Page 9 of 12

OPERATION

Cougar fan coils provide cooling and heating of air

when used in conjunction with chilled water and/or low

temperature hot water systems. They are designed for

mounting in a ceiling or roof void, connected to

ductwork.

When running, the fan draws air from the room and the

primary air supply, through an inlet filter and over the

finned tubes of a heating/cooling coil. The air is then

discharged through spigots, along ductwork and

through grilles or diffusers to the room space.

Alternative options include chilled water cooling only,

and intake through ductwork and spigots.

Fans normally run continuously, with an automatic

control system varying the flow rates of chilled water

and hot water through the coil (waterside control), thus

varying the cooling and heating outputs. Depending

upon the particular type of controls fitted, user control

is provided by 0-10VDC signal and/or temperature

control.

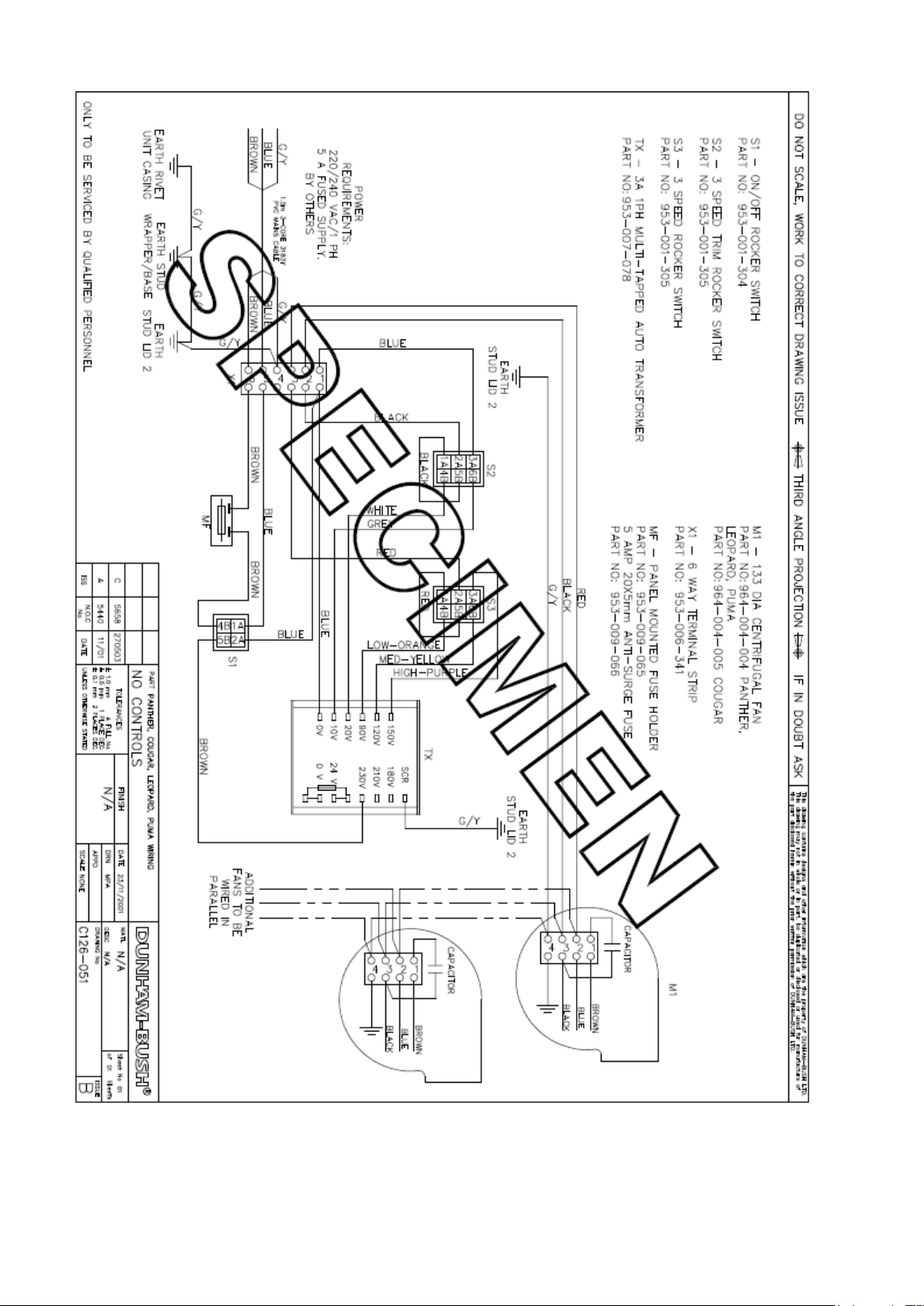

