Disassembly/Assembly Instructions-.7 Hp Rear Exhaust

Important: Manufacturer’s warranty is void if tool is disassembled before warranty expires.

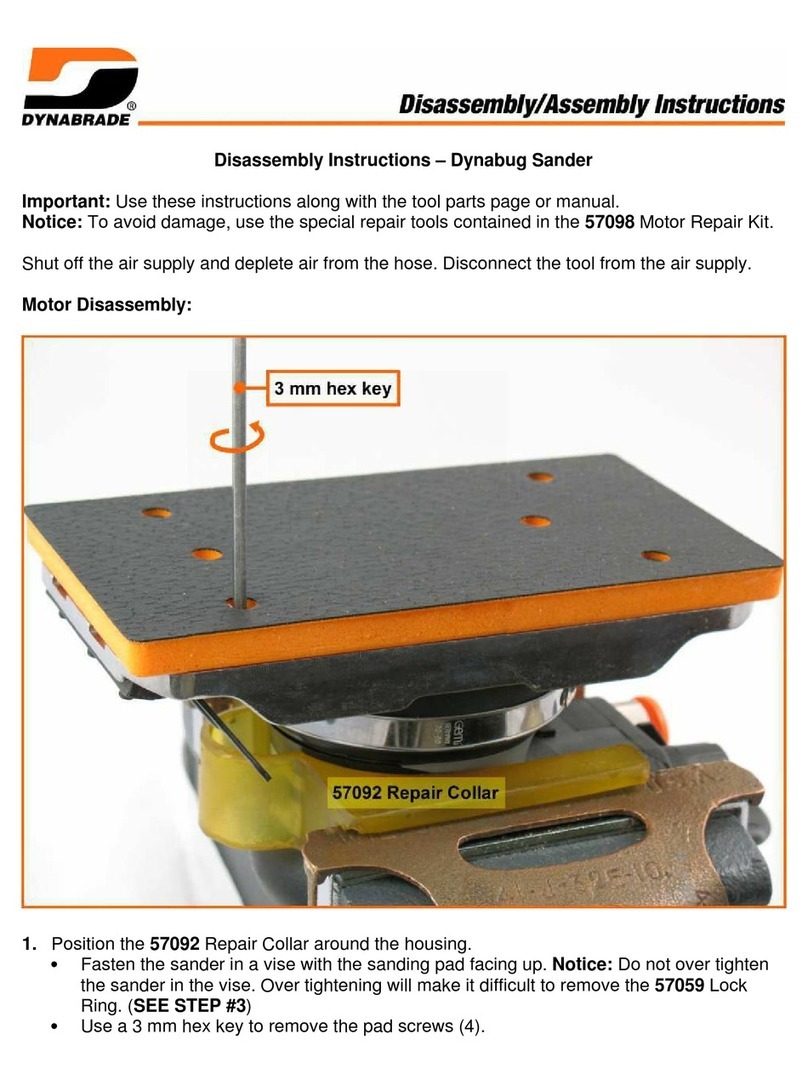

Notice: Dynabrade strongly recommends the use of their 52296 Repair Collar (sold separately) during assembly/disassembly activities. Failure to

use this collar will highly increase the risk of damage to the valve body of this tool. Please refer to parts breakdown for part identification.

1.

Disconnect tool from power source.

2.

Secure air tool in vise using

52296

Repair Collar. Remove disc pad.

3.

With an open-end or adjustable wrench remove

04034

Exhaust Cover by turning counter-clockwise.

4.

Pull motor assembly from housing.

5.

Attach a 2 in. bearing separator around the rear portion of the

01028

Cylinder nearest the rear bearing plate.

6.

Place the separator on the table of a #2 arbor press with the rotor spindle pointing down.

7.

Press the rear rotor shaft out of the rear motor bearing by using a 3/16 in. flat nose drive punch.

8.

Remove

01028

Cylinder, and

01185

Blades (4) from rotor.

9.

Hold the body of the

55025

Rotor in a soft (bronze or aluminum) jaw vise, and remove the

01708

Rotor Nut by turning it counter-clockwise.

10.

Remove

01007

Bearing,

01008

Front Bearing Plate and

01010

Spacer by sliding them from the rotor spindle.

11.

Remove

02649

Rear Bearing from the

01743

Rear Bearing Plate by using Bearing Removal Tool

96213

.

