2

Imp rtant Operating, Maintenance and Safety Instructi ns

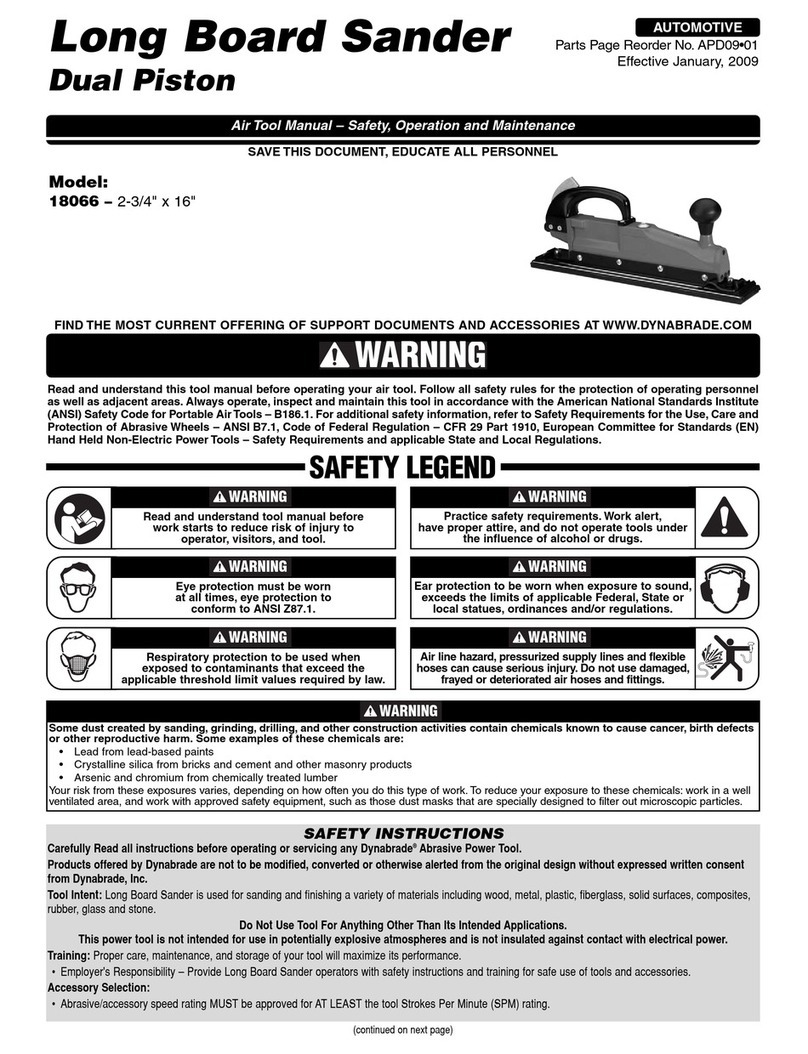

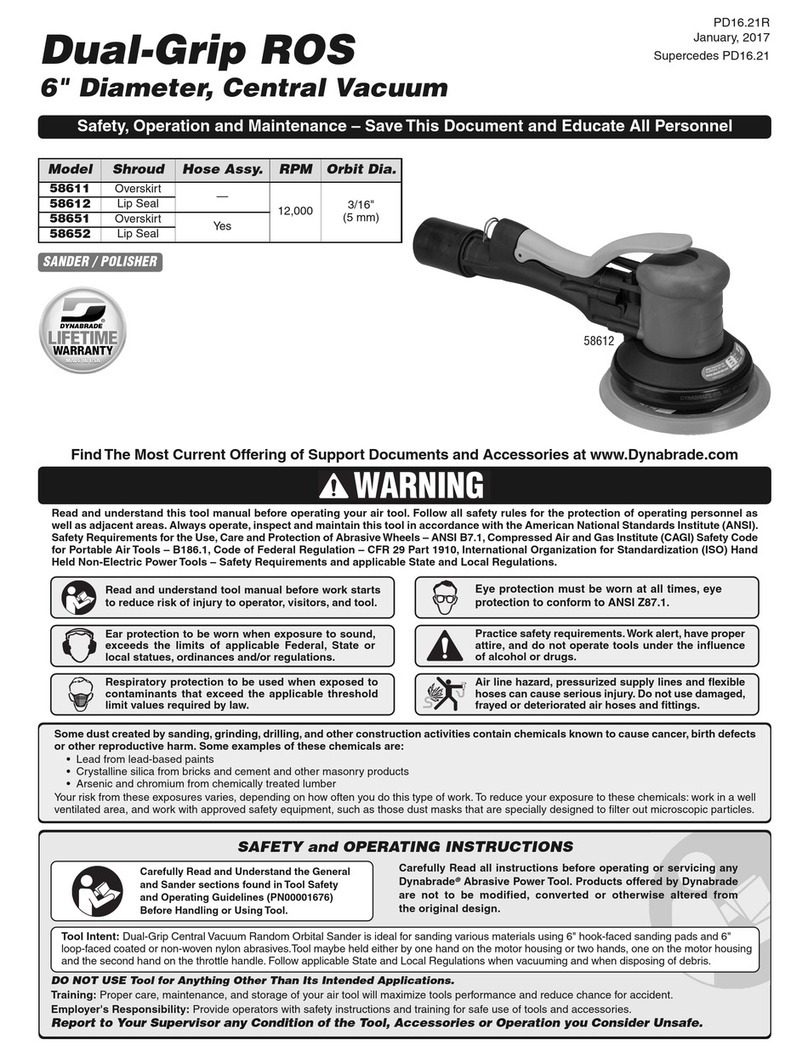

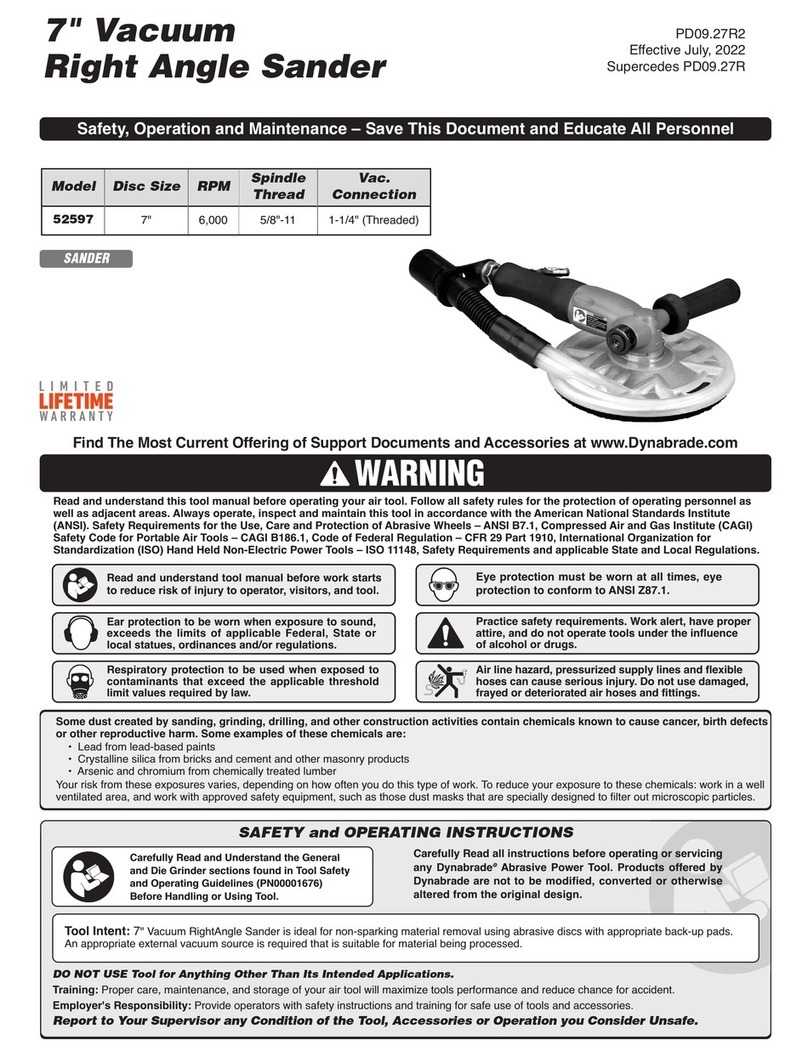

Carefully read all instructions before operating or servicing any Dynabrade®Abrasive Power Tool.

Warning: Hand, wrist and arm injury may result from repetitive work motion and overexposure to vibration.

Important: All Dynabrade rotary vane air tools must be used with a Filter-Regulator- ubricator to maintain all warranties.

Operating Instructions:

Warning: Eye, face, sound, respiratory, and body protection must be worn while operating power tools. Failure to do so may result in serious injury or death. Follow safety

procedures posted in workplace.

Caution: This tool is not to be run at free speed for any length of time. The tool is specifically designed to be low in vibration under load. Running the tool at free speed may

cause the buffing pad to become dislodged from the back-up pad.