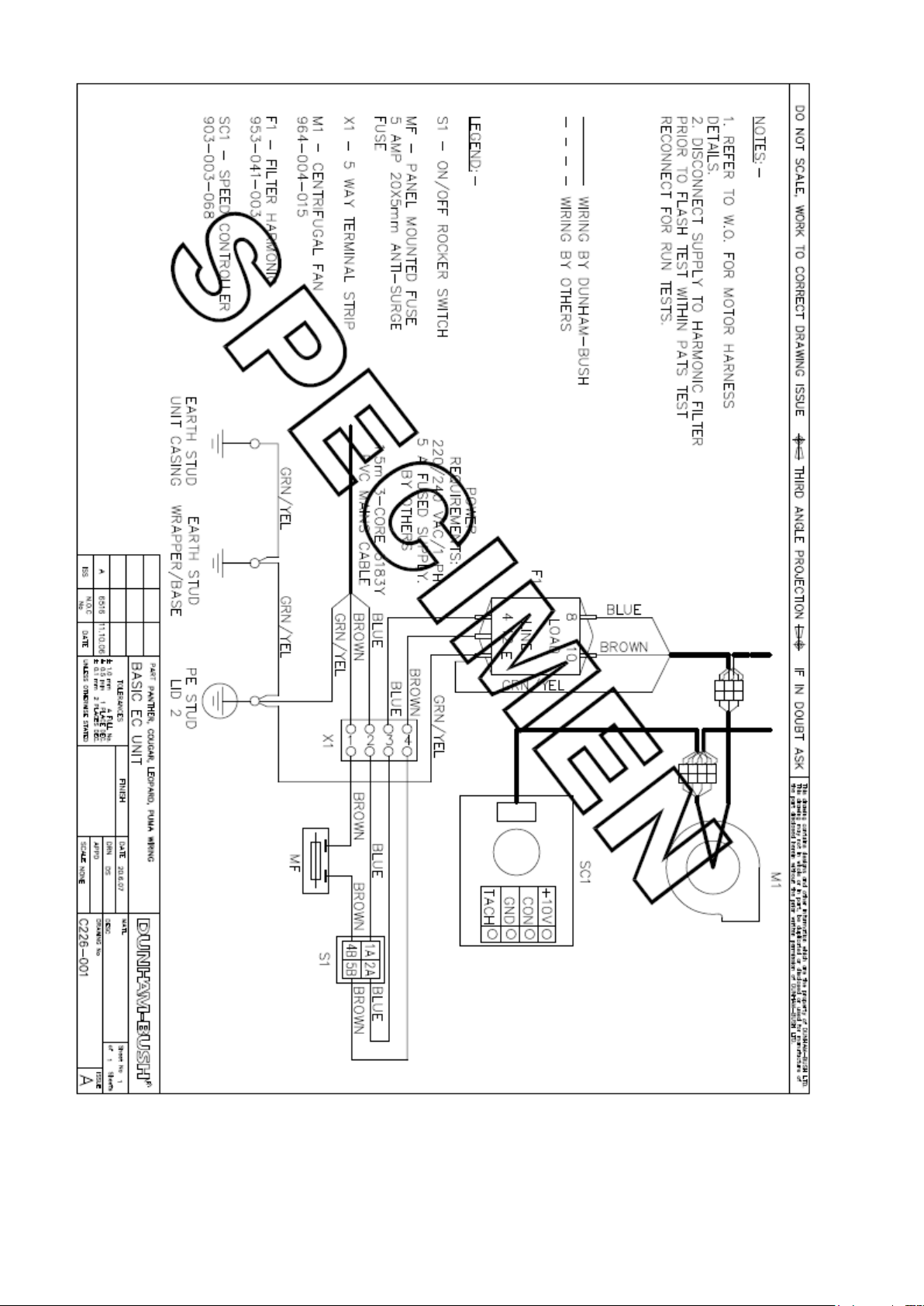

CONTROLS

Cougar fan coil units are fitted with a waterside control

system, which typically comprises the following

elements: -

Fitted fan on/off switch

Fan speed change switches (AC motor units)

Fan speed potentiometer (EC motor units)

Fan coil controller

Return air sensor

Valve actuators (Two or four port valves)

Additional optional accessories include: -

Remote room air sensor

Remote setpoint adjuster

Remote fan on/off and speed switches

Fitted relays for master/slave or BMS control

Dunham-Bush also fit non-standard controls supplied

by others; refer to the wiring diagram supplied with the

unit.

CLEANING

Cleaning and maintenance must be carried out by

competent persons

Inspection

The frequency of cleaning and inspection depends

upon the conditions in which the fan coil unit

operates. Initially, it is suggested that the air filter

and drip tray are inspected after 6-8 weeks normal

operation.

