Page 64990395005 Date:02/11 SC200 Installation, Operating & Maintenance Manual

3

Installation

3.1 General

The screw compressor must only be installed and started by trained

personnel. Damage due to improper handling is not covered by the

manufacturers warranty.

The machine is delivered completely assembled

Ensure that the drive shaft rotates freely; if not, do not force the shaft, please

inform our service department.

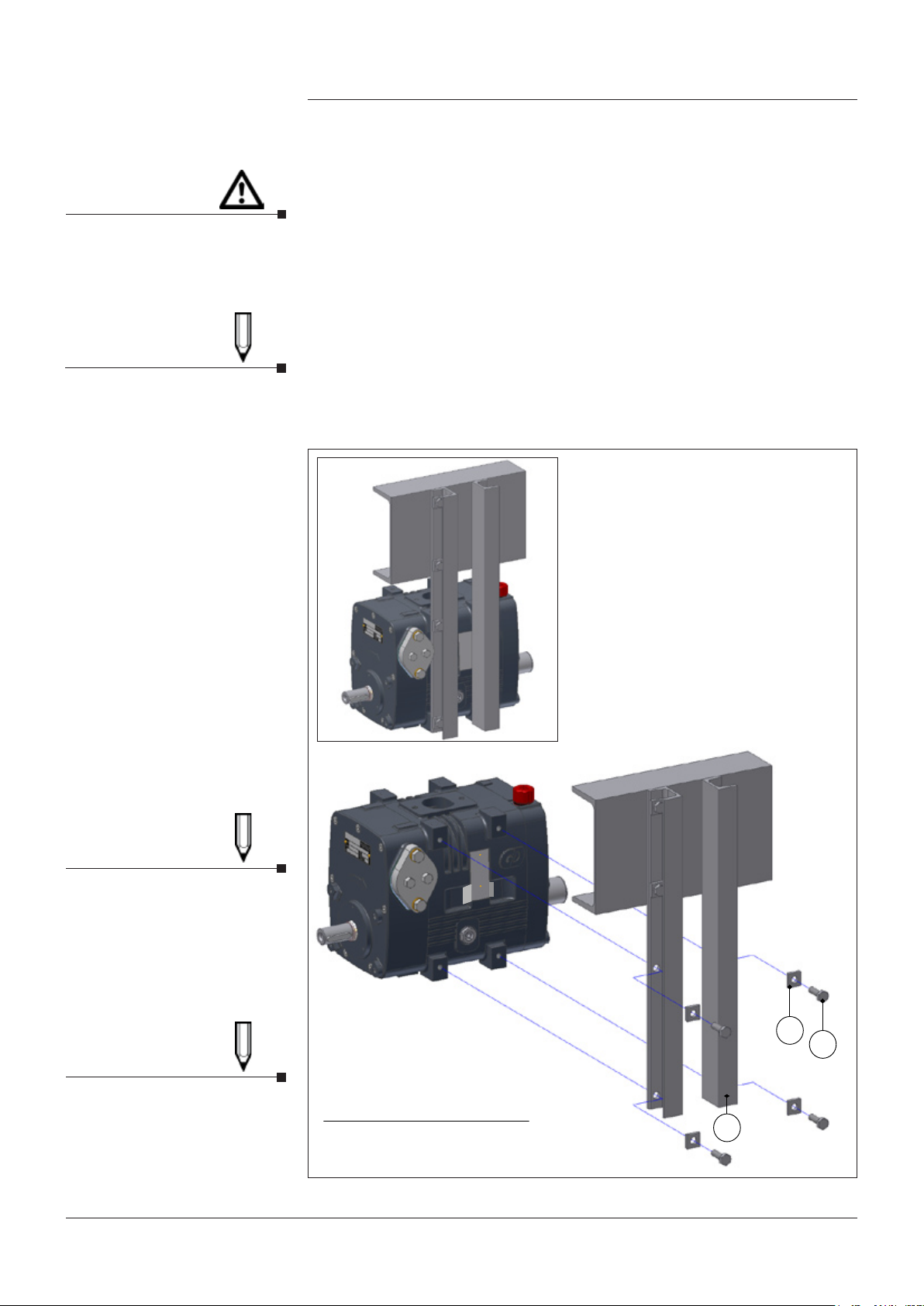

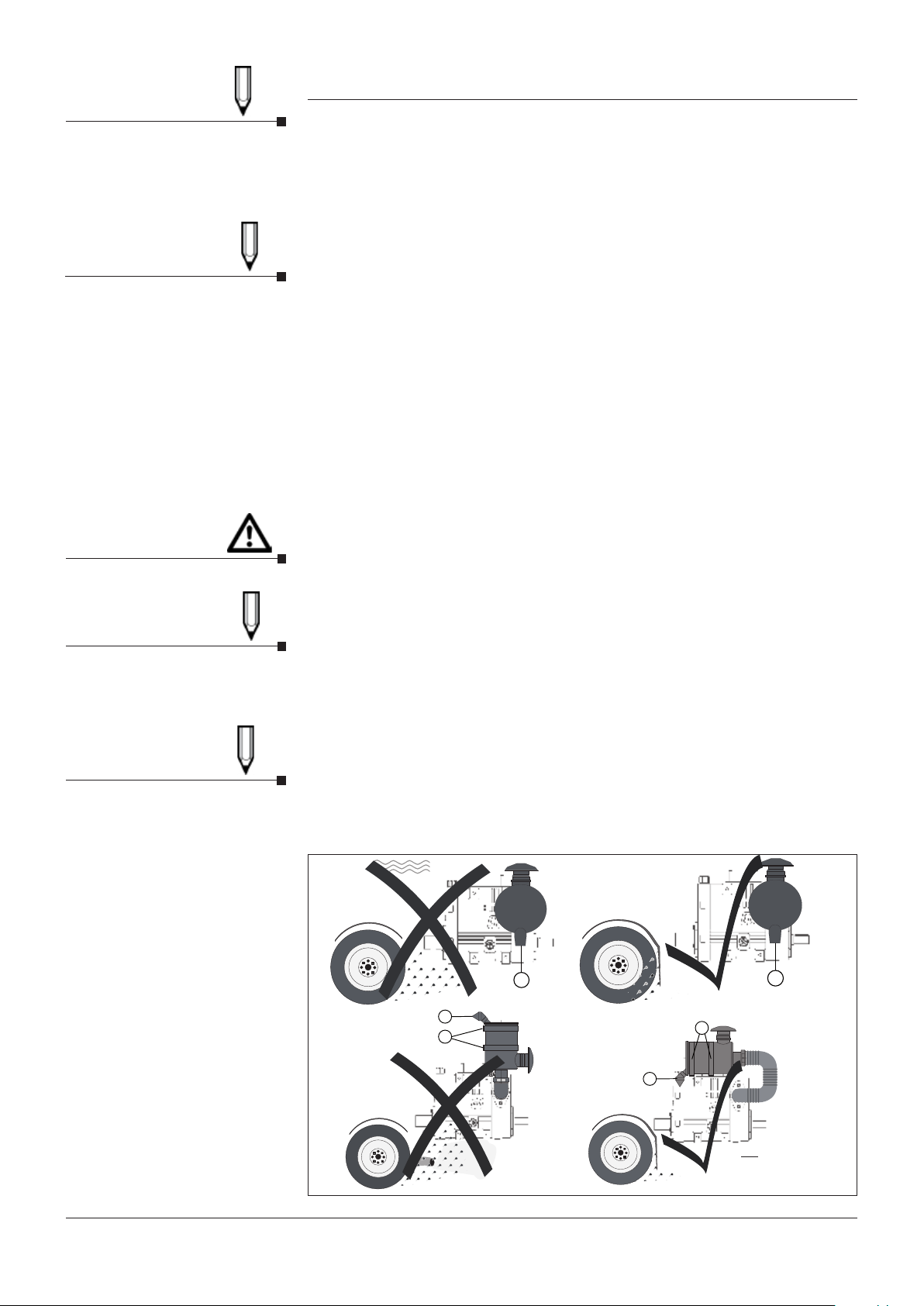

When selecting the machine mounting position, the following points should

be considered:

• Access to oil fill/level and drain plugs

• Adequate clearance to allow the cooling air to circulate around the

machine.

• Allow sufficient space for the installation of the Inlet and discharge lines,

including discharge silencer, if fitted.

• The machine should be protected from dust, flying stones and water

splashes.

• Install away from sources of heat, e.g. vehicle exhaust or hot pipes that

could effect the compressor temperature in any way.

• Venting relief/control valve air must be unobstructed and direct to the

atmosphere.

