Contents

Safety Precautions .................................................................................................................... 5

Pre-Installation Checklist ........................................................................................................... 6

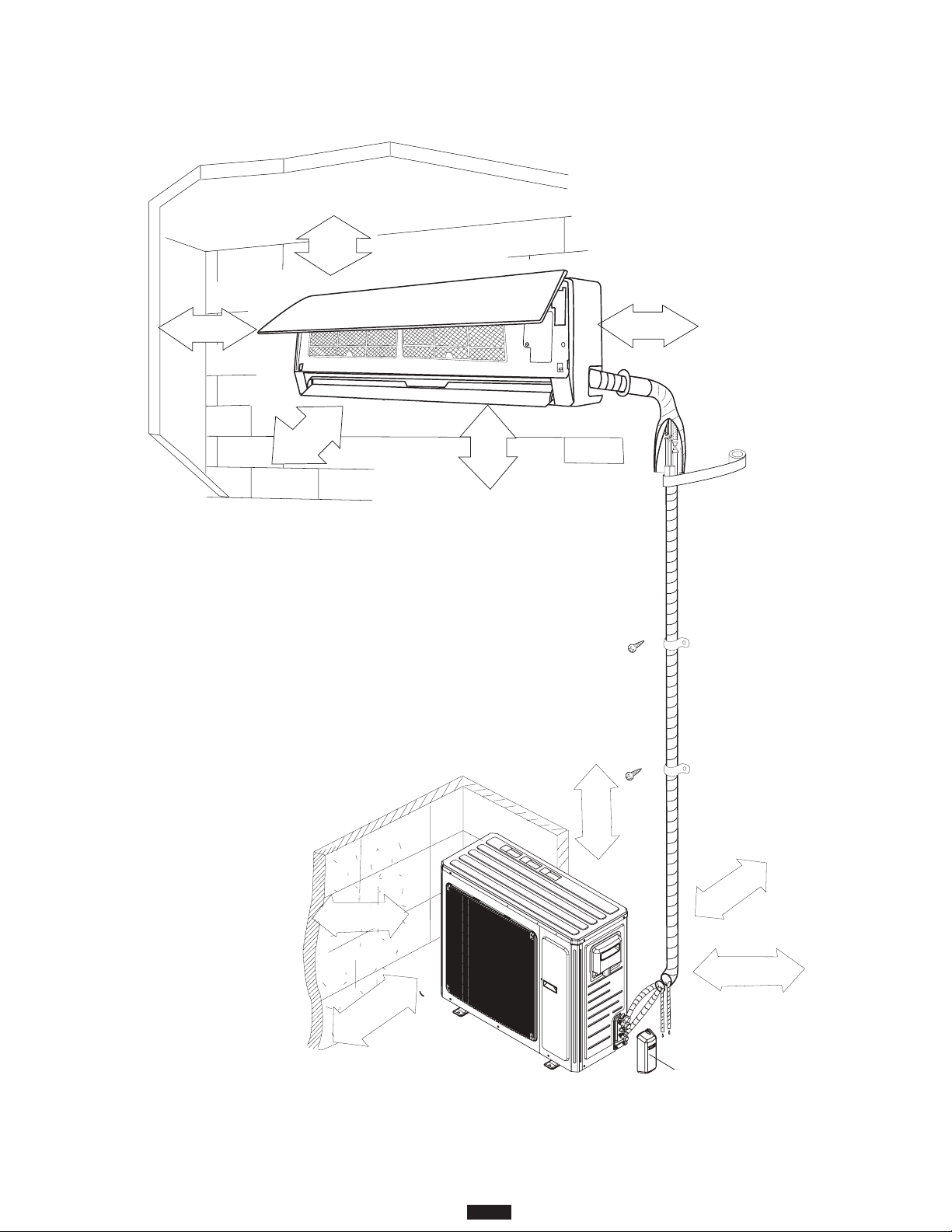

Typical Installation Setup ........................................................................................................... 7

