E02A INTEGRATED RACK TYPE AIR CONDITIONER UM.ICUBE2.0-IRTAC.SG.0822 August 2022 www.eaton.com iii

Table of Contents

1. Introduction ........................................................................1

1.1 Foreword ............................................................................... 1

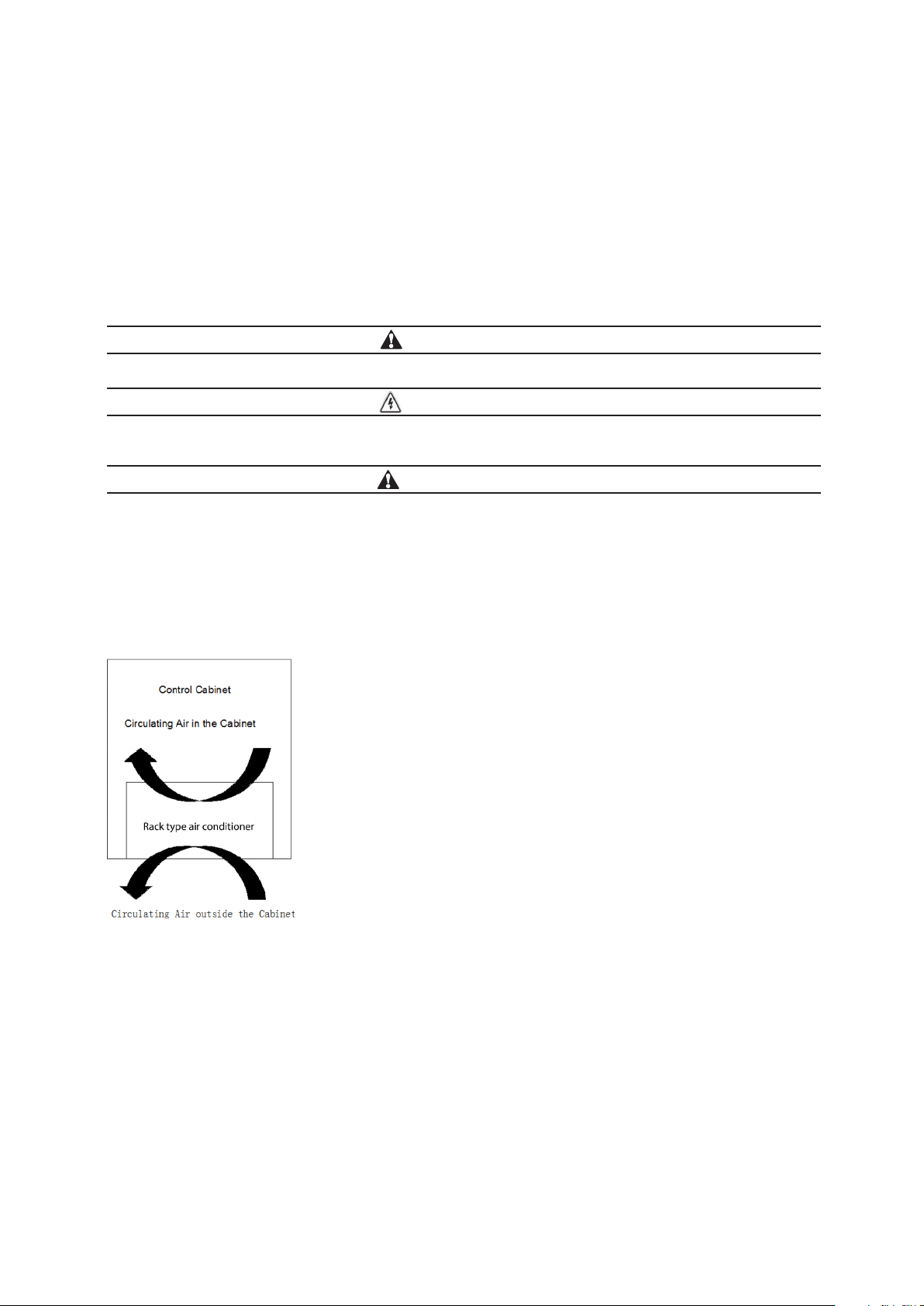

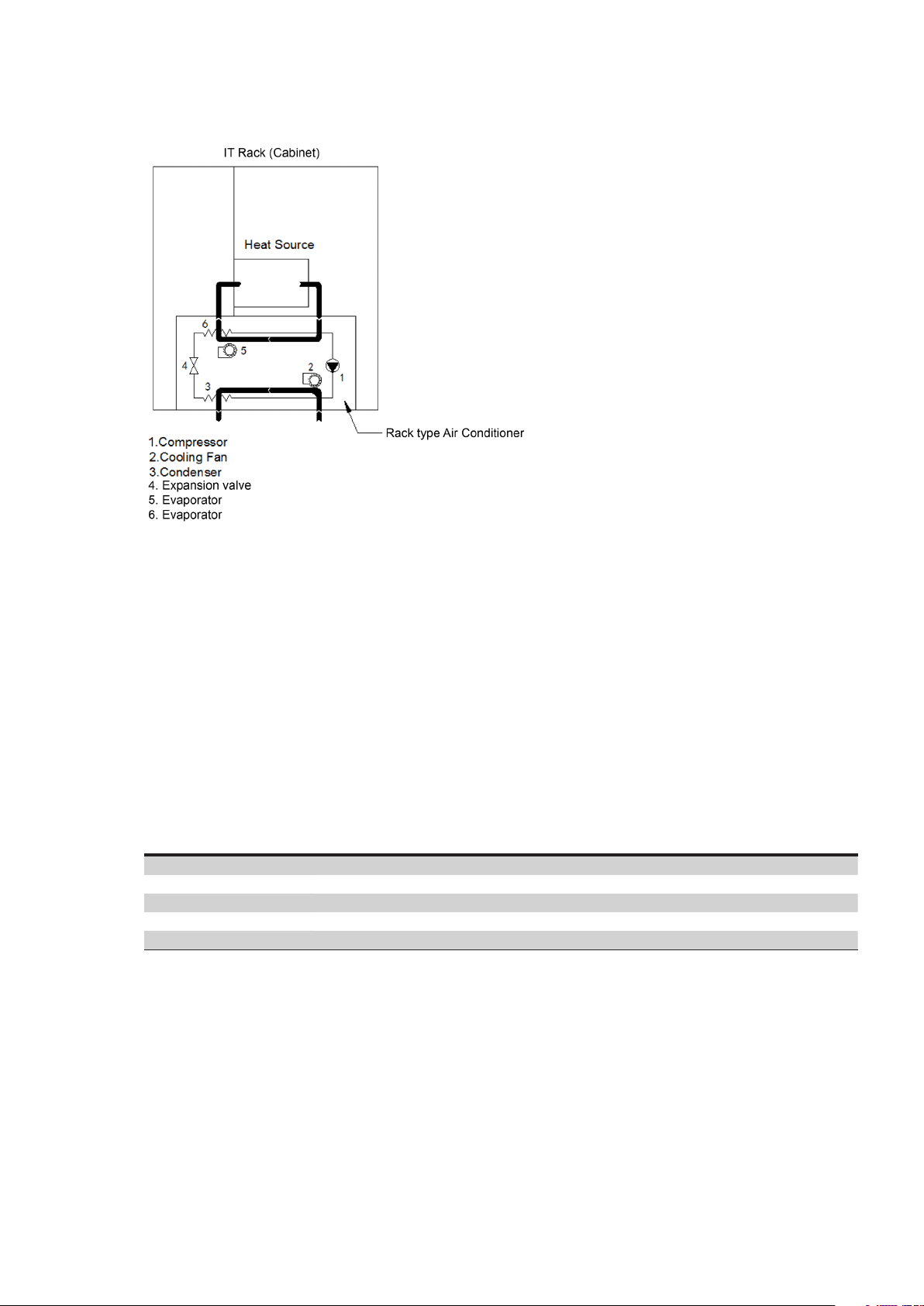

1.2 Air conditioner description .................................................................. 1

1.2.1 Principles of function ................................................................ 1

1.2.2 Operating conditions ................................................................ 2

1.3 Standards ............................................................................... 2

2. Safety notices ......................................................................3

2.1 Transport................................................................................ 3

2.2 Storage ................................................................................. 3

2.3 Unpacking............................................................................... 3

2.4 Installation .............................................................................. 3

3. Installation and operation ............................................................4

3.1 Mechanical installation ..................................................................... 4

3.2 Electrical installation....................................................................... 4

3.3 Power-on steps........................................................................... 6

4. System function introduction .........................................................7

4.1 Cooling ................................................................................. 7

4.2 Heating (Option) .......................................................................... 7

4.3 Component control mode .................................................................. 8

4.4 Unit sequencing control (option) ............................................................. 8

4.4.1 Time Switching ..................................................................... 8

4.4.2 Temperature switch ................................................................. 8

4.4.3 Both working with high temperature .................................................... 8

4.4.4 Disturbance switching ..................................................................8

4.5 Self testing ............................................................................... 8

4.6 Hydrogen discharging/emergency fan (option) .................................................... 9

4.7 Alarm .................................................................................. 9

4.8 Unit menu structure ........................................................................10

4.8.1 Operation interface ...................................................................10

4.8.2 Menu structure .................................................................... 10

5. Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.1 Daily maintenance ..........................................................................12