1. All initial set-up and maintenance to the tool should be done with the air line disconnected from the tool.

2. Install air fitting into inlet bushing of tool. The inlet bushing is a 1/4" NPT, for optimal performance of the tool, directly couple the air line to the tool or use a quick

couple fitting with a large inlet hole such as Dynabrade’s P/N 95675. Important: Secure inlet bushing of tool with a wrench before attempting to install the air fitting to

avoid damaging valve body housing.

3. While there may be other applications suited for this tool it has been specifically designed for the automotive market to be used as the second step of a special two step

operation to remove paint imperfections in the clear coat of automotive finishes. It is imperative that the correct weight mated back-up pad be used with the tool to avoid

excessive vibration. The tool is designed to use a Dynabrade P/N 56142 Pad; this pad has a mass of 27 grams.

4. A waffle pad such as 3M P/N 02648 is required to be attached to the back-up pad, other pads may be available contact a Dynabrade or 3M representative for additional

information. Pre-condition a virgin pad thoroughly with 3M Final Finish Finesse-It Compound 3M P/N 82876 before attaching it to the tool. Once the pad has been

conditioned this process need not be done until a new waffle pad is required either due to wear or the compound has been allowed to set up rendering the pad useless.

5. Apply a small (15mm) dab of Final Finish on the repaired area, and position tool on the repair surface. Apply approximately a 3 pound load on the pad before throttling

the tool on. Adjust the force on the pad as required to feel the “sweet spot” (low vibration). Buffing for approximately 5 seconds with the pad flat on the work surface

should remove the sand scratches of the initial process. Release the throttle lever and then remove the tool from the work piece.

aintenance Instructions:

