EBOX 1.6 User manual

OWNER’S MANUAL

Please read and understand this manual fully before use.

Note: The manual illustrations are for demonstration purposes only.

Illustrations may not reect the exact appearance of the product.

Specication subject to change without notice.

OFF ROAD USE ONLY

DO NOT OPERATE THIS VEHICLE IF

YOU ARE UNDER THE AGE OF 13

INTRODUCTION

Thank you for purchasing an EBOX.

The proper care and maintenance that your vehicle requires is outlined in

this manual. Following these instructions will ensure the long and

trouble-free operating life of your bike.

This owner’s manual corresponds to the latest version of this vehicle at

the time of printing. Slight deviations resulting from continuing

development and design cannot be completely excluded. All

specications are non-binding and we reserve the right to modify or

delete technical specication, parts, design, etc without prior notice.

SAFETY WARNINGS

This vehicle is NOT A TOY and should ONLY be used o road and away

from public roads.

Never let children under the age of 13 operate this vehicle.

Adult supervision is required if children are under the age of 16.

WARNING:

Riding the EBOX can be a hazardous activity. Certain conditions may

cause the equipment to fail without fault of the manufacturer. Like other

vehicles, the EBOX can, and is, intended to move. It is therefore

possible to lose control, fall and/or get into dangerous situations that no

amount of care, instruction or expertise can eliminate. If this situation

occurs you can be seriously injured or die, even when using safety

equipment and other precautions.

RIDE AT YOUR OWN RISK AND USE COMMON SENSE.

This manual contains many warnings and cautions concerning the

consequences of failing to maintain, inspect or properly use your EBOX.

Any incident can result in serious injury or even death, therefore we do

not repeat the warning of possible serious injury or death each time such

a possibility is mentioned.

APPROPRIATE RIDER USE AND PARENTAL SUPERVISION

This manual contains important safety information and use tips to help

you and your child operate and handle the EBOX. Carefully read the

manual in its entirety together with your child before letting them ride for

the rst time. The manual also contains important information on

servicing the vehicle.

It is your responsibility to review this manual and make sure that all riders

understand the warnings, cautions, instructions and safety topics. Also

please ensure that the riders are able to safely and responsibly use this

product and protect your child from injury. We recommend that you

periodically review and reinforce the information in this manual with the

rider and that you inspect and maintain the vehicle to ensure its safety.

The recommended rider age of 13 is only an estimate and can be

eected by the rider’s size, weight or skills. Any rider unable to t

comfortably on this vehicle should not attempt to ride it.

It is important and necessary to conduct the relevant technical training

with your child before rst use. To obtain the training information, please

contact the dealer who you purchased the vehicle from. Do not let your

child use this vehicle before they have completed this training.

Children often underestimate or fail to recognize dangerous situations.

You should make it clear to your child that they should not, under any

circumstances, operate the vehicle without supervision and that your

child may only drive at speeds that are suited with the child’s riding

ability and other terrain conditions.

A parent’s decision to allow his or her child to ride this vehicle should be

based on the child’s maturity, skill and ability to follow rules.

Keep this product away from small children, younger than 13 and

remember that this product is intended for use only by people who are at

a minimum, completely comfortable and competent while operating the

vehicle.

Do not exceed 85kgs (187lbs) total weight on this vehicle. The rider

weight does not necessarily mean a person’s size is appropriate to t or

maintain control of this vehicle.

Do not touch the brakes or motor on your bike when in use as they can

become very hot.

The rider and/ or parent assumes all risk associated with riding activities.

Maintain grip of the handlebars at all times.

Never carry passengers or allow more than one person at a time to ride

the vehicle.

Never use near steps or swimming pools.

Keep your ngers and other body parts away from the drive chain,

steering system, wheels and all other moving components.

Never use headphones or a mobile phone when riding.

Never hitch a ride with another vehicle.

Do not ride the vehicle in wet or icy weather and never immerse the

vehicle in water, as the electrical and drive components could be

damaged or create other unsafe conditions.

The vehicle is intended for use on at level ground without loose debris

such as rocks or gravel. Wet, slick, bumpy, uneven or rough surfaces

may impair traction and contribute to accidents. Do not ride the vehicle

in mud, ice, puddles or water. Avoid excessive speed that can be

associated with downhill rides.

Never risk damaging surfaces such as a carpet or ooring by using the

vehicle indoors.

Do not ride at night or when visibility is limited.

ACCEPTABLE RIDING PRACTICES AND CONDITIONS

Always check and obey any local laws or regulations which may aect

the locations where you intend to use the vehicle.

Ride defensively. Watch out for potential hazards that could catch your

heel or force you to swerve suddenly or lose control.

Be careful to avoid pedestrians, skaters, skateboards, scooters, bikes,

children or animals who may enter your path, and respect the rights and

property of others.

The EBOX is meant to only be used in controlled environments free of

potential trac hazards and not on public streets or roads. Do not ride

your vehicle in any areas where pedestrians or trac are present.

Do not activate the throttle unless you are on the vehicle and in a safe,

outdoor environment suitable for riding.

The EBOX was manufactured for performance and durability but is not

impervious to damage. Jumping or other aggressive riding can

stress and damage any product, including this vehicle and the rider

assumes all risks associated with high-stress activities. Be careful and

know your limitations. Risk of injury increases as the degree of riding

diculty increases.