5.2 Compressor maintenance ....................................................................12

5.3 Common fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.4 Charge refrigerant ..........................................................................13

5.5 Tools preparation ...........................................................................13

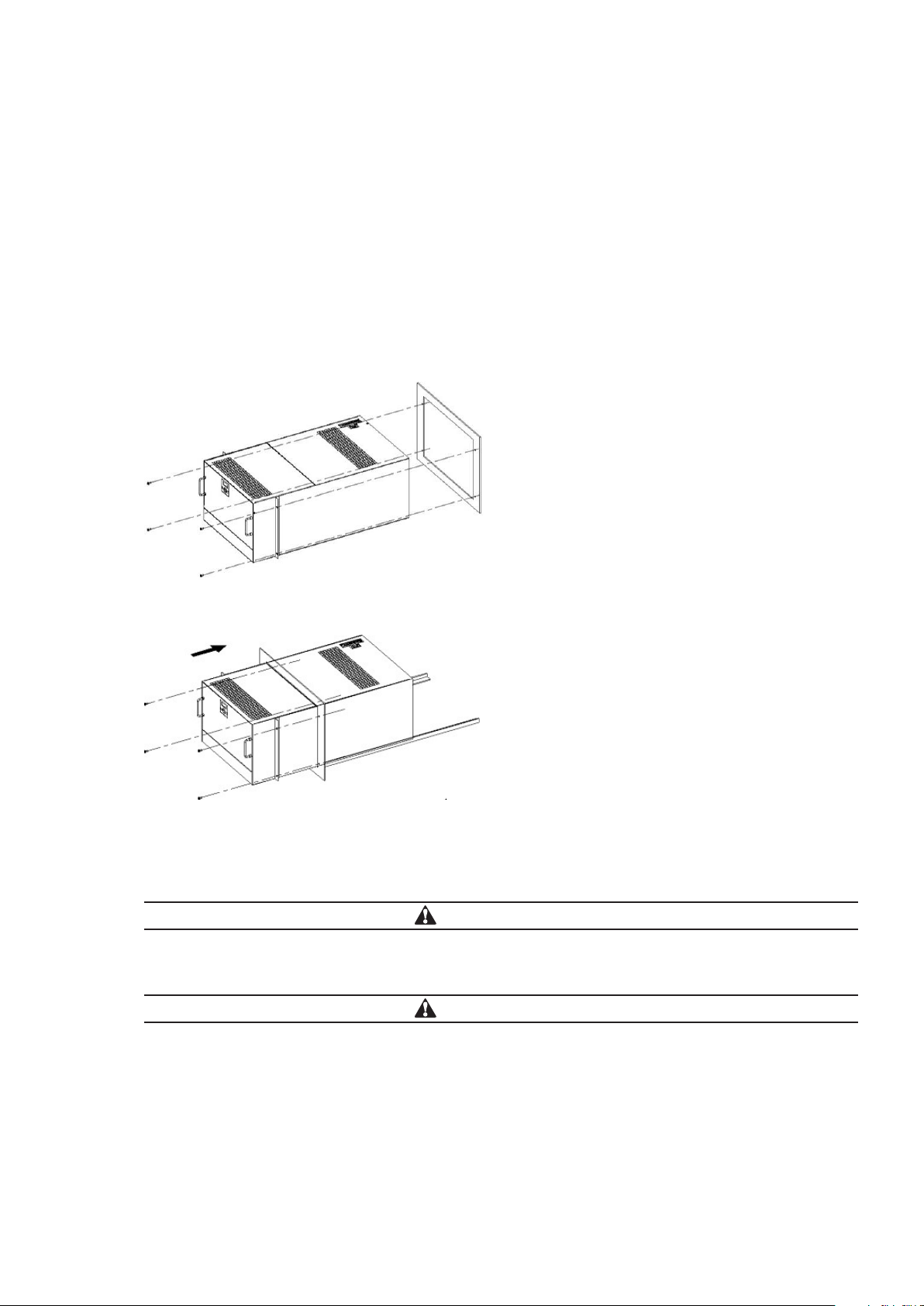

