6

Placing Battery into Service

Battery voltage, specific gravities of each individual cell as well

as temperature of pilot cell should be taken and recorded prior

to battery being placed on charge. See Battery Maintenance

Report Appendix A

Proper charging is essential for maximum battery life.

A temperature compensated voltage regulated charger is

recommended to be used in renewable energy applications.

When a discharged battery is initially placed on charge,

it draws a current equal or close to the charger’s maximum

output. As the battery’s voltage rises, the charger output

should adjust to the changing voltage to assure a safe,

efficient charging rate during all stages of the charge.

A freshening charge at the absorption charge rate should

be given to a new battery before putting it into service. The

battery should be cool; less than 90°F (32°C), when it’s

installed. The battery should remain in equalize until the

specific gravity shows no change for a three-hour period

with readings taken hourly or a max. of 12 hrs.

Proper maintenance is essential to obtain long life and

maximum efficiency from any renewable energy battery.

Carefully following a scheduled maintenance routine will

help increase battery performance and prolong service life.

Maintain an accurate records system of battery cycles and

maintenance/repair work for each battery. A records system

is particularly important for operations that use a large

number of batteries.

f you don’t already have one, these procedures should help

you create a reliable records system:

1. Assign a code/identification number to each battery / cell.

2. Designate a “pilot cell” for each battery. Record the specif-

ic gravity, voltage and temperature of the pilot cell when

the battery is first received and equalized, and before and

after each charge. The readings taken on the pilot cell are

considered to represent the specific gravity, voltage and

temperature of all the cells. Always use the same cell for

the pilot cell. The pilot cell should be positioned near the

center of the battery and can be identified with a marking

of some sort on the intercell connector shroud or cell

cover.

3. At least once each month, measure and compare the

specific gravity of all the cells. The readings should be

uniform from cell to cell. f the specific gravity readings

fall 20 points (0.20) below the nominal specific gravity

reading of 1.250, the electrolyte levels should be checked

and brought up to a uniform level before checking for a

second time. f, at any time, the readings are 20 points

(.020) greater than the nominal specific gravity readings

of 1.250, or the range of the on-charge cell voltage

readings is more than 0.15 volts, the battery could be

showing signs of cell failure. Contact your authorized

East Penn Mfg Representative.

4. Remember to accurately record the number of cycles,

specific gravity, temperature and voltage readings; and

all maintenance and repair information for every battery.

Maintenance Report Appendix A is an example of a basic

record-keeping form.

BattEry maintEnancE

Batteries should be inspected periodically to avoid damage

resulting from previously undetected problems or improper

maintenance and operational procedures.

Look for:

• Corrosion on the tray, terminals or intercell connectors.

•Leaks or damage to the tray.

• Damaged cable leads, terminals or connections.

• Damaged, clogged or missing vent caps.

Repair or replace any damaged parts and thoroughly clean

the battery. n case of serious damage or for major repairs,

contact nearest authorized East Penn representative.

