EBS Ink-Jet Systems 1500 Series User manual

EBS

Ink Jet Systems

EBS 1500 series

USER'S MANUAL

In

k

-Jet technology for the future

EBS-1500 Series Printers User's Manual EBS

Ink Jet Systems

2 20060920#3.1

©2006 EBS Ink-Jet Systems GmbH, D-51588 Nümbrecht

EBS

Ink Jet Systems EBS-1500 Series Printers User's Manual

20060920#3.1 3

TABLE OF CONTENTS

1. GENERAL INFORMATION ..................................................................................7

1.1. ENVIRONMENTAL PROTECTION ............................................................................................7

1.2. APPLICATION .....................................................................................................................7

Short Description of the Printer:.............................................................................7

EBS-1500

Print Heads.................................................................................8

EBS-1500

General-purpose Controller........................................................9

1.3. PRINCIPLE OF OPERATION ................................................................................................10

Electromagnetic Print Heads................................................................................10

2. INSTALLING THE PRINTER..............................................................................11

2.1. SAFETY REQUIREMENTS ...................................................................................................11

2.2. POWER AND AIR SUPPLY REQUIREMENTS .........................................................................12

Power Supply.............................................................................................................................12

Air Supply...................................................................................................................................12

2.3. INSTALLING THE UNIT........................................................................................................12

2.3.1. Printer accessories ......................................................................................................12

2.3.2. Preparatory Steps ........................................................................................................13

2.3.3. Removing Transport Protections ...............................................................................14

2.3.4. Connections..................................................................................................................14

Earthed neutral system.........................................................................................15

Connecting the head ............................................................................................15

Connecting the photo detector.............................................................................15

Connecting the shaft-encoder ..............................................................................16

Connecting external data transfer devices...........................................................16

Connecting the Ink Monitor System - IMS............................................................16

Connecting the head to the ink and compressed air systems..............................16

Connecting the head to the pump-based ink system...........................................18

2.3.5. Installing a new Bottle of Ink (or Replacing an Empty One)....................................18

Connecting a new ink bottle (or replacing an ink bottle) in the compressor-

based system .......................................................................................................18

Connecting a new ink bottle (or replacing an ink bottle) in the ink system

with an ink pump...................................................................................................19

2.4. REMOVING THE HEAD COVER............................................................................................19

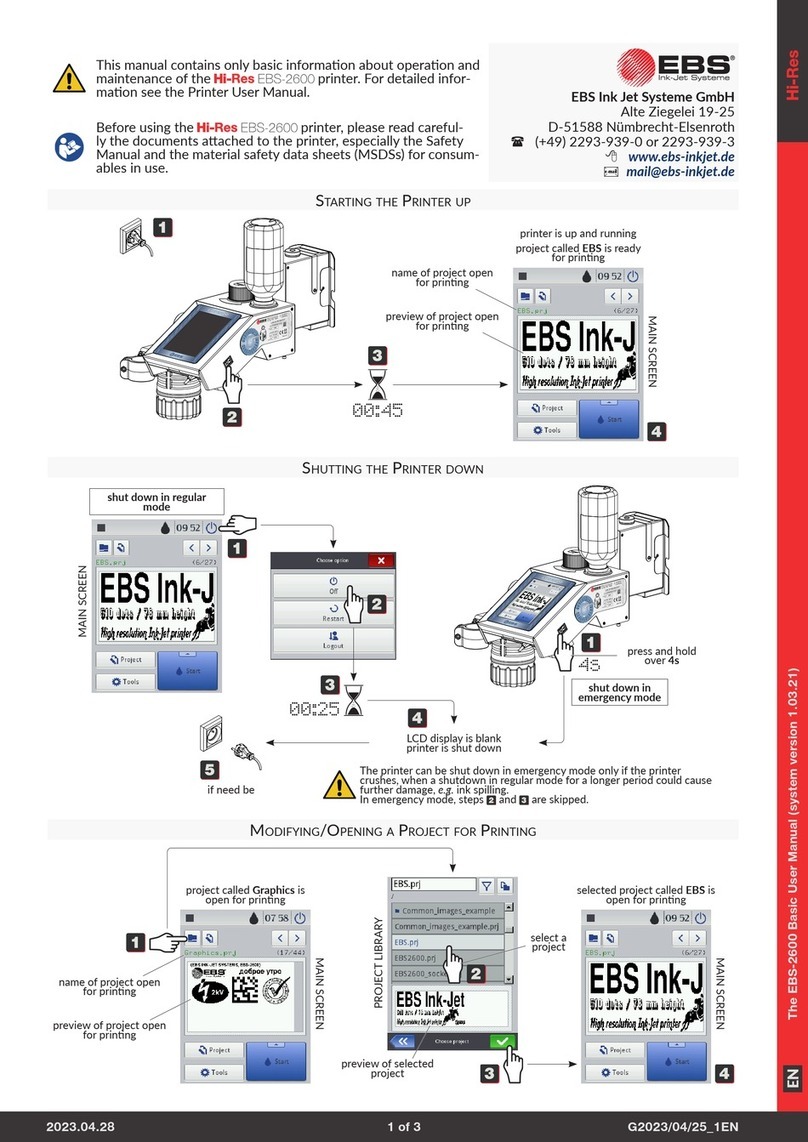

3. STARTING THE PRINTER.................................................................................20

3.1. SWITCHING THE PRINTER ON............................................................................................20