5.6 Disassemble the unit .........................................................................15

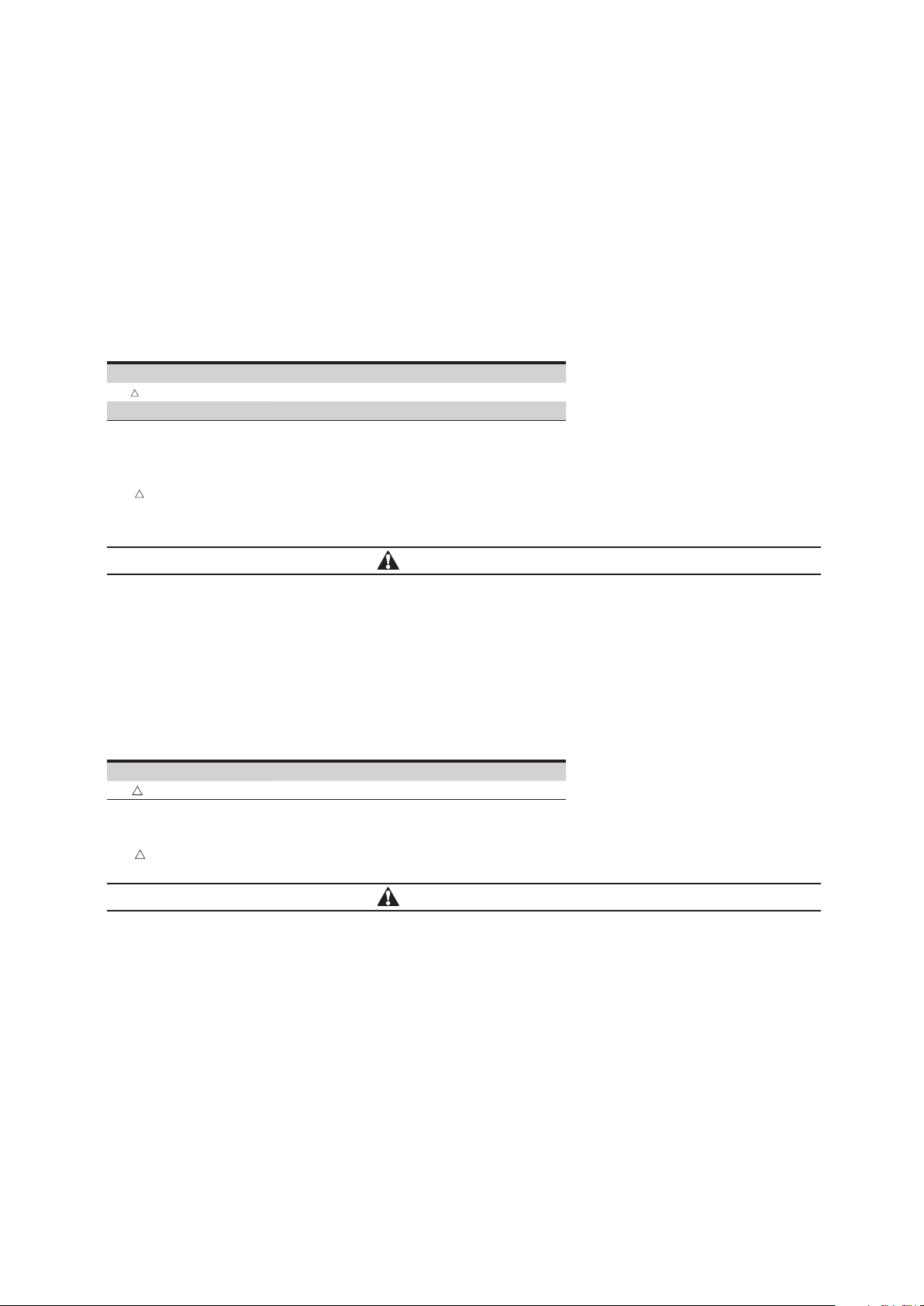

5.7 Charge refrigerant ..........................................................................15

5.8 Power on and test the air conditioner...........................................................17

5.9 Reinstall the air conditioner into the cabinet .....................................................17