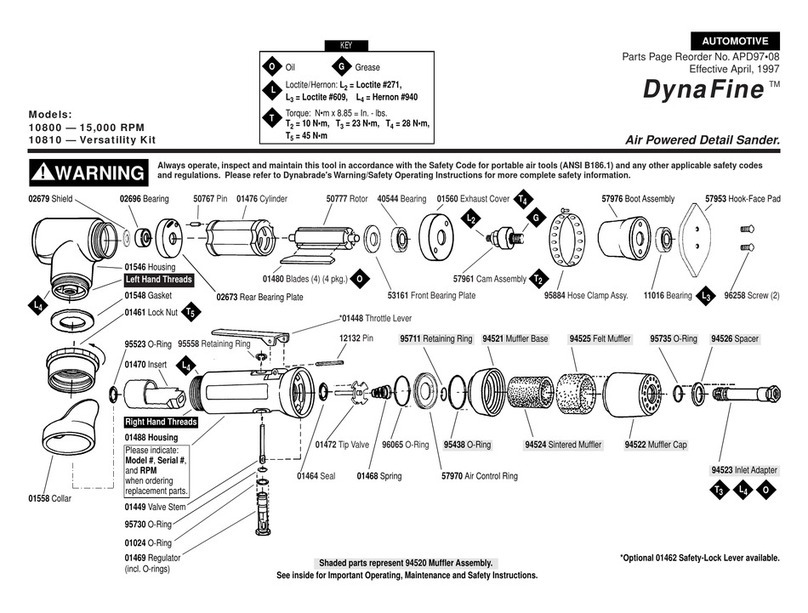

1. Through use of tool the mufflers may clog, hamper performance and require replacement.

2. Check tool speed regularly with a tachometer. A Magnetic Tachometer such as Dynabrade P/N 96368 is the simplest way to perform this operation. There are two test

conditions to assure that the tool is running properly, these conditions being free speed and under load. The free speed is a simple check to quickly determine if the tool is

out of specification. Checking under load requires additional test equipment but assures the proper operation of the tool. All speed testing must be done with 80 psig of air

at the inlet bushing, a Pressure Gage such as Dynabrade P/N 94315 is required. The tool should run between 9,000 RPM and 11,000 RPM free speed with 80 psig at the

tool inlet bushing. If the tool is running outside these speeds it should be serviced to correct the cause before use. The under load condition can be checked by outfitting

the tool with the proper back-up pad, waffle pad and buffing cream as outlined in the operating instructions. Apparatus is also required to monitor the load applied to the

work surface. Dynabrade offers a oad Cell P/N 80025 that allows the tool to be tested on a bench. First zero out the scale by adjusting the knob on the side of the load

cell to read zero when the tool, back-up pad, and waffle are resting on the wear plate of the load cell while connected to the air line. Apply a 3 pound load to the load cell

and using the digital tachometer check the operating speed of the tool. The tool should be running 5,500 RPM minimum. If the tool is running outside this range it should

be serviced to correct the cause before use.

3. All Dynabrade rotary vane air motors should be lubricated. Dynabrade recommends using Dynabrade Air ube (P/N 95842: 1 pt. 473 ml.) at a rate of 1 drop per minute.

If Dynabrade Air ube is not compatible with paint system it may be substituted with a compatible air tool lubricant with water absorbing properties to prevent internal

components from rusting.

4. It is strongly recommended that all Dynabrade rotary vane air tools be used with a Filter-Regulator- ubricator to minimize the possibility of misuse due to unclean air, wet

air or insufficient lubrication. Dynabrade recommends the following: 10681 Air ine Filter-Regulator- ubricator — Provides accurate air pressure regulation, two-stage

filtration of water contaminants and micro-mist lubrication of pneumatic components.

