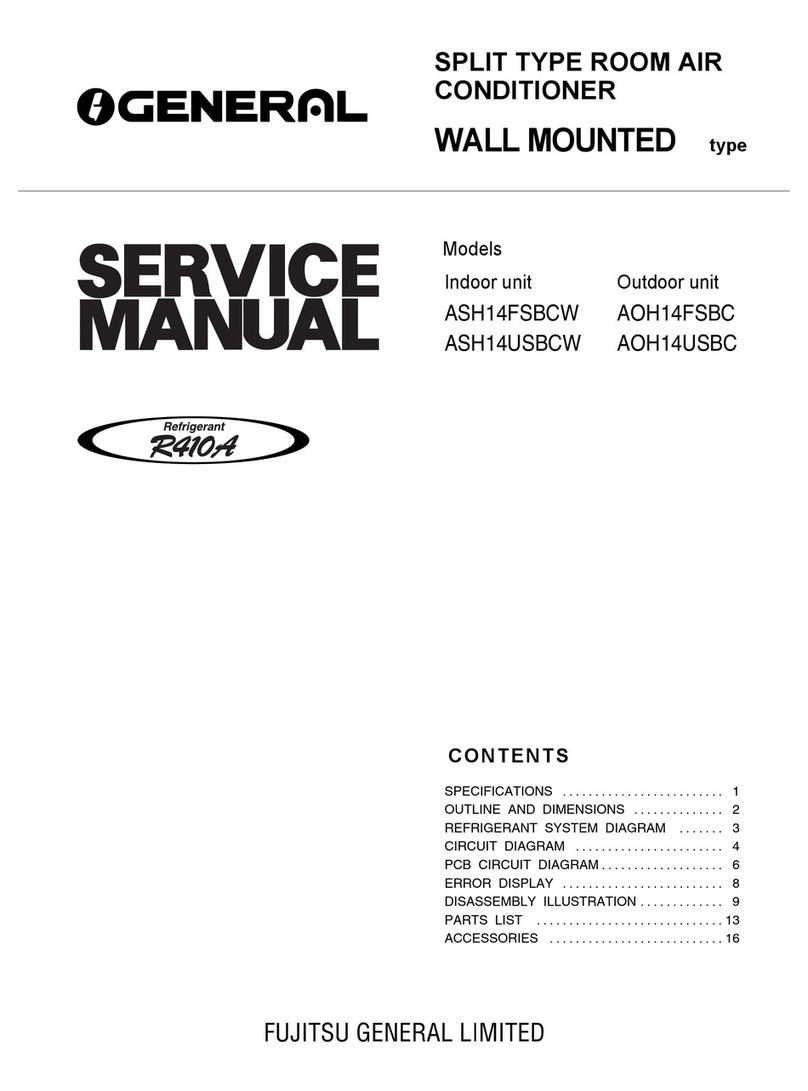

Allied Air 4SCU14LE SERIES User manual

506251-01 Page 1 of 20Issue 1015

TABLE OF CONTENTS

INSTALLATION ...................................... 2

START-UP............................................ 12

OPERATION ........................................ 16

MAINTENANCE ................................... 16

CONNECTION DIAGRAM ................... 18

WARRANTY......................................... 19

ManufacturedBy

ALLIEDAIR ENTERPRISES, INC.

A Lennox International Inc. Company

215 Metropolitan Drive

West Columbia, SC 29170

*506251-01*

Theequipmentcoveredinthismanualistobeinstalledbytrainedandexperiencedserviceandinstallation

technicians.Improperinstallation,modification,service,orusecancauseelectrical shock, fire, explosion,

orother conditions which maycausepersonal injury,death,orpropertydamage. Use appropriatesafety

gear including safety glasses and gloves when installing this equipment.

WARNING

Installation and servicing of air conditioning equipment

can be hazardous due to internal refrigerant pressure

andliveelectricalcomponents.Onlytrainedandqualified

servicepersonnelshouldinstallorservicethisequipment.

Installationandserviceperformedbyunqualifiedpersons

canresult in propertydamage, personal injury, or death.

WARNING

Risk of electrical shock. Disconnect all remote power

supplies before installing or servicing any portion of the

system.Failureto disconnect powersupplies canresult

in property damage, personal injury, or death.

WARNING

Sharpmetaledges can cause injury.When installing the

unit, use care to avoid sharp edges.

WARNING

Save these instructions for future reference

INSTALLATION AND MAINTENANCE INSTRUCTIONS

4SCU14LE SERIES

Split System Air Conditioner

Page 2 of 20 506251-01Issue 1015

INSTALLATION If any damages are discovered and reported to the carrier

DO NOT INSTALL THE UNIT, as claim may be denied.

Check the unit rating plate to confirm specifications

are as ordered.

Location of Unit

Refer to Figure 1 for installation clearances.

General

Read this entire instruction manual, as well as the

instructions supplied in separate equipment, before

startingthe installation.Observe and followallwarnings,

cautions, instructional labels, and tags. Failure to

complywith these instructions could result in an unsafe

condition and/or premature component failure.

These instructions are intended as a general guide only for

useby qualifiedpersonnelanddonot supersedeanynational

or local codes in any way. The installation must comply with

all provincial, state, and local codes as well as the National

ElectricalCode (U.S.)orCanadianElectricalCode (Canada).

Compliance should be determined prior to installation.

4SCU14LEcondensingunitsuse R410Awhich is an ozone-

friendly HFC refrigerant. The unit must be installed with a

matching indoor coil and line set. 4SCU14LE units are

designed for use in expansion valve (TXV) systems only.

The TXV expansion valve must be ordered separately from

themanufacturer.Afilterdrier approved forusewith 410Ais

installed in the unit.

Whenservicing orrepairingHVAC components,ensurethe

fastenersare appropriately tightened.Table 1showstorque

values for fasteners.

Slab Mounting

When installing unit at grade level, install on level slab high

enough so that water from higher ground will not collect

around unit (see Figure 2).

Roof Mounting

Install unit at a minimum of 4" above surface of the roof.

Care must be taken to ensure weight of unit is properly

distributed over roof joists and rafters. Either redwood or

steel supports are recommended.

Electrical Wiring

Allfieldwiring must be doneinaccordancewith the National

Electrical Code (NEC) recommendations, Canadian

Electrical Code (CEC) and CSAStandards, or local codes,

whereapplicable.

Inspection of Shipment

Upon receipt of equipment, carefully inspect it for possible

shipping damage. If damage is found, it should be noted on

the carrier’s freight bill. Take special care to examine the

unitinside the cartonifthecartonisdamaged.Anyconcealed

damage discovered should be reported to the last carrier

immediately, preferably in writing, and should include a

request for inspection by the carrier’s agent.

Figure 1

Installation Clearances

* Aservice clearance of 30" must be maintained on

one of the sides adjacent to the control box.

Clearance to one of the other three sides must be

36". Clearance to one of the remaining two sides

may be 12" and the final side may be 6".

Aclearance of 24" must be maintained between units.

48" clearance required on top of unit. Maximum soffit

overhang is 36".

36 *"

36"

36"

36 *"

Torque Table

Table 1

Compressor Bolts 90 in. lbs.

#10 Machine Screws 28 in. lbs.

#8 Machine Screws 16 in. lbs.

Sheet Metal Screws 16 in. lbs.

Service Port Caps 8 ft. lbs.

Stem Caps 8 ft. lbs.

Fastener Torque

506251-01 Page 3 of 20Issue 1015

Refrigerant Piping

If the 4SCU14LE unit is being installed with a new indoor

coilandlineset, the refrigerant connections shouldbe made

asoutlinedinthissection.Ifan existing line set and/or indoor

coilwill be used tocompletethe system, refertothis section

aswellasthesectionthatfollowsentitled Flushing Existing

Line Set and Indoor Coil.

