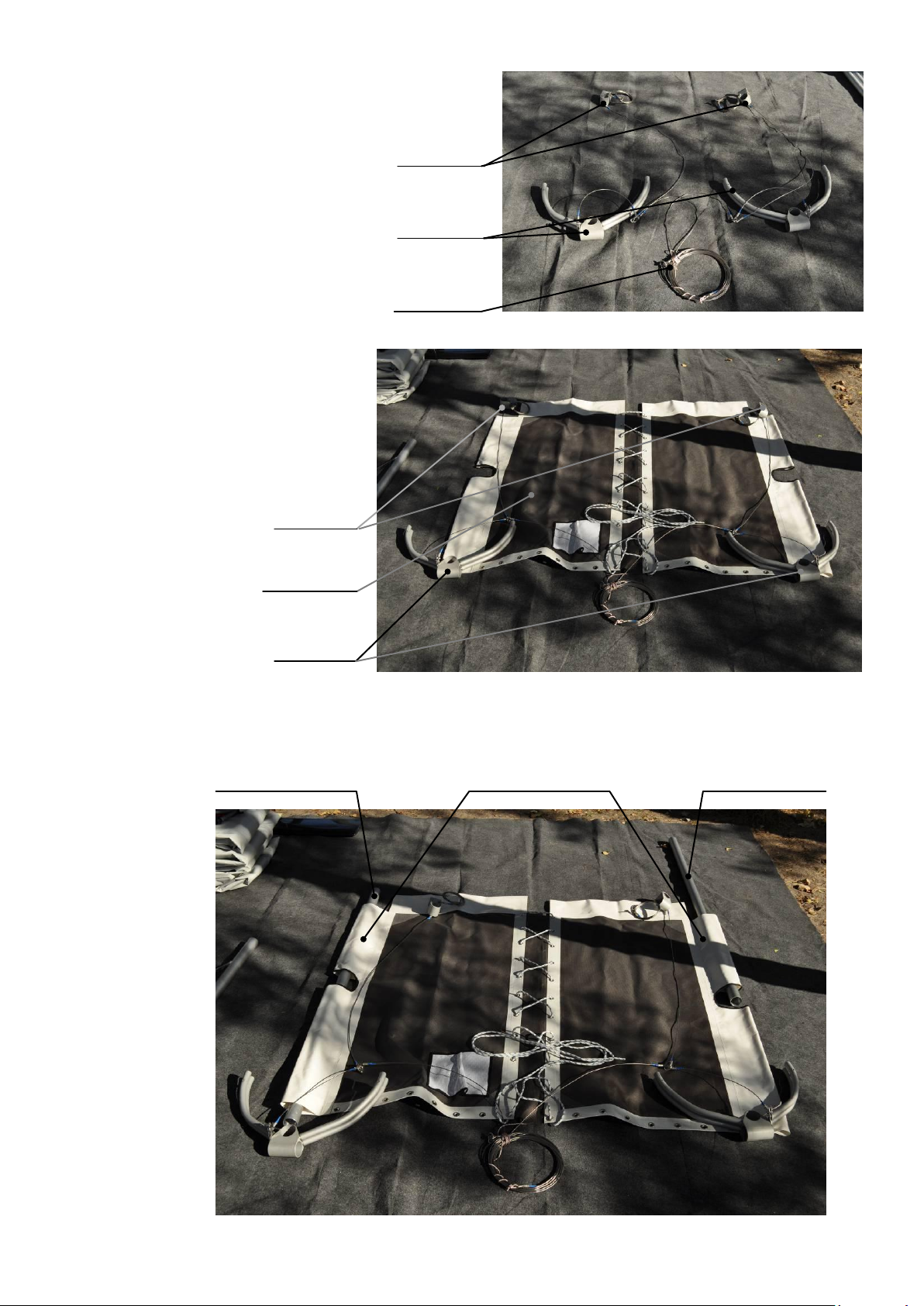

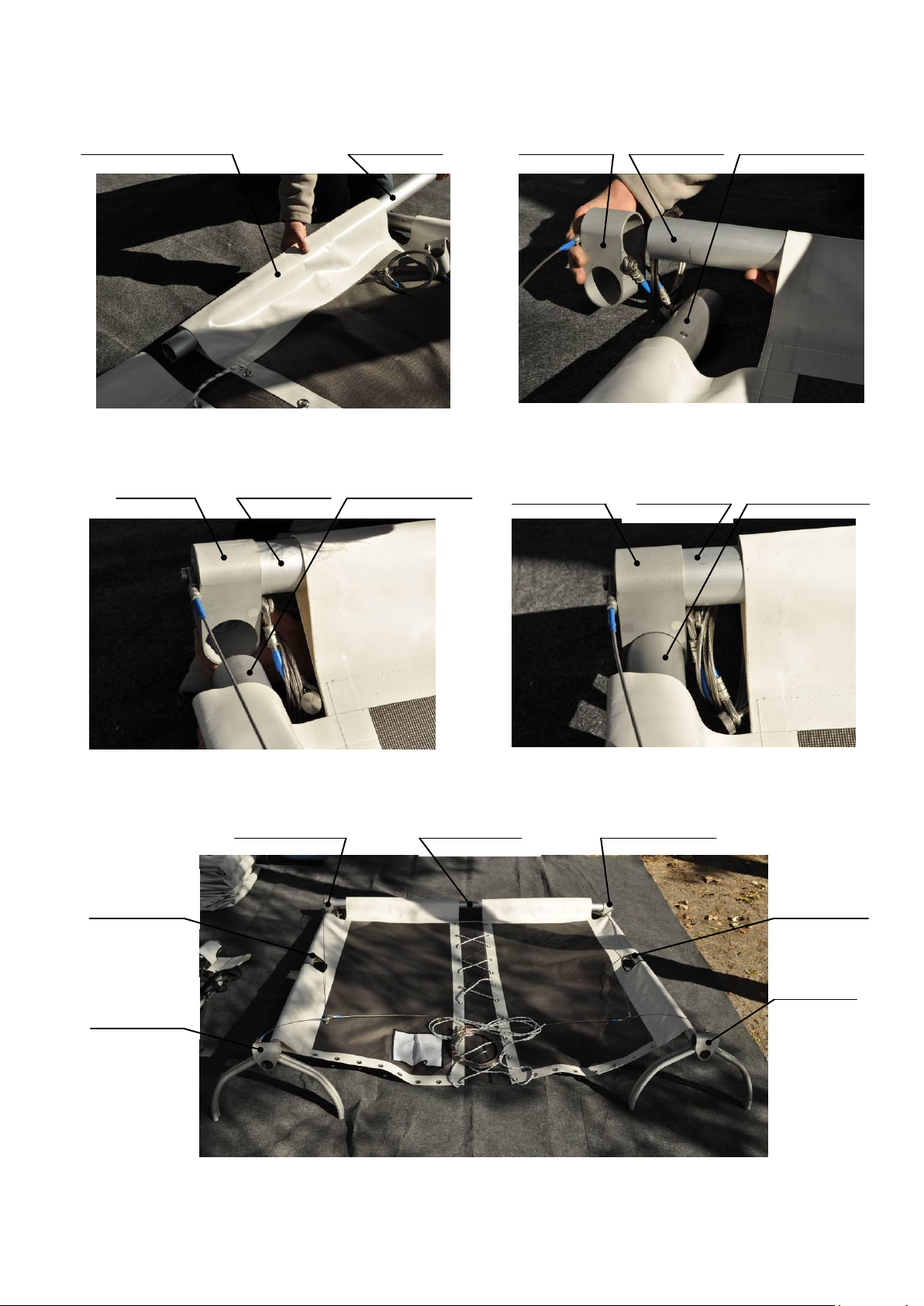

Cargo nets are made from a nylon ribbon and intended for placing of luggage and crew. Cargo

net is put on bow and stringer beams by sleeves and tensioned by lacing to the submast beam.

Bow cargo net’s sleeves are put on the bow and stringer beams and is tensioned by lacing to

submast beam. Stern cargo net’s sleeves are put on the stern and stringer beams and is

tensioned with strapping beam by lacing it at three places.

Centerboard unit consists of the centerboard and the centerboard box. The centerboard is used to

reduce the drift of catamaran when sailing upwind. The centerboard is installed into centerboard

box that attached to submast joint unit. In the operational (vertical) position the centerboard is put

by centerboard trim line and is held by the rubber expander. Expander absorbs the hitting of

underwater obstacles, thus allowing avoid the serious damage of the centerboard. In moorage

(horizontal) position centerboard is raised by halyard and held with clam cleat on the submast joint

unit.

Rudder units consist of two rudder blades, two rudder joint units, two rudder boxes, two tillers

interconnected by tiller crossbar, and two rubber expanders. Rudders are used to control the

catamaran. They are mounted in the rudder boxes, which are attached to the rudder joint units on

stringer stern parts. Rubber expanders put and hold the rudder blades in operational (vertical)

position. Expander absorbs the hitting of underwater obstacles, thus allowing avoid the serious

damage of the rudder blade. In moorage (horizontal) position rudder blades are raised by halyard

and held with clam cleat on every rudder tiller.

