Electronic board model CTH48 2.0 for swinging gate opener

7

Technical data and features

CTH48 2.0

(equips the KONTROL 9048 2.0 control unit)

Use made to manage 12V dc actuators to automate a swinging gate with 1 or 2 leaves

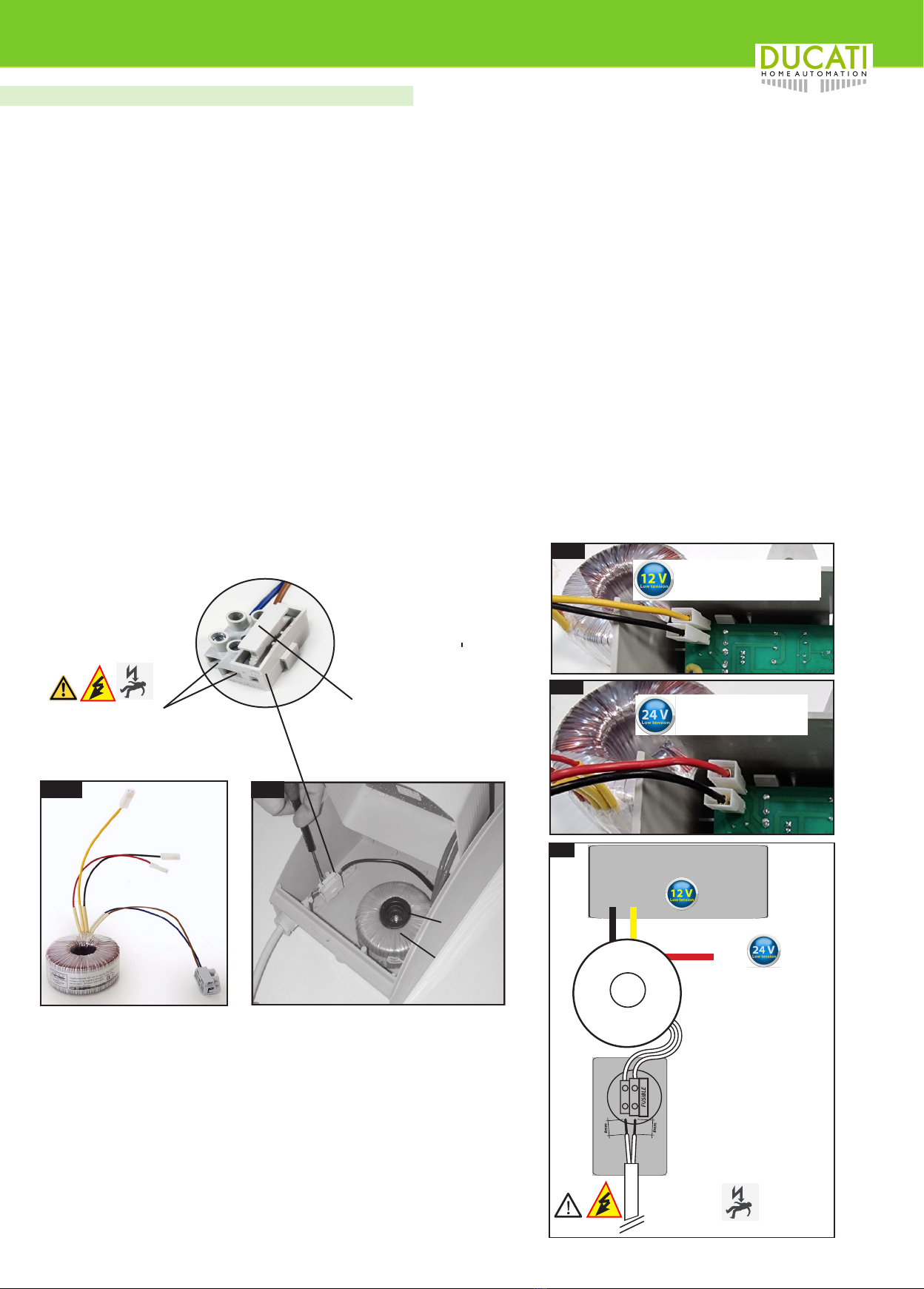

Mains AC Power supply

√12V ac/dc by means of a toroidal transformer 105W input AC 230V 50/60Hz or AC110V 50/60Hz transformer output 12Vac (yellow+ black cable). A rectifier on

