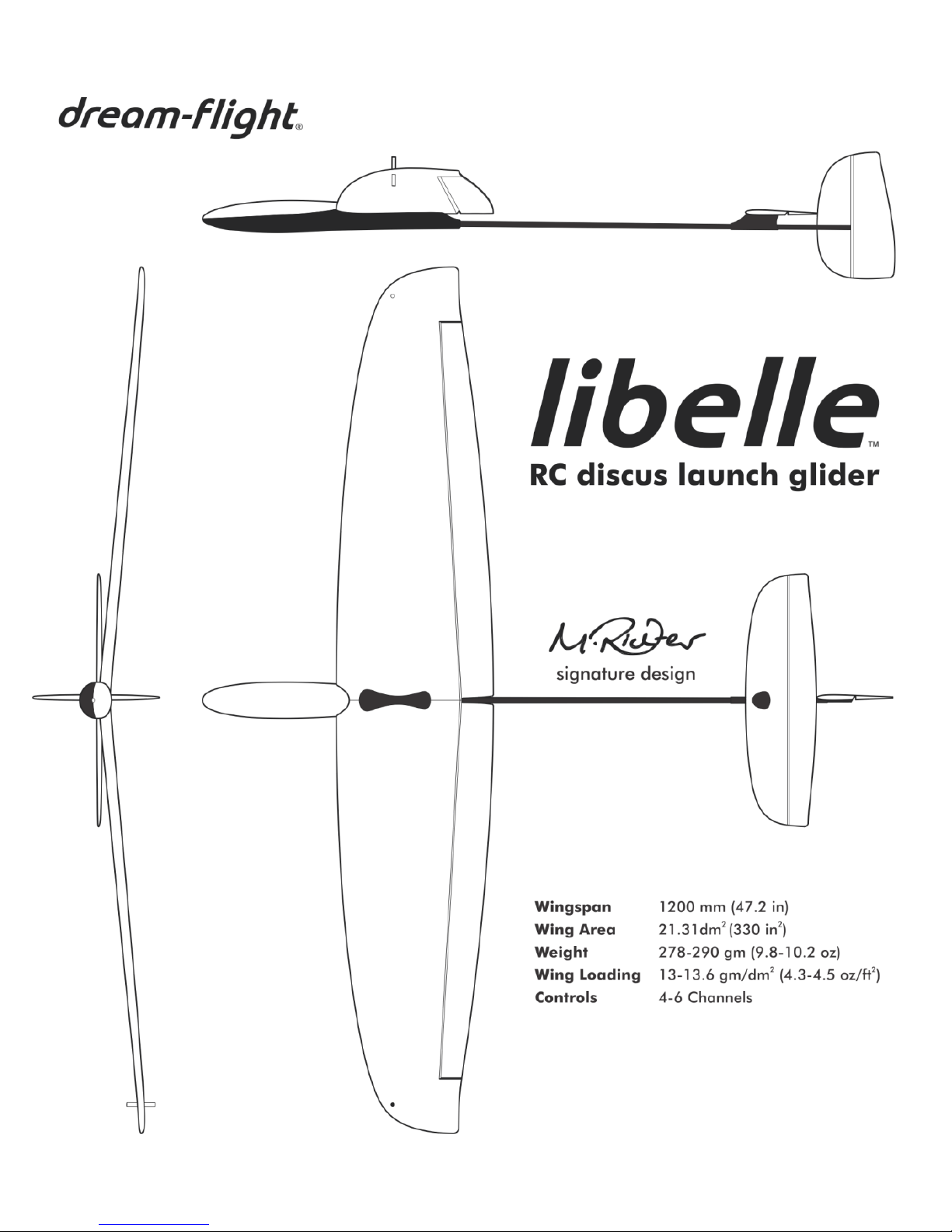

Designer's Notes - The Libelle's 1.2 meter wingspan is user-friendly and easy to transport (designed to fit across

most automobile rear cargo spaces). When compared to the conventional 1.5 meter DLGs, the Libelle's compact

wing gives a little more ground clearance for those pilots just developing their discus launch technique. The Libelle

packs in a lot of wing area by utilizing a lower aspect ratio wing tuned for slow, turning flight- perfect for

thermalling at low altitude like a bird! We started from the ground up, fusing in-house airfoil and wing design to

provide the Libelle with a wide speed range, great launch performance, and efficient flight behavior. Generous

control surfaces provide a nimble control feel that will satisfy even the most experienced pilots.

“Libelle”- Why the Name?

Here in the Goleta Valley, we are fortunate to share the air with

a very wide variety of flying creatures. One of our favorites, the

Green Darner dragonfly, began to appear quite often both

physically and symbolically during the development of the

Libelle. Watching these dragonflies catch even the slightest bit of

air current or lift while not moving their wings was greatly

inspiring. The nimble flight characteristics and beautiful shapes

resonated deeply with our mindset. It could not have evolved

more organically... Libelle- the word for dragonfly in German.