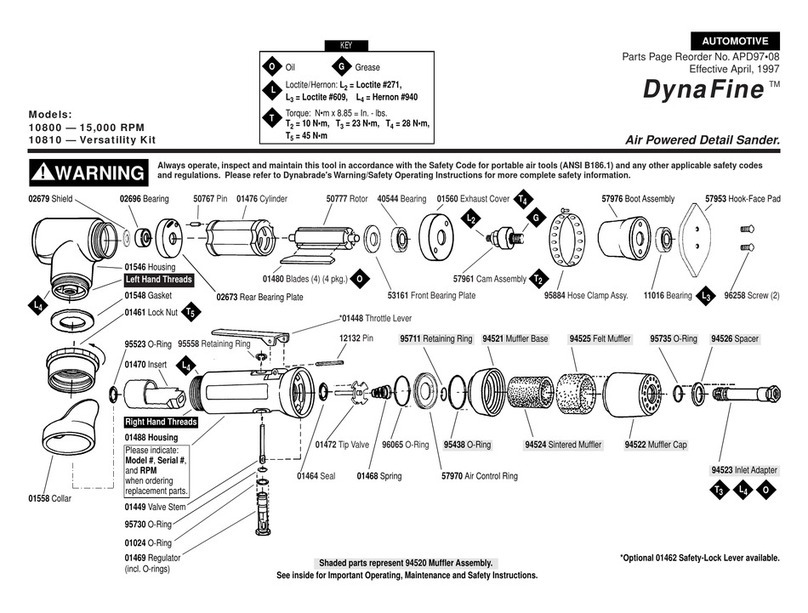

Optional:

To disassemble the valve body from the motor housing, peel back

01558

Collar to expose

01461

Lock Nut. Unscrew lock nut/valve body from

housing (left hand threads).

Motor Disassembly Complete.

1.

Position valve body in vise using

52296

Repair Collar with air inlet facing up.

2.

Remove air fitting by securing

94523

Inlet Adapter with a wrench and twist air fitting from inlet adapter.

Important: 94523

Inlet Adapter must be secured before attempting to remove air fitting to avoid damaging valve body housing.

3.

Remove

94523

Inlet Adapter.

4.

Remove

95711

Retaining Ring from inlet adapter and separate

94521

Muffler Base from

94522

Muffler Cap. Remove sintered muffler and felt muffler.

5.

Remove air control ring from valve body. Using needle nose pliers, remove

01468

Spring,

01472

Tip Valve and

01464

Seal.

6.

Using a 2.5 mm drift pin, tap

12132

Pin from housing and remove throttle lever.

7.

Remove

95558

Retaining Ring. Push

01469

Regulator from valve body and remove O-Rings.

Disassembly Complete.

Important:

Be sure parts are clean and in good repair before assembling.

1.

Hold the body of the

55025

Rotor in a soft (bronze or aluminum) jaw vise, and slide

01010

Spacer onto rotor spindle.

2.

Place a .002" shim into front bearing plate as an initial spacing and slip

01007

Bearing into plate.

Note: 01121

Shim Pack contains .001" and .002" shims.

3.

Slide bearing/bearing plate assembly onto rotor.

4.

Install

01708

Rotor Nut and tighten onto rotor (torque to 17 N•m/150 in. - lbs.).

5.

Check clearance between rotor and bearing plate by using a .001" feeler gauge. Clearance should be at .001" to .0015". Adjust clearance by repeating

steps 1-5 with different shim if necessary.

6.

Once proper rotor/gap clearance is achieved, install well lubricated

01185

Blades (4) into rotor slots. Dynabrade air lube P/N

95842

is recommended.

7.

Install cylinder over rotor. Be sure air inlet holes of cylinder face away from bearing plate.

8.

Press

02649

Rear Bearing into

01743

Rear Bearing Plate. Press bearing/bearing plate assembly onto rotor.

Note: 96240

Bearing Press Tool can be used. Be sure that pin and air inlet holes line-up with pin slot and air inlet holes in cylinder.

Important:

Fit must be snug between bearing plates and cylinder. If too tight, rotor will not turn freely. Rotor must then be lightly tapped at press fit end so

it will turn freely while still maintaining a snug fit. A loose fit will not achieve the proper preload of motor bearings.

9.

Secure motor housing in padded vise so motor cavity faces upwards.

10.

Install motor assembly into housing. Be sure motor drops all the way into housing.

11.

Install

04034

Lock Nut onto motor housing (torque 34 N•m/300 in. - lbs.).

12.

Motor adjustment must now be checked. With motor housing still mounted in vise, pull end of rotor and twist (10-15 lbs. force), rotor should turn

freely without drag. If drag or rub is felt, then increase preload or remove shim. Also, push end of rotor and twist (10-15 lbs. force), rotor should

turn freely without drag. If drag or rub is felt, then deload or add shim.

1.

Insert

01469

Regulator with o-rings and valve stem in place into valve body. Secure with

95558

Retaining Ring.

2.

Secure valve body in vise using

52296

Repair Collar with air inlet facing upwards. Insert

01464

Seal.

3.

Line up hole in valve stem with hole in housing (looking past brass bushing). Insert

01472

Tip Valve so that the metal pin passes through the hole in the

valve stem. Install

01468

Spring (small end towards tip valve).

4.

Assemble sintered muffler and felt muffler together and place in

94522

Muffler Cap. Install

94521

Muffler Base onto muffler cap.

5.

Install

95438

O-Ring into groove on muffler base. Place

95375

O-Ring and

94526

Spacer into recessed area of muffler cap.

6.

Slip

94523

Inlet Adapter through muffler assembly and install

95711

Retainer Ring into groove on inlet adapter.

7.

Install air control ring into valve body housing.

3