EBS Ink-Jet Systems EBS-6200 User manual

EBS-6200 Printer User's Manual

2 200

©Copyright 2009 EBS Ink-Jet Systeme – All rights reserved. Changes may apply.

91020#1.0

EBS-6200 Printer User's Manual

#1.0 3

20091020

TABLE OF CONTENTS

1. GENERAL INFORMATION ..................................................................................7

1.1.

A

PPLICATION

.....................................................................................................................7

1.2.

P

RINCIPLE OF

O

PERATION

................................................................................................10

2. INSTALLING THE PRINTER..............................................................................11

2.1.

S

AFETY

R

EQUIREMENTS

...................................................................................................11

In case of accident …...........................................................................................11

2.2.

P

OWER

S

UPPLY

R

EQUIREMENTS

.......................................................................................12

Mains Requirements.............................................................................................12

2.3.

I

NSTALLING THE

P

RINTER

.................................................................................................12

2.3.1.

Standard and Optional Accessories ..........................................................................12

2.3.2.

Preparatory Steps ........................................................................................................13

2.3.3.

Removing Transport Protections ...............................................................................14

2.3.4.

Connections..................................................................................................................15

2.3.5.

Connecting Bottles of Ink and Solvent ......................................................................15

2.4.

R

EMOVING

H

EAD

C

ASING

.................................................................................................16

3. STARTING THE PRINTER.................................................................................17

3.1.

S

WITCHING THE

P

RINTER

O

N

............................................................................................18

3.2.

S

WITCHING THE

P

RINTER

O

FF

...........................................................................................18

3.2.1.

Switching the Printer Off in Regular Mode................................................................18

3.2.2.

Switching the Printer Off in Emergency and Service Modes...................................19

4. OPERATING THE PRINTER..............................................................................20

4.1.

C

ONTROL

P

ANELS

............................................................................................................20

4.1.1.

External Panel...............................................................................................................20

4.1.2.

Internal Panel................................................................................................................22

4.2.

O

PERATING THE

P

RINTER WITH THE

C

ONTROL

MENU .......................................................23

4.3.

P

RINT

H

EAD

S

TATUS

........................................................................................................27

4.4.

C

ONTROLLING THE

P

RINTER

.............................................................................................28

4.4.1.

Text Files.......................................................................................................................28

4.4.1.1.

General Information on Text Files ...........................................................................28

WORD PROCESSOR - A Description of Control Keys........................................29

4.4.1.2.

Opening and Editing a New Text File ......................................................................30

Subfile Type: Text - ASCII Characters.................................................................30

Subfile Type: Graphics..........................................................................................32

GRAPHICS PROCESSOR - A Description of Function Keys..............................33

Subfile Type: B

AR

C

ODE

........................................................................................34

Subfile Type: T

EXT

N

AME

.......................................................................................35

4.4.1.3.

Editing an Existing Subfile .......................................................................................36

4.4.1.4.

Copying and Editing a Text File...............................................................................36

4.4.1.5.

Deleting a Text File..................................................................................................36

4.4.1.6.

Deleting the File Library...........................................................................................36

4.4.1.7.

Accessing the File Library........................................................................................37

4.4.1.8.

Linking File Names with Parameter-Block Names ..................................................38

4.4.1.9.

Using the Password.................................................................................................38

Defining a User Password....................................................................................38

Enabling the User Password................................................................................39

Changing the User Password...............................................................................39

EBS-6200 Printer User's Manual

4 20091020#1.0

................................39

4.4.1.10.

Using Special Registers...........................................................................................39

Object Counters....................................................................................................40

Date and Time......................................................................................................40

Universal Counter.................................................................................................41

Universa ........................................46

Expiry D ........................................47

Special Channel Data...........................................................................................48

.2.2.

.2.3.

.2.6.

4.4.3.

Printi

.3.1.

S

Quick Stoppi Printing

.

.

.3.7.

.

.

erv

4.4.4.2.

S

4.4.4.3.

C

4.4.4.4.

T

4.4.4.5.

T

4.4.4.6. T

ux

Deleting the User Password.................................................

l Date and Time..............................................

ate Registers...................................................

4.4.2.

Using Print-Parameter Blocks ....................................................................................48

4.4.2.1.

Creating and Editing a New Parameter Block .........................................................49

Modifying Parameters...........................................................................................49

4.4

Editing Existing Blocks of Parameters.....................................................................49

4.4

Copying and Editing Blocks of Parameters .............................................................49

4.4.2.4.

Deleting a Block of Parameters ...............................................................................50

Deleting the Paramete4.4.2.5. r-Block Library......................................................................50

4.4

Accessing the Parameter Block Library...................................................................50

ng..........................................................................................................................51

4.4

Stopping Printing .....................................................................................................51

4.4.3.2. tarting Printing .......................................................................................................51

4.4.3.3. ng ...........................................................................................52

4.4

Suspending Printing, Editing Text and Resuming Printing......................................53.3.4

4.4.3.

Print Parameters......................................................................................................535

Modifying Print Parameters..................................................................................53

Vertical Direction ..................................................................................................54

Initial Distance......................................................................................................54

Number of Repetitions..........................................................................................54

Distance Between Overprints...............................................................................55

Horizontal Direction..............................................................................................55

Print Height...........................................................................................................55

Date Offset ...........................................................................................................55

Counter Increment................................................................................................56

Row Repetition.....................................................................................................56

Print-Rate Mode ...................................................................................................56

Print Rate..............................................................................................................56

Interleaving...........................................................................................................57

Timing Mode.........................................................................................................58

Print Resolution....................................................................................................58

Travel Speed ........................................................................................................58

Number of Pulses Generated by External Encoder.............................................58

Saving Current Parameters in a Block ....................................................................4.4.3.6. 58

4.4

Monitoring Counting.................................................................................................59

Accessing Object Counters..................................................................................59

Modifying Object Counters...................................................................................60

4.4

Monitoring Print Rate ...............................................................................................60

.3.8

4.4.3.9

Printing with the Use of a Code Switch ...................................................................61

4.4.3.10. Viewing Files on Terminal Display...........................................................................61

4.4.4. S i

4.4.4.1.

Service Mode...........................................................................................................61

cing Print Head ....................................................................................................61

ucking Ink/Solvent .................................................................................................62

losing and Opening Ink Valve ...............................................................................62

urning Head off Quickly .........................................................................................63

urning Ink Flow on .................................................................................................63

4.4.4.7.

Turning Flow of Solvent On .....................................................................................64

urning Head off ......................................................................................................63

4.4.4.8.

Adjusting Ink Jet Path ..............................................................................................64

4.4.4.9.

Switching Over Stroboscope ...................................................................................67

4.4.4.10. Monitoring High Voltage during Printing ..................................................................68

4.4.4.11 Defining Some Print Parameters by Measuring Conveyor Travel Speed ...............68

.

