33

PLUG CONFIGURATIONS

Freestanding Units

All freestanding units are factory supplied with a cord and plug. Please check to make sure that the plug matches the receptacle:

1) 120V units supplied with a NEMA 5-15P plug configurations.

2) 240V units supplied with a NEMA 6-15P plug configurations.

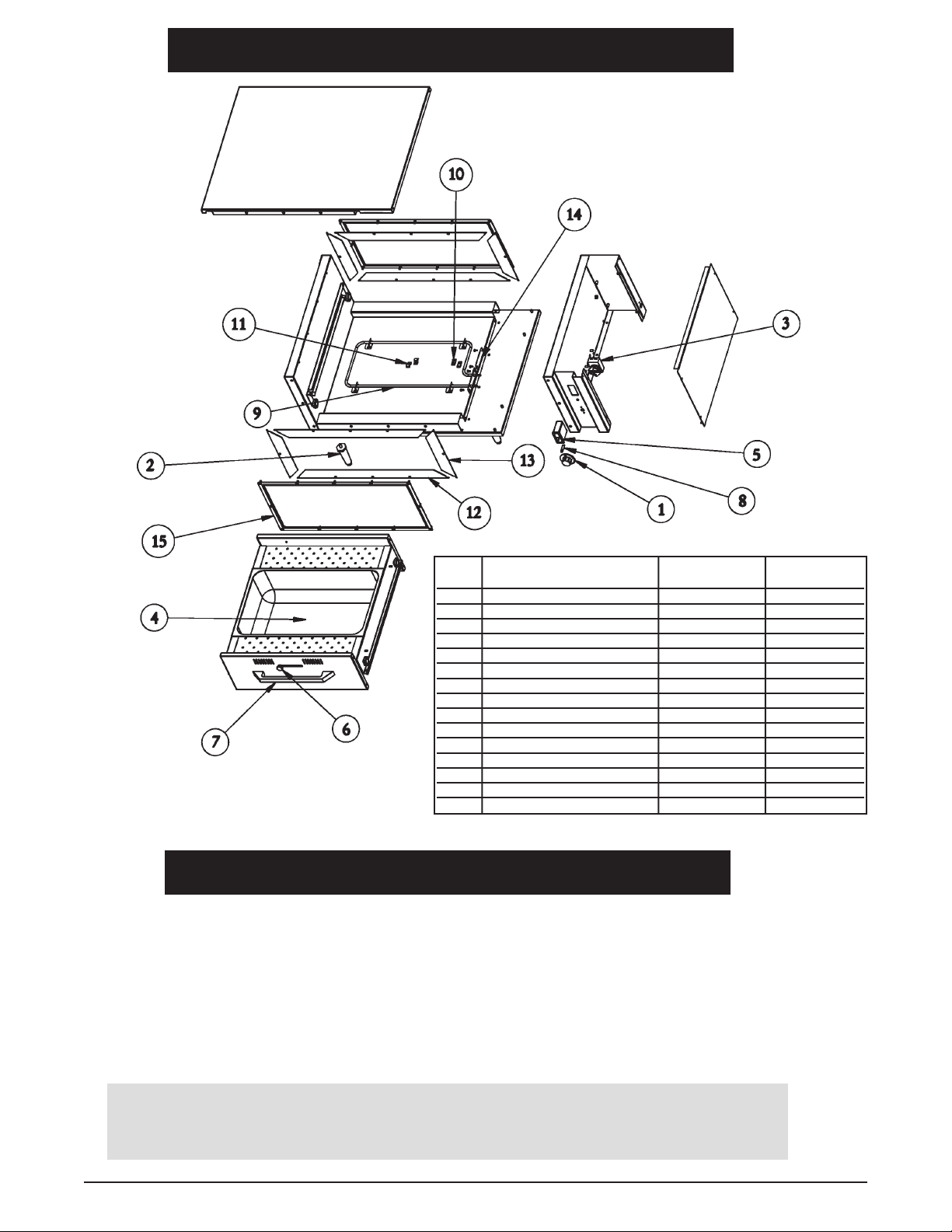

Model Volts Watts Amps Plug

DWP-1x- 120 450 3.8 NEMA 5-15P

DWP-1x- 240 450 1.9 NEMA 6-15P

Electrical Rating Chart

CAUTION!

FOR FREESTANDING UNITS, ONLY PLUG UNIT INTO A RECEPTACLE OF COMPATIBLE

VOLTAGE AND PLUG CONFIGURATION. IF THE APPROPRIATE RECEPTACLE IS NOT

AVAILABLE, CONTACT A CERTIFIED ELECTRICIAN TO INSTALL THE CORRECT OUTLET.

OPERATION FOR ALL MODELS

1. On freestanding models, plug unit into an electrical outlet of the correct voltage, size and plug configuration.

2. To turn the power on, turn the thermostat control to the desired setting. See chart below for Recommended Settings.

3. Allow the unit 30-40 minutes to reach operating temperature.

4. Adjust the drawer vents for desired humidity by unscrewing front door knob to unlock the vent and slide the vent to desired location.

Opening the vent all the way allows maximum moisture to escape.

Food Holding Guide

Product Rec. Storage Temp. Heat Type Vent Control

Rolls, Hard 160-185˚F (71-85˚C) Dry Open

Rolls, Soft 150-175˚F (66-79˚C) Moist Open-Half

Vegetables 175-185˚F (66-85˚C) Moist Open-Half

Meat, Poultry165-185˚F (74-85˚C) Dry Open

Fish 165-185˚F (74-85˚C Moist Closed

Casseroles 150-175˚F (66-79˚C) Dry Open

Pies, Desserts 160-185˚F (71-85˚C Dry Open

Food Holding Capacity

for standard drawer

Product Capacity

Dinner Rolls 6-8 Dozen

Ribs 25-30 lbs.

Potatoes 3 to 3-1/2 Dozen

CLEANING AND MAINTENANCE

WARNING

To avoid injury, turn the power off and allow unit to cool before cleaning or performing maintenance.

On freestanding units, unplug the electrical cord from the power source as well.

To preserve the finish of the Drawer Warmer, it is recommended that the surface be wiped daily with a

damp cloth. Food pans should be removed and washed. Stubborn stains may be removed with a good

non-abrasive cleaner. Hard to reach areas should be cleaned with a small brush and mild soap.

CAUTION!

ABRASIVE CLEANERS COULD SCRATCH THE FINISH OF THE DRAWER WARMER.