Ifthisunitisbeing matchedwithanapprovedlinesetorindoor

coil which was previously charged with R22 refrigerant, the

linesetandcoil must be flushed prior to installation.Iftheunit

isbeingused with an existingindoorcoilwhichwasequipped

with a liquid line which served as a metering device (RFCI),

the liquid line must be replaced prior to the installation of the

4SCU14LEunit.

Field refrigerant piping consists of liquid and suction lines

from the outdoor unit (sweat connections) to the indoor coil

(flare or sweat connections).

Select line set diameters from Table 2 on page 4 to ensure

that oil returns to the compressor. Size vertical suction riser

Refer to the furnace or blower coil Installation Instructions

for additional wiring application diagrams and refer to unit

rating plate for minimum circuit ampacity and maximum

overcurrent protection size.

1. Install line voltage power supply to unit from a properly

sized disconnect switch. Any excess high voltage field

wiringshould betrimmed or securedaway from thelow

voltage field wiring.

2. Ground unit at unit disconnect switch or to an earth

ground.Tofacilitateconduit, ahole is in the bottom of the

control box. Connect conduit to the control box using a

proper conduit fitting. Units are approved for use only

with copper conductors. 24V Class II circuit connections

aremadetothelowvoltagepigtails.Acompleteunitwiring

diagram is located inside the unit control box cover (see

also page 18 of this instruction).

3. Installroomthermostatonaninsidewallthatisnotsubject

to drafts, direct sunshine, or other heat sources.

4. Install low voltage wiring from outdoor to indoor unit and

from thermostat to indoor unit (see Figure 3).

5. Do not bundle any excess 24V control wire inside control

box. Run control wire through installed wire tie and tighten

wire tie to provide low voltage strain relief and to maintain

separation of field-installed low and high voltage circuits.

Figure 2

Slab Mounting

Discharge Air

Mounting Slab

Ground Level

Building

Structure

Thermostat Designations

Figure 3

See unit wiring diagram for power supply connections.

If the indoor unit is not equipped with a blower relay, one must be

field supplied and installed.

Do not connect C (common) connection between indoor unit and

thermostat except when required by the indoor thermostat. Refer

to thermostat installation instructions. C (common) connection

between indoor unit and outdoor unit required for proper

operation.

Power

Indoor Unit

Thermostat

Outdoor

Unit

Y1 Outdoor Unit

Heat

Cooling

Indoor Blower

R

W1

Y

G

C

R

W

Y

G

CC Outdoor Unit

Unitmustbegroundedinaccordancewithnationalandlocal

codes.Failuretogroundunitproperlycanresultinpersonal

injuryor death.

WARNING

Refrigerant can be harmful if inhaled. Refrigerant must

always be used and recovered responsibly. Incorrect or

irresponsible use of refrigerant can result in personal injury

ordeath.

WARNING

Page 4 of 20 506251-01Issue 1015

to maintain minimum velocity at minimum capacity.

Recommended line length is 50' or less. If more than 50'

linesetisrequired,contactTechnicalServicesat1-800-448-

5872.

Table2 shows the diameters forline setsup to 100'although

vertical lift applications and trapping requirements need to

be reviewed with Technical Services for line sets over 50'.

Installing Refrigerant Line

During the installation of an air conditioning system, it is

important to properly isolate the refrigerant line to prevent

unnecessary vibration. Line set contact with the structure

(wall, ceiling, or floor) may cause objectionable noise when

vibration is translated into sound.As a result, more energy

or vibration can be expected. Close attention to line set

isolation must be observed. If refrigeration lines are routed

through a wall, seal and isolate the opening so vibration is

not transmitted to the building.

Following are some points to consider when placing and

installing a high-efficiency outdoor unit:

Placement

Beaware that somelocalitiesareadoptingsoundordinances

based on how noisy the unit is at the neighbor’s home, not

at the original installation. Install the unit as far as possible

from the property line. When possible, do not install the unit

directly outside a bedroom window. Glass has a very high

level of sound transmission. Figure 4 shows how to place

the outdoor unit and line set to reduce line set vibration.

Line Set Isolation

Illustrationsonthe following pagesdemonstrateprocedures

which ensure proper refrigerant line set isolation. Figure 5

shows how to install line sets on horizontal runs. Figure 6

shows how to make a transition from horizontal to vertical

and Figure 7 on page 6 shows how to install line sets on

vertical runs.

Outside Unit Placement

and Installation

Figure 4

Install unit away

from windows

Two 90° elbows installed in lineset

will reduce lineset vibration

Table 2

Refrigerant Line Set Diameters (in.)

For installations exceeding 50', contact

Technical Services at 1-800-448-5872.

506251-01 Page 5 of 20Issue 1015

Figure 6

Refrigerant Line Sets: Transition from Vertical to Horizontal

Anchored

Heavy Nylon

Wire Tie

Wall

Stud

Metal Sleeve Vapor Line Wrapped

in Armaflex

–

Liquid Line

Wall

Stud

Automotive

Muffler-Type

Hanger

Strap Liquid

Line to Vapor

Line

Metal Sleeve Vapor Line Wrapped

in Armaflex

–

Liquid Line

Strap Liquid

Line to Vapor

Line

Figure 5

To hang line set from joist or rafter,

use either metal strapping material

or anchored heavy nylon wire ties.

Strapping Material

(around vapor line only)

8’

8’

Tape or Wire Tie

Strap the vapor line to the joist or rafter

at 8 intervals then strap the liquid line

to the vapor line.

’

Floor Joist or

Roof Rafter

Metal Sleeve

Floor Joist or Roof Rafter

Tape or Wire Tie

Wire Tie

(around vapor line only)

Refrigerant Line Sets: Installing Horizontal Runs

Page 6 of 20 506251-01Issue 1015

6. Remove light maroon washers from service valves and

shieldlightmaroonstickerstoprotectthemduringbrazing.

Wrapawet cloth around the valvebody andcopper tube

stub to protect it from heat damage.

7. Braze the line set to the service valve. Quench the joints

with water or a wet cloth to prevent heat damage to the

valve core and opening port. The tube end must stay

bottomedinthe fittingduringfinalassemblyto ensure

proper seating, sealing, and rigidity.

Brazing Connection Procedure

1. Install a thermal expansion valve kit (sold separately)

that is approved for use with R410A refrigerant in the

liquid line at the indoor coil. Install the equalizer port

from the kit in the suction line.

2. Cut ends of refrigerant lines square (free from nicks or

dents). Debur the ends. The pipe must remain round;

do not pinch end of line.

3. Beforemakinglinesetconnections,usedrynitrogentopurge

therefrigerantpiping.Thiswillhelptopreventoxidationand

the introduction of moisture into the system.

4. Use silver alloy brazing rods (5% or 6% silver alloy for

copper-to-copperbrazingor45% silver alloy forcopper-

to-brass or copper-to-steel brazing) which are rated for

use with R410A refrigerant.

5. Remove the Schrader core assemblies before brazing

to protect them from damage due to extreme heat.

Replace the cores when brazing is complete.

Polyolester (POE) oils used with R410A refrigerant

absorb moisture very quickly. It is very important that

the refrigerant system be kept closed as much as

possible.DONOTremoveline set caps or servicevalve

stub caps until ready to make connections.

WARNING

Figure 7

Refrigerant Line Sets: Installing Vertical Runs (new construction shown)

Outside Wall

Wood Block

Between Studs

IMPORTANT: Refrigerant

lines must not contact wall.

Vapor Line Liquid Line

Wire Tie

Inside Wall

Strap

Sleeve

Wire Tie

Wire Tie

Strap

Wood Block

Sleeve

Vapor Line Wrapped

with Armaflex

Liquid Line

Caulk

PVC Pipe Fiberglass

Insulation

Outside Wall

IMPORTANT:

Refrigerant

lines must not

contact structure.

NOTE: Similar installation practices

should be used if line set is to be

installed on exterior of outside wall.

506251-01 Page 7 of 20Issue 1015

Flushing Existing Line Set and Indoor Coil

This procedure should not be performed on systems

which contain contaminants, such as compressor

burn out.