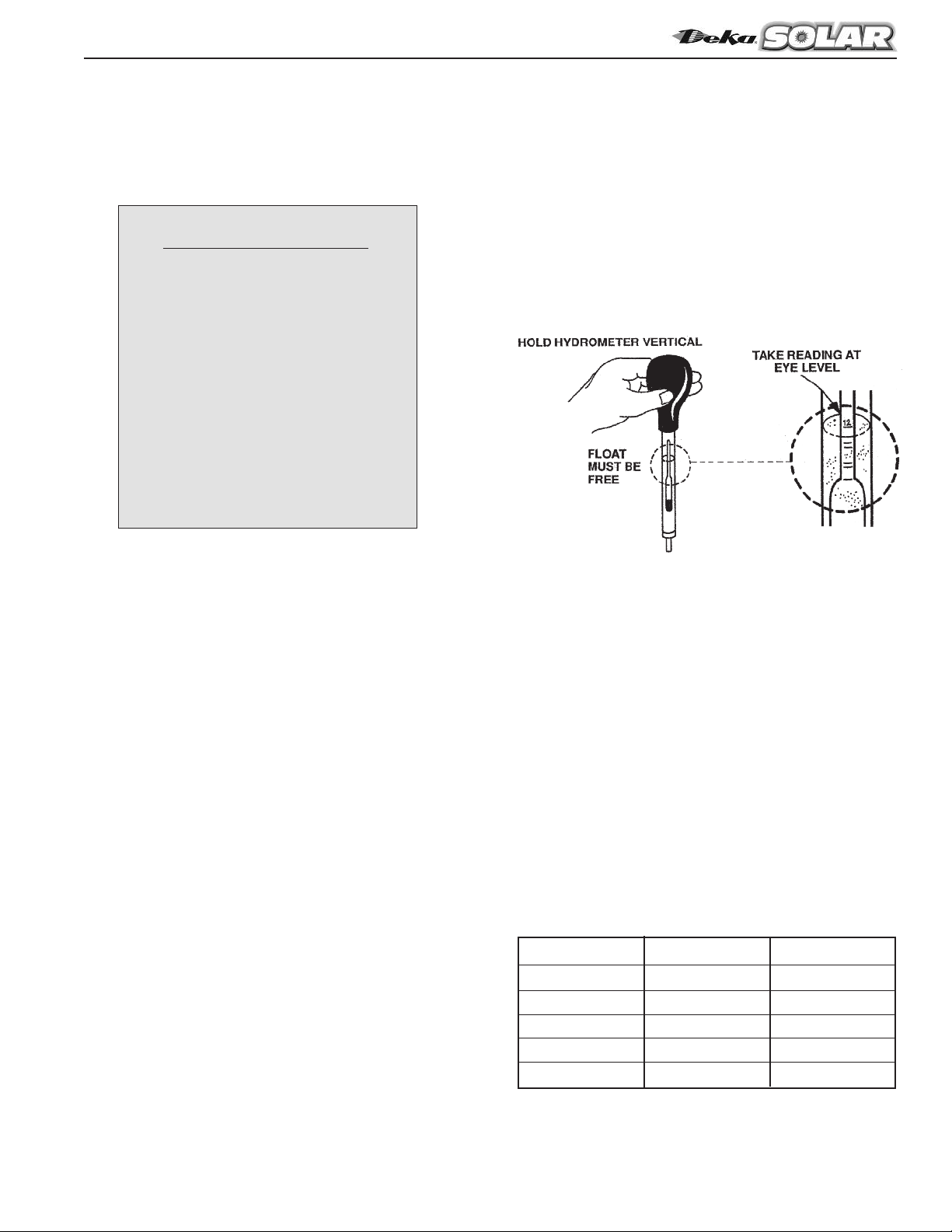

Before taking any specific gravity or voltmeter readings,

the battery should be fully charged. Take specific gravity and

voltage readings for each cell and record the readings on

your battery inspection form. Use the battery’s positive

terminal cell as cell #1 and follow the intercell connectors to

the last cell (the battery’s negative terminal cell). Look for

any unusual readings that might indicate a problem cell.

Neutralizing Acid and Electrolyte

For cleaning batteries, non-corrosive, water based battery

cleaning products are all that should be used. For user safety

and environmental regulatory compliance, the cleaning liquid

should contain no hazardous chemical ingredients. Even

some products labeled “Battery Cleaner” must be avoided

because of hazardous ingredients and damage to batteries

and related equipment.

Acid spills are common in battery rooms. When acid spills

occur it is critical to minimize:

1. Health and safety risk to personnel and the environment.

2. Damage to batteries, equipment,

and surrounding surfaces.

3. Time to neutralize, absorb, and clean-up.

4. Disposal costs of waste materials.

5. Regulatory compliance risks and fines.

Neutralizing acid absorbers and spill kits have the per-

formance attributes required when dealing with acid spills.

The ph neutral dry and non-hazardous waste is easy to

sweep-up and dispose as non-hazardous waste.

Adding Water/Adjust Electrolyte Levels

Batteries normally lose a certain amount of water due to

evapo-ration and electrolysis during charging. The electrolyte

level should be maintained at a ¼” below the bottom of the

vent well opening of the cover. t is important not to allow the

electrolyte level in any cell to drop below the top of the moss

guard, since low levels can damage the plates and shorten life.

t is equally important to avoid overfilling the cells, as

electrolyte will be forced out of the vent caps during charg-

ing onto the top of the battery, causing tray corrosion and

reducing battery capacity.

Only distilled or de-ionized water should be used to water

cells because certain impurities and chemicals found in tap

water can be harmful to batteries. Warranty may be affected if

water other than distilled or de-ionized is used.