3.2. SWITCHING THE PRINTER OFF...........................................................................................20

4. OPERATING THE PRINTER..............................................................................21

4.1. OPERATION PANEL...........................................................................................................21

4.2. OPERATING THE PRINTER WITH CONTROL MENU..............................................................23

4.3. PRINT HEAD STATUS ........................................................................................................26

4.4. CONTROLLING THE PRINTER .............................................................................................27

4.4.1. Text Files.......................................................................................................................27

4.4.1.1. Introduction to Text Files .........................................................................................27

WORD PROCESSOR – A Description of Control Keys.......................................28

4.4.1.2. Opening and Editing a New File ..............................................................................29

Subfile type: TEKST – ASCII characters................................................................29

Subfile type: GRAPHICS..........................................................................................31

GRAPHIC PROCESSOR – A description of function keys..................................32

EBS-1500 Series Printers User's Manual EBS

Ink Jet Systems

4 20060920#3.1

Subfile type: BAR CODE .........................................................................................33

Subfile type: Text file Name .................................................................................34

4.4.1.3. Editing an Existing Subfile .......................................................................................35

4.4.1.4. Copying and Editing a Text file ................................................................................35

4.4.1.5. Deleting a Text file ...................................................................................................35

4.4.1.6. Deleting the File Library...........................................................................................36

4.4.1.7. Accessing the File Library........................................................................................36

4.4.1.8. Linking File Names with Parameter-block Names...................................................37

4.4.1.9. Using the Password.................................................................................................37

Defining a User Password....................................................................................37

Switching the Password Function On...................................................................38

Changing the User Password...............................................................................38

Deleting the user password..................................................................................38

4.4.1.10. Using Special Registers...........................................................................................39

Object Counters....................................................................................................39

Date and Time......................................................................................................40

Universal Counter.................................................................................................41

Universal Date and Time......................................................................................46

Expiry Date Registers...........................................................................................47

Data from Special Channel...................................................................................48

4.4.2. Using Print-parameter Blocks.....................................................................................48

4.4.2.1. Creating and Editing a New Parameter Block .........................................................49

Modifying Parameters...........................................................................................49

4.4.2.2. Editing Existing Blocks of Parameters.....................................................................50

4.4.2.3. Copying and Editing Blocks of Parameter ...............................................................50

4.4.2.4. Deleting a Block of Parameters ...............................................................................50

4.4.2.5. Deleting the Parameter-block Library ......................................................................50

4.4.2.6. Accessing the Parameter Block Library...................................................................51

4.4.3. Printing..........................................................................................................................52

4.4.3.1. Stopping the Printing ...............................................................................................52

4.4.3.2. Starting the Printing .................................................................................................52

4.4.3.3. Quick Stopping the Printing .....................................................................................53

4.4.3.4. Print Parameters......................................................................................................53

Modifying Print Parameters..................................................................................54

Vertical Direction ..................................................................................................55

Initial Distance......................................................................................................55

Number of Repetitions..........................................................................................55

Distance Between Overprints...............................................................................56

Horizontal Direction..............................................................................................56

Overprint Height ...................................................................................................57

Date Offset ...........................................................................................................58

Counter Increment................................................................................................58

Row Repetition.....................................................................................................58

Ink drop Intensity..................................................................................................59

Timing Mode.........................................................................................................59

Character Resolution............................................................................................59

Conveyor travel speed..........................................................................................60

Number of Pulses Generated by External Encoder.............................................60

Number of purging rows during the automatic nozzle-purge procedure..............60

Purge period during the automatic nozzle-purge procedure................................61

4.4.3.5. Saving Current Parameters in a Block ....................................................................61

4.4.3.6. Controlling Object Counters.....................................................................................62

Accessing object counters....................................................................................62

Modifying Object Counters...................................................................................62

4.4.3.7. Printing with the use of a code switch .....................................................................63

4.4.3.8. Viewing Files on the Terminal Display.....................................................................63

4.4.4. Servicing the Head.......................................................................................................64

4.4.4.1. Defining Some Print Parameters with the Conveyor Travel Speed.........................64

4.4.4.2. Other Commands ....................................................................................................64

4.4.5. Auxiliary Commands....................................................................................................65

EBS

Ink Jet Systems EBS-1500 Series Printers User's Manual

20060920#3.1 5

4.4.5.1. System information ..................................................................................................65

4.4.5.2. Accessing Alarm Messages.....................................................................................65

4.4.5.3. Setting Date and Time .............................................................................................65

4.4.5.4. Checking the Printer Run Hours ..............................................................................66

4.4.5.5. Choosing a Language..............................................................................................66

4.4.5.6. Releasing Protections..............................................................................................66

4.4.6. Replacing ink bottle .....................................................................................................68

General information..............................................................................................68

Replacing the bottle of ink....................................................................................69

4.4.6.1. Checking the validity date........................................................................................70