Required Equipment

The following equipment is needed to flush the existing line

set and indoor coil (see Figure 8): Two clean R22 recovery

bottles, an oil-less recovery machine with a “pump down”

feature, and two sets of gauges (one for use with R22 and

one for use with R410A).

Flushing Procedure

IMPORTANT:Thelinesetand/orindoorcoilmustbeflushed

with at least the same amount of refrigerant that previously

chargedthe system.Checkthecharge intheflushingcylinder

before flushing the unit.

1. Remove existing R22 refrigerant using the appropriate

procedure.

If the existing outdoor unit is not equipped with shutoff

valves, or if the unit is not operational AND the existing

R22 refrigerant will be used to flush the system:

Disconnectallpowertotheexistingoutdoorunit.Connect

theexistingunit,acleanrecoverycylinder,andtherecovery

machine according to the instructions provided with the

recovery machine. Remove all R22 refrigerant from the

existing system. Refer to the gauges after shutdown to

confirm that the entire system is completely void of

refrigerant. Disconnect the liquid and suction lines from

the existing outdoor unit.

If the existing outdoor unit is equipped with manual

shutoff valvesAND new R22 refrigerant will be used to

flush the system:

Start the existing R22 refrigerant system in cooling mode

and close the liquid line valve. Pump all the existing R22

refrigerant back into the outdoor unit.

(Itmaybenecessarytobypassthe lowpressureswitches

to ensure complete refrigerant evacuation.)

When flushing existing line set and/or indoor coil, be sure

to empty all existing traps. Residual mineral oil can act as

aninsulator,preventingproperheattransfer.Itcanalsoclog

thethermalexpansionvalve,reducingsystemperformance

andcapacity.Failuretoproperlyflushsystem asexplained

inthese instructionswillvoid warranty.

CAUTION

Figure 8

Flushing Connections

Note: The inverted R22 cylinder must contain at least the

same amount of refrigerant as was recovered from

the existing system.

Page 8 of 20 506251-01Issue 1015

When the low side system pressures reach 0 psig, close

thesuction line valve.Disconnectall power to theexisting

outdoorunit.Refertothegaugesaftershutdowntoconfirm

that the valves are not allowing refrigerant to flow back

into the low side of the system. Disconnect the liquid and

suction lines from the existing outdoor unit.

2. Remove the existing outdoor unit. Set the new R410A

unitandfollowthebrazingconnection procedureoutlined

previously on this page to make line set connections.

Do not install the R410Athermal expansion valve at

this time.

3. Makelowvoltageandlinevoltageconnectionstothe new

outdoor unit. Do not turn on power to the unit or open

the outdoor unit service valves at this time.

4. Removetheexisting R-22 refrigerant flowcontrolorifice

or thermal expansion valve before continuing with

flushing procedures. R-22 flow control devices are not

approved for use with R410A refrigerant and may

prevent proper flushing. Use a field-provided fitting to

reconnect the lines.

5. Remove the pressure tap valve cores from the

4SCU14LE unit’s service valves. Connect an R-22

cylinder with clean refrigerant to the suction service

valve.Connectthe R-22 gauge set to the liquidlinevalve

andconnectarecovery machine with an empty recovery

tank to the gauge set.

6. Set the recovery machine for liquid recovery and start

the recovery machine. Open the gauge set valves to

allow the recovery machine to pull a vacuum on the

existing system line set and indoor coil.

7. Invert the cylinder of clean R-22 and open its valve to

allow liquid refrigerant to flow into the system through

thesuction linevalve.Allow the refrigerantto passfrom

the cylinder and through the line set and the indoor coil

before it enters the recovery machine.

8. After all of the liquid refrigerant has been recovered,

switch the recovery machine to vapor recovery so that

all of the R-22 vapor is recovered. Allow the recovery

machine to pull a vacuum on the system.

NOTE: A single system flush should remove all of the

mineral oil from the existing refrigerant lines and indoor

coil. A second flushing may be done (using clean

refrigerant) if insufficient amounts of mineral oil were

removedduringthefirstflush.Aftereach system flush,

allow the recovery machine to pull a vacuum on the

system at the end of the procedure.

9. Close the valve on the inverted R22 cylinder and the

gauge set valves. Pump the remaining refrigerant out

of the recovery machine and turn the machine off.

10. Use nitrogen to break the vacuum on the refrigerant

lines and indoor coil before removing the recovery

machine, gauges, and R22 refrigerant drum. Re-install

pressure tap valve cores into the 4SCU14LE unit’s

service valves.

11. Install a thermal expansion valve kit (sold separately)

that is approved for use with R410A refrigerant in the

liquid line at the indoor coil.

Refrigerant Metering Device

4SCU14LE units are designed for use withTXV systems only.

Expansion valves equipped with Chatleff-type fittings are

availablefromthemanufacturer.SeeTable 3 for properTXV

for each unit.

To install an expansion valve (see Figure 9):

1. Separate thedistributor assembly andremovethe piston

orifice and used teflon seal. Insert nozzle end of the

expansion valve along with a new teflon seal into the

distributorandtightento20–30ft.lbs.Usebackupwrench

onall wrenchflats.Overtighteningwill crush the teflon

seal and may cause a leak.

2. Attach liquid line portion of distributor assembly along

with new teflon seal to the inlet of the expansion valve.

Tighten to 20 – 30 ft. lbs. Use backup wrench on all

wrenchflats.Overtightening will crush the teflon seal

and may cause a leak.

3. Connectthe external equalizerlineto the equalizerport

on the suction line and tighten to 8 ft. lbs.

4. Strap the superheat sensing bulb to the suction header.

If installing an expansion valve on an indoor coil that

previouslyusedafixed orifice, be sure to remove the existing

fixedorifice. Failure toremovea fixed orificewheninstalling

an expansion valve to the indoor coil will result in improper

operation and damage to the system.

Table 3

TXV Data

Model Part

Number

4SHP14LE-18.-24, -30

4SHP14LE-36, -41,

-42, -47, -48

4SHP14LE-48, -60

H4TXV01

H4TXV02

H4TXV03

506251-01 Page 9 of 20Issue 1015

3. Replace the stem cap. Tighten finger tight, then tighten

an additional 1/6 turn.

To Close Liquid or Suction Line Service Valve:

1. Remove the stem cap with an adjustable wrench.

2. Use a service wrench with a hex-head extension to turn

the stem clockwise to seat the valve. Tighten firmly.

3. Replace the stem cap. Tighten finger tight, then tighten

an additional 1/6 turn.