the board transforms the AC current into DC current. Warning: for optimal performance it is recommended to always keep a backup battery battery wired to

the system

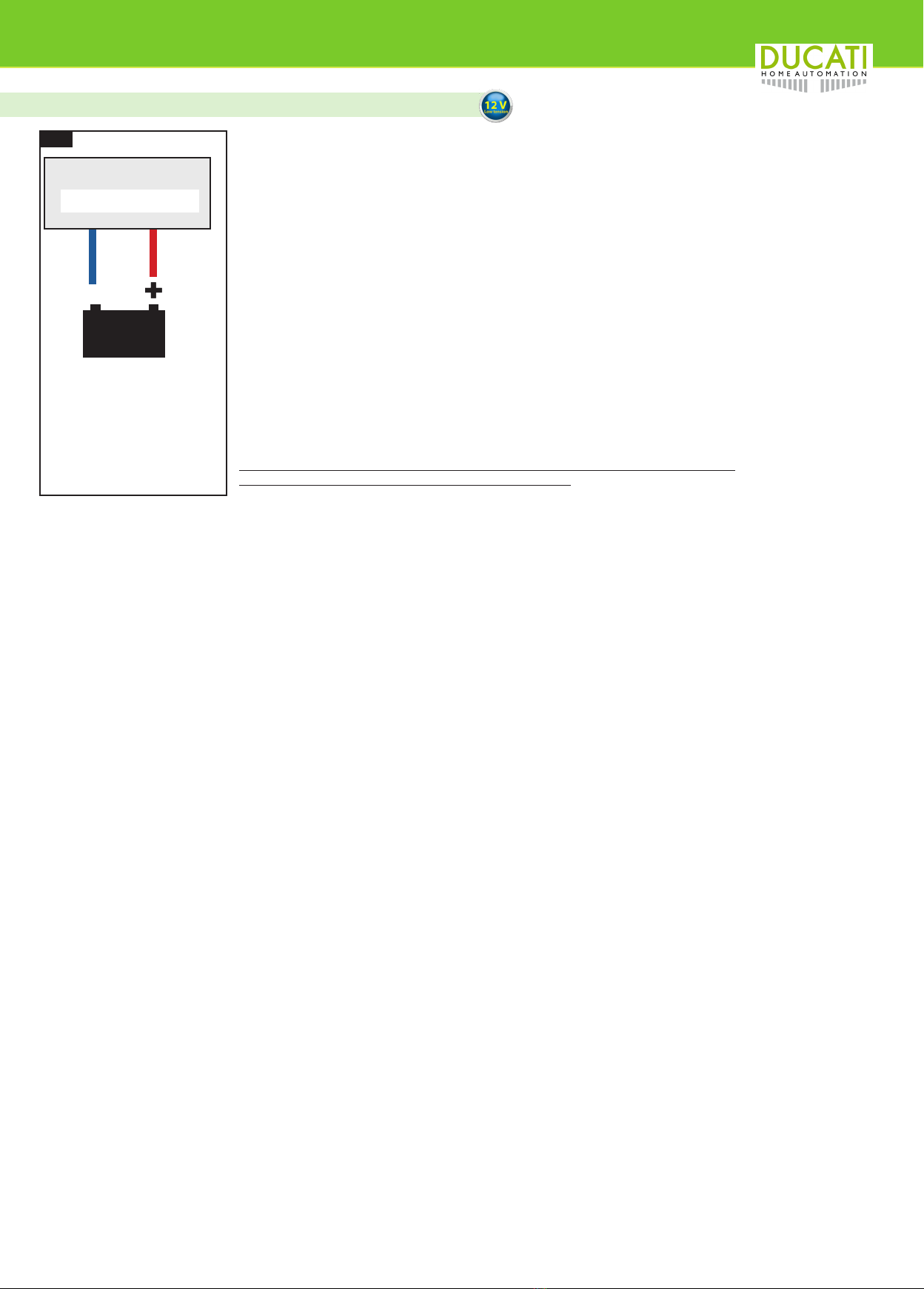

power supply from emergency battery for

autonomous use during main AC power

supplu power failure (black-out)