4.4.4.12. Other Commands ....................................................................................................68

4.4.5.

A iliary Commands....................................................................................................68

EBS-6200 Printer User's Manual

#1.0 5

20091020

4.4.5.1.

System D

4.4.5.2.

Accessing Alarm Messages.....................................................................................69

4.4.5.3.

Clearing Alarms .......................................................................................................69

4.4.5.4.

A

4.4.5.5.

S

4.4.5.6.

V

4.4.5.7.

S

4.4.6.

Ink an

4.4.6.1.

C

4.4.6.2.

P

4.4.6.3.

A

.

4.

LA

le

4.

DJ

nte

ef

nfo

ro

ax

5. EXAMP ES

5.1.

H

OW T

5.2.

C

REAT

5.2.1.

How t

5.2.2.

How t

5.2.3.

How t

5.2.4.

How t

5.2.5.

How t

5.2.6.

How t

6. SERVICE AN

6.1.

R

OUT

6.2. C

HE

6.3.

W

HEN

he

is

um

cc

ed

o

w

om

Irregular defects of print quality ...............................................................................109

ata ............................................................................................................68

ccessing Error Reports..........................................................................................69

etting Date and Time .............................................................................................69

iewing Printer Operation Time...............................................................................70

electing a Language ..............................................................................................70

4.4.5.8.

Releasing Protections..............................................................................................70

d Solvent Bottle Monitoring System................................................................72

General Information..............................................................................................72

Replacing Bottle of Ink (Solvent)..........................................................................72

hecking Expiry Dates ............................................................................................74

rinter Operation Time vs. Solvent Consumption Time Limit..................................74

ccessing Ink Monitoring System Data ...................................................................74

4.4.6.4

Checking How Many Text Files Can be Printed with 1 litre of Ink...........................75

4.4.6.5.

Printer Operation Problems while Replacing Ink and Solvent Bottles.....................76

Ink Monitoring System Flow Diagram...................................................................76

5.

A

RMS

,

E

RRORS AND

I

NDICATIONS

.................................................................................76

4.5.1.

C aring Alarms............................................................................................................82

6.

A

USTING

P

RINT

R

ATE

...................................................................................................82

4.6.1.

I rnal Generator ........................................................................................................82

4.6.2.

Shaft-encoder ...............................................................................................................83

4.6.3.

D ining Maximum Print Rate for a Given Text File..................................................84

4.6.4.

I rmation for Advanced Users ................................................................................85

4.6.5.

P blems with Reaching Maximum Print Rate when Shaft-encoder is Used ........86

4.6.6.

M imum Print Rate vs. Resolution Settings............................................................89

L OF HOW TO OPERATE THE PRINTER .......................................91

O RINT THE IRST AMPLE EXT ILE

P F S T F ...................................................................91

ING AND

P

RINTING

V

ARIOUS

T

EXT

F

ILES

.................................................................93

o Print the Current Date and Time....................................................................93

o Print Consecutive Numbers ...........................................................................94

o Print Expiry Dates ...........................................................................................95

o Print Logos ......................................................................................................96

o Print a Bar Code ..............................................................................................97

o Print a Complex Subfile..................................................................................97

D MAINTENANCE........................................................................99

INE

M

AINTENANCE

...................................................................................................99

Replacing the Main Ink Filter..............................................................................100

Replacing Ink Filter Inside the Gun....................................................................101

Replacing Air Filter.............................................................................................102

Replacing Air Filter Element in Electronics Compartment Ventilation

System................................................................................................................103

CKING

A

DJUSTMENTS

...............................................................................................104

P

ROBLEMS

A

RISE DURING

O

PERATION OR

S

ERVICE

..............................................104

6.3.1.

T printer cannot be started ...................................................................................104

6.3.2.

M aligned jet of ink...................................................................................................104

6.3.3.

Clogged nozzle - cleaning the nozzle.......................................................................105

6.3.4.

No nominal ink pressure can be generated by pump ............................................106

6.3.5.

P p does not produce negative pressure ............................................................107

6.3.6.

O luded Ink Filter in the Gun ..................................................................................107

6.3.7.

R uced partial vacuum............................................................................................107

6.3.8.

N flow of solvent in the head ..................................................................................108

6.3.9.

Lo er part of overprint is missing ...........................................................................108

6.3.10.

S e vertical rows of overprints are spaced widely .............................................109

6.3.11.

EBS-6200 Printer User's Manual

6 20091020#1.0

..............................110

6.3.13.

Names of text files in the library are changed - battery is discharged.................110

6.

ON

7. S E

7.

7.

A

8. T I

9. LAYOUT O

KEYPAD...

10.L O

KEYPAD...

Inde

D Us

This M nu

J e

Thi o

prin f

cor

As

differ slightly from your equipment. As we need to keep pace with new

te log

d

illu

be

sho

any I

6.3.12.

Slopping, rippled or jagged overprints......................................

4.

C

TACTING

S

ERVICE

P

OINTS

........................................................................................111

TORA AND CARRIAGE ...........................................................................112G

1.

S

TORING THE

P

RINTER

...................................................................................................112

2.

T P .........................................................................................115

R NSPORTING THE RINTER

ECHN CAL SPECIFICATIONS ......................................................................116

F CYRILLIC CHARACTERS ON THE PRINTER’S TERMINAL

........................................................................................................118

AYOUT F ARABIC CHARACTERS ON THE PRINTER’S TERMINAL

........................................................................................................119

x......................................................................................................................120

ear er,

a al contains very useful information on how to operate your Ink-

et h

Print r. Please read t is Manual carefully.

s editi n of the document includes most of the changes introduced to the EBS

ters or software version 22_1A and the descriptions contained therein

respond to the printers that are equipped with this software version.

the machine and options can be customised, the product delivered to you

depends on your specific order. Therefore some descriptions or illustrations may

chno ical advancement, we reserve the right to introduce changes in the

esign nd technical solutions adopted. In view of the above, no data,a

strations or description shall make grounds for any claims. Should your printer

equipped with options that are not described or illustrated in the Manual or

uld you have additional queries after having read the Manual, please contact

EBS nk-Jet Systeme representative for more information.

EBS-6200 Printer User's Manual

Chapter 1 - General Information

#1.0 7

20091020

1. General Information

NOT

There

attrac a

E:

are warning and information signs on the right or left hand-side margins of some pages to

t user’s ttention to messages that are provided next to them. They are the following signs:

!

Information signs indicating:

•that the actions described should be taken carefully,

•additional, printer-specific option and features,

•untypical behaviour of the unit,

•other hints.

!e action that might have a critical impact on the proper

operation of the unit or user’s safety. It requires the user to follow closely th

instructions given therein.