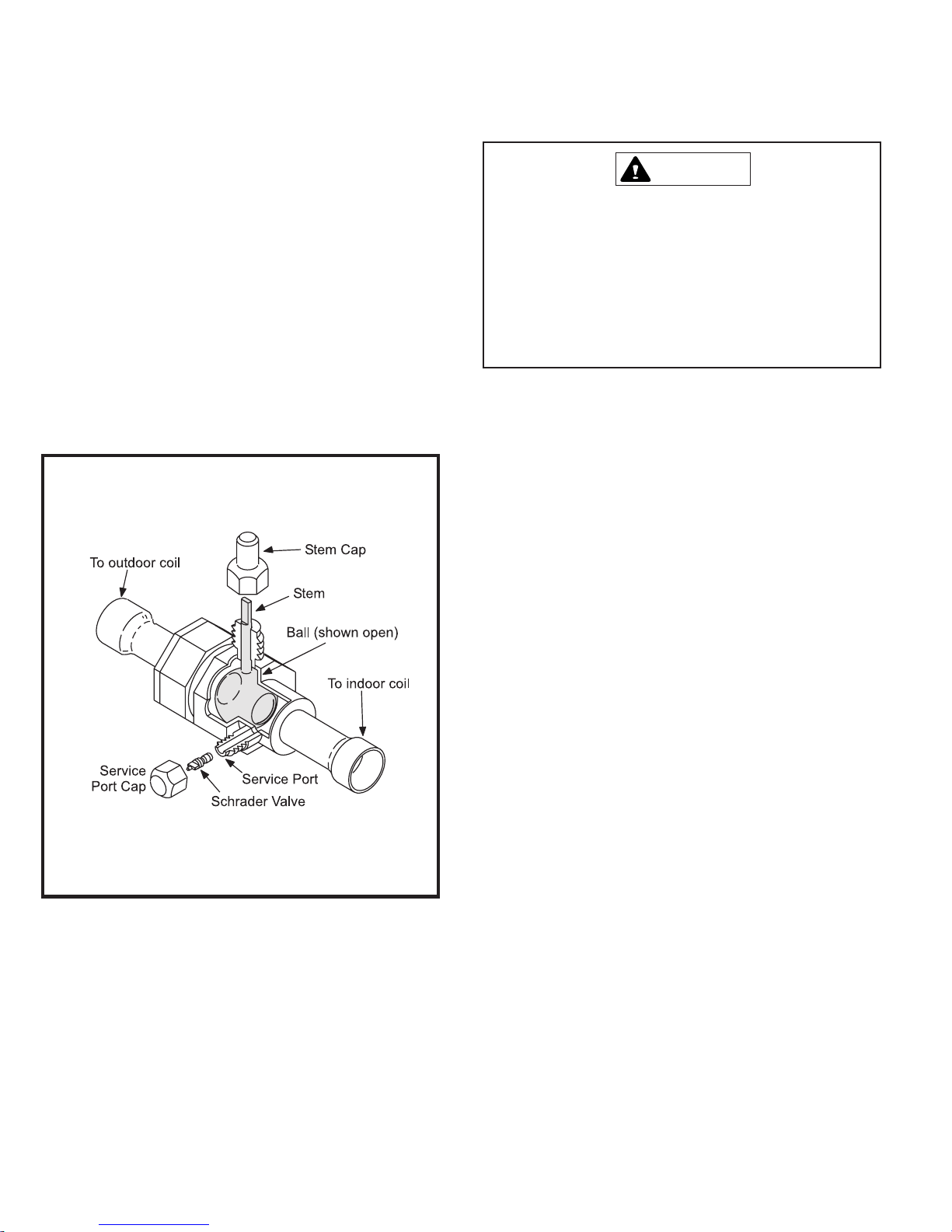

Suction Line (Ball Type) Service Valve

Suctionline(ball type) service valves functionthesameway

astheother valves; thedifferenceis in theconstruction (see

Figure 11).

Manifold Gauge Set

Manifoldgaugesetsusedwithsystemscharged with R410A

refrigerant must be capable of handling the higher system

operating pressures. The gauges should be rated for use

with pressures 0 – 800 on the high side and a low side of

30" vacuum to 250 psi with dampened speed to 500 psi.

Gauge hoses must be rated for use at up to 800 psi of

pressure with a 4000 psi burst rating.

Liquid and Suction Line Service Valves

The liquid line and suction line service valves and service

ports are used for leak testing, evacuating, charging, and

checking charge.

Eachvalveisequippedwithaserviceportwhichhasafactory-

installed Schrader valve (see Figure 10). A service port cap

protectstheSchradervalvefromcontaminationandservesas

the primary leak seal.

To Access the Schrader Port:

1. Remove the service port cap with an adjustable wrench.

2. Connect gauge to the service port.

3. When testing is completed, replace service port cap.

Tighten finger tight, then an additional 1/6 turn.

To Open Liquid or Suction Line Service Valve:

1. Remove stem cap with an adjustable wrench.

2. Useaservicewrenchwithahex-headextensiontoback

thestem out counterclockwise asfaras it willgo.Use a

3/16" hex head extension for liquid line service valves

and a 5/16" extension for suction line service valves.

Metering Device Installation

Figure 9

Figure 10

Service Valve

Valve Closed

Valve Open

Page 10 of 20 506251-01Issue 1015

The ball valve is equipped with a service port with a factory-

installed Schrader valve. A service port cap protects the

Schradervalvefromcontaminationandservesastheprimary

seal.

Leak Testing

After the line set has been connected to the indoor and

outdoor units, the line set connections and indoor unit must

be checked for leaks.

Using an Electronic Leak Detector

1. Connect the high pressure hose of the manifold gauge

set to the suction valve service port. (Normally the high

pressure hose is connected to the liquid line port;

however, connecting it to the suction ports helps to

protectthe manifold gaugesetfrom damage causedby

high pressure.)

2. With both manifold valves closed, connect the cylinder

of R410A refrigerant. Open the valve on the R410A

cylinder(vapor only).

3. Open the high pressure side of the manifold to allow

R410Ainto the linesetand indoor unit.Weighin atrace

amount of R410A. (A trace amount is a maximum of 2

oz. of refrigerant or 3 lbs. pressure.) Close the valve on

the R410A cylinder and the valve on the high pressure

side of the manifold gauge set. Disconnect the R410A

cylinder.

4. Connectacylinderofnitrogenwithapressureregulating

valvetothecenterport of the manifold gaugeset. When

using high pressure gas such as nitrogen for this

purpose, be sure to use a regulator that can control

the pressure down to 1 or 2 psig.

5. Adjustnitrogenpressure to 150psig.Open the valveon

the high side of the manifold gauge set to pressurize

the line set and the indoor coil.

6. After a short period of time, open a refrigerant port to

make sure that an adequate amount of refrigerant has

been added for detection (refrigerant requirements will

vary with lengths). Check all joints for leaks. Purge

nitrogen and R410A mixture. Correct any leaks and

recheck.

Ball Type Service Valve

(Valve Open)

Figure 11

Use adjustable wrench. To open, rotate stem counterclock-

wise 1/4 turn (90°). To close, rotate stem clockwise 1/4 turn

(90°).

Fire, Explosion, and Personal Safety Hazard.

Failure to follow this warning could result in damage,

personal injury, or death.

Never use oxygen to pressurize or purge refrigeration

lines. Oxygen, when exposed to a spark or open flame,

cancause damagebyfireand/oran explosion,thatcould

result in personal injury or death.

WARNING

506251-01 Page 11 of 20Issue 1015

7. Shut off the nitrogen cylinder and remove the manifold

gaugehosefrom the cylinder. Openthe manifoldgauge

valvesto releasethenitrogenfromthe linesetandindoor

unit.

8. Reconnect the manifold gauge to the vacuum pump,

turn the pump on, and continue to evacuate the line set

and indoor unit until 500 microns is maintained within a

20-minute period after shutting off the vacuum pump

and closing the manifold gauge valves.

9. When the requirements above have been met,

disconnect the manifold hose from the vacuum pump.

Openthe service valvesto break thevacuumin the line

set and indoor unit.

Evacuation

Evacuating the system of noncondensables is critical for

proper operation of the unit. Noncondensables are defined

as any gas that will not condense under temperatures and

pressures present during operation of an air conditioning

system. Noncondensables and water vapor combine with

refrigeranttoproducesubstancesthatcorrodecopperpiping

and compressor parts.

Usea thermocouple orthermistorelectronic vacuum gauge

that is calibrated in microns. Use an instrument that reads

down to 50 microns.

Do not use a compressor to evacuate a system. Avoid

deep vacuum operation. Extremely low vacuums can

cause internal arcing and compressor failure. Danger

ofequipment damage.Damagecausedbydeepvacuum

operation will void warranty.

WARNING

1. Connect the manifold gauge set to the service valve

ports as follows:

• Low pressure gauge to suction line service valve

• High pressure gauge to liquid line service valve

2. Connect micron gauge.

3. Connect the vacuum pump (with vacuum gauge) to the

center port of the manifold gauge set.

4. Open both manifold valves and start vacuum pump.

5. Evacuate the line set and indoor unit to a minimum of 500

micronsorlower.Duringtheearlystagesofevacuation,itis

desirabletoclosethemanifoldgaugevalveatleastonceto

determine if there is a rapid rise in pressure.Arapid rise in

pressure indicates a relatively large leak. If this occurs, the

leak testing procedure must be repeated.

