READ ME FIRST

Doc ID: 193-711A

Doc Revision: 021517

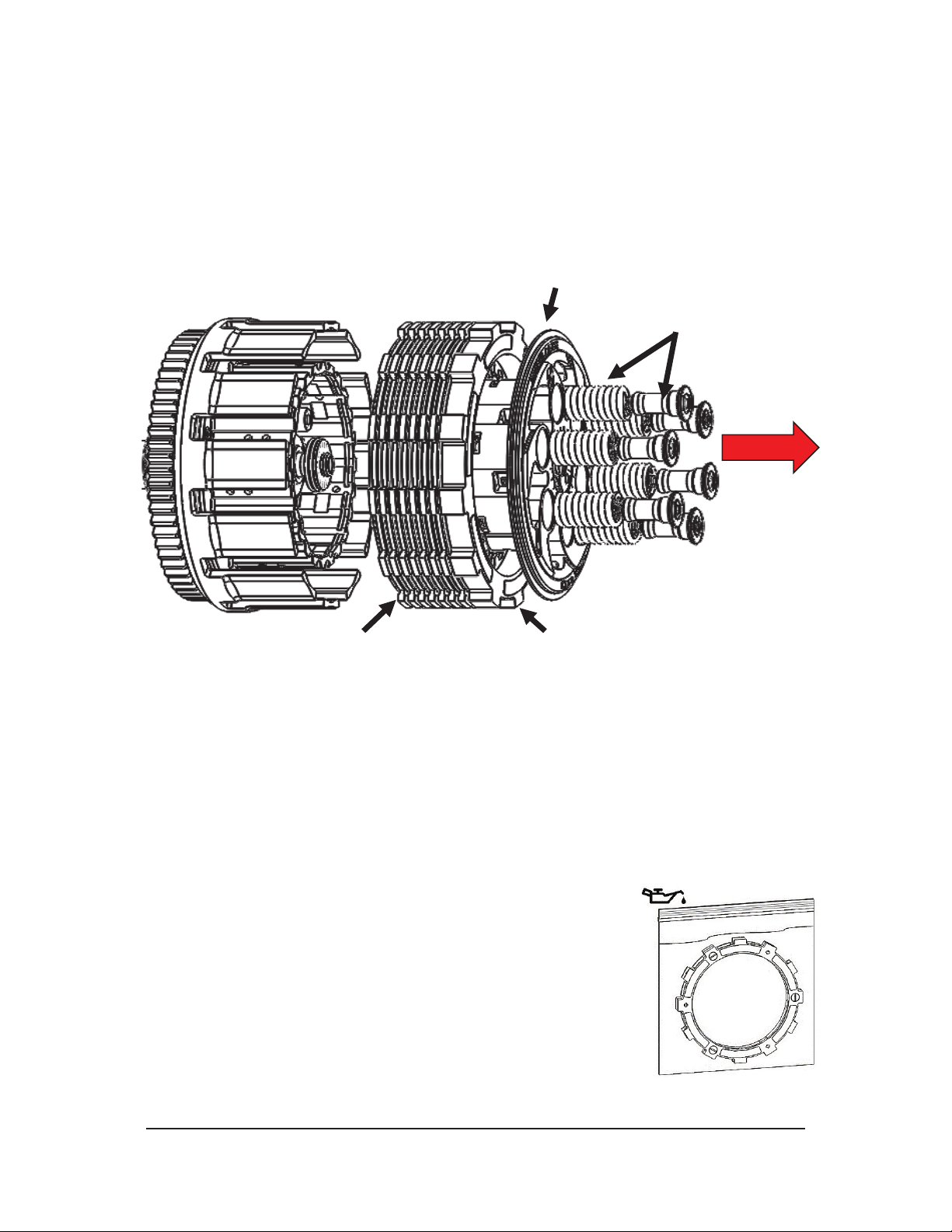

There are several crucial steps that must be understood and performed to ensure your Radius X clutch

will function properly. Failure to properly install, break-in and maintain your clutch components will

result in premature wear or failure.

New Friction Disk Break-In Procedure

Failure to follow the break-in procedure and oil filter inspection process could cause motor oil

delivery failure which can result in motor failure, serious injury, or death.

xDO NOT install a new set of friction disks and ride without following the break in procedure and

oil screen inspection process found in the installation manual.

oSoak new friction disks in oil

oInstall new friction disk and set the installed gap

oCheck and verify free play gain

oPerform the break-in procedure found in the installation manual

oFollow the oil filter inspection process found in the installation manual

Clutch Lever Optimization

xThere are some brands of bikes that ship with stock adjustable reach levers. It is important

when setting up any adjustable reach lever to adjust the lever position first, and then adjust Free

Play Gain second. If you were to do it the other way around, you could alter the FPG setting

while changing the reach of the lever, which could cause poor performance and early clutch

wear.

xRekluse offers an adjustable reach lever upgrade for most cable actuated models. This optional

upgrade provides the user with the ability to optimize the clutch lever position for your hand size

and personal preference. This will maximize lever feel for each individual.

xSee the lever optimization section in the manual for more details.

Checking Free Play Gain

Check free play gain at the start of each ride. Details on how to check free play can be found in your

installation manual.

xUnderstand how to properly check for free play gain

oDo not ride if you cannot verify free play gain

oClutch may seem to work fine but could be slipping excessively

xIf you cannot detect free play gain, reset the installed gap