A warning not to take th

e

A sign informing that the installation or service operation can be performed by the user

who does not need to be qualified for servicing EBS equipment.

EBS

A sign informing that the installation or service operation should be performed by the

user who is qualified for servicing EBS equipment.

The Manufacturer reserves the right to introduce changes whose description may not be

provided in this manual.

The Manufacturer shall not be liable for any damages resulting from the failure to follow the

instructions or consequences of editorial or publishing errors within the instructions.

!

1.1. Application

BS-6200 is a non-contact ink-jet printer designed for putting print on objects of various types,

oving for example, on a factory conveyor. The printer provides clear and firm overprints on materials

uch as:

•paper and cardboard,

•plastics,

•fabric,

•leather and leatherette,

•wood and wood-like products,

•glass and ceramic products,

•metal surfaces of any type, etc.

Short description of the printer:

´The unit is equipped with one print head of small outer dimensions.

´The head produces print varying between 1.5 and 14 mm in height.

´The head can be set at any position.

´The head is connected with the controller via a 4 m long flexible cord as standard.

E

m

s

EBS-6200 Printer User's Manual

Chapter 1 - General Information

8 200

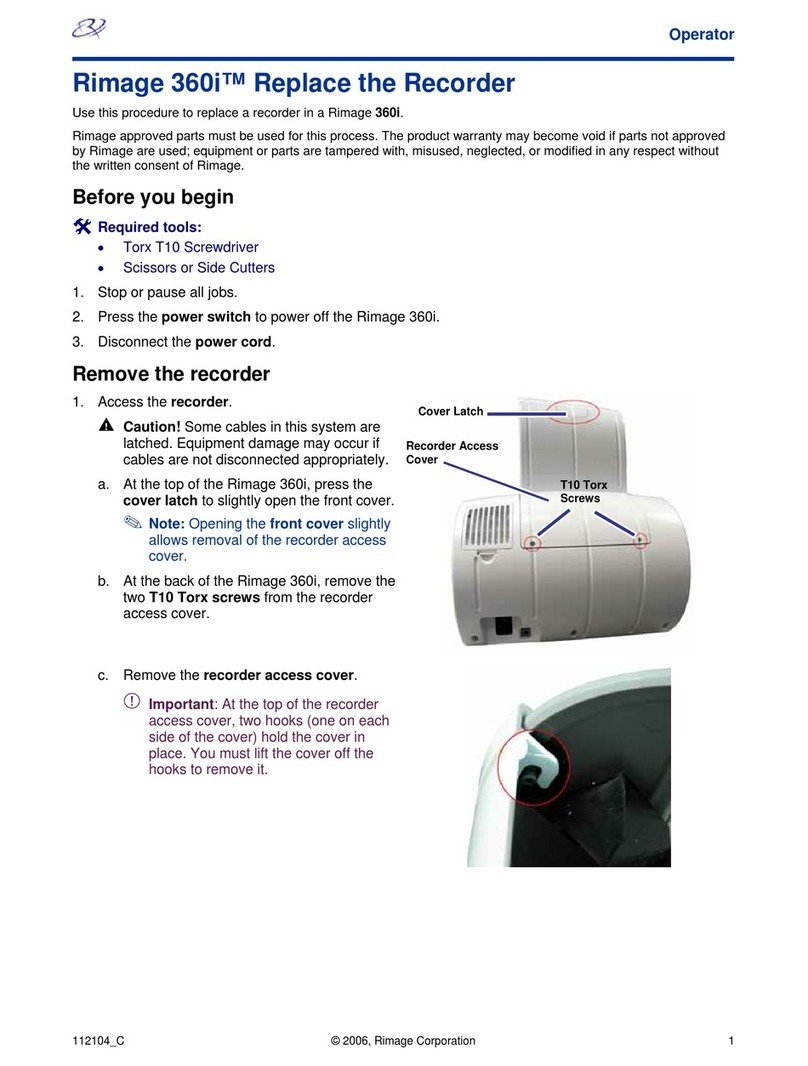

Fig. 1.1.1.

´Printing capabilities:

•texts composed of small and capital letters out of various matrices, also printed in boldface or

rotated,

•several lines of text printed during a single run of an object in front of the print head: a

maximum of four lines (with 1-dot space between the lines for the 7x5 matrix) or six lines (with

no space between the lines for the 5x5 matrix), with a maximum print height of 32 dots,

4

lines

(7x5)

5

lines

(5x5)

6

lines

(5x5)

•diacritical national characters,

•graphics – a built-in set of ready-to-use graphic symbols and a tool-kit for creating user-

