6

Instruction Manual

Effective March 2020

eaton www.eaton.com

Safty Requirement

Please read this Instruction Manual carefully before

installation and operation of this product.

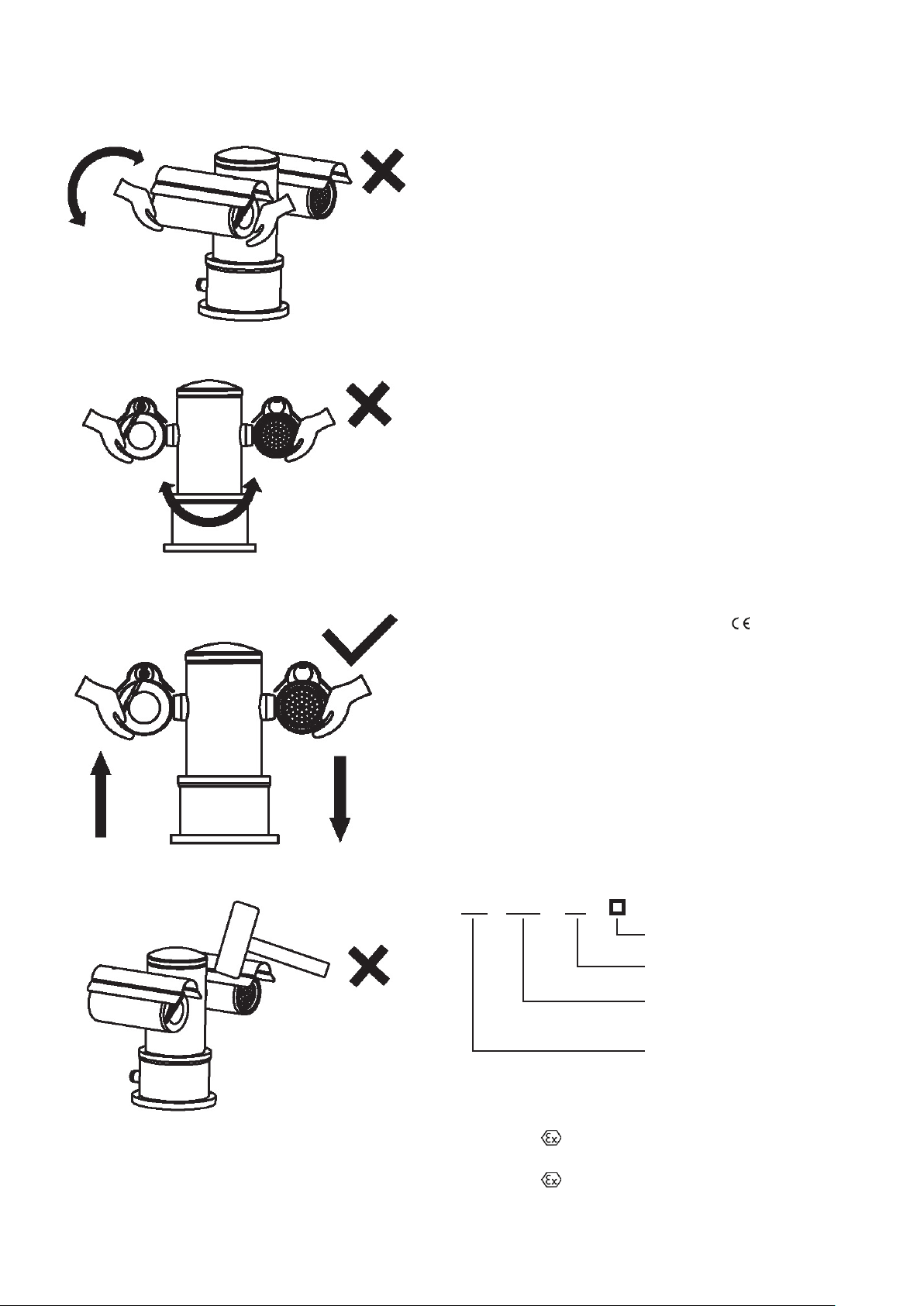

1. Safety cautions in installation

• Cut off the power supply before any maintenance or repair of

the product.