PROPER RIDING ATTIRE

Always wear appropriate safety equipment such as an approved

safety helmet, elbow and knee pads. A helmet may be legally required by

local law or regulation in your area. A long-sleeved shirt, long pants and

gloves are recommended. Always wear motorcycle boots, never ride

barefooted or in sandals,

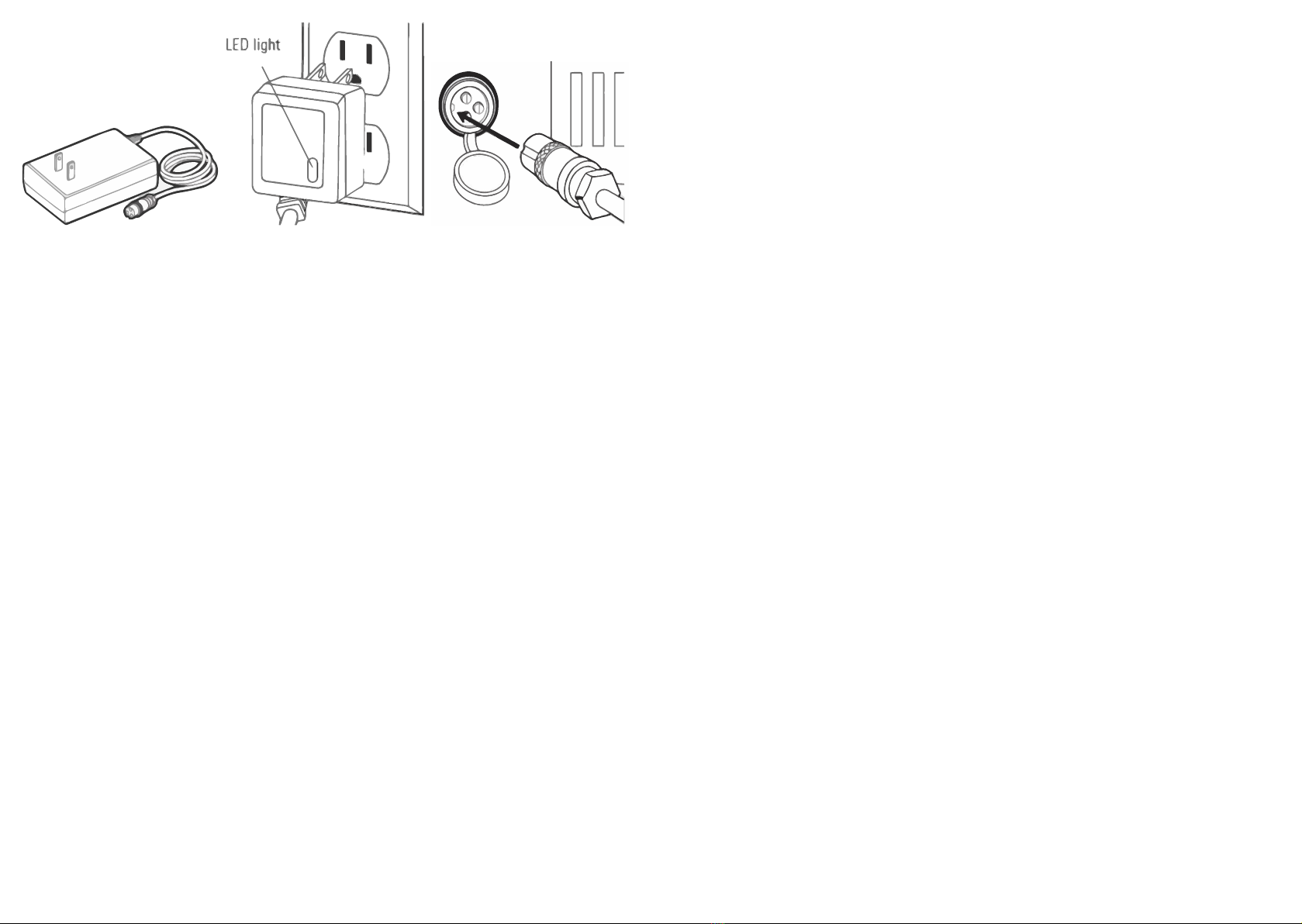

USING THE CHARGER

The charger supplied with the vehicle should be regularly examined for

damage to the cord, plug, enclosure and other parts. In the event of

such damage, the bike must not be charged until the charger has been

repaired or replaced.

Use only with the recommended charger. e.g.

• 48V lithium battery charger with label: 54.6V

• 60V lithium battery charger with label: 67.2V

Use caution when charging.

The charger is not a toy and should be operated by an adult.

Do not use the charger near ammable materials.

Unplug the charger and disconnect from the bike when not in use.

Always disconnect the charger prior to wiping down and cleaning the

vehicle with liquid.

FAILURE TO USE COMMON SENSE AND HEED THE ABOVE

WARNINGS INCREASES RISK OF SERIOUS INJURY. USE WITH

APPROPRIATE CAUTION AND SERIOUS ATTENTION TO SAFE

OPERATION.

LOCATION OF WARNING STICKER

VIN Location

The VIN is stamped on an aluminium plate

that is riveted to the steering column.

VIN means the Vehicle Identify Number

which is unique for each EBOX.