defined graphics,

91020#1.0

EBS-6200 Printer User's Manual

Chapter 1 - General Information

#1.0 9

20091020

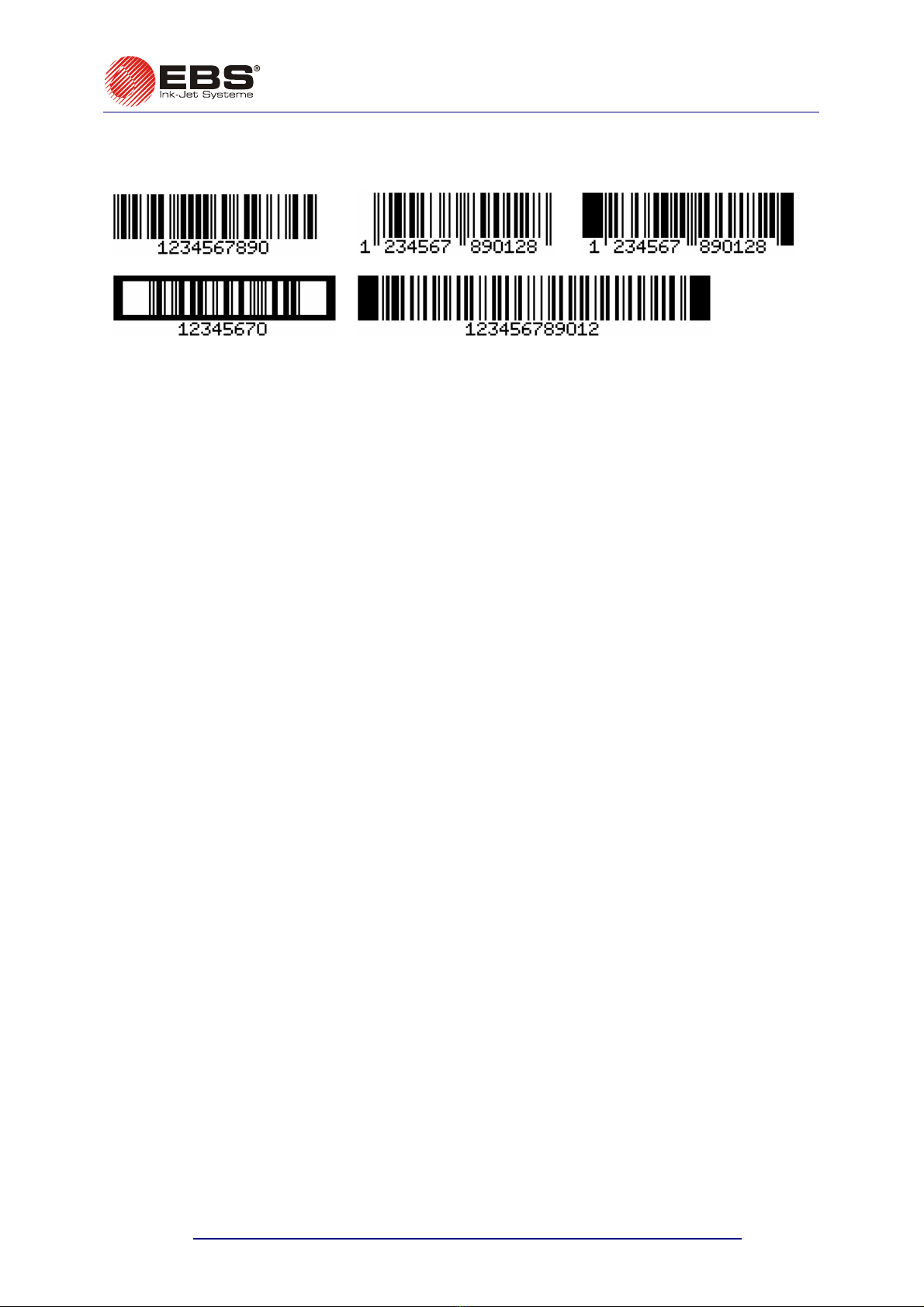

•bar codes of variou

caption; an option of introducing on-going changes to the digital contents of the code (bar

code as an incremental or decremental counter),

s kinds, printed in a regular way or in reverse, with or without a numerical

•variable data - such as current date, warranty expiry date, current time, ascending and

descen any types of data which is transferred from a PC or

ex erna d arranged by the user.

´Texts o be in e of a built-in terminal, an external

code switch a terface).

´An optional cted in order to:

•ration of one printer via the EdGraf program,

•allow a

co troll

´Objec to b hoto-detector.

´Fully automatic operation of the printer with status indication and instructions for performing

service operations.

´Full monito

incompatibl

´The unit can operate continuously over 24 hours a day.

ding numbering (counters),

evt

t

l d ices (via an optional special channel), as required an

pr ted can be input or modified easily with the us

or PC (via RS-232C or RS-485 in

PC can be conne

control ope

number of EBS printers of various types, linked together into a network, to be

ed from one computer via the InkNet program.

e labelled are detected by a p

n

ts

ring of ink and solvent bottles. For this reason, bottles designed for different,

e types of EBS printer will not be accepted.

EBS-6200 Printer User's Manual

Chapter 1 - General Information

10 200

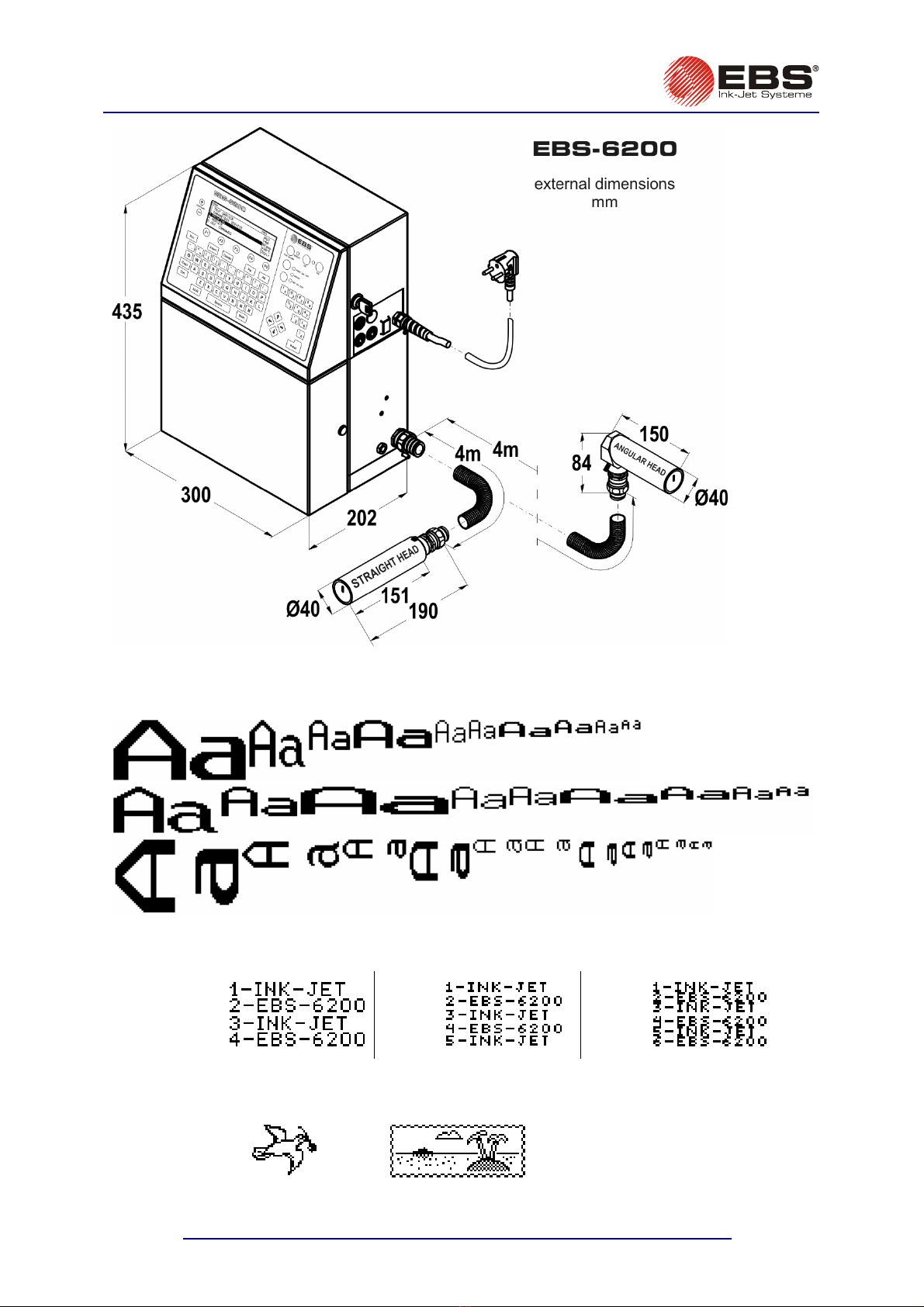

1.2.