• Fit the relief and/or protection control valves as close as possible to the

SC200 discharge port.

• Venting valves must be positioned so that hot air cannot vent onto the

operator or the compressor

• Silencers should be fitted to the discharge port.

• Machine should be easily accessible for maintenance.

For the recommended layout of the machine and ancillaries see Pages 24 & 25.

Do not lift using other parts of

the machine.

CAUTION

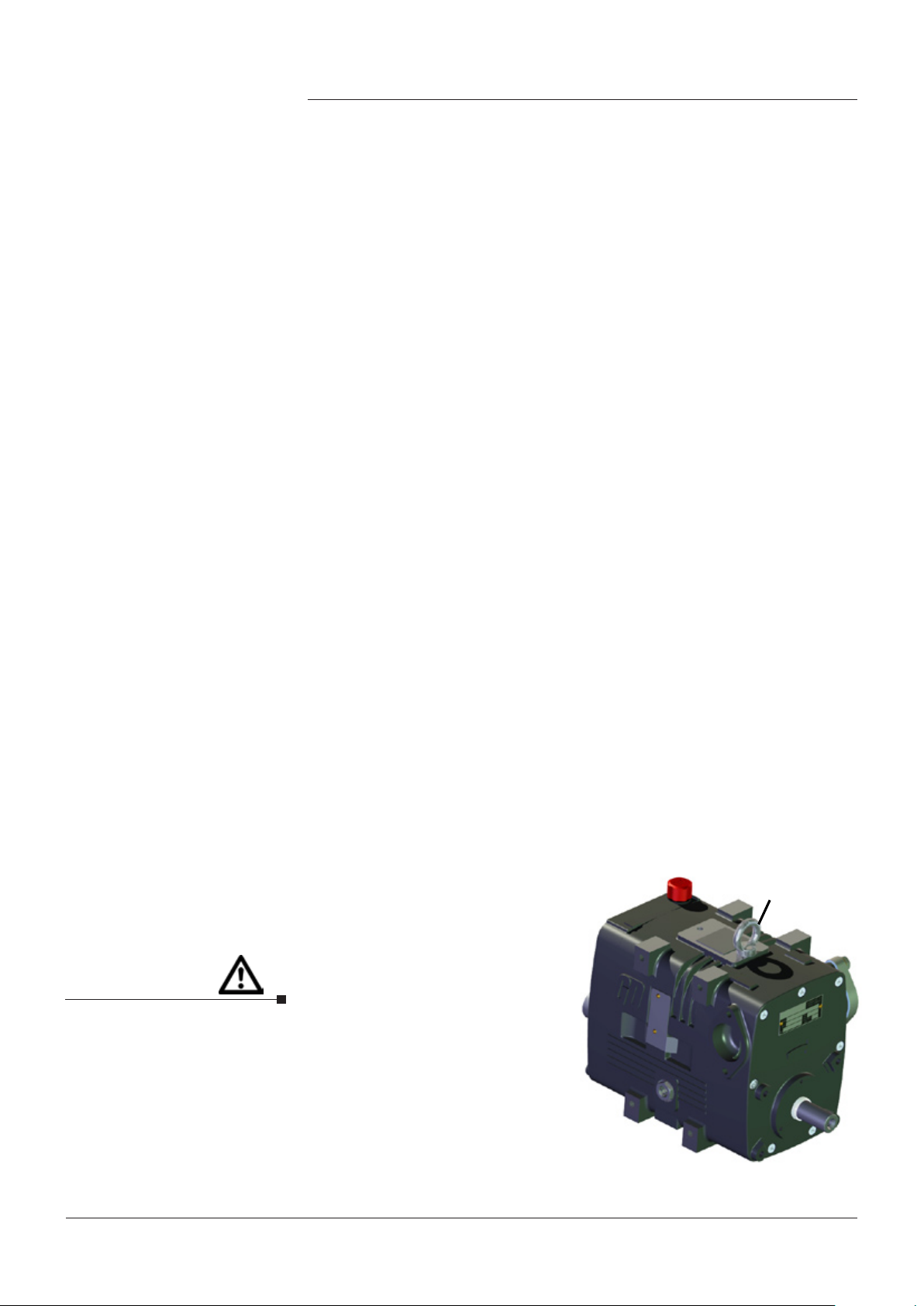

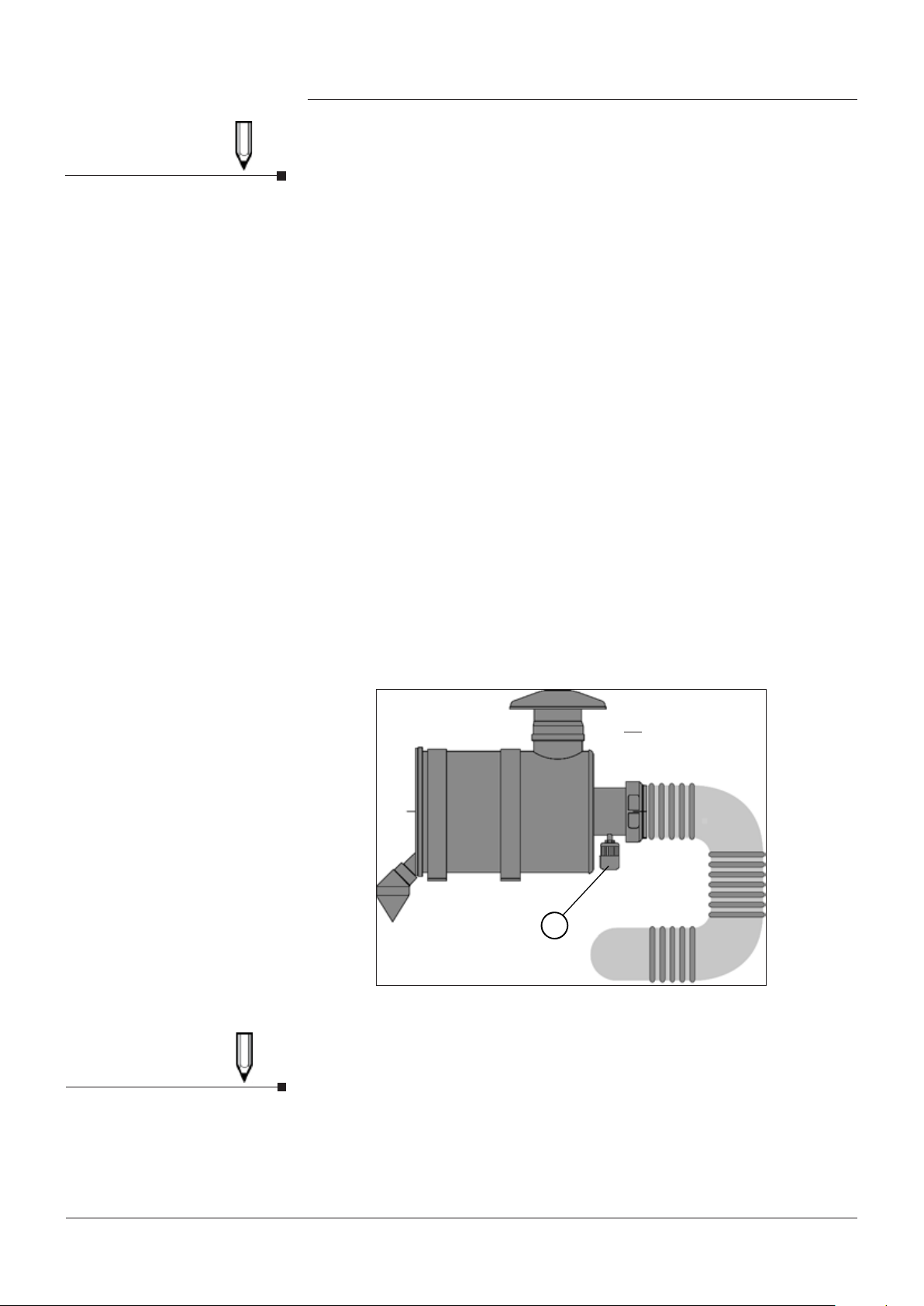

3.2 Lifting (see fig. 1)

• Avoid any use of force and load/

unload the packages with care.

• The weight of the basic compressor

without ancillaries is 42.5 kg.

• Remove all transport guards.

• Lift the machine using only the

securely mounted ring eye

bolt provided. (See Fig. 1/1).

• When the machine has been

installed, the supplied lifting eye

bolt should be removed and the

cover holes fitted with blanking

grommets.

• Any equipment used for lifting

should be rated accordingly. Figure 1. Lifting Eye Bolt