Hand Drive Controls

1. Front brake lever

2. Rear brake lever

3. Key switch

4. Battery indicator

5. Safety ON/OFF switch

6. Throttle

ATTENTION: BATTERY STATE!

STOP USE and charge the battery once the indicator shows 10%

BEFORE YOU BEGIN

Open the box and inspect the contents

for any scratches, dents or cable kinks

that may have occurred during shipping.

Your EBOX was 85 percent assembled

and packed at the factory, so there

should not be any problems, even if your

box has a few scratches or dents from

shipping.

However, if you do nd an issue, please

report it immediately via our contact

form which can be reached here:

Http://www.stomp-group.com

Remove the bike and place on a suitable assembly stand, ensuring the

bike is secure and will not tip over.

Remove all protective packaging taking care not to cut any cables or

components if using a sharp blade. DO NOT remove the graphics’

protective lm until the bike is fully assembled to avoid any accidental

damage. DO NOT cut the zip ties that group the control cables together.

Remove all loose items such as the front wheel, number board, front

mud guard and accessory box.

Check that all components are present and nothing appears to have

been damaged or missing from transit.

Place these items in a safe place to avoid any accidental damage.

Discard all packaging along with the cardboard box via the appropriate

recycling stations.

You are now ready to begin assembling your bike.

MAKE SURE THE KEY SWITCH IS TURNED “OFF”.

Estimated Assembly and Set-Up Time

We recommend assembly by an adult with experience in motorbike

mechanics.

• Allow up to 30-40 minutes for assembly.

• Allow up to 1 hour to conduct a full PDI after assembly (PDI

instruction can be found at the back of this manual).

• Allow up to 7-9 hours for initial charge depending on the model.

1. Rear shock

2. Crossbar pad

3. Assembly bolts, fuse, handle bar clamps

4. Crossbar pad graphics

5. Tool kit

6. Charger lead

7. Charger

The list of tools required is as follows:

- Wrench or Socket

8mm / 13 mm / 14mm / 15mm / 17mm

- Allen key

5mm / 6mm

ASSEMBLY ILLUSTRATION AND INSTRUCTION

Handlebar Assembly

Caution: Failure to properly adjust and tighten the bolts that afx the

handlebars can cause you to loose control and crash.

1. Place the handlebar in

the bottom clamp, then

install the top clamp

section and 4 retaining

bolts, do not fully tighten

at this point.

Front Mud Guard

Mount the front mud guard to the fork lower stantions and secure with

the 3 provided bolts.

The mud guard has 2 sets of mounting holes, you should use the

forward most set of holes (as seen in the above photo) to secure your

mudguard to the fork stantion. Tighten the guard down securely.

Number board

Remove the allen head bolt from

the fork mounting tab. This is

located on the upper fork stantion.

Locate the lower number board

dowels into the corresponding

mounts on the front mud guard.

3. Put the moulded foam barpad

over the clamps and secure into

place with the crossbar pad

graphics. This will loop around the

pad and secure with velcro

underneath.

2. Move the handlebar to a comfortable riding position, then tighten all 4

bolts securely with an allen key, making sure to tighten in a cross

formation to ensure even clamping pressure (See diagram).

Tools Required

Tools may be supplied; however, we recommend the use of

mechanic grade tools. Use the supplied tools only as a last resort.

As well as the bike, you will nd a small box with the below parts inside.

Front Wheel

1. Undo the retaining nut and remove the

axle from the forks. Be careful not to lose

either of the wheel washers.

2. Place the wheel between the forks

ensuring that the disc is situated between

the brake calliper pads.

3. Insert the axle through the left fork

dropout.

4. Slide the longer 28mm spacer onto the

axle between the wheel (disc side) and fork

leg.

5. Continue sliding the axle through the

wheel and right fork leg, making sure to

install the second shorter (24mm) spacer.

5. Secure the axle in place using the

nut we previously removed and tighten to

47Nm.

1.Start by removing the brace that

has been tted between the 2 shock

mounts to protect your Ebox during

shipping.

Rear Shock Absorber

3. Lift the frame allowing the shock

and swingarm to pivot. Align the lower

mounting hole with the corresponding

mount point on the swing arm.

2. Install the shock into the upper shock

mounting position. There are 2 upper

shock mounting points. Mounting in

either position A or B will eect the seat

height of your Ebox.

Secure the shock in the mounting point

and tighten down to 27Nm.

Then, using the bolt we

previously removed, secure the

number board to the fork

mounting tab and tighten down

securely. Keep the control cable

behind the number board to

secure them into position.

4. Use the bolt to secure the shock to

the swing arm mount and tighten the

nut to 27Nm using a wrench.

1. Remove the front right fairing. This

will allow easy access to the fuse holder.

To do so, remove the single allen bolt

and carefully slide the plastic to the rear

of the bike to unhook the plastic from

the retaining tab, being careful not to

damage anything.

2. Locate the fuse. This is in the bag of

accessories we put to one side earlier.

3. Disconnect the battery.

4. Carefully insert the fuse into the fuse

holder.

5. Reconnect the battery power supply.

6. Replace the fuse holder into the body

of the bike.

7. Re-install the side fairing, this is the

opposite process of removal.

CAUTION: There may be residual

charge in the power system causing

the fuse to ‘pop’ on installation. To

avoid this you should disconnect the

battery when installing the fuse.