Printing with co s (CIJ printers).

Principle of Operation

ntinuous ink jet printer

Ink

Gun

Nozzle Charging

electrode

Ink return

Gutter

HV deflection

electrode

INK-JET

Overprints are produced in the following

way:

•A continuous ink jet is broken into

droplets.

•Then the droplets are charged and

deflected in an electric field.

•Every label consists of drop-wide

vertical rows.

•The droplets are deflected on the

vertical plane. Every droplet within a row

is broken off the continuous jet, then

charged and deflected while passing

under a high-voltage electrode.

•Objects to be labelled move in front of

the print head and vertical rows are

printed one by one to complete the

entire label.

•Uncharged droplets fall into a gutter and

from there are pulled back and returned

to the ink system cylinders.

This method of printing is applied to all CIJ

printers.

Fig. 1.2.1. Labelling with Continuous Ink-Jet printers

pate s.

The EBS-6200 printer incorporates many unique solutions, including those protected by

nt Therefore it is in the top flight of units of this type in the world.

91020#1.0

EBS-6200 Printer User's Manual

Chapter 2 - Installing the Printe

r

#1.0 11

20091020

2. Installing the Printer

2.1. irements

All efforts have been put into designing this printer carefully and making it safe and reliable. However,

the safe operation of the device is conditioned by the user’s awareness of, and obedience to the

following safety rules and precautions.

The un

operatio

1. A fire extinguisher designed to extinguish electrical equipment and flammable solvent fires

must be placed within easy reach of the unit.

2. The unit must not be operated in rooms where an explosion hazard exists.

3. No overprints can be m de on products whose temperature exceeds 100°C at the time

printing.

4. No open fire or spark producing devices are allowed in the area where the unit operates.

5. Power supply cord must be connected to a socket where an earthed pin is used. The

prin

inst

power has been switched off.

7. ons, animals or accidental objects

8. Pro o be worn by persons performing any

9. should be used to do the washing as they collect static electricity. Metal

10. the outside of the building through

11. No ink, solvent or wash-up (or waste fluid remaining after the head has been washed) should

be left in open vessels as these inflammable fluids may ignite from accidental sources of fire.

WARNING:

Static electricity collected by people (on their plastic clothes or in their hair, for example) may spark-

over to ink or wash-up vessels when they are left open. The ink and wash-up are inflammable

and may ignite! Therefore, before you approach the open vessels containing inflammable fluids,

discharge static electricity by touching the metal printer housing or another metal object that is

connected to earth.

Safety Requ

it should be operated by the staff that has been trained. It is recommended that the

n of the printer is supervised.

!

aof

efficiency of earth should comply with the applicable standards. Additionally, in some cases the

ter-housing earth terminal needs to be connected appropriately (according to the

ructions given in section 2.3.4 Connections).

6. As high voltage occurs in the printer, make sure that all manipulations in the electrical part

of the system and inside the head are performed after

The outlet of the head must not be directed towards pers

during printing in order to avoid splashing anybody or anything with ink.

tective clothes and possibly protective glasses need t

work on the ink system.

No plastic vessels

vessels are recommended.

Air contaminated with solvent should be carried away to

a clear duct.

In case of accident …

´When ink or solvent spills occur, the spilled fluid should be wiped with a piece of absorbent

material and then disposed of in compliance with fire, health and safety at work regulations.

´If the clothing has been splashed, remove it as soon as possible.

´Should the eyes or skin get irritated:

EYES need to be rinsed with running water for at least 15 minutes, then you should see your

eye doctor,

SKIN needs to be washed with water and soap.

!

!

EBS-6200 Printer User's Manual

Chapter 2 - Installing the Printer

12 200

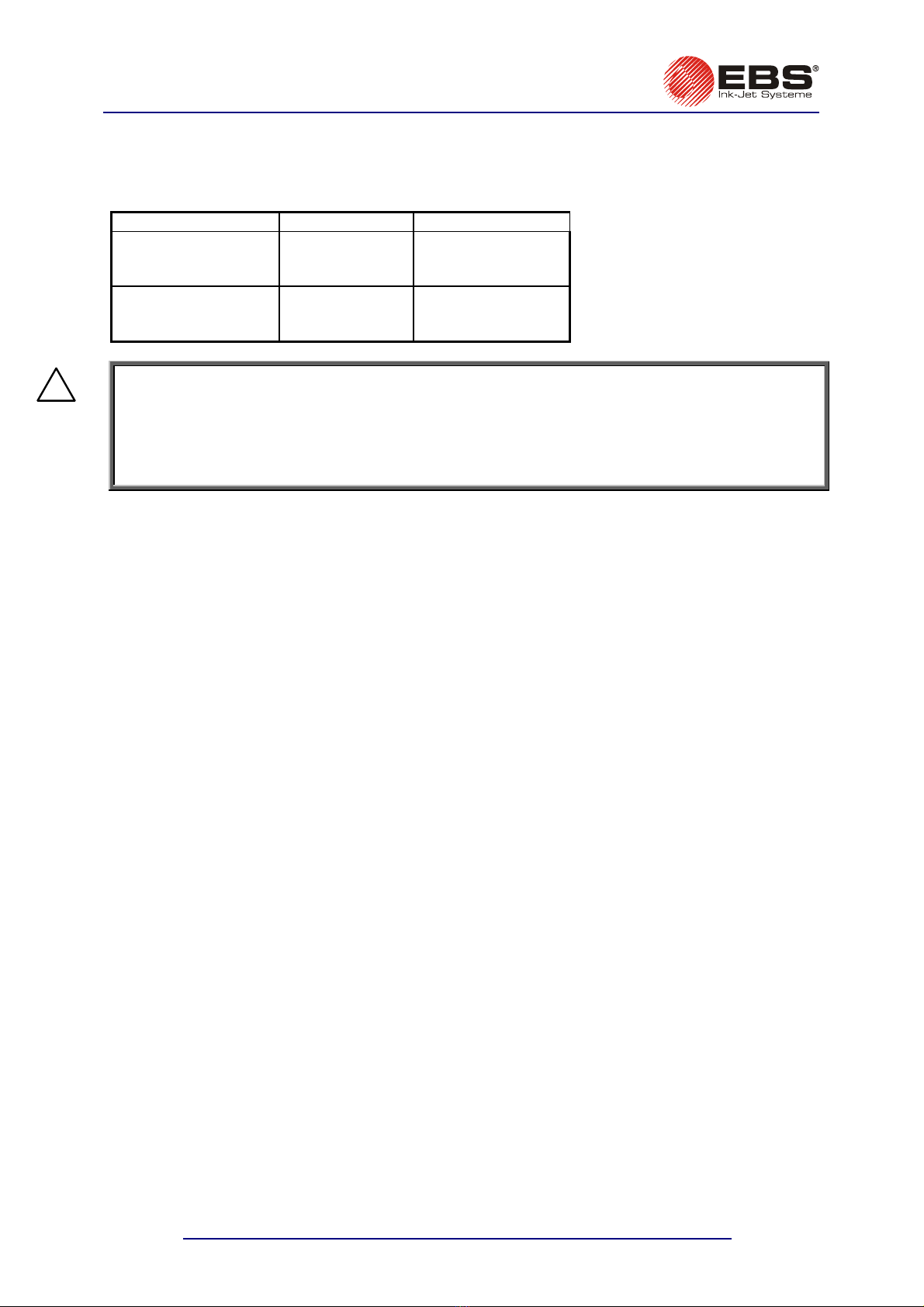

2.2.

