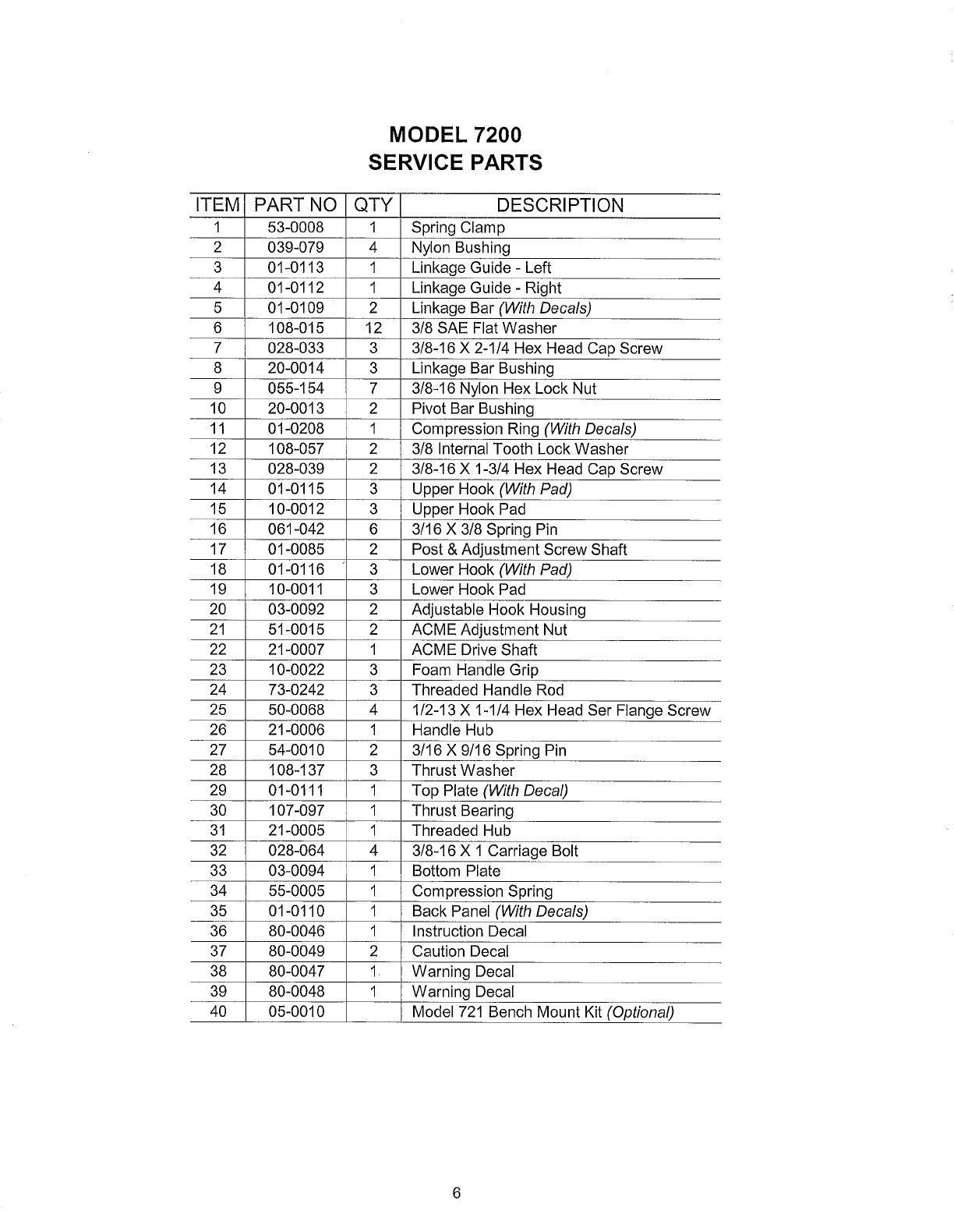

STRUT

SPRING

COMPRESSOR

ASSEMBLY

AND

SETUP

INSTRUCTIONS

WALLIPOST

MOUNTING

BENCH

MOUNTING

(Optional)

Locate

holes

and

secure

to

wall/post

using

Fasten

the

bench

mount

bracket

to

the

tool

six

3/8"

fasteners

(not

provided).

with

fasteners

provided.

Locate

holes

and

secure

to

bench

using

four

1/2"

fasteners

(not

provided).

~'

J

=

\%

\_.

\_

l\_

$

it

‘I

V

%

&

.,

6...-’j,/Q

,/ls,

Ali“

‘I

.

,

—

1

\:-fi

%

._:.

2,

\

,

er

g

==

sq

_

Q.»

Q»

E

5

§-_//

:

;

\’

_

-4.

,

=

5

a

5

,|

\/

~

3

\-’

:

;

>4

\\-1

\—’

\€

%

,

%

*-’

\_/

\

,,

,

‘cw’

'71‘

~

\_/

=

:1

‘-’

:

1;

\’

-

-

\’

\€

é

‘I

‘-4

€

\'

%

\’

I

'

e

/ftv";

ti

,4

;

'

,,

_

‘,_7//"Xi

//to

*4

"1’

'f/I//

Ikl

% ?s@/

4

ti

”

\\8

.

,

Mic

,

2_._.-_,-2.L--_.._.._.._-.Z;

;

\

4

\

§

A

\

/N;

_,

-v

V

,..

V

$2

%

_::

%

NOTE:

What

ever

mounting

method

is

used,

the

tool

must

be

securely

_/T

*0

. I

~

®~.

®,

K

_/

fastened

before

use.

If

the

tool

has

any

damaged

or

missing

parts,

call

Branick

Industries,

Inc.

customer

sen/ice

at

1-800-437-4394

SEE

OPERATING

INSTRUCTIONS

FOR

TOOL

OPERATION