Note: The tyres are inated when shipped but they invariably lose some

pressure between the point of manufacture and your purchase. Always

inate the tyres to the correct PSI before rst use.

We recommend 26psi for use on tarmacked surfaced and anywhere

between 20-30psi for o road use depending on conditions.

Use a bicycle-style pump to inate the tyre to the PSI indicated on the

sidewall.

Note: The pressurised air pumps found at petrol stations are designed

to inate high-volume car tyres. If you decide to use such an air pump to

inate your tyres, rst make sure the pressure gauge is working, then use

very short bursts to inate to the correct PSI. If you

inadvertently over-inate the tyre, release the excess pressure

immediately.

Important information for tyre use

Note: The tyre is the only contact between the vehicle and the road, the

safety of various driving activities depends on the small area contact

patch of the tyre with the road. Therefore, it is very important to keep the

tyre in good condition at all times and use the correct size and standard

tyre to replace worn items. These are available from your EBOX dealer.

Guide:

Tyre assembly and disassembly

It is strongly recommended that the tyre assembly and disassembly is

done by an authorised technician with the necessary skills.

Tyre pressure

It is very important to keep the tyre properly inated and check tyre

pressures before use. Inating should be done while the tyre is cold.

Tyre maintenance

Tyre tread depth should be checked regularly. (Shallower tread means

Inate The Tyres

Fuse

Rear Mud Guard

1. Locate the mounting plate and 2x M6 bolts for the rear mudguard.

2. Feed the bolts through the mounting plate, mud guard and then

tighten down to the bracket that is axed to the swingarm. This will

sandwich the guard in place.

of time the battery may reach a stage at which it will no longer hold a

charge.

WARNING: Rechargeable batteries are only to be charged under adult

supervision. Always disconnect your EBOX from the charger before

cleaning.

NOTE: EBOX chargers have built-in over charge protection. Chargers will

get warm during use, this is normal for some chargers and is no cause

for concern. If your charger does not get warm during use, it does not

mean that it is not working.

The charger has a small window with an LED to indicate the charge

status. A Red LED means the battery is charging and a Green LED

means that the battery is fully charged.

Be sure to properly align the keyway on the charger input port with the

corresponding socket on the vehicle and tighten snugly; otherwise,

your vehicle may not charge.

less grip). You must stop use of the vehicle if the tyre is punctured.

If your tyre is punctured remove the tyre and check it carefully

taking care not too injure yourself as there may be sharp objects

embedded in the tyre. Tyre maintenance should be done by an

authorised technician. If the tyre becomes distorted or damaged it

should be replaced immediately.

Tyre replacement

It is important to use the correct size and standard tyre as per the

specication (see details in technical specication sheet)

Do not use part worn/ used tyres if you are not sure of its previous

service condition.

Tyre aging

Tyre aging is unavoidable. Even if the tyre has never been used or just

used a few times. Tyre aging is mainly reected in visible cracking on the

sidewall of and tyre tread itself, sometimes the tyre can become

distorted as well.

Charging the Battery

Your EBOX may not have a fully charged battery upon purchase;

therefore it is essential to charge the battery prior to use.

- Initial charge time: 7-9 hours depending on level of depletion.

- Run time: up to 45 minutes of continuous ride time at MAX speed; run

time may vary depending on riding conditions.

- Average battery life: 250-500 charge/discharge cycles depending on

which type of battery. To ensure long battery life, do not store the batter-

ies in temperature above 40℃ or below 0℃.

- Recharge time: Always remember to turn the EBOX power switch o

and recharge for at least 7-9 hours after each use depending on the

model. When the vehicle is not in regular use, recharge the battery at

least once a month until normal use is resumed. If you have left the

power switch on or your product has not been charged for a long period

Warning: Failure to recharge the battery at least once a month may

result in a battery that will no longer hold a charge.

SAFETY REMINDERS

PRE-RIDE CHECKLIST

Loose Parts

Check and secure all fasteners before every ride. You should make sure

that the handlebar riser clamp bolts are adequately tightened. There

should be no unusual rattles or sounds from loose parts or broken

components. If you are not sure, ask an experienced mechanic to check

the bike over for you.

Brakes

Check the brakes for proper function. When you squeeze the lever, the

brake should provide positive braking action and lock up the wheel while

stationary.

Frame, Fork and Handlebars

Check for cracks or broken connections. Although broken frames are

rare, it is possible for an aggressive rider to cause damage to their frame

from a cash or hard impact. Get in the habit of inspecting yours regularly

to avoid accidents.

Tyre Ination

Periodically inspect the tyres for excess wear, regularly check the tyre

pressure and re-inate as necessary. If you get a at tyre, the inner tube

can be patched or a new tube can be purchased from an EBOX

authorised dealer.

Safety Gear

Always wear proper protective equipment such as an approved

safety helmet, elbow and knee pads. Always wear motorcycle boots,

never ride barefoot or in sandals. Keep and loose objects away from the

wheels, motor and the drive system.

Starting The Bike

Always take care when starting the bike as it is very powerful, with

adjustable motor response and speed limiter. Always check these

settings before starting the bike.

Note: Make sure the power

is turned OFF when unit is

not in use. If the

power switch is left on for

an extended period of time,

the battery may reach a

stage at which it will no

longer hold a charge.