• Avoid opening of this product in environment where oil smoke,

heavy dust, high temperature or dewing may exist. These will

cause the decrease of the image definition.

• Connect the cables according to the requirement indicated in

the Instruction Manual, or fault may happen.

• Protect the flame proof joint in maintenance; avoid any metal

fragment or other substances get access in the internal chamber.

• No disassembly or modification allowed.

2. Construction Safety

• The protective regulations on construction spot shall be

followed strictly.

• Measurement shall be carried out immediately when any security

risks found to eliminate the risks, stop construction if necessary.

• All kinds of safety facilities shall be inspected, calibrated or

repaired in the event of severe weather.

• The ice, fog, rain and snow shall be removed before opening.

• Alert area shall be set and a person shall protect the area

when protective casing and other safety facilities are

constructed or dismantled.

• Work high above the ground may require in installation of this

product, the operating personnel shall be qualified.

3. Power supply requirements

• Local electrical safety standard shall be followed in installation

and service of this product.

• Convenient de-energizing device shall be adopted for

immergence cutting off.

• Check if the power supply is suitable for operation before start.

• Protect the power cable from trample or compressing,

especially for the plug, socket and joint out from devices.

• Explosion-proof measurement is necessary for Ex products.

4. Service condition requirements

• Please do not focus the camera to hard light (such as lamp or

sunlight), which will cause too bright of the image, it will not

malfunction but it will affect the operational life of the CCD

(or CMOS).

• Transport, operate and store this product in applicable

temperature and humidity range. Do not locate it in wet,

overheated (over +60°C), extreme cold (less than -30°C)

environment or area with strong electromagnetic radiation or

power lighting conditions.

• The product shall be protected from any entry of water

or other conductive fluid, which may damage the internal

electrical element.

• Avoid overheated, the product shall be well ventilated.

• Avoid damage caused by compressing or violent vibration in

transmission, storage or operation.

• The product shall be well packaged as new product or

equivalent in transmission.

• We suggest using this product with Surge Protection Devices.

• Internal and external grounding shall be reliable.

5. Operation & maintenance requirements

• Do not dismantle this product; there is no user serviceable

part inside.

• Do not touch the CCD (or COMS) directly; a proper way

is to blow away the dust with a blower on the lens. If it is

necessary to clean it, use soft cloth with a little alcohol to

wipe the lens gently. Replace the cover when not use to

protect the CCD (or COMS).

• Soft, dry cloth can be used for camera body cleaning. For dirt

not easy to clean, some neutral detergent can be used, clear

the dirt away then dry the camera body. Corrosive agent,

abrasive cleaner can not be used for camera cleaning; they may

damage the surface or even degree the service performance.

• This product shall be installed and repaired by authorized

personnel, please do not dismantle or repair it by yourself. Only

manufacturer indicated components / accessories can be used

when replacement is necessary.

• The CCD (or COMS) may damage by laser beam, it’s better to

avoid the camera suffering radiation of laser beam.

6. Environmental protection

• For components of the products made by our company may

pollute the environment, such as PCB, electrical elements,

plastic and lubricant, collection and control measurement

shall be taken in maintenance and scrapping of the products.

These pollution sources shall be delivered to the government

for further treatment, no casually discard allowed, avoid any

adversative effect to the environment.

Special announcement

• Some pictures in this manual is a diagram for reference only,

if the picture does not match with the real product, the real

product is the standard.

• Cooper Yuhua remains the right to modify the content and

technical specifications of the product in this Instruction Manual

without any form of notification when the product updates,

there may exist little differences after updating.

• You can get the latest software and description document by

consulting the customer service department.

• Any problem in operation of this product, please contact the

distributor or customer service department.

• We always try to make this instruction manual as perfect as

we can, but there still may be some de-tolerance between the

real data and the data we provide, if you have any questions or

disputes, please refer to our company for finally explanation.

• The operator or user shall be responsible for damages or

losses caused by misuse or operations do not comply with

this manual.