EC-PACK EC-JET 1000Pro User manual

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

1

Copyright Notice

This publication may not be reproduced, stored in a retrieval system, or transmitted in

whole or in part, in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, for any purpose without the written permission of EC-JET.

Neither whole nor part of the product described in this user manual, may be adapted or

reproduced in any material form without prior written permission of EC-JET.

Disclaimer

Information of a technical nature and particulars of the product and its use are given by

EC-JET in good faith. However, it is acknowledged that there may be errors or omissions

in this user manual.

EC-JET shall not be liable for any loss or damage arising from the use of any information,

particulars or errors in this user manual, or maintenance carried out by unauthorized

personnel, or any incorrect use of the product, whatsoever.

At all times the printer must be operated with EC-JET approved spares and consumables.

Maintenance not identified in this user manual must be carried out by EC-JET engineers

or authorized distributors.

About this Manual

The purpose of this user manual is to provide the operator with sufficient information to

operate the ECJET Ink Jet Printer. The information in this manual applies to

EC-JET1000Pro series inkjet printers.

Products described in this user manual are subject to continuous development, and

reviews of this user manual will be made accordingly in subsequent editions or reissues.

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

2

Contents

Copyright Notice..........................................................................................................1

Disclaimer.....................................................................................................................1

About this Manual........................................................................................................1

1. Safety .........................................................................................................................8

1.1 Warnings and Cautions.............................................................................8

1.2 Lethal Voltages.........................................................................................8

1.3 Operation...................................................................................................9

1.4 Inks and Solvents......................................................................................9

1.5 First Aid ..................................................................................................10

1.5.1 Eye Contact.....................................................................................................10

1.5.2 Skin Contact....................................................................................................10

1.5.3 Inhalation.........................................................................................................10

1.5.4 Ingestion..........................................................................................................10

1.6 In Case of Emergency.............................................................................10

1.7 Noise Emissions......................................................................................10

2. Introduction..............................................................................................................11

2.1 Printer System Overview........................................................................11

2.2 System Description.................................................................................12

2.2.1 Operating Simplicity.......................................................................................12

2.2.2 Diagnostics......................................................................................................12

2.2.3 Print head Design............................................................................................12

2.2.4 Printing Drops.................................................................................................12

2.2.5 Leaving Gaps ..................................................................................................12

2.2.6 Detecting Products ..........................................................................................13

2.2.7 Conveyor Speed..............................................................................................13

2.2.8 Ink Blockage Prevention.................................................................................13

2.2.9 Blockages........................................................................................................13

2.2.10 Automatic Cleaning at Shutdown....................................................................13

2.2.11 Velocity of Drop .............................................................................................14

2.3 Principles of Operation...........................................................................15

3. Controls and Indicators............................................................................................16

3.1 Getting Started ........................................................................................16

3.2 Installation...............................................................................................16

3.3 Connection..............................................................................................17

3.3.1 Switch on the printer.......................................................................................17

3.3.2 Start and Stop keys..........................................................................................18

3.4 Screen Display ........................................................................................19

3.4.1 Display Brief Introduction ..............................................................................20

3.4.2 Cursor Control Keys........................................................................................21

3.4.3 Text Control Keys...........................................................................................21

3.4.4 General Control Keys......................................................................................21

3.5 Creating a Simple Message.....................................................................22

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

3

3.6 Advanced Editing Features.....................................................................24

3.6.1 Moving to Pixel (Drop) Locations ..................................................................24

3.6.2 Moving to the Beginning of Message .............................................................24

3.6.3 Quick shifting the Character Font or New line ...............................................24

3.6.4 Quick selecting the message withArrows Key...............................................25

3.6.5 Copying and Pasting the Message...................................................................25

3.7 Starting the Printer..................................................................................25

3.8 Stopping (switching off) the printer........................................................25

3.9 Passwords................................................................................................26

3.10 Screen Calibration...................................................................................26

4. Using the System .....................................................................................................27

4.1 Moving around the Menus......................................................................27

Selecting Menus....................................................................................................27

4.2 Select and edit.........................................................................................28

4.2.1 Current Message Screen..................................................................................28

4.2.2 Editing a Message...........................................................................................29

4.3 Checking the Current Status of the Printer .............................................30

4.3.1 System Status Line..........................................................................................30

4.3.2 Print Status Screen ..........................................................................................30

4.4 Checking the Printer Status.....................................................................30

4.5 Listing Error Messages...........................................................................31

4.6 4.6 Password ...........................................................................................32

4.6.1 Password Level ...............................................................................................32

4.6.2 Password .........................................................................................................33