Plug the charger into a wall

outlet. If the lights on the

charger do not light up,

check the power to the

outlet. If necessary, try a

dierent outlet.

Turn the power OFF before

charging. Plug the

charger into the charger port

to charge your EBOX. Then

turn the power back ON.

ATTENTION

We recommend re-checking all parts after the rst ride to ensure they are

still correctly tightened and have not come loose. We

recommend special attention be paid to the following parts:

- Foot pegs

- Motor sprockets

- Shock absorber

- Motor bolts and nuts

- Rear sprocket

- Wheels

- Chain Tension

- Brakes and Callipers

TECHNICAL SPECIFICATION SHEET

MODEL EBOX 1.6 EBOX 2.0

MOTOR 48V 1600W - BLDC motor 60V 2000W - BLDC Motor

MAX SPEED 30mph 33mph

FINAL DRIVE 10t/ 70t, chain 219H

CONTROLLER

OUTPUT

42A 45A

BATTERY 48V/ 15.6Ah lithium 60V 18.2Ah lithium

CHARGER 110-240v/ 54.6V 2A 110-240V, 67.2V 2A

CHARGE TIME 7-8hrs

RANGE PER CHARGE 17-19miles 20-23miles

FRAME High tensile steel double cradle tube frame, powder coated

SUBFRAME Removable

HANDLEBAR Aluminium Ø 22mm

FRONT SUSPENSION Upside-down forks, Φ39x Φ41, 550mm

REAR SUSPENSION Mono shock 270mm

BRAKE SYSTEM Hydraulic brake

DISC BRAKE F/R Ø 180mm

FRONT/REAR RIM 1.4 x 12”, 1.6 x 10” 1.4 x 14”, 1.85 x 12”

FRONT/REAR TYRE 2.75 x 12”, 3.0 x 10” 60/100 x 14”, 80/100 x 12”

WHEELBASE 940mm 955mm

GROUND

CLEARANCE

235mm 255mm

SEAT HEIGHT 630mm 660mm

MAX LOAD 85kg

N.W/ G.W 40.5kg/ 50kg 42.5kg/ 52kg

BIKE DIMENSIONS 1330 x 645 x 850mm 1400 x 645 x 890mm

PACKING SIZE 1220 x 380 x 640mm 1250 x 380 x 640mm

The motor controller is located within

the frame of the bike between the

battery and rear shock.

Response

This controls the throttle response of

the bike. Turn the adjustment knob

clockwise to increase and

anti-clockwise to decrease.

Attention, we recommend tuning

the response to its lowest setting

when children and new users are

riding the bike.

Speed

Turning the dial clockwise will

increase the top speed of the bike,

anti-clockwise will lower it.