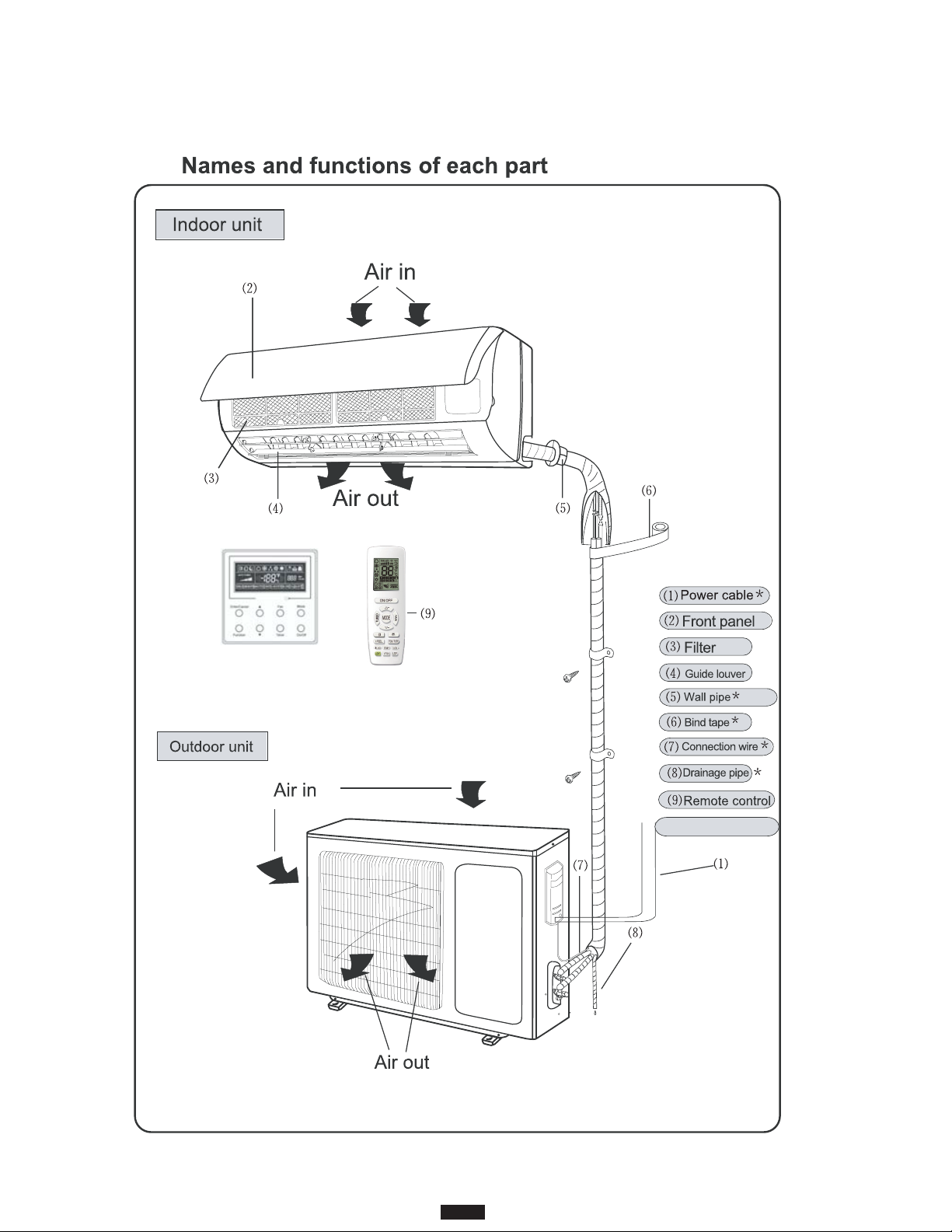

Names and Functions of Each Part........................................................................................... 7

Clearance Requirements........................................................................................................... 8

Connection Pipe Requirements................................................................................................. 9

Refrigerant Piping Precautions................................................................................................ 10

Nitrogen Purging While Brazing............................................................................................... 10

Installation Location................................................................................................................. 11

Installing the Indoor Unit.......................................................................................................... 12

Mounting Location ................................................................................................................... 12

Drilling the Piping Hole ............................................................................................................ 13

Refrigerant Piping at the Indoor Unit ....................................................................................... 13

Installing the Condensate Pipe................................................................................................ 15

Wiring at the Indoor Unit.......................................................................................................... 15

Binding the Pipes and Cables ................................................................................................. 17

Hanging the Indoor Unit........................................................................................................... 17

Installing the Outdoor Unit....................................................................................................... 18

Condensate Management of the Outdoor Unit........................................................................ 18

Installing the Refrigerant Piping............................................................................................... 19

Flaring Process and Bending Pipes ........................................................................................ 19

Refrigerant Piping at the Outdoor Unit .................................................................................... 20

Insulating the Pipe Joints......................................................................................................... 20

Piping Requirements ............................................................................................................... 21

Vacuum and Refrigerant Leakage Detection........................................................................... 22

Wiring Precautions .................................................................................................................. 23

Outdoor Wiring Connections ................................................................................................... 23

Stranded Wiring Connections.................................................................................................. 24

Electrical Connections............................................................................................................. 25

Cable Specifications ................................................................................................................ 26

Grounding Requirements ........................................................................................................ 26

Installation of Controllers......................................................................................................... 26

Post Installation Checklist........................................................................................................ 27

Test Operation ......................................................................................................................... 27

Refrigerant System Diagrams ................................................................................................. 28

Wiring Diagrams ...................................................................................................................... 29

Unit Dimensions ...................................................................................................................... 32

Common Error Codes............................................................................................................. 35

Emergency Operation.............................................................................................................. 35

Troubleshooting ....................................................................................................................... 36

Maintenance of the Indoor Unit ............................................................................................... 37

General Maintenance .............................................................................................................. 38