6. When 500 microns or lower is maintained, close the

manifold gauge valves, turn off the vacuum pump, and

disconnectthemanifoldgaugecenter port hose from the

vacuum pump. Attach the manifold gauge center port

hose to a nitrogen cylinder with pressure regulator set to

150 psig and purge the hose. Open the manifold gauge

valves to break the vacuum in the line set and indoor

unit. Close the manifold gauge valves.

Page 12 of 20 506251-01Issue 1015

line set. For varying lengths of line set, refer to Table 4 for

refrigerant charge adjustment.

If the system is void of refrigerant, clean the system using

the procedure described below.

1. Use dry nitrogen to pressurize the system and check

for leaks. Repair leaks, if possible.

2. Evacuatethesystemtoremoveasmuchofthemoisture

as possible.

3. Use dry nitrogen to break the vacuum.

4. Evacuate the system again.

5. Weigh the appropriate amount of R410A refrigerant

(listed on unit nameplate) into the system.

6. Monitorthesystemtodetermine the amount of moisture

remaining in the oil. Use a test kit to verify that the

moisture content is within the kit’s dry color range. It

maybenecessarytoreplacethefilterdrierseveraltimes

toachieve therequireddrynesslevel.If system dryness

is not verified, the compressor will fail in the future.

The outdoor unit should be charged during warm weather.

However,applications arise in whichchargingmust occur in

the colder months. The method of charging is determined

by the outdoor ambient temperature.

Measuretheliquidlinetemperatureandtheoutdoorambient

temperature as outlined below:

1. Connect the manifold gauge set to the service valve

ports as follows:

• Low pressure gauge to suction line service valve

START-UP

1. Rotate fan to check for frozen bearings or binding.

2. Inspect all factory and field-installed wiring for loose

connections.

3. Afterevacuation is complete, openliquidlineandsuction

line service valves to release refrigerant charge

(contained in outdoor unit) into system.

4. Replace the stem caps and secure finger tight, then

tighten an additional 1/6 of a turn.

5. Check voltage supply at the disconnect switch. The

voltage must be within the range listed on the unit

nameplate.Ifnot, do notstart equipment untilthepower

companyhasbeen consulted andthevoltagecondition

corrected.

6. Set thermostat for cooling demand, turn on power to

indoor blower and close the outdoor unit disconnect

switch to start the unit.

7. Recheck unit voltage with unit running. Power must be

within range shown on unit nameplate.

Refrigerant Charging

ThissystemischargedwithR410Arefrigerantwhichoperates

atmuchhigherpressuresthanR22.Theliquidlinedrierprovided

with the unit is approved for use with R410A. Do not replace it

withonedesignedforusewithR22.ThisunitisNOTapproved

forusewithcoilswhichuse capillarytubesas arefrigerant

metering device.

R410Arefrigerant cylinders are rosecolored. Refrigerant

should be added through the vapor valve in the liquid

state.

CertainR410Acylinders areidentifiedas being equipped

with a dip tube. These allow liquid refrigerant to be

drawn from the bottom of the cylinder without inverting

the cylinder. Do not turn this type of cylinder upside

down to draw refrigerant.

Units are factory charged with the amount of R410A

refrigerant indicated on the unit rating plate. This charge is

based on a matching indoor coil and outdoor coil with 15'

Ifunit is equippedwitha crankcase heater, itshouldbe

energized 24 hours before unit start-up to prevent

compressor damage as a result of slugging.

CAUTION

Mineral oils are not compatible with R410A. If oil must be

added, it must be a polyol ester oil.

IMPORTANT

Refrigerant Charge Adjustment

* If line length is greater than 15 ft., add this amount.

If line length is less than 15 ft., remove this amount.

Table 4

Liquid Line Set

Diameter

Oz. per 5 ft. adjust

from 15 ft. line set *

3/8 in. 3 oz. per 5 ft.

506251-01 Page 13 of 20Issue 1015

• High pressure gauge to liquid line service valve

2. Close manifold gauge set valves. Connect the center

manifold hose to an upright cylinder of R410A.

3. Ifroomtemperatureisbelow70°F,settheroomthermostat

to call for heat. This will create the necessary load for

properly charging the system in the cooling cycle.

4. Useadigitalthermometer to recordthe outdoor ambient

temperature.

5. When the heating demand has been satisfied, switch

the thermostat to cooling mode with a set point of 68°F.

When pressures have stabilized, use a digital

thermometer to record the liquid and suction line

temperatures.

6. Theoutdoortemperature willdeterminewhich charging

method to use. Proceed with the appropriate charging

method.

Charge Using Weigh-In Method

If the system is void of refrigerant, or if the outdoor ambient

temperature is cool, first locate and repair any leaks then

use the weigh-in method to charge the unit.

1. Recover the refrigerant from the unit.

2. Conduct a leak check, then evacuate as previously

outlined.

3. Weighinthechargeaccordingtothetotalamountshown

on the unit nameplate.

If weighing facilities are not available or if unit is being

charged during warm weather, follow one of the other

procedures outlined below.

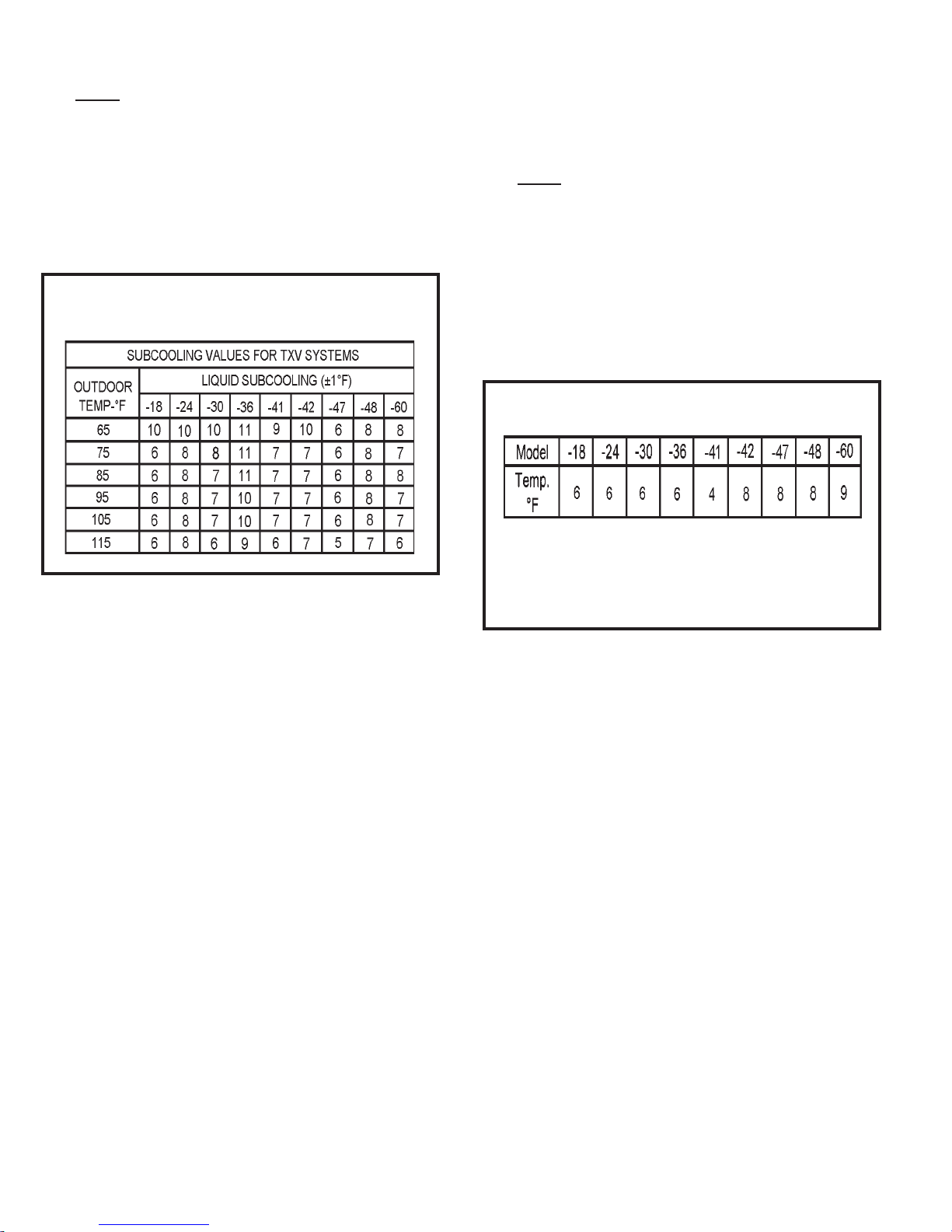

Charge Using Subcooling Method –

Outdoor Temperatures 65°F or Above

When the outdoor ambient temperature is 65°F or above,

the subcooling method can be used to charge the unit.