Motor

controller

location

REPAIR AND MAINTENANCE

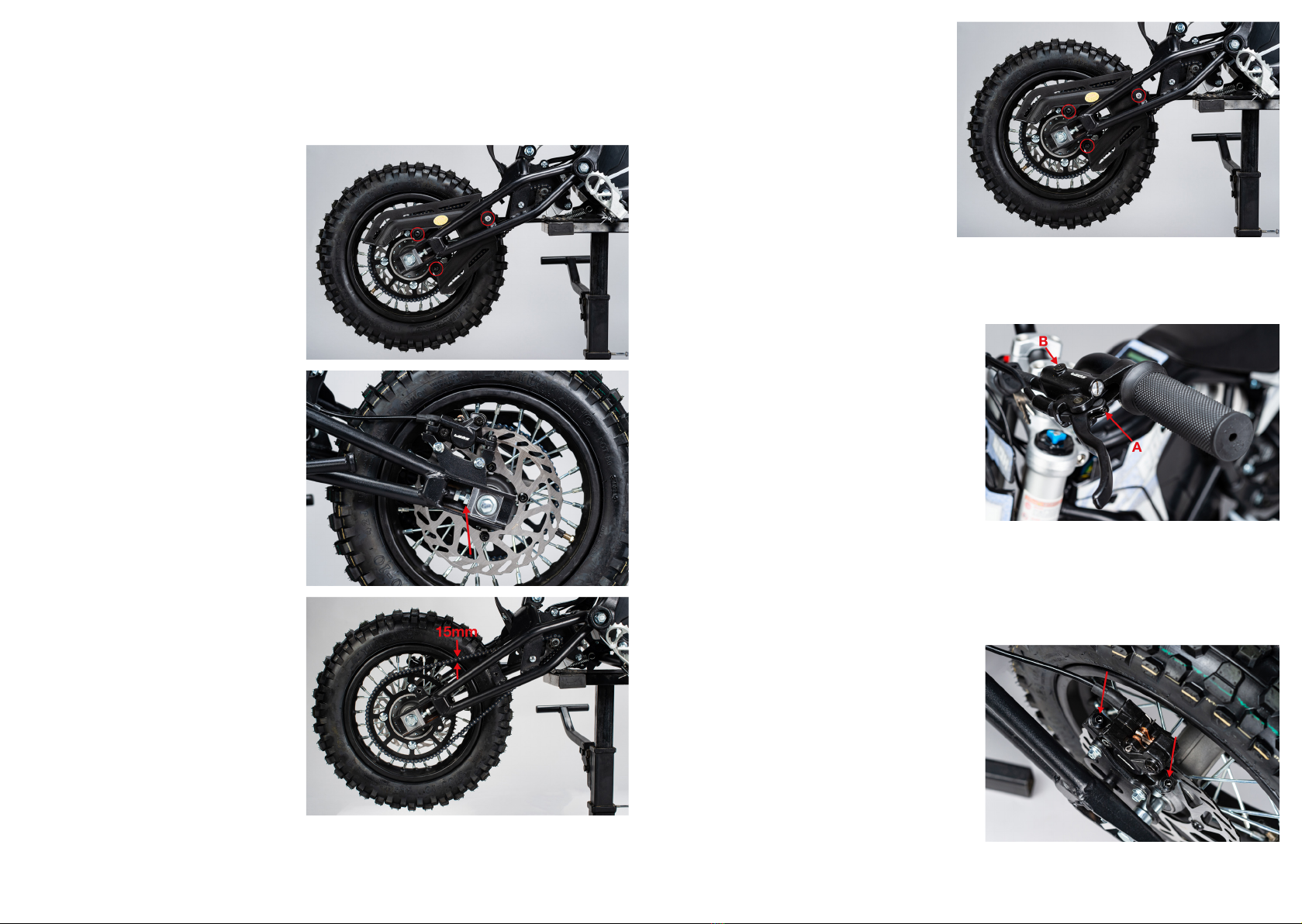

Chain Adjustment

Checking the drive chain periodically will ensure longer chain life.

Always keep it lubricated and tighten the chain correctly as follows:

Step 1

Loosen the 3 bolts used to hold

the chain cover in place. Once

undone, remove the chain cover

by sliding it around the swing

arm.

Step 2

Loosen the rear axle using a 17

and 14mm socket, you do not

need to remove it completely.

Undo the chain tensioner lock

nuts.

Step 3

Adjust the position of the rear

wheel and re-tighten the axle.

Check that your chain is

correctly tensioned, 15mm

movement up and down from

centre, then tighten your

adjuster lock nuts to the swing

arm and alloy block and torque

your axle to secure.

Make sure that your wheel is

centrally positioned within the

swing arm.

Step 4

Ret the chain cover and tighten

the bolts to secure.

Tuning Your Brake

Step 1

Brake bite point is adjustable on the

EBOX. To adjust the bite point, wind

in/out screw A. This will enable you

to ne tune how soon your pads

start to contact the brake disc.

If your brakes start to feel soft or

stop working, they may need to be

bled. This can be done by using

screw B. It is recommended that

this process is completed by a

competent mechanic who is trained

in bleeding hydraulic brake systems.

Step 2

To make sure your brake is

performing optimally you may need

to adjust your calliper position.

Loosen the 2x 5mm allen bolts that

hold the calliper to the bracket. Pull

the brake lever, this will centre the

brake to the disc.

Re-tighten the calliper bolts, while

keeping the lever depressed. Check

that the wheel spins freely with no

interference of pad and disc. If there

is interference repeat the process.

Pad Wear

You should regularly check the condition of your

brake pads and inspect for excessive wear. The

thickness of the braking material on the lead and

trailing edge of the four pads should never be

less than 1mm. Should the material be thinner,

immediately replace the brake pads.

We recommend having the brake pads replaced by an authorised dealer.

Warning:

The brake is capable of causing the bike to lock the rear wheel and

skid, potentially throwing an unsuspecting rider. Practice in an open

area free from obstacles until you are familiar with the brake

performance. Avoid skidding to stop as this can cause you to loose

control or damage the rear tyre.

Testing the Brakes

To use the brake, squeeze the lever to increase the pressure on the

brake. If your brake is not engaging properly, follow instructions for

adjusting the brakes.

Chain and Sprocket

The chain will typically have a “loose spot” and “tight spot”

corresponding with a particular sprocket rotational position. This is

normal and common to all chain-driven products due to run-out

tolerance of the free wheel and sprocket. It is possible to minimise these

loose/ tight spots in the chain by centering the rear sprocket to the hub.

This can be done by loosening the sprocket bolts, spinning the wheel

a number of rotations then correctly re-torquing the bolts. The chain

should then be adjusted to the ideal tension with the chain in the

tightest spot.

Proper chain alignment must be maintained. The wheel must not be

skewed, if the chain is noisy or rough running, check the lubrication,

tension and alignment of sprockets, in that order.

Warning:

To avoid a pinch or injury, keep ngers away from moving sprockets

and chain.