√. we recommend the use of a 12V 7A or 12V 12A lead- acid battery which can be housed inside the compartment of the control box unit

(CTh48 is ompatible with commercial batteries) The 12V battery charger management system is integrated on board

Power supply by battery and solar panel

√. 12V max 20W solar panel can be wired directly to the electronic board input connecotors. The battery will be automatically recharges rby the 12V 10W or 20W

solar panel (on-board battey charger management). The solar panel autonomously recharges the back-up battery (12V min.7A) and do not require any wiring to the

mains AC power supply. Provides 100% autonomous use from renewable energetical sources, protecting the environment and savings on bills

stand-by absorption 0,008A

Anti-crushing safety system √ Obstacle detection safety system in compliance with the EU EN12453. 2017 norms.

Radio receiver √ Ducati rolling coded radio revceiver wuth 2 radio receiver channles: 1channel to store a remote control button that commands the full manoeuvre. 1 channel to

store a remote control button to comman the pedestrian opening maneuvre. compatible with any Ducati rolling code radio remote control

Internal memory capacity for storing remote

controls

Maximal storage capacity= 48 buttons. They can be stored indifferently on the 1st or 2nd radio reception channel. AAttention: memory position means 1 occupied

position for each memorized button of a remote control

SOFT STOP soft approach of the door

at low speed √. Always active. both opening and closing. during travel at low speed the blue LED remains lit

Reverse direction in case of contact

with an obstacle

√. during the initial phase of the manoeuvre, at high speed, in the event of contact with an obstacle, the gate reverses the direction of travel. during the final phase

of the low speed maneuver (SOFT STOP) in case of contact with an obstacle, the gate stops.

Pedestrian opening cycle

(partial opening of only 1 door)

to allow pedestrians transit only)

√. It can be controlled both by radio control and by wired control (e.g. key switch, intercom button or similar)

Compatibility with use of electric lock √. electric lock power output: 12V dc. compatible with 12V DC electic locks or 12V AC electric locks with booster module (transforms dc current into ac current).

Compatibility with the use of safety photo-

cells √. NC contact input (normally closed) the photocells are active during the closing cycle and produce the immediate reopening of the gate

Compatible with the use of a button for

an emergency TOTAL STOP √. NC contact input (normally closed) the emergency stop contact stops the gate and disables any function for the entire time the contact remains open.

Compatible with the use of a timed courtesy

light

√ courtesy light power output 12V max 10W. The light will automatically turn on when the gate starts and will remain on for 40 seconds after the end of the manoeu-

vre. It is also possible to connect courtesy lights with 230V power supply using a power relay and the appropriate diagram

Compatible with the use of a remote light that

signals the status of the gate √

Compatible with the use of wired control

systems such as key switch / push button/

GSM command/Wifi command to operate

total

√it is possible to connect in wire (use a bipolar cable min. 0.3mm2) control devices for starting the gate operation such as, for example, key switch, button, intercom

button, control devices with Wi-fi system, GSM. Attention: clean contact input normally open. to command the start of the maneuver cycle the contact must be closed

for 1 second only

anti-wind man-operate command

√. by keeping the START contact closed with the hold-to-run command, the forced maneuver is commanded with maximum motor power and without anti-obstacle

amperometric control. This maneuver is only permitted with a man present who watches over the gate during the entire maneuver and aimed at concluding the ma-

neuver in conditions of strong gusts of wind

AVAILABLE ADJUSYTMENTS

Motor power adjustment during SOFT STOP

(final part of the maneuver at low speed)

it is possible to increase or decrease the thrust force by rotating the potentiometer T2. In this way you can set the sentsitiveness in the event of an impact on an

obstacle to comply with the anti-crushing EU norms. This adjustment affects the low speed stroke ( SOFT STOP) which must correspond to the area of greatest risk

of crushing foreseen by the EN12453- standards

Adjustment of the starting point of the SOFT

STOP phase (deceleration)