4.4.6.2. Checking the calculated ink consumption level .......................................................71

4.4.6.3. Accessing information in the Ink Monitoring System...............................................71

4.4.6.4. Problems that might arise in the printer operation when a bottle of ink is

replaced ...................................................................................................................72

Flow diagram for the ink monitoring system.........................................................72

4.5. ALARMS,ERRORS AND INDICATIONS .................................................................................73

4.5.1. Clearing Alarms............................................................................................................75

4.6. ADJUSTING THE PRINT RATE.............................................................................................75

4.6.1. Internal Generator ........................................................................................................75

4.6.2. Shaft-encoder ...............................................................................................................76

4.6.3. Defining the Maximum Print Rate for Various Fonts................................................78

5. EXAMPLES OF HOW TO OPERATE THE PRINTER .......................................79

5.1. HOW TO PRINT THE FIRST SAMPLE TEXT FILE? .................................................................79

5.2. CREATING AND PRINTING SAMPLE TEXT FILES ..................................................................81

5.2.1. How to Print the Current Date and Time?..................................................................81

5.2.2. How to Print Consecutive Numbers?.........................................................................82

5.2.3. How to Print Expiry Date? ...........................................................................................83

5.2.4. How to Print Logos? ....................................................................................................84

5.2.5. How to Print a Bar Code?............................................................................................85

5.2.6. How to Print a Complex Subfile?................................................................................85

6. SERVICING AND MAINTENANCE OF THE PRINTER .....................................88

6.1. ROUTINE MAINTENANCE ...................................................................................................88

6.2. REMOVING AIR FROM THE INK SYSTEM..............................................................................89

6.3. REPLACING THE INK FILTER ..............................................................................................89

6.4. WHEN PROBLEMS ARISE WHILE OPERATING OR SERVICING THE PRINTER ..........................89

The printer does not switch on................................................................................................89

No overprints are made after the print command has been accepted ................................90

Clogged nozzles in the head....................................................................................................90

Some dots are much smaller than others or are missing.....................................................91

Adjusting valve electromagnets in electromagnetic heads ..................................91

Overprints are distorted ...........................................................................................................93

Overprints made with the electromagnetic head look like printed in bold and

blurred ...........................................................................................................................95

Overprints are slanted ..............................................................................................................95

Lower (upper) parts of overprints are distorted.....................................................................96

Some vertical rows are missing in overprints........................................................................96

Overprints are not straight, they are wavy or jagged............................................................97

Mixed text names in the library – the battery is discharged.................................................97

6.5. HOW TO CONTACT YOUR SERVICE REPRESENTATIVE? ........................................................98

7. STORAGE AND TRANSPORTATION...............................................................99

7.1. STORING THE PRINTER .....................................................................................................99

7.2. TRANSPORTING THE PRINTER .........................................................................................100

EBS-1500 Series Printers User's Manual EBS

Ink Jet Systems

6 20060920#3.1

8. MULTI-HEAD INK-JET PRINTERS..................................................................101

9. TECHNICAL SPECIFICATIONS ......................................................................102

APPENDIX A - LAYOUT OF CYRILLIC CHARACTERS ON THE PRINTER

TERMINAL KEYPAD ...................................................................105

APPENDIX B - LAYOUT OF ARABIC CHARACTERS ON THE PRINTER

TERMINAL KEYPAD ...................................................................106

Index......................................................................................................................107

Dear User,

This Manual contains very useful information on how to operate your Ink-

Jet Printer. Please read this Manual carefully.

This version (3.1) of the document applies to EBS-1500 printers with a single electromagnetic

head and is the continuation of the operating instructions (version 20.8), which applied to

EBS-1500 printers with all head types, including multi-head systems. The document incorporates

most changes introduced to EBS printers in software versions from 16_1A to 21_0A and the

descriptions contained therein apply to the equipment where such software versions are installed.

As the machine and options can be customised, the product delivered to you depends on your

specific order. Therefore some descriptions or illustrations may differ slightly from your

equipment. As we need to keep pace with new technological advancement, we reserve the right

to introduce changes in the design and technical solutions adopted. In view of the above, no

data, illustrations or description shall make grounds for any claims. Should your printer be

equipped with options that are not described or illustrated in the Manual or should you have

additional queries after having read the Manual, please contact any EBS representative for more

information.

EBS

Ink Jet Systems

EBS-1500 Series Printers User's Manual

Paragraph 1 - General Information

20060920#3.1 7

1. General Information

NOTE:

There are warning and information signs on the right or left hand-side margins of some pages to

attract user’s attention to messages that are provided next to them. They are the following signs:

!

Information signs indicating:

•that the actions described should be taken carefully,

•additional, printer-specific option and features,

•untypical behaviour of the unit,

•other hints.

!

A warning not to take the action that might have a critical impact on the

proper operation of the unit. It requires the user to follow closely

instructions given therein.

The Manufacturer reserves the right to introduce changes whose description

may not be provided in this manual.

The Manufacturer shall not bear any responsibility for damages resulting from

the failure to follow the instructions or consequences of editorial or

publishing errors within the instructions.