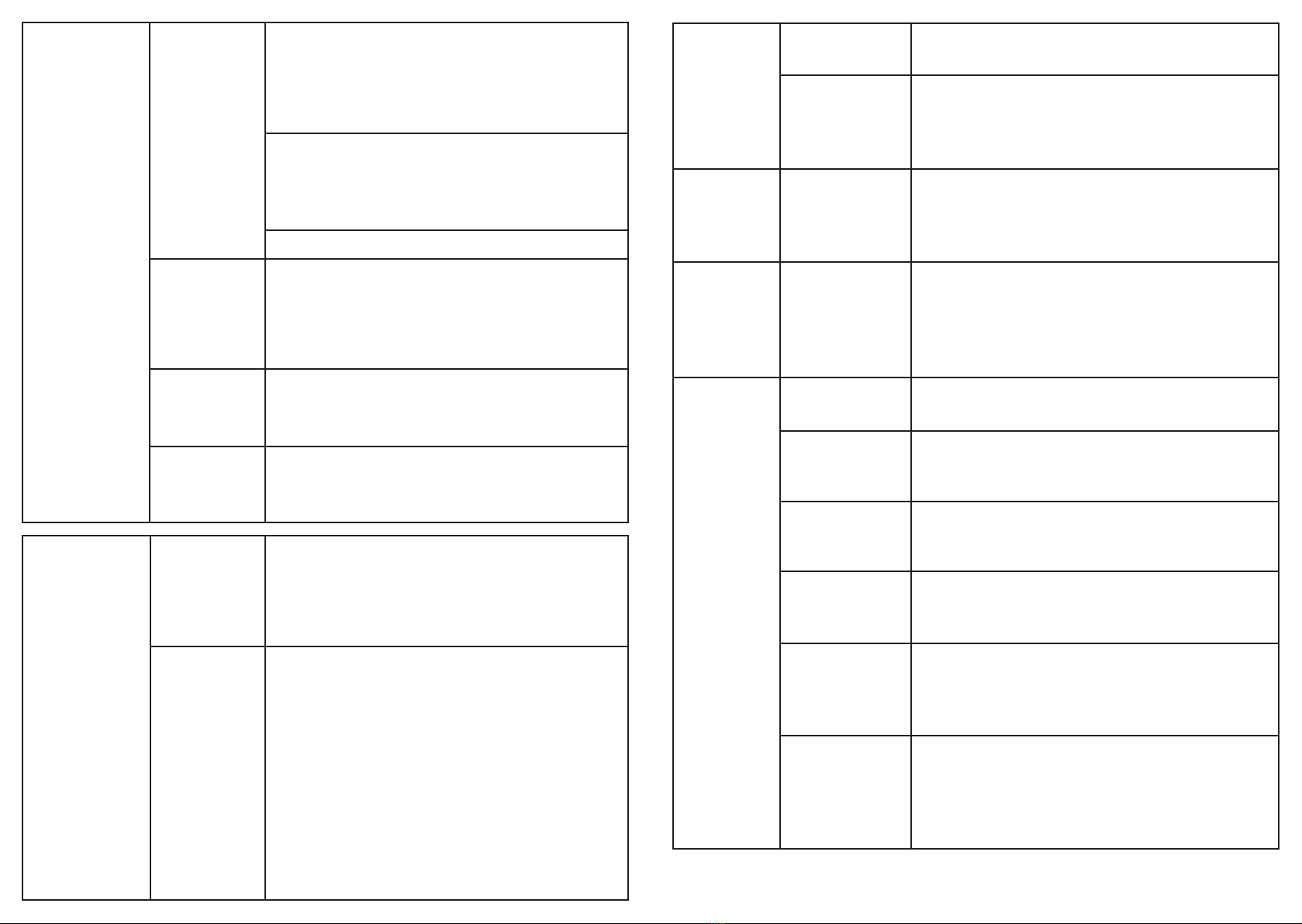

Problem Possible cause Solution

Vehicle

does not

run

Undercharged

battery

Charge the battery. A new battery should

have been charged for at least 7-9 hours

before using the vehicle for the rst time

depending on the model, and up to 8 hours

after each subsequent use.

Check all connectors. Make sure the charger

connector is tightly plugged into the charging

port, and that the charger is plugged into the

wall.

Make sure power ow to wall outlet is on.

Charger is not

working

Check to see if your charger is working by

using a volt meter or asking the authorised

service centre to test your charger for you.

Fuse Check the fuse has not burnt out and replace

as necessary.

Vehicle was

running but

suddenly

stopped

Loose wires or

connectors

Check all wires and connectors to make sure

they are tight.

Burnt Fuse The fuse will burn out and automatically shut

o the power if the motor is overloaded.

An excessive overload could cause the

motor to overheat. Refer to replacing the fuse

section of this manual. Correct the conditions

that caused the fuse to burn out and avoid

repeatedly burning out fuse.

Motor or

electrical switch

damage.

Contact your authorised service centre for

diagnosis and repair.

Speed

controller

damaged

Contact your authorised service centre for

diagnosis and repair.

Trouble shooting guide

1mm

Short run time

less than 15

minutes per

charge

Under-

charged

battery

Charge the battery. A new battery should

have been charged for at least 7-9 hours

before using the vehicle for the rst time

depending on the models, and up to 8 hours

after each subsequent use.

Check all wires and connectors. Make sure

the battery connector is tightly plugged into

the charger connector, and that the charger is

plugged into the wall.

Make sure the wall outlet is turned on.

Battery is old

and will not

accept full

charge.

Even with proper care, a rechargeable battery

does not last forever. Average battery life is 1

to 2 years depending on vehicle use and

conditions. Replace only with a genuine

EBOX replacement battery.

Brakes are

not adjusted

properly

Refer to brake adjustment instructions.

Faulty battey

charger

Check the charger is outputting the correct

voltage. If it is not, contact your dealer to

source a replacement.

Vehicle runs

Sluggishly

Tyres are

not properly

Inated.

The tyres are inated when shipped, but they

invariably will lose some pressure Between

the point of manufacturing and your

purchase. Refer to tyre instructions to

properly inate tyres.