Mains Requirements

Option

Power Supply Requirements

Standard

Supply voltage

100-240V (AC)

90-350V (DC)

Mains frequency

45-440Hz

DC

NOTE:

•The mains electricity must meet the requirements of e standards. Otherwise

measures need to be taken or devices used to ens

printer.

•The mains socket should be equipped with a protec

The efficiency of the earth needs to comply with the

91020#1.0

the applicabl

ure that the proper power is applied to the

tive pin properly connected to earth.

applicable standards.

2.3. Installing the Printer

2.3.1. Standard and Optional Accessories

As a variety of configurations of EBS-6000 series printe

installed by the user depends on a specific user application

a). Elements and units which are needed for printing in ev

b). Additional and supportive elements and units which are nee guration to satisfy

user requirements.

List of the accessories that are used most frequently in various printer configurations:

1. Printer (control cabinet and the head),

2. Complete head holder,

3. Photo detector, an optical sensor,

r,

5. Bottle of ink,

. Wash-up spray,

9. Filters:

a). Main ink filter,

b). Ink filter in head gun,

c). Filter elements for suction tubes in bottles,

d). Air filter

e). Air filter element for electronics compartment ventilation system.

10. RS232 interface cable to PC,

11. Original rack for EBS-6000 series printers,

12. Holder for labelling immovable objects manually,

13. Additional external alarm device,

14. Additional external alarm device with conveyor control and stop indication,

15. External code switch,

16. Movable platform with a cable for making overprints manually.

In addition, a variety of special service tools are available, such as:

a). Open end spanner to unscrew nozzles,

b). Service microscope to adjust ink jet parameters in the head,

c). Service tool: a template for adjusting the HV electrode position,

!

rs are available, the set of accessories

. Typical printer accessories include:

ery configuration,

ded for a given confi

4. Shaft-encoder, a conveyor’s travel-speed indicato

6. Bottle of solvent,

7. Bottle of wash-up,

8

EBS-6200 Printer User's Manual

Chapter 2 - Installing the Printe

r

#1.0 13

20091020

d). Service tool: a template

e). Service tool for shaping Ø 3 Teflon (PTFE) pipe tips.

NOTE:

•The above list shall not be considered a specification of accessories (to be) delivered together

wi

Th ountry to country.

for adjusting the distance between the gutter and nozzle.

th a printer or printing system.

•e list of accessories may vary from c

!

2.3.2. Preparatory Steps

In order to prepare a new or transported printer to operation, you should perform the following

operations:

´Place the unit in a room that is free from vibration, shocks, dust, smoke, soil, aggressive or

inflammable vapours and gases.

!

NOTE: The room shall meet the following requirements:

Environmental conditions: operating temperature from +5°C to +40°C,

at the max. frequency of 10Hz,

´

´Secu

´

relative humidity up to 90% without condensation.

Mechanical requirements: max. vibration 1g

max. shocks of 1g over the maximum of 2ms.

´Ensure that free and easy access to the unit is

provided.

´Place the printer on a 0.7 to 1.1 m high horizontal

table or original rack for EBS-6000 series

printers for convenience.

Check for mechanical damages to the unit, head

and connecting hose, which might have been

caused during carriage.

re the print head holder in a convenient

position.

Secure the print head in the holder in any required

position.

´Install the photo detector in clamps fixed to the

head holder or in any other place which would be

most suitable for the object under print.

Fig. 2.3.2.1.

Head holder

Photo detector holder

Head axis

37 mm

Fig. 2.3.2.2.

Fixing the standard head

holder to a conveyor

stable

in contact with the conveyor.

2xM5

Oten the head holder on aN TE: If conveyor vibration is too strong, it would be better to fas

rack or on a wall, provided that the rack and the wall are not

!

EBS-6200 Printer User's Manual

Chapter 2 - Installing the Printer

14 20091020#1.0

2.3.3.