1.1. Environmental protection

On withdrawing EBS-1500 printers and printing systems from use do not take

system elements out together with other waste. Pursuant to Directive No. 2002/96/EC of

the Council of the European Community on waste electrical or electronic equipment, the

elements of the EBS-1500 printers and printing systems must be separated from

other waste after they have been withdrawn from use and processed in an environmentally

friendly way.

1.2. Application

EBS-1500 is a family of industrial INK JET printers designed for labelling in a non-

contact way, various objects that move on a line conveyor, for example. The printer provides

clear and firm overprints on such materials as:

•paper and cardboard,

•(porous) plastics,

•fabric,

•leather and leatherette,

•wood and wood-like products,

•(porous) ceramic products,

•metal surfaces of any type, etc.

Short Description of the Printer:

Every EBS-1500 series printer consists of a general-purpose controller and

a print head.

!

EBS-1500 Series Printers User's Manual

Paragraph 1 - General Information EBS

Ink Jet Systems

8 20060920#3.1

EBS-1500

Print Heads

The print heads have the following traits:

´They are independent on the controller and therefore the heads can be installed closely

next to the object being labelled, which is not in an easily accessible place very often.

´They are connected with the controller via a 3 m long flexible cord as a standard (up to

30 m optionally).

1500/00 series electromagnetic heads, where the nozzle valve is controlled with an

electromagnet. One head can contain 5, 7, 12, 16, 25, 32 or 64 nozzles. A printer equipped

with such heads can produce 6 to 115 mm high overprints with one head.

´The electromagnetic head can be set at any position.

´Inks of various types and colours can be used according to the surface to be printed on.

Electromagnetic 7to 16-nozzle head

Electromagnetic 25 to 32-nozzle head

Electromagnetic 64-nozzle head

EBS

Ink Jet Systems

EBS-1500 Series Printers User's Manual

Paragraph 1 - General Information

20060920#3.1 9

EBS-1500

General-purpose Controller

The controller has the following traits:

´Separate controller types for electromagnetic or piezoceramic print head families.

´Splash-proof stainless steel INOX housing and a membrane keypad to ensure that the

controller is resistant to water and all types of solvent that might be used in the real

working environment.

´All connectors grouped on the same side wall to facilitate the installation of the printer in

a place where the space is very limited.

´Printing capabilities:

•texts composed of small and capital letters of various types, also printed in boldface

or rotated,

•several lines of text printed during a single run of an object in front of the print head

(a maximum of 6 lines with no space between the lines),

4

lines

(7x5)

5

lines

(5x5)

6

lines

(5x5)

•diacritical national characters,

•graphics – a built-in set of ready-to-use graphic signs and a tool-kit for creating