Vehicle is

overloaded.

Make sure you do not overload the vehicle by

allowing more than one rider at one time,

exceeding the maximum weight limit, going

up too steep a hill or towing objects behind

the vehicle. If the vehicle is overheated, the

temperature circuit protector will slow the

motor down and if the condition continues,

will shut o power to the motor. Correct the

driving conditions that caused the

overheating, wait 5-10 minutes and then

resume riding. Avoid repeatedly overheating

the unit.

Sometimes

the vehicle

doesn’t run,

but other

times it

does.

Loose wires or

connectors

Check all wires around the motors and all

connectors to make sure they are tight.

Motor or

electrical

switch

damage.

Contact the authorized service centre for

diagnosis and repair.

Charger

gets warm

during use

Normal

response to

charger use

No action required. This is normal for some

chargers and is no cause for concern. If your

charger dose not get warm during use, it does

not mean that it is not working properly.

Vehicle

does not

stop when

applying the

brake.

Brakes are

not adjusted

properly

Refer to the brake adjustment instructions in

this manual to properly adjust brakes.

Vehicle

makes loud

noises or

grinding

sounds

Chain is too

dry

Apply a lubricant to the chain.

Worn chain /

Sprocket

Replace/ change the worn item. We

reccomend that this is done by an authorised

dealer.

Misaligned rear

wheel

Check the alignment of your rear wheel. If it

is out of line then re-centre using the guide

found earlier in this manual.

Brake pads

worn

Measure the matierial left on your pad. If it is

less than 1mm on the lead or trailing edge of

the pad then please replace them.

Wheel bearing

failed

If your wheel has side to side play then it is

likely that the rear wheel bearings have failed.

These can be changed by your local

authorised dealer.

Motor bearings

failed

If there is movement in the motor’s drive shaft

then the motor bearings may have failed.

Please get in contact with your local

authorised dealer who will be able to source

replacement parts.

EBOX PDI

Please ensure you complete a full PDI of your EBOX after initial assembly

to thoroughly check the safety of all components.

1. Starting at the rear of the bike, work your way to the front on both

sides checking that all nuts, bolts and screws are tight. Don’t assume

that because it is new from the factory that everything will be tight.

A drop of thread compound (non-permanent type) is advised on the

threads of the brake calliper bolts, front sprocket drive bolt and motor

mounting bolts.

Check the following points on your EBOX to ensure that they are tight.

(This is not an extensive list and there may be others).

• Rear wheel axle nut

• Rear wheel spokes

• Chain adjuster lock nut

• Rear shock bolt and nut at the top and bottom of the shock

• Swing arm pivot bolt/ nut

• Rear brake caliper bolts

• Rear brake disc bolts

• Rear sprocket bolts

• Chainguard bolts and chain roller bolt

• Rear subframe bolts (where applicable)

• Motor mounting bolts/ nuts

• Front drive sprocket bolt

• Footrest bracket bolts (where applicable)

• Rear brake pedal bolt

• Side stand bolt/ nut

• Handlebar bolts

• Tighten head set bearing making sure to eliminate all freeplay

• Front fork pinch bolts

• Front mudguard bolts

• Steering head bolt

• Front wheel axle nut

• Front wheel spokes

• Front wheel axle clamp bolts (where tted)

• Front brake caliper bolts

• Front brake disc bolts

2. Checking the settings

2.1 Chain tension

With the bike’s rear wheel o the ground rotate the wheel and check the

run of the chain. The chain should run straight between both sprockets

with no major deviation left or right. Check the chain freeplay with a ruler.

It should have about 15 mm of slack up and down from the mid-position

(that’s a total of 30mm slack). Adjust if necessary.

2.2 Wheels

Check all spokes on the wheels are correctly tightened and the wheels

are true. Working from the valve round all spokes toghtening spokes 1/4

turn at a time (anti-clockwise) if needed .

Check the tyre pressures, setting them to 26psi. For o road use the

pressure can be anywhere between 20-30psi according to personal

preference.

2.3 Brakes

Check that both brakes are capable of locking the wheels when fully

applied and that they free o fully when released.

2.4 Suspension

While standing alongside the bike push on the handlebars to compress

the forks, checking to see if they run smoothly without any binding.

Compress the rear suspension several times. It should move up and

down freely without binding.

2.5 Battery

Always use the correct lithium charger provided, using the incorrect

charger will damage the battery and void your warranty.

For prolonged life and to avoid damaging the battery, it is recommended

that the battery is fully charged at least once a month.

Please read the owner’s manual before riding.

Never operate this vehicle if you are under the age of 13.

Never use this vehicle on public roads. OFF ROAD USE ONLY.

Never ride with a passenger.

Always use an approved helmet and protective gear.

Never use with drugs or alcohol.

Check tyre pressures when cold.

This manual suits for next models

1

Table of contents

Popular Motorcycle manuals by other brands

BMW Motorrad

BMW Motorrad R 1250 RT special vehicle 2018 Rider's manual

Baja motorsports

Baja motorsports SSR200 owner's manual

APRILIA

APRILIA MANA GT ABS - 2009 manual

Cobra Moto

Cobra Moto CX50 owner's manual

Yamaha

Yamaha X650 Assembly manual

Rekluse

Rekluse Core EXP 3.0 TorqDrive Installation & user guide