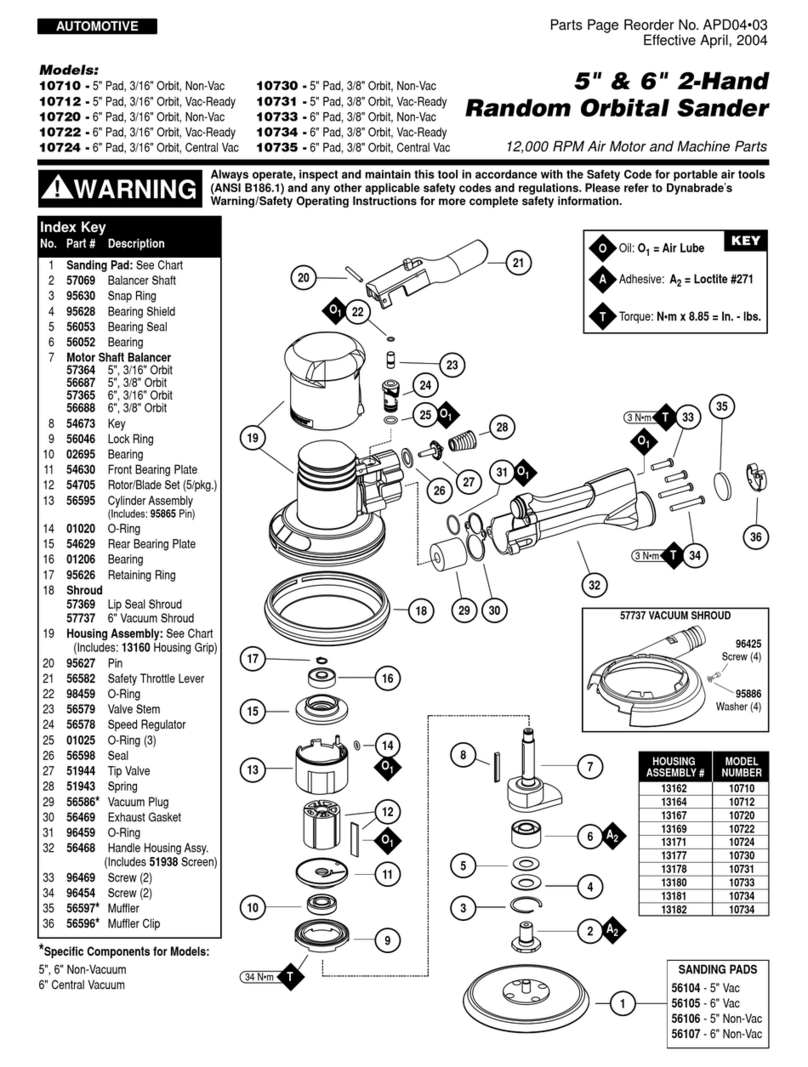

5. Use only genuine Dynabrade replacement parts. To reorder replacement parts, please specify the odel #, Serial # and RP of your machine.

6. A Motor Tune-Up Kit (P/N 96537) is available which includes assorted parts to help maintain motor in peak operating condition.

7. Mineral spirits are recommended when cleaning the tool and parts. Do not clean tool or parts with any solvents or oils containing acids, esters, keytones, chlorinated hydro

carbons or nitro carbons.

Notice

All Dynabrade motors use the highest quality parts and metals available and are machined to exacting tolerances. The failure of quality pneumatic motors can most often be

traced to an unclean air supply or the lack of lubrication. Air pressure easily forces dirt or water contained in the air supply into motor bearings causing early failure. It often scores

the cylinder walls and the rotor blades resulting in limited efficiency and power. Our warranty obligation is contingent upon proper use of our tools and cannot apply to equipment

which has been subjected to misuse such as unclean air, wet air or a lack of lubrication during the use of this tool.

LIFETIME WARRANTY

To validate Dynabrade Li etime Warranty, you must register each tool at: www.dynabrade.com. Registration o each tool at website is required.

Dynabrade will not honor Li etime Warranty on unregistered tools. Please view the entire Li etime Warranty Policy at www.dynabrade.com.

DO NOT USE T l f r Anything Other Than Its Intended Applicati ns.

Training: Proper care, maintenance, and storage o your air tool will maximize tool per ormance and reduce chance or accident.

Employer's Responsibility: Provide operators with sa ety instructions and training or sa e use o tools and accessories.

Rep rt t Y ur Supervis r any C nditi n f the T l, Access ries r Operati n y u C nsider Unsafe.

C refully re d nd underst nd the Gener l

nd S nder/Polisher sections found in Tool

S fety & Oper ting Guidelines (PN00001676)

before h ndling or using tool.

•Important: User of tool is responsible for following accepted safety codes such as those published by the American National Standards Institute (ANSI).

•Tool should not be running for extended periods of time free speed as it is not balanced for this condition. Avoid running the tool at free speed with a buffing pad installed

onto the back-up pad as it may dislodge from the tool.

•Always disconnect the air line before changing the back-up pad or making machine adjustments.

•Inspect abrasives/accessories for damage or defects prior to installation on tools.

•Warning: Hand, wrist and arm injury may result from repetitive work, motion and overexposure to vibration.