user-defined graphics,

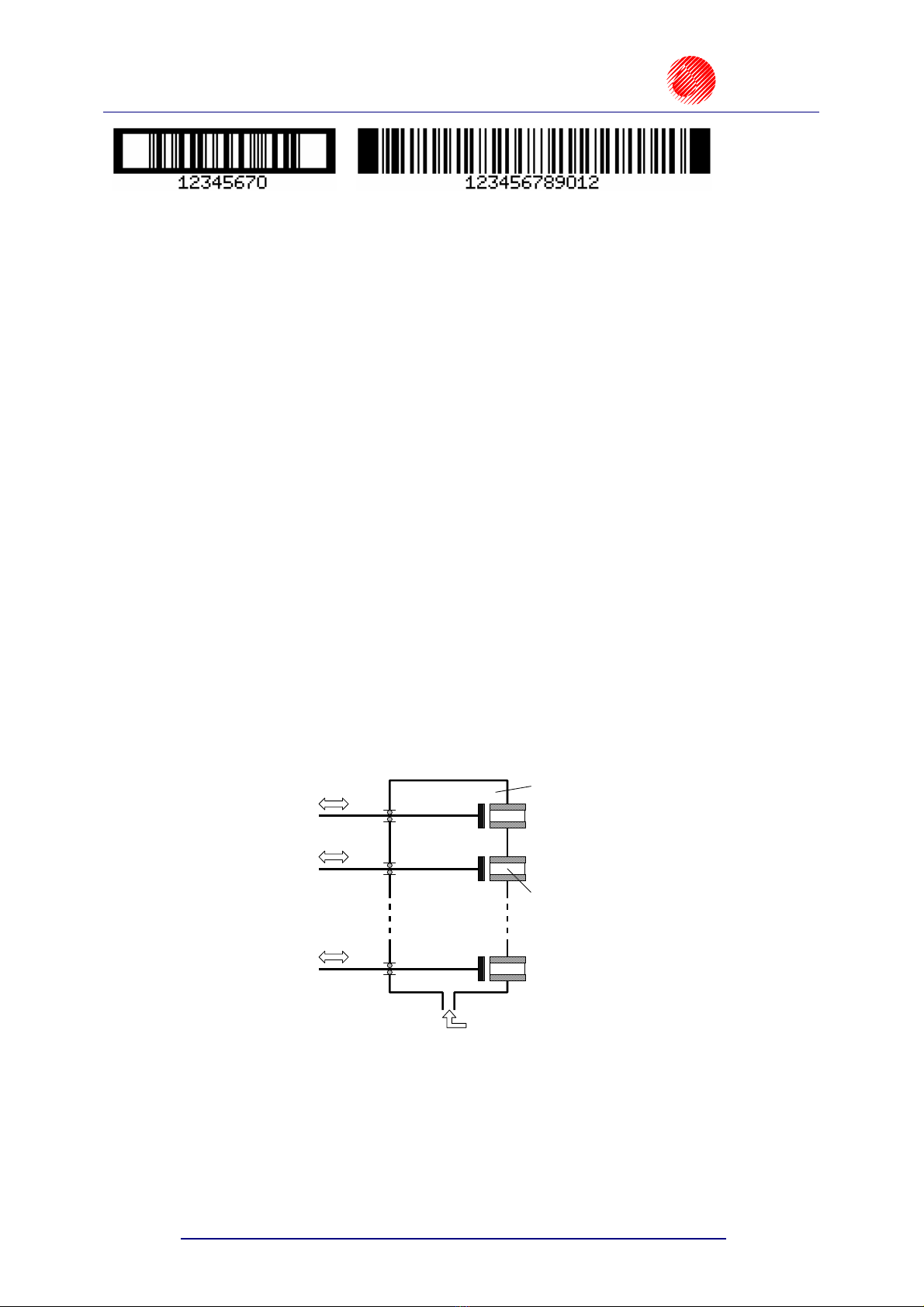

•bar codes of various kinds, printed in a regular way or in reverse, with or without

a caption of digits; an option of introducing on-going changes to the digital contents of

the code (bar code as an incremental or decremental counter)

EBS-1500 Series Printers User's Manual

Paragraph 1 - General Information EBS

Ink Jet Systems

10 20060920#3.1

•variable data - such as current date, warranty expiration date, current time, ascending

and descending numbering (counters), any types of data, which are transferred from

a PC or external devices (via an optional special channel), as required and arranged

by the user.

´Labels can be input or modified easily with the use of a built-in terminal or a PC (via

RS-232 or RS-485 interface).

´An optional PC can be connected in order to:

•control the operation of one printer via the program EdGraf,.

•allow a number of EBS printers of various types, linked together into a network, to be

controlled from one computer via the program InkNet.

´Objects to be labelled are detected by a photo-detector.

´Fully automatic printer’s operation with the status indication and instructions for

performing service operations.

´Bottles of ink are fully controlled and bottles designed for different, incompatible types of

EBS printers are not accepted.

´Continuous operation over 24 hours a day.

