SW Series Washer User Manual

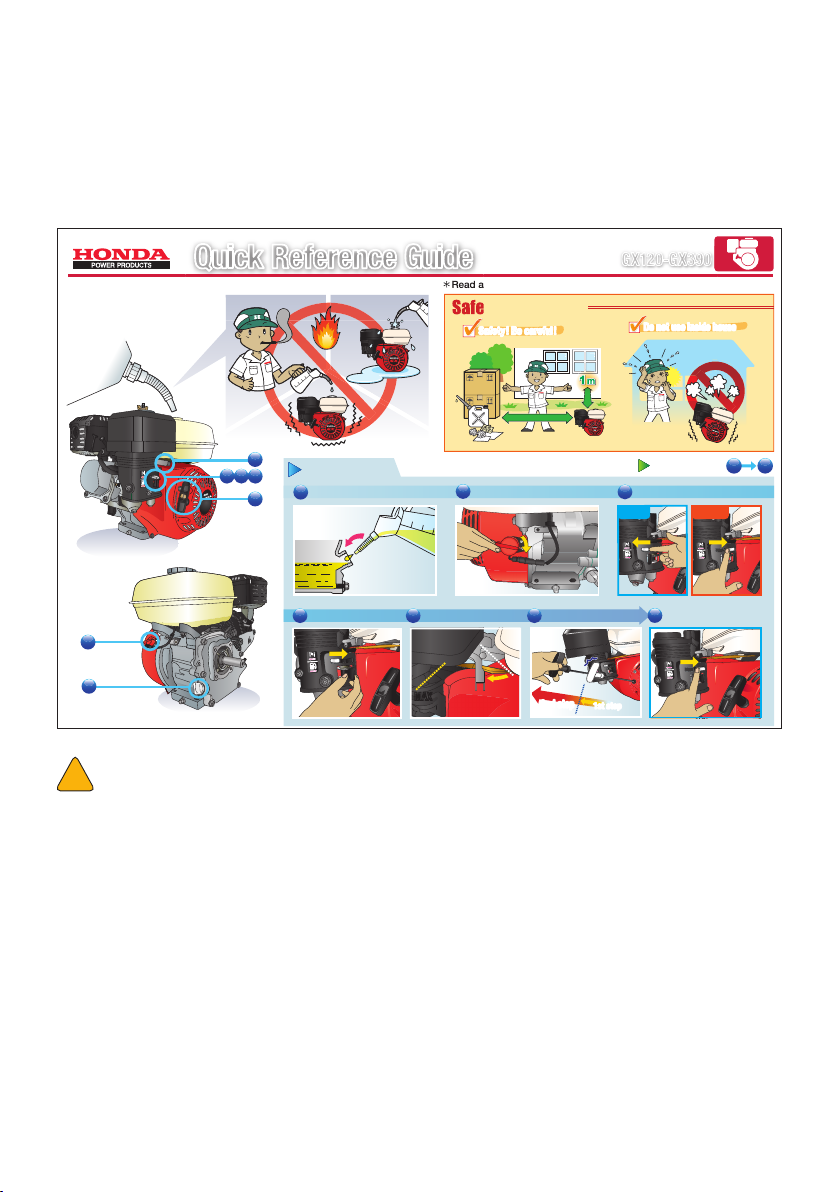

This manual and any other literature supplied should be read thoroughly before

assembling and operating the Washer. Pay particular attention to any instructions relating

to safety, and the starting, stopping and maintenance of the Washer. Following these

instructions will ensure operator safety and prolong the life of the Washer.

This manual should be kept for future reference as it contains important safety, user

and maintenance information. The model and serial number on the cover of this booklet

must be quoted should you need to contact the dealer or manufacturer regarding usage,

maintenance and warranty queries.

Recommended Safety Standards & Directives

This manual highlights certain safety measures which should be taken in to consideration

when using the Washer. However, each contractor and operator should make their

own risk assessments whilst considering their individual application and environment

and ensure the user is properly trained and wearing protective clothing to the required

regulatory standards. We recommend visiting the Health and Safety Executive website

at www.hse.gov.uk to be properly informed on best practice whilst operating Pressure

Washers in the UK.

Contents Page

1. Safety Information...................................................................................... 1

2. Model Information...................................................................................... 2

3. Intended Use.............................................................................................. 3

4. Component & Accessory Identification ..................................................... 4

5. Pre-Operation Set Up ................................................................................ 5

6. Engine Start Up / Shut Down Procedure................................................... 6

7. Operating Information................................................................................ 7

8. Maintenance Schedule .............................................................................. 8

9. Storage Information ................................................................................... 9

10. Troubleshooting ....................................................................................9-10

11. Warranty Information ..........................................................................11-12

12. Environmental Protection ........................................................................ 12

13. EC Declaration of Conformity .................................................................. 13