It is possible to advance or postpone the beginning of the low speed maneuvering phase (SOFT STOP) by rotating potentiometer P3 in order to adapt the maneuver

to the individual system. The slowdown occurs at least 8 seconds after the start of the maneuver and can be postponed up to max. 25 seconds from the start of the

manoeuvre. The SOFT STOP function intervenes both in opening and closing. Pay attention that the slowdown occurs at the points where the regulation requires

carrying out pressure tests with a specific dynamometer to certify the system in compliance with the EN12453-2017 norms

Gate wings lag time adjustment during in

closing, to adjust the delay between M2 and

M1 start in closure maneuver (only for gates

with 2 swing leaves)

The phase shift between the start of motor M1 and M2 during opening is fixed. the phase shift of the leaves during closing is set by default and is adjustable with a

range from 0 to 30 seconds.

Adjustment of the width of the pedestrian

opening manoeuvre (timed adjustment)

Pedestrian opening is a time-controlled manoeuvre. by default the M1 leaf will open for 4 seconds. during this time it will be able to make a variable opening angle

depending on the structure and the fixing position of the actuators. However, it is possible to manage and adjust the working time during pedestrian maneuvering as

desired in order to open the M1 leaf with more or less degrees. The maximum time that can be set is 26 seconds.

WORKING MODE

Step by step √ lin step-by-step mode the impulses given by the radio control or by the wired device, both for the total maneuver and for the pedestrian manoeuvre, produce the

following sequence: 1 impulse opens, 1 impulse during the movement stops, 1 impulse closes

FULL AUTOMATIC closing

√ In FULL-automatic closing mode, the impulses given by the radio control or wired device, to control the total manoeuvre, produce the following sequence:

1 impulse opens until the door reaches the mechanical end stop, it remains open and counts the set pause time (max. 100 sec.) then it closes automatically. During

opening and pause time, it does not accept further commands, during closing a further impulse reopens the gate

Attention for the pedestrian maneuver cycle: it is not possible to interrupt the movement either during opening or closing... the door opens, reaches the stop, stops,

counts the time and then closes automatically after the set pause time (from 1 to 100 sec)

SEMI-AUTOMATIC closing

√ In SEMI-automatic closing mode, the impulses given by the radio control or wired device, to control the total manoeuvre, produce the following sequence:

1 impulse opens until the door reaches the mechanical end stop, gate remains open and counts the set pause time (max. 100 sec.) then it automatically closes. Both

during opening as during the open pause, a command causes the gate to close immediately, while during closing a further impulse reopens the gate. Attention for

the pedestrian maneuver cycle: it is not possible to interrupt the movement either during opening or closing. the door opens, reaches the stop, stops, counts the time

and then closes automatically after the set pause time (from 1 to 100 sec)

Model CTH48 2.0

Mains Power supply (V-50/60Hz) 230V -550/60Hz AC or 110V 50/60Hz AC check the the toroidal transformer in use

Motor power supply (V) 12V DC

Power supply to the electroni cbaord (V) 14-15 AC (form 105VA toroidal transformer)

Stand-by consumption (A) 0,008A

TWorking temperature(°C) -20°C / + 55°C

Cycles/hour 120

Consecutive cycles no limits

Average life (cycles)** 1.000.000

**The average life of the product is purely

indicative and estimated in consideration of

compliant conditions of use, installation and

maintenance. It is also inuenced by further

factors, such as climatic and environmental

conditions.

CTH48 2.0 technical data (standard 12V version)