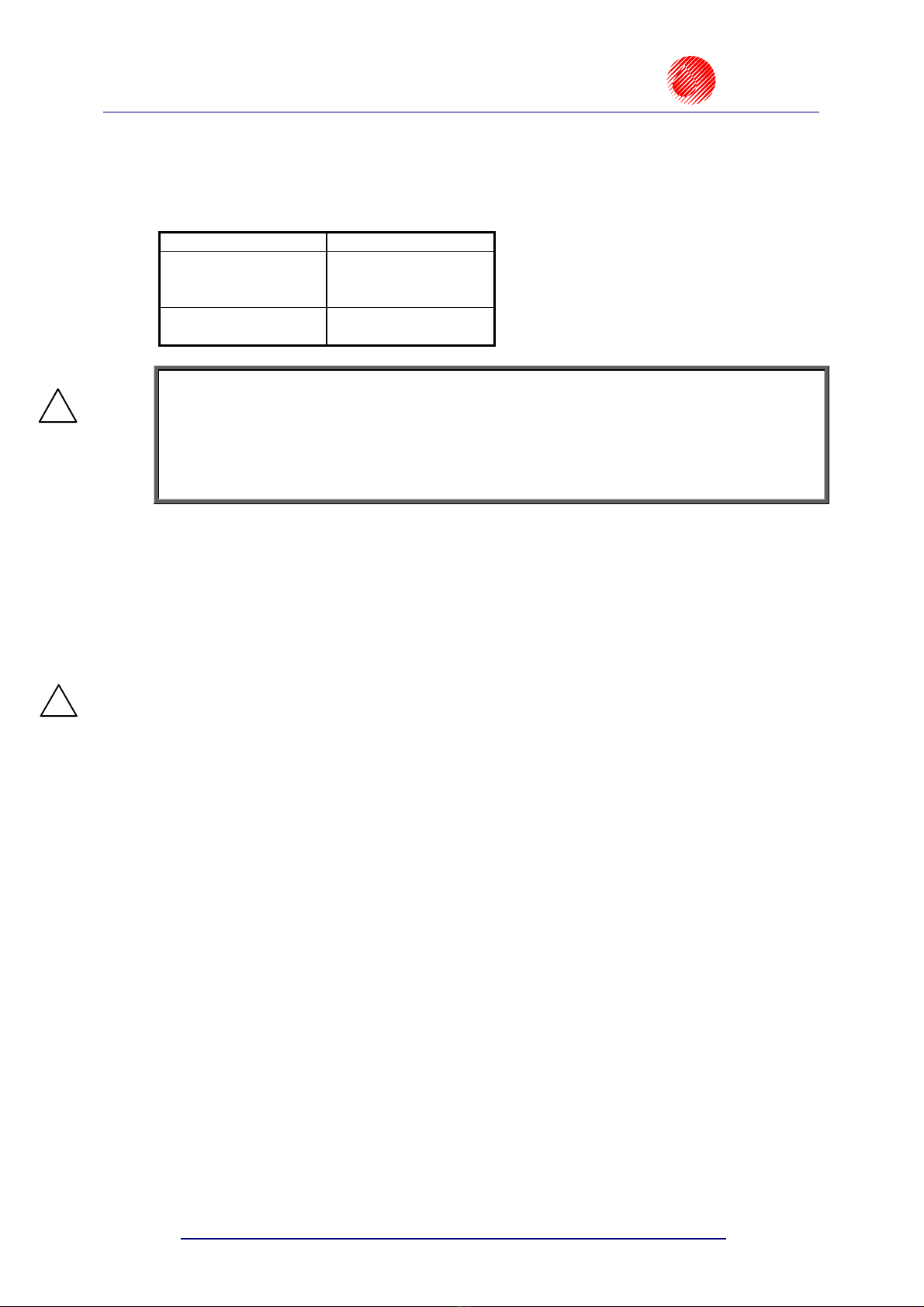

1.3. Principle of Operation

Electromagnetic Print Heads

Every label consists of a number of a droplet-wide vertical rows. Nozzles are set in the

print head vertically, at regular intervals from each-other. This determines the maximal height

of the label. Every nozzle is equipped with an electromagnet-controlled valve. Labels are

made by ink droplets that are jetted at a pressure when the valves open. The pressure is

generated by an external system and controlled with a pressure regulator. Objects to be

labelled move in front of the print head and vertical rows are printed one by one to complete

the entire label.

A

n electromagnet to

control the valve

Supply of ink to the

chamber at high pressure

Surge chamber

Nozzle

Valve 1

Valve 2

Valve n

EBS

Ink Jet Systems

EBS-1500 Series Printers User's Manual

Paragraph 2 - Installing the Printe

r

20060920#3.1 11

2. Installing the Printer

2.1. Safety Requirements

All efforts have been put into designing this device carefully and making it safe and reliable.

However, the safe operation of the device is conditioned by the user’s awareness of, and

obedience to the following safety rules and precautions.

The unit should be operated by the staff that has been trained. It is recommended that

the operation of the printer is supervised.

1. A fire extinguisher designed to extinguish electrical equipment and flammable

solvent fire must be placed within easy reach near the unit.

2. The unit must not be operated in rooms where an explosion hazard exists.

3. The unit must not make overprints on objects whose temperature exceeds 100 °C.

4. No open fire or spark producing devices are allowed in the area where the printer

operates.

5. Power supply cord must be connected to a socket where a protective pin is used.

The efficiency of the earth should comply with the applicable standards.

6. As high voltage occurs in the printer, make sure that all manipulations in the

electrical part of the system and inside the head are performed after power has

been switched off.

7. The outlet of the head must not be directed towards persons, animals or accidental

objects during printing in order to avoid splashing anybody or anything with ink.

8. Protective clothes and possibly protective glasses need to be warn by persons

performing any work on the ink system.

9. No plastic vessels should be used to do the washing as they collect static electricity.

Metal vessels are recommended.

10. No ink, solvent or wash-up (or waste fluid remaining after the head has been washed)

should be left in open vessels as these inflammable fluids may ignite from accidental

sources of fire.

WARNING:

Static electricity collected by people (on their plastic clothes or in their hair, for example) may

spark-over to ink or wash-up vessels when they have been left open. The ink and wash-up

are inflammable and may get ignited! Therefore, before you approach the open vessels

with inflammable fluids, discharge the static electricity by touching the metal printer housing or

another metal object that is connected to the earth.

In the case of accident...

´When ink or solvent spills occur, the spilled fluid should be wiped with a piece of

absorbent material and then removed in compliance with fire and health and safety at

work (HSE) regulations.

´If the clothing has been splashed, remove it as soon as possible.

´Should the eyes or skin get irritated:

EYES need to be rinsed with running water for at least 15 minutes, then you

should see your oculist,

SKIN needs to be washed with water and soap.

!

!

!

EBS-1500 Series Printers User's Manual

Paragraph 2 - Installing the Printer EBS

Ink Jet Systems

12 20060920#3.1

2.2. Power and Air Supply Requirements

Power Supply

Standard

Supply voltage 100 - 240V (AC)

90 - 350V (DC)

Mains frequency 45 - 440Hz

NOTE:

•The mains electricity must meet the requirements of the applicable standards. Otherwise

measures need to be taken or devices used to ensure that the proper power is applied to

the printer.

•The mains socket should be equipped with a protective pin properly connected to

earth. The efficiency of the earth needs to comply with the applicable standards.

Air Supply

Ink pressure can be generated by an external compressor system or inside the ink

system if the system is equipped with an ink pump. The application of the ink system with

a pump simplifies the structure of the printing system significantly. A detailed description of

the device is contained in the document entitled Ink System with an Ink Pump.

Regulator inlet air pressure: 0,5 - 10 bar (0,05 - 1,0 MPa).

NOTE: If a compressor system is used, supply air must be free from any impurities.