1. With the manifold gauge hose on the liquid service port

and the unit operating stably, use a digital thermometer

to record the liquid line temperature.

2. At the same time, record the liquid line pressure reading.

3. Use the temperature/pressure chart (Table 5) to

determine the saturation temperature for the liquid line

pressure reading.

4. Subtract the liquid line temperature from the saturation

temperature (according to the chart) to determine

R410A Temperature/Pressure Chart

Table 5

.pmeT F°

e

russerP gisP

238.001

339.201

430.501

531.701

632.901

734.111

836.311

938.511

040.811

143.021

246.221

340.521

443.721

547.921

642.231

746.431

841.731

946.931

052.241

158.441

254.741

351.051

458.251

555.551

652.851

750.161

859.361

957.661

066.961

166.271

265.571

365.871

466.181

563.481

667.781

769.091

861.491

963.791

076.002

179.302

272.702

376.012

.pmeT F°

e

russerP gisP

470.412

574.712

679.022

774.422

870.822

976.132

083.532

180.932

287.242

385.642

483.052

581.452

680.852

780.262

880.662

980.072

091.472

192.872

293.282

395.682

498.092

591.592

694.992

798.303

892.803

997.213

0012.713

1018.123

2014.623

3010.133

4017.533

5015.043

6013.543

7011.053

8010.553

9010.063

0110.563

1110.073

2111.573

3112.083

4114.583

5117.093

.pmeT F°

e

russerP gisP

6110.693

7113.104

8117.604

9112.214

0217.714

1212.324

2218.824

3215.434

4212.044

5219.544

6218.154

7216.754

8215.364

9215.964

0316.574

1316.184

2318.784

3310.494

4312.005

5315.605

6319.215

7313.915

8318.525

9314.235

0410.935

1416.545

2413.255

3411.955

4419.565

5418.275

6418.975

7418.685

8418.395

9410.106

0511.806

1514.516

2517.226

3511.036

4515.736

5510.546

Page 14 of 20 506251-01Issue 1015

_____ ° Liquid Line Temperature °F

_____ ° OutdoorAmbient Temperature °F

_____ ° Approach Temperature °F

–

=

Charge Using Approach Method –

Outdoor Temperatures 65°F or Above

The following procedure is intended as a general guide and

isforuse on expansionvalvesystems only. For bestresults,

indoor temperature should 70°F to 80°F. Monitor system

pressures while charging.

1. Record outdoor ambient temperature using a digital

thermometer.

2. Attach high pressure gauge set and operate unit for

several minutes to allow system pressures to stabilize.

3. Compare stabilized pressures with those provided in

Table 8. Minor variations in these pressures may be

expected dueto differencesin installations. Significant

differences could mean that the system is not

properly charged or that a problem exists with some

componentin the system. Pressureshigherthanthose

listedindicatethat the system is overcharged. Pressures

lower than those listed indicate that the system is

undercharged. Verify adjusted charge using the

approach method.

4. Use the same digital thermometer to check liquid line

temperature.

5. Subtracttheoutdoorambienttemperaturefromtheliquid

subcooling.

5. Comparethesubcoolingvaluewiththoseshown inTable

6. If subcooling is greater than shown, recover some

refrigerant. If subcooling is less than shown, add some

refrigerant.

_____ ° Saturation Temperature °F

_____ ° Liquid Line Temperature °F

_____ ° Subcooling Value °F

–

=

linetemperature todeterminetheapproachtemperature.

6. Comparethe approach valuewiththose shown inTable

7. If the values to do not agree with those provided in

Table 7, add refrigerant to lower the approach

temperature or recover refrigerant from the system to

increase the approach temperature.

Check Charge Using Normal Operating Pressures

Use Table 8 to perform maintenance checks. Table 8 is not

a procedure for charging the system. Minor variations in

these pressures may be due to differences in installations.

Significant deviations could mean that the system is not

properly charged or that a problem exists with some

component in the system.

Approach Values for TXV Systems

Approach value is the liquid line temperature minus the

outdoor ambient temperature (±1°F).

NOTE: For best results, use the same digital thermometer

to check both outdoor ambient and liquid temperatures.

Table 7

Subcooling Values for

TXV Systems

Table 6

506251-01 Page 15 of 20Issue 1015

Normal Operating Pressures

Table 8

L = Liquid S = Suction

Values provided above are typical pressures. Indoor unit matchup, indoor air quality, and indoor load will cause

pressures to vary.

Page 16 of 20 506251-01Issue 1015

OPERATION

Outdoor unit and indoor blower cycle on demand from the

room thermostat. When the thermostat blower switch is

moved to the ON position, the indoor blower operates

continuously.

Maintenance and service must be performed by a qualified

installer or service agency.

Atthe beginning ofeachcooling season, thesystemshould

be checked as follows:

1. Clean and inspect condenser coil. Coil may be flushed

witha water hose.Be sure thepower is offbefore using

water to clean the coil.

2. Outdoor fan motor is pre-lubricated and sealed. No

further lubrication is needed.

3. Visually inspect connecting lines and coils for evidence

of oil leaks.

4. Check wiring for loose connections.

5. Check for correct voltage at unit (with unit operating).

6. Check amp-draw outdoor fan motor.

Unit nameplate _________ Actual _________

NOTE–Ifownercomplainsofinsufficientcooling,the unit

should be gauged and refrigerant charge checked. Refer

to the Refrigerant Charging section on page 12.

Indoor Coil

1. Clean coil, if necessary.

2. Check connecting lines and coils for evidence of oil

leaks.

3. Check condensate pan line and clean, if necessary.

Indoor Unit

1. Clean or change filters.

2. Adjust blower speed for cooling. Measure the pressure

drop over the coil to determine the correct blower CFM.

3. Belt drive blowers: Check belt for wear and proper

tension.

MAINTENANCE

Before performing maintenance operations on system,

turn the electric power to unit OFF at disconnect

switch(es). Unit may have multiple power supplies.

Electrical shock could cause personal injury or death.

WARNING

506251-01 Page 17 of 20Issue 1015

4. Check all wiring for loose connections.

5. Check for correct voltage at unit (with unit operating).

6. Check amp-draw on blower motor.

Unit nameplate _________ Actual _________

Start-Up and Performance Checklist

Job Name _______________________________ Job No. ________________ Date ______________

Job Location _____________________________ City ___________________ State ______________

Installer _________________________________ City ___________________ State ______________

Unit Model No.______________ Serial No. ___________________

Service Technician ________________________________________ Nameplate Voltage ______________

Rated LoadAmpacity ________ Compressor _______________ Outdoor Fan ___________________

Maximum Fuse or Circuit Breaker________________________

Electrical Connections Tight? Indoor Filter Clean? Supply Voltage (Unit Off) ________________

Indoor Blower RPM _____________ S.P. Drop Over Indoor (Dry) ____________

Outdoor Coil EnteringAir Temperature _____________ Voltage with Compressor Operating _____________

Discharge Pressure___________ Vapor Pressure ____________

Refrigerant Charge Checked? Outdoor Fan Checked?