5. Creating, Editing and Deleting Message Fields.......................................................34

5.1 Introduction.............................................................................................34

5.1.1 The message used has a complete mix of all field types:................................34

5.1.2 Message Fields................................................................................................35

5.2 Editing and Deleting Message Fields .....................................................36

5.2.1 Editing Fields..................................................................................................36

5.2.2 Text Fields.......................................................................................................36

5.2.3 Other Fields.....................................................................................................37

5.2.4 Deleting Fields................................................................................................37

5.3 Creating Text Fields................................................................................37

5.3.1 Creating Date Fields........................................................................................37

5.3.2 Creating Sequential Number Fields ................................................................41

5.3.3 Creating Time Fields.......................................................................................43

5.3.4 Creating Timed Message Fields......................................................................45

5.3.5 Creating Remote Fields...................................................................................49

5.3.6 Creating Logo Fields.......................................................................................50

5.4 Logo Editor.............................................................................................51

6. Changing the System Setup.....................................................................................52

6.1 Adjusting Ref. Information.....................................................................53

6.1.1 Print Height.....................................................................................................53

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

4

6.1.2 Scale Height....................................................................................................53

6.1.3 Print Width ......................................................................................................53

6.1.4 Print Delay ......................................................................................................53

6.1.5 Print Interval....................................................................................................53

6.1.6 Print Count......................................................................................................53

6.1.7 Reverse Message (Vertical).............................................................................53

6.1.8 Reverse Message (Horizontal) ........................................................................53

6.1.9 Bold Ratio .......................................................................................................54

6.1.10 Aux In..............................................................................................................54

6.1.11 Photocell..........................................................................................................54

6.1.12 Shaft Encoder..................................................................................................54

6.1.13 Repeated Trigger.............................................................................................54

6.1.14 Alarm Set Up...................................................................................................54

6.2 Changing the Installation Setup..............................................................55

6.2.1 Set Time ..........................................................................................................55

6.2.2 Set Date...........................................................................................................55

6.2.3 Conduit Length................................................................................................55

6.2.4 Head Height ....................................................................................................56

6.2.5 Meter Counter .................................................................................................56

6.3 Changing System Set Up........................................................................56

6.3.1 Print Head Code..............................................................................................56

6.3.2 Ref. Modulation ..............................................................................................56

6.3.3 Ink Selection....................................................................................................57

6.3.4 Password .........................................................................................................57

6.3.5 Change Password............................................................................................57

6.3.6 Change Language............................................................................................57

6.3.7 Remote Setup Menu........................................................................................57

6.3.8 Diagnostic Menu.............................................................................................57

6.3.9 Solvent Add Time............................................................................................58

7. Diagnostics...............................................................................................................59

7.1 Start Jet....................................................................................................59

7.2 Stop Jet....................................................................................................60

7.3 Quick Start Jet.........................................................................................60

7.4 Start Print ................................................................................................60

7.5 Stop Print ................................................................................................60

7.6 Clear Nozzle............................................................................................61

7.7 Flush Nozzle ...........................................................................................61

7.8 Flush Shut Down.....................................................................................61

7.9 Monitor Jet..............................................................................................62

7.10 System Times (System Timing Information)..........................................63

7.11 System Configuration Information.........................................................63

7.12 Set Pressure.............................................................................................64

7.13 Filter Purge..............................................................................................64

7.14 Real-Time Switch or Edit Message ........................................................65

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

5

7.14.1 Real-time Switch Message..............................................................................65

7.14.2 Real-time Edit Message ..................................................................................65

7.14.3 Real-time New Message..................................................................................65

8. Routine Maintenance ...............................................................................................66

8.1 Cleaning the Printer Cabinet...................................................................66

8.1.1 General............................................................................................................66

8.1.2 Ink Spillages....................................................................................................66

8.1.3 Cleaning the Nozzle........................................................................................66

8.1.4 Cleaning the Print head...................................................................................66

8.2 Replenishing Ink and Solvent.................................................................67

8.2.1 NOTE..............................................................................................................67

8.2.2 EC1000 Consumable verification ...................................................................68

8.2.3 Refilling the ink or solvent..............................................................................71

8.3 Cleaning/Replacing the Air Filter...........................................................72

8.3.1 Cleaning and replacement of air inlet filter.....................................................72

8.3.2 Cleaning/Replacing the air outlet filter ...........................................................73

8.4 Quick Maintenance Mode.......................................................................74

9. Warning and Fault Messages ...................................................................................77

9.1 Warning and Fault Messages ..................................................................77

9.2 Summary of Warning Messages .............................................................77

9.2.1 System Failures...............................................................................................77

9.2.2 Print Failures...................................................................................................77

9.2.3 System Warnings.............................................................................................77

9.3 System failures........................................................................................78

9.3.1 Print Failures...................................................................................................78

9.3.2 2.00 Print head Temperature...........................................................................79

9.3.3 2.01 Deflector Voltage....................................................................................79