Otherwise ink gets dirty sooner inside the ink system and overprints of lower

quality may result.

If air supplied from the compressor system is likely to contain any of the

above-mentioned substances, filtering elements absolutely need to be

installed immediately before the ink system connection to remove such

impurities as water, oil or others.

The Manufacturer shall not bear any responsibility for

improper operation of the unit, if the malfunction is caused

by air contamination.

2.3. Installing the unit

2.3.1. Printer accessories

In view of a great number of EBS printers and printing systems, the set of accessories

depends on a specific user application. This section gives a specification of the accessories

that are used most frequently in various printer configurations.

Typical printer accessories include:

a). Elements and units which are needed for the printing process in every configuration,

b). Additional and supportive elements and units which are needed for a given configuration

to satisfy user requirements.

List of elements and subassemblies:

Head controller.

!

!

EBS

Ink Jet Systems

EBS-1500 Series Printers User's Manual

Paragraph 2 - Installing the Printe

r

20060920#3.1 13

Electromagnetic head.

Complete head holder.

Interface cable.

Photo detector - optimeter.

Ink system.

Ink system with an ink pump.

Ink Monitoring System (IMS) with cable.

Bottle of ink.

Shaft-encoder – conveyor’s speed indicator.

Object holder, the so called gun (used for making overprints manually).

Additional external alarm indicator.

Additional external alarm device (with conveyor control and stop indication).

Code switch.

Starting kit for RS-232 (or RS-485) serial interface.

Movable platform with a cable for making overprints manually.

Bottle of wash-up.

Wash-up spray.

NOTE:

•The above list shall not be considered a specification of accessories (to be) delivered

together with a printer or printing system purchased by the user.

•The list of accessories may vary from country to country.

2.3.2. Preparatory Steps

In order to prepare a new or transported printer to operation, you should perform the

following activities:

1. Remove all parts of the system out of their packing.

2. Place the controller in a room that is free from vibration, shocks, dust, smoke, soil,

aggressive or inflammable vapours and gases.

NOTE: The room shall meet the following requirements:

Environmental conditions: operating temperature from +5°C to +40°C,

relative humidity up to 90% without condensation.

Mechanical requirements: max. vibration 1g at max. frequency 10Hz,

max. shocks 1g over max. 2ms.

3. Secure the print head holder in a convenient position.

NOTE: If the conveyor vibration is too strong, the head holder should be fastened to

a stable rack or on a wall that are not part of the conveyor system.

4. Install the print head in a holder. Make sure, however, that the front planes of the head

and objects to be labelled are parallel. The electromagnetic print-head can work in any

position in space.

!

!

!

EBS-1500 Series Printers User's Manual

Paragraph 2 - Installing the Printer EBS

Ink Jet Systems

14 20060920#3.1

5. Fix the photo detector on a cradle which has been fastened to the print head, head holder

or in any other place convenient for releasing prints. Whereas the slide - in the opening

from the side of a coming object.

fitting

tube

head

holder

distance holder

for packages

photo detector

cradle

connection to

the controller

Fig. 2.3.2.1. Fixing a standard electromagnetic head holder to the conveyor

2.3.3. Removing Transport Protections

The controller and head are protected against mechanical pressure and the spilling of ink

in case the head is tilted or shocked. Therefore some ink system connections are

disconnected and protected with plugs, caps or non-return valves. All protection needs to be

removed during the installation.

2.3.4. Connections

All electrical connections are situated on the right-hand side wall of the controller.

round sockets with external

thread M18x0.75

MAIN

POWER

SWITCH

Fig. 2.3.4.1. Controller - view of connection sockets (without plugs)

There can be seven female connectors available on the side wall:

1. Ink System socket to connect a cable from the Ink Monitoring System (IMS).

2. Serial Interface socket to connect the so called special channel.

EBS

Ink Jet Systems

EBS-1500 Series Printers User's Manual

Paragraph 2 - Installing the Printe

r

20060920#3.1 15

3. Custom socket, an option to connect external devices.

4. PC Serial Interface socket to connect a serial interface cable from a PC.

5. Shaft-encoder socket to connect a shaft-encoder’s cable.

6. Photo detector socket to connect a photo detector cable.

7. Head socket to connect a head interface cable.

NOTE:

•Make sure that protection tabs are matched while plugging in every male connector into

the female connector to avoid damaging the contacts.

•Make sure that the external tapped ring on the male connector is tightened up to ensure

firm connection between male and female connectors. Failure to tighten up the ring

causes the external cable screen to disconnect from the controller and head body.

This damages the electric shock protection and may result in unstable or improper

operation of the head.

Earthed neutral system

Connect the earthed neutral system as specified in subsection 2.2 Power and Air Supply

Requirements with an outlet plug as shown in the drawing. Make sure that the earth contacts

of a mains socket are effectively earthed in compliance with the applicable standards.

Connecting the head

Plug the (16-pin) interface cable carefully into female connector No 7 on the controller and

tighten up the tapped ring. Connect the other end (female connector) of the cable with

a similar male connector on the head cover. The controller connection is shown in

Fig. 2.3.4.1.

interface connection to

the next head

interface connection

between the head

and the controller

Fig. 2.3.4.2.

