DST80S Installation Instructions

1.)

Floor should be level +/- 1/8”. If the floor is not level, the turnsle will need to be

shimmed.

2.)

Use the cross arm and main channel assembly as a template to mark the 5x anchor holes

onto concrete.

3.)

Drill the 5x 7/8” holes for the curved yokes and staonary barrier 4” deep, clean holes of

debris.

4.)

Insert rods into yokes and barrier. The hollow rods (to be used as wire races) should be on the

card reader mounng side of the yoke assemblies. The solid rods belong to the inner posts of

the yoke assemblies and the staonary barrier.

5.)

Erect frame of turnsle by standing curved yoke assemblies and staonary barrier upright and

insert the rods into the drilled holes in the concrete.

6.)

Rest the mainframe ontop of the curved yoke assemblies and staonary barrier, fing the rods

through the holes provided. Do NOT install nuts for the rods yet.

7.)

Block the yoke assemblies and barrier up to provide space underneath and pour epoxy grout

into each of the 5 holes. Allow epoxy to cure before removing blocks.

8.)

Once the epoxy has cured, remove the blocks from under the curved yokes and staonary

barrier. Thread the 3/4"-10 nuts onto the threaded rods to secure frame to concrete. Shim

where necessary to ensure mainframe is level +/- 1/8”.

9.)

Using a plumb-bob, mark the rotor’s bearing locaon on the concrete.

10.)

Set the PVC bearing cup so that the bearing aligns to the center of the plumb-bob and drill 3x

3/8” holes. Secure bearing block assembly to concrete with provided 3/8” anchors.

11.)

Place the bearing with 7/8” hex insert onto bearing cup and install rotor onto bearing

assembly.

12.)

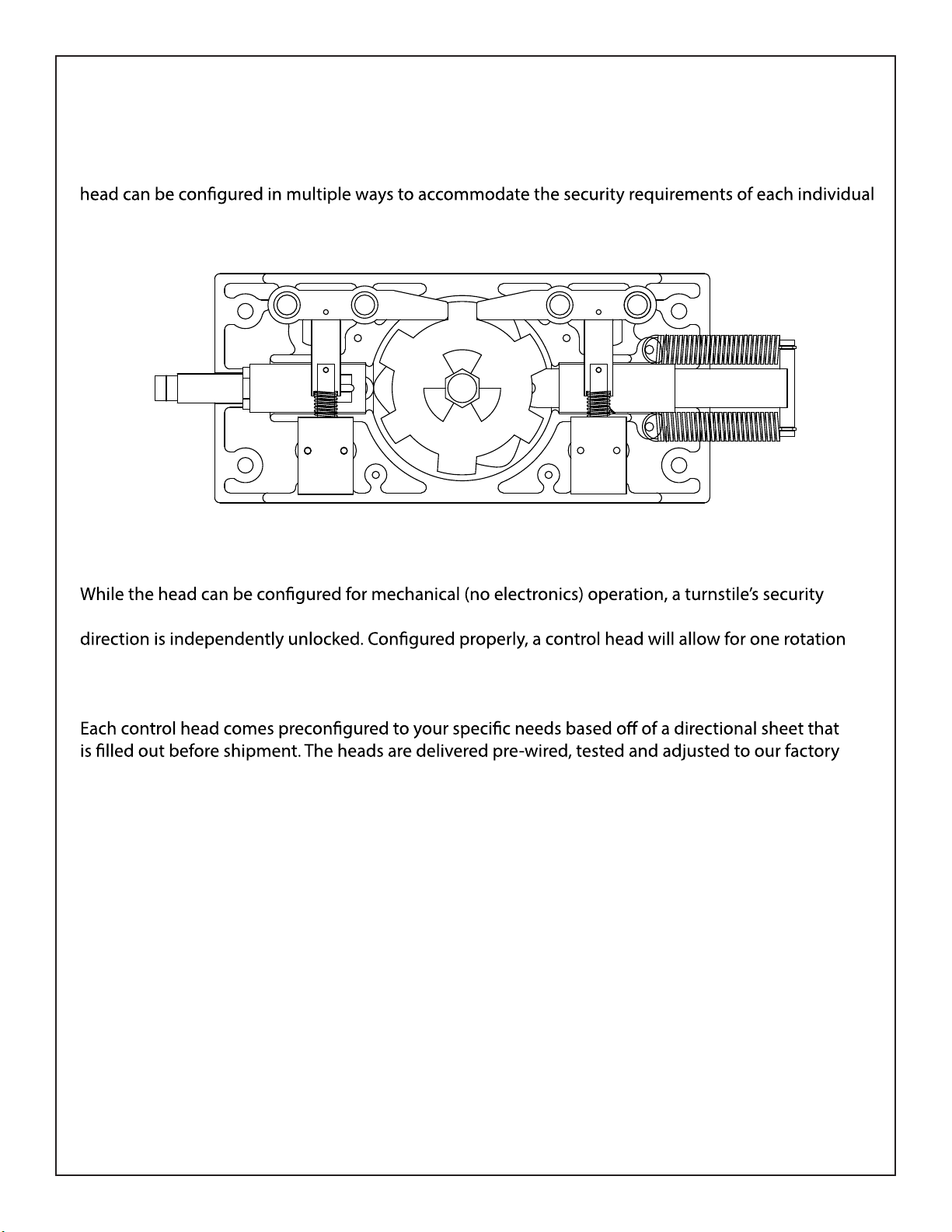

Install control head into the rotor and mainframe. Ensure that the alignment on the rotor is so

there is one set of arms in between the two curved yoke assemblies (see diagram below).

13.)

Refer to control head informaon in the remainder of the book for electrical informaon,

troubleshoong, and other informaon about operaon of the turnsle.

512-321-4426

INS-DST80S-190401

Designed Security, Inc - 1402 Hawthorne Street, Bastrop Texas 78602 - (800) 272-3555