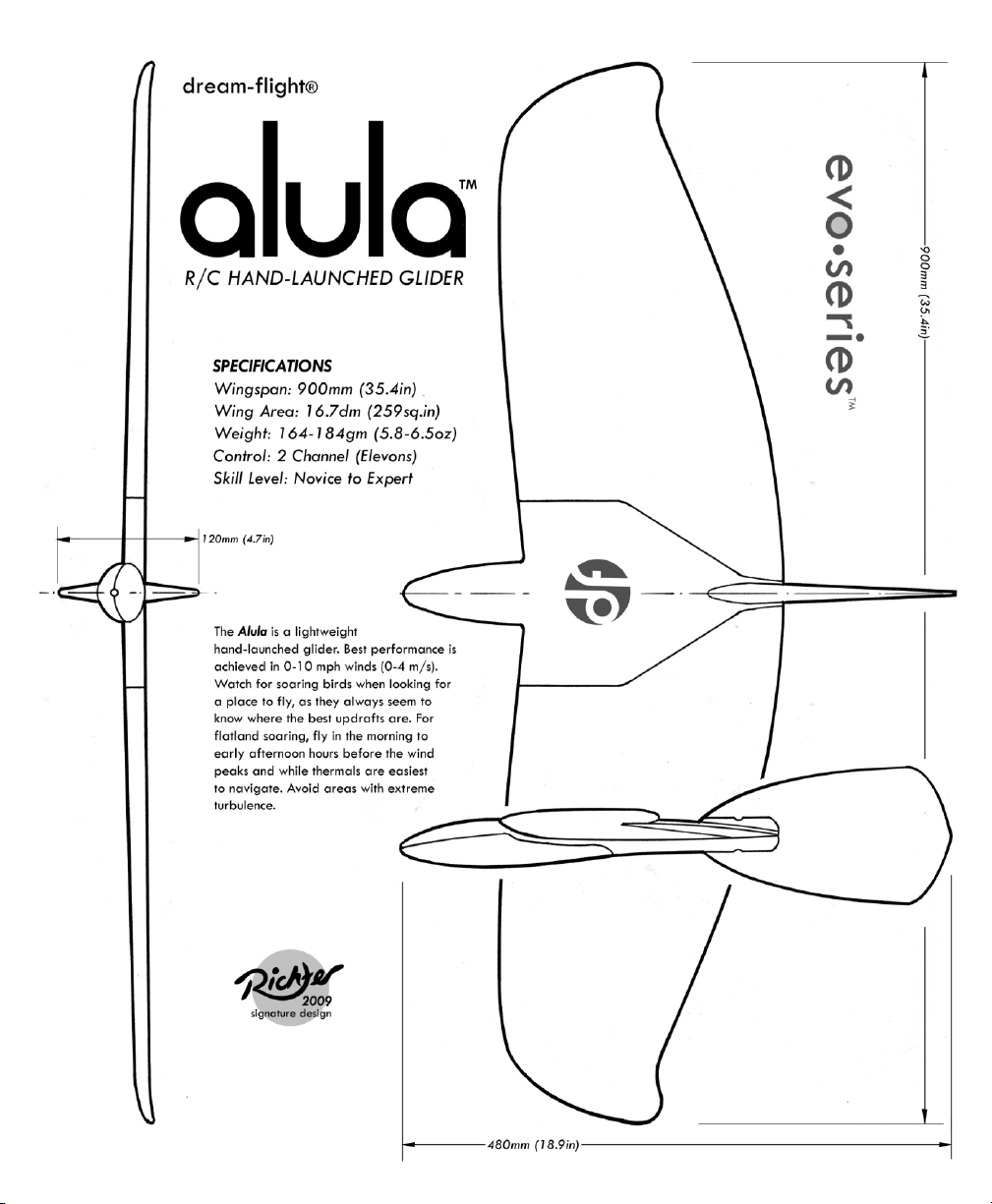

About the Alula

This design, inspired by the local red-tailed hawks that frequent the sky above

our workshop, is in reality a very functional glider. Often overlooked is

the forward swept wing configuration utilized by many birds

during soaring flight. This configuration is perfect for a hawk

flying slow, tight circles to stay within small, near ground

thermals while searching for its next meal.

Not only does the Alula’s forward sweep allow you to

navigate small, confined sources of lift like a soaring bird,

but it also eliminates tip stalling and maintains good control surface authority even at very low speeds. The Alula

was designed specifically with the side-arm launch method in mind, since this is a more effective way to launch a

glider by hand. The forward-swept wing facilitates the side-arm launch method by aligning the launch point

(wingtip) with the Center of Gravity. This, coupled with the large tail fin, reduces the twisting tendency of a glider

upon launch, making for straighter, easier flings to altitude.

We call the Alula our "urban glider," due to its ability to soar in the most unconventional of locations. No high-

starts, motors, or spinning propellers required... just fling and fly. It’s as close to an R/C boomerang as it gets!

What’s New?

We’ve been experimenting with swept forward designs on and off over the last ten years but it wasn’t until 2004

that we refined the Alula design as a side-arm launched glider and made it available for purchase. The first

Alulas were hand-cut, and since then our business and products have steadily evolved. In an effort to modernize

our operation, we’ve switched to a molded manufacturing process, which allows us to minimize material usage and

achieve a more refined product. The Alula design has been completely overhauled. It now employs a computer-

designed modular ARCEL foam airframe that can be built as one piece for maximum strength and simplicity or as

a collapsible version for easy travel and storage. All parts were redesigned so that the use of adhesives is

minimized, making assembly a breeze and reducing health/environmental hazards. Further versatility,

aerodynamic and aesthetic refinements, and simplified assembly are hallmarks of the new evo-series gliders. They

demonstrate R/C soaring, evolved.

“Alula” -Why the Name?

We understand that we have a knack for coming up with some

pretty unusual names for our gliders. We love birds and as a

result we stumbled onto the word “alula” while looking through

bird anatomy books for inspiration. The name simply stood out

due to its simplicity and symmetry (it’s a palindrome and thus can

be read the same forwards and backwards). Officially

pronounced “al-you-la” in the birdworld, we like the sound of “ah-

loo-la” when referring to our glider. Upon researching further, we

learned that the “alula” on a bird wing (see figure to the right) is a

set of feathers attached to the bird’s equivalent of a thumb. These “thumb

feathers” on a bird serve as a quasi leading edge slotted flap that helps to delay the

onset of a stall. It works by reinvigorating the airflow over the top of the wing at high angles of

attack. This serves the bird well during take-off, landing, and perching in difficult locations. Simply put, we

thought this name fitting due to the low speed performance of this little glider and its bird-like appearance. Given that

many of us use our thumbs to control our R/C aircraft, this little glider provides us with some “thumb feathers” of our

own.