Refrigerant Lines: Leak Checked? ProperlyInsulated?

Service Valves: Fully Opened? Caps Tight?

Thermostat: Calibrated? ProperlySet? Level?

Page 18 of 20 506251-01Issue 1015

Figure 12

HCF

1

DESCRIPTION

KEY COMPONENT

A4 CONTROL - TIMED OFF

B1 COMPRESSOR

B4 MOTOR - OUTDOOR FAN

C12 CAPACITOR - DUAL

HR1 HEATER - COMPRESSOR

K1-1 CONTACTOR - COMPRESSOR

S4 SWITCH - HIGH PRESSURE

S24 SWITCH - LOSS OF CHARGE

FOR USE WITH COPPER CONDUCTORS ONLY. REFER TO UNIT RATING

PLATE FOR MINIMUM CIRCUIT AMPACITY AND MAXIMUM OVERCURRENT

PROTECTION SIZE.

WARNING--

ELECTRIC SHOCK HAZARD, CAN CAUSE INJURY OR DEATH.

UNIT MUST BE GROUNDED IN ACCORDANCE WITH NATIONAL

AND LOCAL CODES.

OUTDOOR

FAN

FCH

1

23

RSC

C

2

3

1

EQUIPMENT

GROUND

HR1

L2

208-230/60/1

L1

K1-1

BLACK

YELLOW

RED

RED

C12

BLACK

ORANGE

B4

PURPLE

K1

S4 S24

A4

CY1

TO 24 VAC

POWER SOURCE

20 VA MINIMUM

NEC CLASS 2

S4 HIGH

PRESSURE

SWITCH

(IF USED)

S24 LOSS

OF CHARGE

SWITCH

(IF USED)

B1

GROUND

LUG

GROUND

L2

L1

208-230/60/1

CY1

TO 24 VAC

POWER SOURCE

20 VA MINIMUM

NEC CLASS 2

A4

TIMED OFF

CONTROL

(IF USED)

DUAL

CAPACITOR

RED

COMPRESSOR

CONTACTOR

BLACK

COMPRESSOR

CRANKCASE HEATER

(IF USED)

PURPLE

BLACK

ORANGE

RED

YELLOW

SR

LINE VOLTAGE FACTORY INSTALLED

1

LINE VOLTAGE FIELD INSTALLED

24 VOLT FACTORY INSTALLED

CLASS II VOLTAGE FIELD INSTALLED

Wiring Diagram P/N 48352-001

506251-01 Page 19 of 20Issue 1015

ALLIED AIR ENTERPRISES

EQUIPMENT LIMITED WARRANTY

APPLIES IN U.S.A.AND CANADAONLY

FAILURE TO MAINTAIN YOUR EQUIPMENT WILL VOID THIS WARRANTY

COVERED EQUIPMENT

The following Allied Air Enterprises heating and cooling equipment is covered by the Limited Warranty,

Condensing Units: 2SCU13, 4SCU13, 4SCU14, 4SCU16, 4SCU18, 2AC13, 2AC14, 4AC13, 4AC14

Heat Pumps: 2SHP13, 4SHP13, 2SHP14, 4SHP14, 4SHP16, 4SHP18, 2HP13, 2HP14, 4HP13, 4HP14

Gas Furnaces: G1N80, G1D80, G2D80, G1D91, G1D93, G2D93, G2D95, FPBB, CG80, CG90, CG92, CG93, CG95

Oil Furnaces: LBR80, LBF80, LHF80, LUF80, LHR80, RLUF, RLBF, RLBR, RLBU, RLHF, RLHR

Electric Furnaces: EFC, EFV

Evaporator Coils: EC, EU, EH, EM

Air handlers: BCS2, RBCS2

Package Equipment: 2PCE13, 4PCE13, 4PCE15, 2PGE13, 4PGE13, 4PGE15, 2PHP13, 4PHP13, 4PHP15, 2SG13, 2SH13, 2SA13, RGE13, RPGE13, RHP13, RCE13, RPHP13, RPCE13

PARTS and COMPRESSOR COVERAGE

The covered equipment, parts and compressor are warranted byAllied Air for a period of five (5) years from the date of the original installation, when installed in a residential application (which includes

homes, duplexes, apartments and condominiums). For non-residential applications, the covered equipment and parts are warranted for a period of one (1) year and compressor is warranted for five (5)

years from the date of the original installation. If, during this period, a covered component fails because of a manufacturing defect, Allied Air will provide a free replacement part to the owner through a

licensed service contractor utilizing an Allied Air distributor. The purchaser must pay shipping charges and all other costs of warranty service. Allied Air will not pay labor involved in diagnostic calls or

in removing, repairing, servicing or replacing parts. Such cost may be covered by a separate warranty provided by the installer.

HEAT EXCHANGER EXTENDED COVERAGE

All covered heat exchangers are warranted by Allied Air for a period of twenty (20) years from the date of original installation, when installed in a residential application. Heat exchangers in all non-

residential applications are warranted for a period of ten (10) years.

Heat Exchanger Availability: If a replacement heat exchanger is no longer available for a unit covered by this Limited Warranty, Allied Air will allow a credit toward the purchase of an equivalent Allied

Air furnace (at the current suggested distributor’s cost).

NOTE: If the date of original installation cannot be verified, the warranty period will be deemed to begin ninety (90) days after the date of manufacture.

EXCLUDED COMPONENTS

The following components are expressly not covered by this Limited Warranty: cabinets, cabinet pieces, air filters, driers, refrigerant, refrigerant line sets, belts, wiring, fuses, oil nozzles, unit accessories

and any parts not affecting unit operation

CARE OF EQUIPMENT

All new Allied Air units must be properly installed, operated and maintained in accordance with the unit installation, operation and maintenance instructions provided with each Allied Air unit. Failure to

maintain the equipment per Allied Air instructions will void this Limited Warranty.

WARRANTY PROCEDURE

When service or warranty parts are required:

1. Call a local licensed service dealer or contractor.

2. If the installing dealer is unable to provide warranty service, check online at www.alliedair.com.

3. Be prepared to furnish the following information:

a. complete model and serial number;

b. proof of required periodic maintenance, installation date and location; and

c. an accurate description of the problem.

WARRANTY LIMITATIONS

1. This Limited Warranty is void if the covered equipment is removed from the original installation site.

2. This Limited Warranty does not cover damage or defect resulting from:

a. flood, wind, fire, lightning, mold, or installation and operation in a corrosive atmosphere, or otherwise in contact with corrosive materials (chorine, fluorine, salt, recycled waste water, urine,

fertilizers, or other damaging substances or chemicals); accident, or neglect or unreasonable use or operation of the equipment including operation of electrical equipment at voltages other

than the range specified on the unit nameplate (includes damages caused by brownouts);

b. modification, change or alteration of the equipment, except as directed in writing by Allied Air;

c. operation with system components (indoor unit, outdoor unit and refrigerant control devices) which are not an ARI match or meet the specifications recommended by Allied Air;

d. operation of furnaces with return air temperatures of less than 60ºF (16ºC) or operation of a furnace field installed downstream from a cooling coil; and

e. use of contaminated refrigerant or refrigerant not compatible with the unit.

The installation of replacement parts under the terms of this Limited Warranty does not extend the original warranty period.

Allied Air makes no express warranties other than the Limited Warranty specified above. All implied warranties, including the implied warranties of merchantability and fitness for a

particular purpose, are excluded to the extent legally permissible. Should such exclusion or limitation of this Limited Warranty be unenforceable, such implied warranties are in any event

limited to a period of one (1) year. Liability for incidental and consequential damages is excluded. Some states do not allow limitation of incidental damages, so these limitations or

exclusions may not apply to you. Allied Air will not pay electricity or fuel costs, or increases in electricity or fuel costs, for any reason whatsoever, including additional or unusual use of

supplemental electric heat. This Limited Warranty does not cover lodging expenses or labor charges.