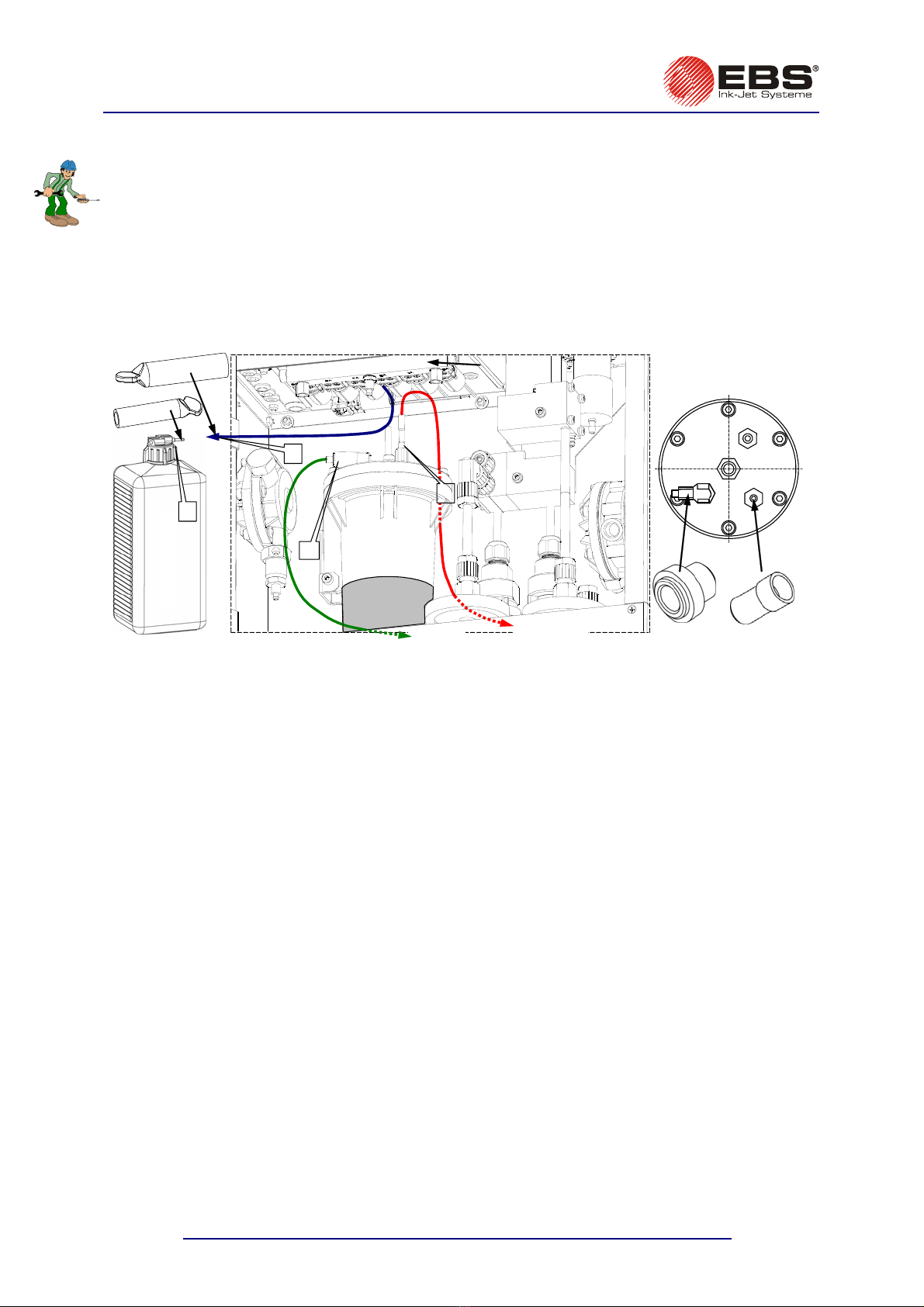

The cylinders are g the liquid contents in the event the printer tilts or shakes

during carriage. internal connections are separated and the tips of the

need to be removed and each of the connections restored.

1.

2. Connec :

vacuum pump - to connector pipe VAC

on

)ector pipe RET

on the R3 cylinder,

c) V3 valve tube

- to connector pipe

on ink bottle.

Removing Transport Protections

protected against spillin

Therefore some of the

connections are capped. The protections

Remove plugs from connectors (couplings)

,

,

and from tube end

.

t the following

a) the tube linking the cylinder (via air filter) with

the R3 cylinder,

b ink return tube (from head gutter) – to conn

RET

V

AC

R3

cylinder

R3

V3 valve manifold

bottle of ink

head gutter

air filter

F 2ig. .3.3.1. View of connections inside the unit and on the cylinder cover.

EBS-6200 Printer User's Manual

Chapter 2 - Installing the Printe

r

#1.0 15

20091020

2.3.4. Connection

On putting the printer in place and removing transport protections make th

shown in the figure below, following the order indicated by the numbers

, ,

s

e connections that are

, , , .

!

Special-channel interface

connector (to connect a PC)

BB

Mains plug

B

or

Mains electricity with an earthing contact

Waste-air pipe

connector

P

Head casing is electrically

connected with an earthed

Earth bar

rminal

M5 A

A

hoto dete Shaft-encoderctor

socket socket min. 4 mm hose to vent contaminated air

Earth te

–

the

maximum resistance

between points A and B and

between A and C should be

0.1 Ohm when the mains

plug is out of the mains

socket

conveyor

C

rinter

olvent

ck for filters on the pipe tips. The caps of

ch other by the number of pipes going from

he ink bottle cap contains one pipe whereas the solvent

bottle cap - three pipes.

2. Screw the bottles into the caps where the pipes are inserted and place them in a cav

system door.

Fig. 2.3.4.1. Major connections in the EBS-6200 p

2.3.5. Connecting Bottles of Ink and S

1. Insert suction pipes to the bottles of ink and solvent. Che

ink and solvent bottles can be distinquished from ea

the printer's ink system to either cap. T

ity in the ink

EBS-6200 Printer User's Manual

Chapter 2 - Installing the Printer

16 200

!

91020#1.0

NOTE:

•Make sure solvent are contained in the bottles. A possible mistake

may result tained in the unit’s containers (due to a change to the

chemical structure of ink) and cause many serious problems.

•Avoid misplacing the bottles of ink and solvent or placing the bottle of solvent where

the bottle of ink should be.

•Different types of ink must not be mixed. Do not add to the bottle any ink whose shelf

life has expired.