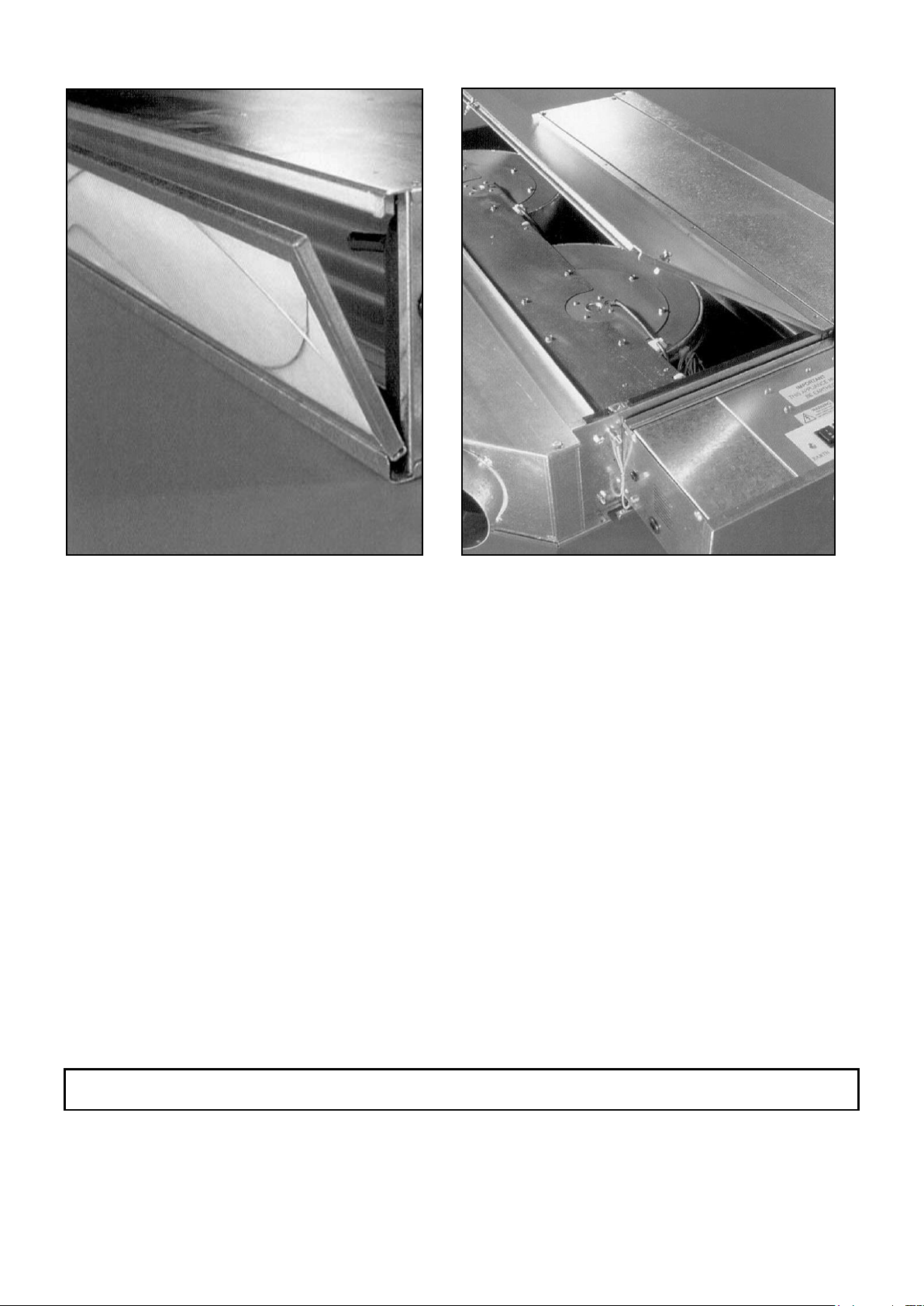

Access

There are four access panels - filter, drip tray/coil,

fans/motors and discharge plenum. All access

panels can be opened by removing screws and

turning quarter-turn fasteners.

The filter can be removed by sliding it out from its

mounting on the fan coil inlet, or from below by

removing its access panel

.

Cleaning

1. Air filters can be cleaned by tapping out

excess dust and washing in warm water (up

to 40°C), using detergent if necessary. The

filter must be rinsed and allowed to dry

naturally before replacing. Do not use a

vacuum cleaner, as it can damage the filter

media. Filters should be replaced after

approximately 20 washes.

2. The drip tray can be cleaned with warm,

soapy water. Ensure the drip tray drains

freely.

3. If a condensate pump is fitted, check any

sensors are clean and wiped dry. Test the

operation of the pump by pouring clean water

into the drip tray.

Because the air filter retains most of the dusty

particles, it will only be necessary to clean the fans,

motors and coil annually. An industrial vacuum

cleaner can be used to clean the inside of the fan

coil, in particular the coil and fans, with the air being

sucked through the coil in the opposite direction to

normal air flow. All accessible surfaces can be

cleaned with a cloth.