Allied Air shall not be liable for any default or delay in performance under this Limited Warranty caused by any contingency beyond its control.

This Limited Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

NOTE TO CUSTOMER:

Please complete information below and retain this warranty for your records and future reference.

Outside Unit Model Number: ____________________________________________________ Serial Number: _______________________________________ Installed Date: __________________

Furnace / Air Handler: _________________________________________________________ Serial Number: _______________________________________ Installed Date: __________________

Indoor Coil Model Number: _____________________________________________________ Serial Number: _______________________________________ Installed Dare: __________________

Installing Company Name: ___________________________________________________________________________________ Phone: _______________________________________________

Installing Company Address: _____________________________________________________________ State/Province: _______________________________ Zip/Postal Code: _______________

215 Metropolitan Drive - West Columbia - SC - 29170

© 2008 Allied Air Enterprises Litho U.S.A. FORM W-2008-2 (9/25/2009)

Page 20 of 20 506251-01Issue 1015

AlliedAirEnterprises Inc. (“AlliedAir”)providesitsairconditioningandheating productswitha Standard LimitedPartsWarrantyfor five (5) years. Thisadditional5-YearLimitedExtended

PartsWarrantyisinadditionto and is intended to supplementAlliedAir’sStandardLimitedPartsWarranty. As such,AlliedAir provides fora totalof10-yearsoflimitedwarrantycoverage

(Standard Limited Parts Warranty plus additional 5-Year Limited Extended Parts Warranty).

This 5-Year Limited Extended Parts Warranty applies only to the original purchaser of the equipment and cannot be transferred. If during the coverage period, a covered part fails

becauseofadefect in materials or workmanshipundernormaluseandmaintenance,AlliedAir will provideafreereplacementparttothepurchaserthroughalicensed service contractor

utilizing an authorizedAlliedAir distributor. The purchaser must pay shipping costs and all other costs of warranty service. AlliedAir will not pay labor involved in diagnostic calls or in

removing, repairing, servicing or replacing parts. EXTENDED COVERAGE -

PARTS/COMPRESSORS

Covered equipment and parts are warranted byAlliedAir for a total of 10 YEARS (Standard Limited Parts Warranty) from installation, except as provided below

HEAT EXCHANGERS

Covered residential heating equipment’s heat exchanger is warranted byAlliedAir for a LIMITED LIFETIME from date of original installation, except as provided below.

EXCLUDED COMPONENTS -

The following components are expressly not covered by this 5-Year Limited Extended Parts Warranty: cabinets, cabinet pieces, air filters, driers, refrigerant, refrigerant line sets, belts,

wiring, fuses, oil nozzles, unit accessories, R-22 compressors, and any parts not affecting unit operation.

If this 5-Year Limited Extended Warranty does not apply, then parts are warranted under the Standard Limited Parts Warranty for a period of 5 YEARS and heat exchangers for 20

YEARS. If the Standard Limited Parts Warranty periods differ from the original warranty certificate, the periods stated on the original warranty certificate apply.

This 5-Year Llimited Extended Parts Warranty does not apply to, and no warranty is offered byAlliedAir, on any unit ordered over the internet. Proof of purchase may be required.

Anypartreplacedpursuanttothis 5-YearLimitedExtended PartsWarranty is warranted onlyfortheunexpiredportion of thelimitedextendedwarrantyterm remaining for theoriginalpart.

The installation of replacement parts under the terms of this 5-Year Limited Extended Parts Warranty does not extend the warranty period.

Steps for obtaining replacement parts under this 5-Year Limited Extended Parts Warranty:

If you suspect a defect in your equipment, please contact the installer of the unit to obtain assistance. If unsuccessful, please contact anAllied Air dealer or distributor in

your area. If unable to obtain local assistance, refer toAlliedAir’s website (www.alliedair.com) or contact AlliedAir at 800-448-5872.

Allied Air is specifically not responsible for:

1.Damageor repairs required asaresultof flood, fire, wind,lighteningstrike(to the home orunit),corrosiveatmosphere, contact with corrosivematerial (chlorine,fluorine,salt,recycled

waste water, fertilizers or other damaging substances) or other conditions beyond the control ofAlliedAir;

2. Use of parts, accessories, or refrigerant not compatible with the unit;

3. Modification, change or alteration of the unit, except as expressly directed in writing byAllied Air;

4. Improper use, accident, neglect or unreasonable use or operation of the unit, including operation of electrical equipment at voltages other than the range specified on the unit

nameplate;

5. Operation with system parts (indoor unit, outdoor unit and refrigerant control devices) which are notARI matched or do not meet the specifications recommended byAlliedAir;

6. Damage or repairs required as a consequence of faulty or installation or application;

7. Normal maintenance as described in the installation and operating manual, such as cleaning of coils, filter cleaning and/or replacement and lubrication; and

8. Changes in the appearance or sound of the unit that do not affect its performance.

This 5-Year Limited Extended Parts Warranty is an extension ofAlliedAir’s Standard Limited Parts Warranty. ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR

APARTICULAR PURPOSE ON THIS PRODUCT IS LIMITED IN DURATION TO THE TERM OF THIS LIMITED EXTENDED WARRANTY. Some states and provinces do not allow

limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

ALLIED AIR SHALL IN NO EVENT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO EXTRA UTILITY EXPENSES OR

DAMAGES TO PROPERTY. Some states and provinces do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not

apply to you

The parties intend this writing as a final expression of their agreement with respect to warranties. Allied Air makes no other warranty beyond that which is expressly

contained in this writing.

AlliedAir shall not be liable for any default or delay in performance under this warranty caused by any contingency beyond its control, including the unavailability of replacement parts.

This warranty gives you specific legal rights, and you may also have other rights that vary from state to state or province to province.

1 Excludes residents of states or provinces where registration requirements are prohibited, such as California and Quebec. Residents of these states or provinces may either register as noted above or

provide proof of when the unit was purchased and installed, such as an original invoice from the contractor with the Owner’s name, address, purchase date, serial and model number.

5-YEAR LIMITED EXTENDED PARTS WARRANTY

1. The unit is anArmstrongAir, Air ease, Ducane, or Concord branded unit;

2. The unit is installed in a residential application, which is an owner-occupied single-family residence. No commercial applications are allowed;

3. The unit is properly registered at www.alliedair.com with Allied Air within 60-days after the original date of installation or occupancy.1To

register, follow the directions and complete the online warranty registration at www.alliedair.com. For customer inquiries, contactAllied Air at

1-800-448-5872.

4. The unit is part of a completeARI matched system and installed by a state certified or licensed contractor in accordance with the unit installation, operation,

and maintenance instructions provided with the unit.

5. Coils and air handlers are covered only when they are branded Armstrong,AirEase, Ducane, Concord or ADPand are purchased and newly installed as a

system along with a qualifying unit. Except forADP-branded products, coverage of other third party coils and air handlers are specifically excluded from

this 5-Year Limited Extended Parts Warranty.

6. Installation of the unit takes place on or after October 3, 2008.

REQUIREMENTS FOR EXTENDED COVERAGE-

Table of contents

Other Allied Air Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Mitsubishi Electric

Mitsubishi Electric MSZ-GE60VAD operating instructions

Nipon Coolair

Nipon Coolair MB18 GA Installation and user manual

Danfoss

Danfoss Optyma OP-LPHE Series instructions

Adler Europe

Adler Europe AD 7915 user manual

LG

LG LP073HDUC/00 owner's manual

Fujitsu

Fujitsu AU A30LBLU Series Design & technical manual

Honeywell

Honeywell MP09 Series user manual

Mitsubishi Electric

Mitsubishi Electric PQRY-P200YEM-A Service handbook

LG

LG ATNH243PLAE Service manual

Fujitsu

Fujitsu ASYG09KMCB Design & technical manual

DeLonghi

DeLonghi PAC N135E instruction manual

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries SRK63ZTL-W user manual