that the original ink and

in damage to ink con

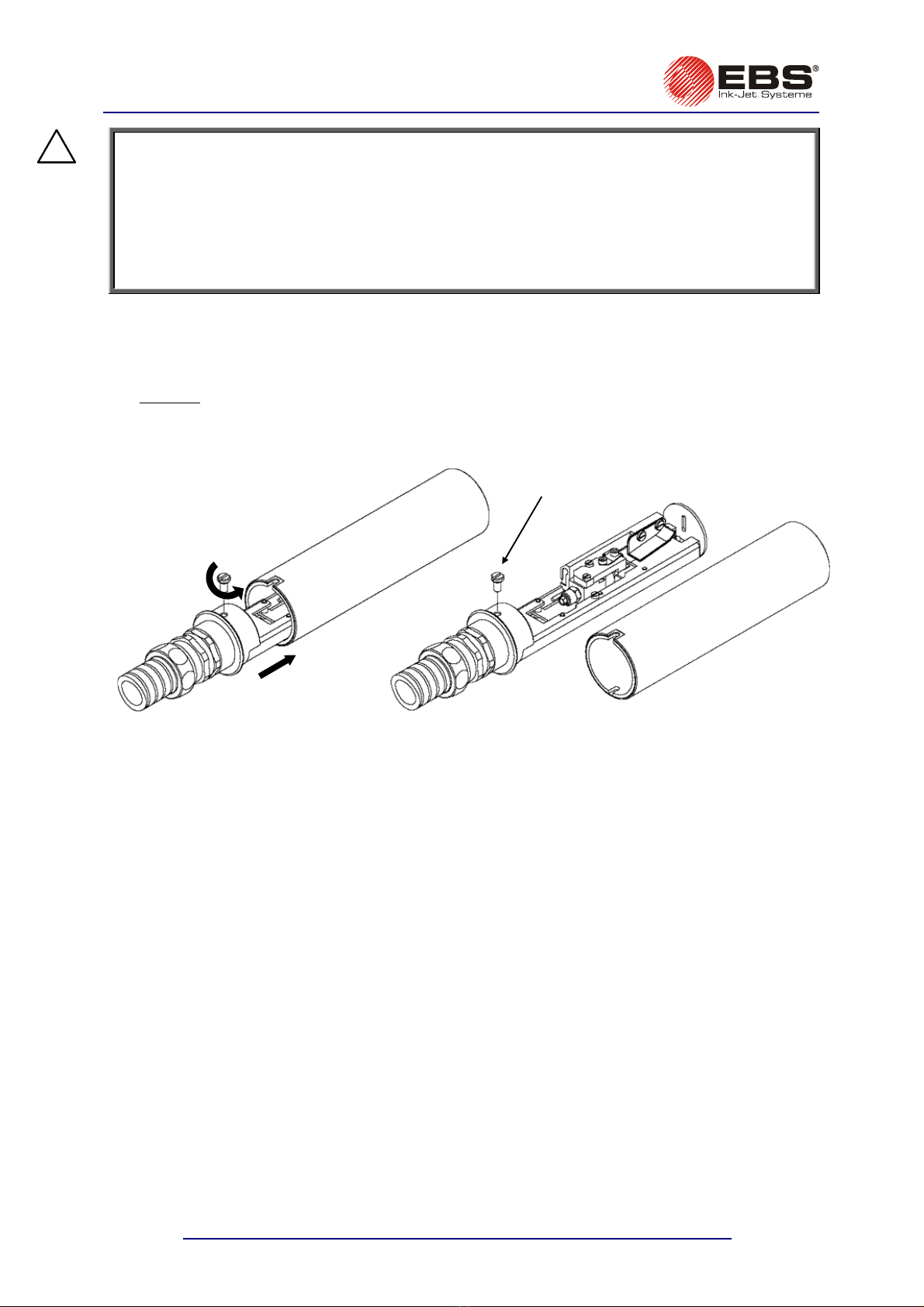

2.4. Removing Head Casing

To gain access to inner parts of the head, remove the head from the holder and remove the casing.

The operation involves the following steps:

•Unscrew the fixing screw on the head casing ,

•Remove the head from the casing carefully .

Direction

Head

casing

of removal

Unscrew in

this direction

The screw secure

casing and ens

contact betwe

casing and the

s the head

ures electrical

en the metal

printer earth

Fig. 2.4.1.

EBS-6200 Printer User's Manual

Chapter 3 - Starting the Printe

r

#1.0 17

20091020

3. Starting the Printer

sed throughout the manual:The following key descriptions are u

•The green ON key is marked with

ON

,

•The red OFF key is marked with

OFF

,

•The yellow CLR. ALARM key is marked with

CRL.

ALARM

.

ON

OFF

CLR.

ALARM

MAIN POWER

SWITCH

Fig. 3.1.

The

EBS-6200

printer is equipped with a power supply with a watch circuit. There are two

power switches that differ from each other over the way mains electricity is switched on or off:

1. The main (bi-stable) power switch, which separates electrically two power wires from the

mains; it is located on the right-hand side of the unit next to the mains cord

. After the main

power switch has been turned on, the printer triggers to the watch mode and the red lamp

between the

ON

and

OFF

keys starts glowing.

2.

The electronic power switch (the

ON

,

OFF

and

CRL.

ALARM

keys on the external panel) designed to

turn the printer on and off by changing the printer’s mode from the watch mode (the lamp emits

red light) to the operation mode (the lamp emits green light) and vice versa. The keys should

normally be used to switch the unit on and off.

If it needs to be separated electrically from the mains, the unit should be turned off, as

described in section 3.2 Switching the Printer Off, and then the main power switch should

be turned off.

ch mode, i.e. with its main switch in the

ON position.

NOTE:

The description below relates to the printer in its wat

!

EBS-6200 Printer User's Manual

Chapter 3 - Starting the Printer

18

200

3.1.

If all the connections are made properly, then it is enough to press the green

Switching the Printer On

ON

button (on the

The procedure is initiated. It involves the following steps:

1

r voltage is applied and electronics cards are tested.

2

a

3.

T

4

5.

th

a

If no head should work after the printer has been turned on, the turning on should be followed by the

CE

. The above mentioned starting procedure

and to activate the head.

) - see

Fig. 4.1.2.2,

indicates the following:

eters stabilize,

START PRINT

command can be selected.

During the entire starting procedure both the parameters and text files can be selected and modified.

If the

START PRINT

command is selected before the READY lamp starts glowing, the command is

not executed (the message

UNIT NOT ACTIVE

is displayed instead). Some errors may also delay the

readiness of the unit for operation by about 2 to 3 minutes. Check for error indications on the terminal

or the internal panel.

If the

EBS-6200

printer has not been used for a period of at least 2 weeks, ink pressure may

drop and the following error messages may appear twice or three times after the unit has been

started:

INK PUMP TIME-OUT

or

INK PRESSURE DROP

. You can clear the alarm with the yellow

external panel) (see

Fig. 3.1

).

n, the starting

.

Powe

T

.

he high voltage module is set to the value that is already stored in the memory (it takes from

few to a dozen or so seconds).

he nozzle is rinsed with solvent (for about 10 seconds).

.

Solvent is sucked out (for about 2 seconds).

The flow of ink in the head starts and the printer waits until ink parameters stabilize. Afterwards,

e automatic process of breaking the ink jet into droplets starts, initiating the phasing procedure

nd ink viscosity measurement (it takes about 2 minutes).

FAST OFF

command within the submenu

SERVI

consists of step 2 only. Use the

INK ON

comm

During the starting procedure the red READY lamp (on the internal panel available on the electronics

card, after the upper door has been opened

´

no light - ink is supplied to the head and ink param

´

flashing - the ink breaking process stabilizes,

´

steady light - the head is ready for printing. The

CRL.

ALARM

key and continue operating the unit as usual.

3.2. Switching the Printer Off

There are several modes of switching the printer off:

´

mode (to switch the printer off for a period of up to 1 week),

mode,

Service mode,

´

Switch-off mode to prepare the printer for storage over a longer time (up to 3 months or longer

than 3 months) – for a detailed description refer to

7.1 Storing the Printer

.

3.2.1. Switching the Printer Off in Regular Mode

In order to switch the printer off in

the regular mode

you just need to press the red

Regular

Emergency

´

´

OFF

key (see

Fig. 3.1

) on the external panel and wait a few minutes for the printer to turn off. Then the lamp

between the

ON

and

OFF

keys changes colour from green to red. The

SWITCHING THE PRINTER OFF .....

message is displayed on the terminal and the time till the end of

the switching off procedure is counted down in the status window.

The following processes are involved when the printer is switched off in the regular mode:

´

Ink is sucked from the ink pipes,

´

The pipes, gun, nozzle and gutter are rinsed,

´

The pipes connected to the head are filled with solvent.

91020#1.0

Table of contents

Other EBS Ink-Jet Systems Printer manuals