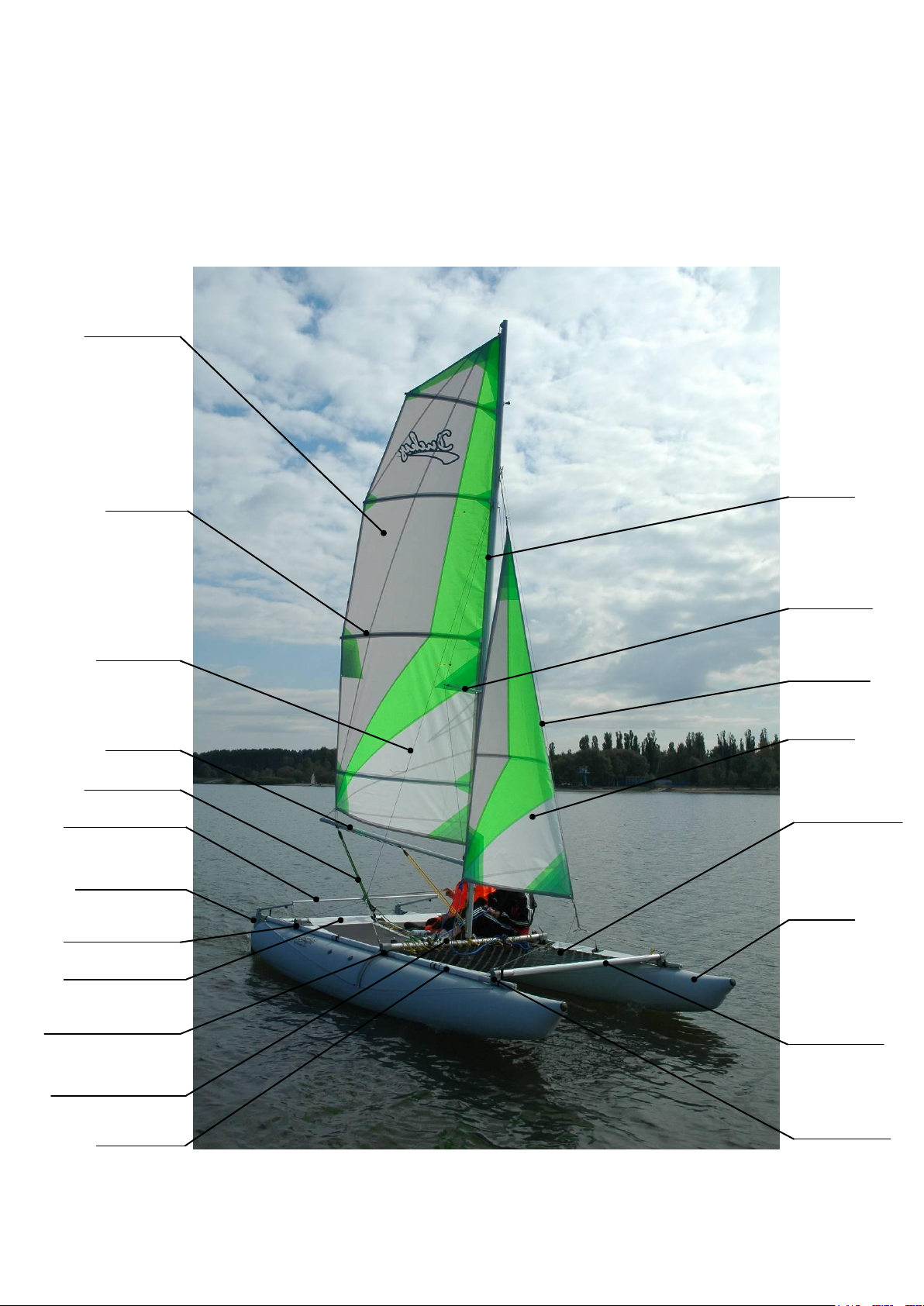

Rigging consists of the mast, sails, boom, standing and running rigging.

The mast consists of four interconnecting segments, spreader and jumper stays.

The mainsail is swayed up by halyard point with a main halyard. The main sail’s tack is fixed with a

downhaul while its clew is attached to the boom by outhaul. Mainsail has battens, which provide

the appropriate shape of sail and the inflexibility of after-leech. Boom is required for control of

mainsail and outhaul serves for sail profile tuning.

Jib is a head sail, which is raised on the mast up by halyard point with the jib halyard. The jib tack is fixed by

the jib downhaul, and the jib sheet is attached to the clew.

Standing rigging includes forestay and shrouds which hold the mast in position. The forestay and

shrouds are attached to mast with a rigging ring (forestay and shrouds are clamped by a rigging ring,

which is put on a mast hook). The shrouds are attached to bridge by guy bridle, and forestay is

attached to bridge by stay bridle. Tensioning of shrouds and forestay is done by forestay's lanyard.

Running rigging are the main-sheet and the jib-sheet.

Main-sheet is intended for a mainsail control. This tackle consists of cord and two blocks, one of

that is attached to boom, and another one with cam cleat - to the sheet beam of catamaran.

Jib-sheet is intended for a Jib control. This tackle consists of cord and two blocks with cam cleats,

which are attached to every end of submast beam.