If the ink system with an ink pump is used, there is no need to apply a compressor

system. Any connections should be made in accordance with the description contained in the

document entitled Ink System with an Ink Pump.

Connecting the photo detector

Connect the photo detector, that is an optimeter detecting objects to be labelled, in front of the

print head, to female connector No 6 - PHOTO (see Fig. 2.3.4.1).

!

EBS-1500 Series Printers User's Manual

Paragraph 2 - Installing the Printer EBS

Ink Jet Systems

16 20060920#3.1

Connecting the shaft-encoder

Connect the shaft-encoder, that is a conveyor speed indicator, to female connector

No 5 - SHAFT (an option for variable-speed conveyors) - see Fig. 2.3.4.1.

Connecting external data transfer devices

An external device for transferring data (a PC, automatic scales, bar-code reader or other

automatic equipment) should be connected to socked No. 3.

Connecting the Ink Monitor System - IMS

Plug in the (8-pin) male connector of the ink monitor system interface cable carefully into

female connector No 1 on the controller and tighten up the tapped ring (for electromagnetic

print heads only).

Connecting the head to the ink and compressed air systems

The ink system for an electromagnetic head is built of the following components (see

Fig. 2.3.4.3.):

•A container for a bottle of ink and grips to fix the container up .

•An Ink Monitoring System .

•A compressed air pressure regulator with a manometer .

•Pressure tubes of polyethylene for supplying ink and compressed air (the direction in

which the medium flows inside the tubes is marked with arrows):

- a tube,

, to supply air under pressure from a compressor system,

- a tube,

, to supply air at a regulator-stabilised pressure,

- a tube,

, to supply ink under pressure from a bottle to the head.

•A bottle of ink ¡.

•A plug to be screwed on the bottle ¢. It contains:

- a tube with an ink filter at one end (inside the ink bottle),

- pipe connectors,

- retaining nuts to secure tubes on the connectors.

In order to connect the ink system to the compressed air system and head to the ink system,

follow the steps below:

a). Supply compressed air out of an external compressor system via a polyethylene tube to

the supply air connection at the pressure regulator (marked with an arrow and a letter P),

as shown in the following picture:

•slide the retaining nut over the pipe,

•slide the pipe over the connector,

•tighten up the retaining nut.

EBS

Ink Jet Systems

EBS-1500 Series Printers User's Manual

Paragraph 2 - Installing the Printe

r

20060920#3.1 17

¡

¢

Fig. 2.3.4.3.

b). Connect the pressure regulator outlet and the horizontal bottle-plug coupling with

a polyethylene pipe .

c). Connect the vertical bottle-plug connector and the non-return valve connector. Insert the

valve into the inlet ink connector and tighten up the nut. The non-return valve prevents

the ink from leaking out of the head after the pipe has been removed.

inlet Ink couple

non-return valve

connectors to

side tubes over

pressure tube to supply ink out of an

ink bottle to the head

Fig. 2.3.4.4.

EBS-1500 Series Printers User's Manual

Paragraph 2 - Installing the Printer EBS

Ink Jet Systems

18 20060920#3.1

NOTE:

Compressed air supplied to the ink system must meet compressed air specifications given in

paragraph 2.2 Power and Air Supply Requirements.

The rated pressure should be set to the value of 0,04 MPa (0,4 bar) with a pressure

regulator.

The rated pressure depends on nozzle diameter and the number of nozzles in the print head.

The nozzle diameter is indicated on the nozzle plate.

For best quality prints on a given surface, the ink pressure inside the head can be slightly

adjusted after the primary print parameters (such as height, rate and intensity) have been

determined. The adjusted pressure should be within the range from 0.03 MPa (0.3 bar) to

0.06 MPa (0.6 bar).

Connecting the head to the pump-based ink system

A detailed description of how to connect the head to the ink system with an ink pump is

given in the document entitled Ink System with an Ink Pump.

2.3.5. Installing a new Bottle of Ink (or Replacing an Empty One)

NOTE:

•Please note that only the recommended ink type should be used. A possible

mistake may result in damage to print head.

•Various types of ink must not be mixed or ink whose usability time prescribed has

been exceed must not be added.

Connecting a new ink bottle (or replacing an ink bottle) in the

compressor-based system

In order to install (replace) a bottle of ink, follow the procedure given below:

a). Depressurise the system and wait until the manometer indicates that the pressure has

dropped to zero in the bottle.

b). Unscrew retaining nuts (and )on the bottle couplings carefully and remove

polyethylene tubes (a tube to supply ink under pressure from the bottle to the head)

and (a tube to supply air at a stabilised pressure from the pressure regulator).

Fig. 2.3.5.1.

!

!

Table of contents

Other EBS Ink-Jet Systems Printer manuals

Popular Printer manuals by other brands

Epson

Epson U220B - TM Two-color Dot-matrix Printer Technical reference guide

MIMAKI

MIMAKI UJF-3042FX Operation manual

Intermec

Intermec EasyCoder PC41 user guide

Canon

Canon imagePROGRAF W6400 user guide

Seiko

Seiko LTPD245E Technical reference

Epson

Epson R2880 - Stylus Photo Color Inkjet Printer Start here