9.3.4 2.02 Charge.....................................................................................................80

9.3.5 2.03 Velocity Of Drop.....................................................................................80

9.3.6 2.04 300V Power Supply ................................................................................80

9.3.7 2.05 Temperature/Deflector............................................................................80

9.3.8 2.06 Ink Tank Empty.......................................................................................80

9.3.9 2.16 Internal Spillage Fault.............................................................................81

9.4 System Warnings ....................................................................................81

9.4.1 3.00 No VOD Adjustments.............................................................................82

9.4.2 3.01 Jet Shut Down Incomplete ......................................................................82

9.4.3 3.02 Over Speed (Print Go).............................................................................82

9.4.4 3.03 Ink Low...................................................................................................83

9.4.5 3.04 Solvent Low............................................................................................83

9.4.6 3.05 Print Go / Remote Data...........................................................................83

9.4.7 3.06 Service Time ...........................................................................................83

9.4.8 3.07 Print Head Cover Off ..............................................................................83

9.4.9 3.08 Bad Print Head Code...............................................................................84

9.4.10 3.09 New Print Head Fitted.............................................................................84

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

6

9.4.11 3.10 Charge Calibration Range.......................................................................84

9.4.12 3.11 Safety Override Detected ........................................................................84

9.4.13 3.12 Low Pressure...........................................................................................84

9.4.14 3.14 Over Speed (Variable Data)....................................................................85

9.4.15 3.15 Default Language....................................................................................85

There is little chance of fault of default language...........................................................85

9.4.16 3.16 Memory Failure.......................................................................................85

9.4.17 3.17 Memory Corrupt......................................................................................85

9.4.18 3.18 No Message Stored In Memory...............................................................85

10. Troubleshooting.....................................................................................................86

10.1 Where to Start .........................................................................................86

10.2 Identifying Faults....................................................................................87

10.3 Identifying Faults by Print Sample.........................................................87

10.4 Identifying Faults by Symptom ..............................................................88

10.5 Problem Solving......................................................................................90

10.5.1 Problem Solving - Print Samples ....................................................................91

10.5.2 Problem Solving - Ink System Mechanical Faults..........................................93

10.5.3 1 Problem Solving - Printhead Mechanical Faults..........................................94

10.5.4 Blockage Caused by Knocking and Strong Vibration...................................100

Appendix 1:Installation & Setting Up ....................................................................103

1.1 Unpacking the System ..........................................................................103

1.2 Where to Put the Printer........................................................................103

1.3 Accessories ...........................................................................................103

1.4 Power Connection.................................................................................104

1.5 Attaching the Printhead to the Production Line....................................104

1.5.1 Print Height...................................................................................................104

1.6 Setting up the Photocell........................................................................105

1.6.1 Photocell Connections...................................................................................105

1.7 Setting up the Shaft Encoder.................................................................106

1.7.1 Shaft Encoder Connections...........................................................................106

1.7.2 Selecting the Encoder, Gearing, and Print Width..........................................107

1.7.3 Encoder and Print Width Problems...............................................................111

1.8 Using the Printer Alarm Output............................................................112

1.9 Filling with Ink and Solvent .................................................................112

1.10 Purging (or priming) the Filters............................................................113

Appendix 2:Technical Specification.......................................................................114

2.1 Introduction...........................................................................................114

2.2 Technical Data ......................................................................................114

2.2.1 Cabinet..........................................................................................................114

2.2.2 Dimensions....................................................................................................114

2.2.3 Weight...........................................................................................................114

2.2.4 Power Requirements .....................................................................................114

2.2.5 Environmental...............................................................................................114

2.3 Ink System ............................................................................................115

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

7

2.3.1 Construction..................................................................................................115

2.3.2 Capacity.........................................................................................................115

2.3.3 Pressure.........................................................................................................115

2.3.4 Level Control ................................................................................................115

2.3.5 Performance ..................................................................................................115

2.4 Memory Capacity..................................................................................115

2.5 Printhead ...............................................................................................115

2.5.1 Types.............................................................................................................115

2.5.2 Construction..................................................................................................115

2.5.3 Dimensions....................................................................................................116

2.5.4 Throw Distance (recommended)...................................................................116

2.6 Printing Performance Data....................................................................116

2.6.1 Raster Information.........................................................................................116

2.6.2 Character Height Range................................................................................116

2.7 Certificate Acquired..............................................................................117

2.7.1 EMC..............................................................................................................117

2.7.2 LVD...............................................................................................................118

Appendix 3: Printable Line Speeds............................................................................119

Ideal Pitch ...........................................................................................................119

Double Pitch........................................................................................................119

Triple Pitch..........................................................................................................119

Appendix 4: Dimension Layout.................................................................................120

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

8

1. Safety

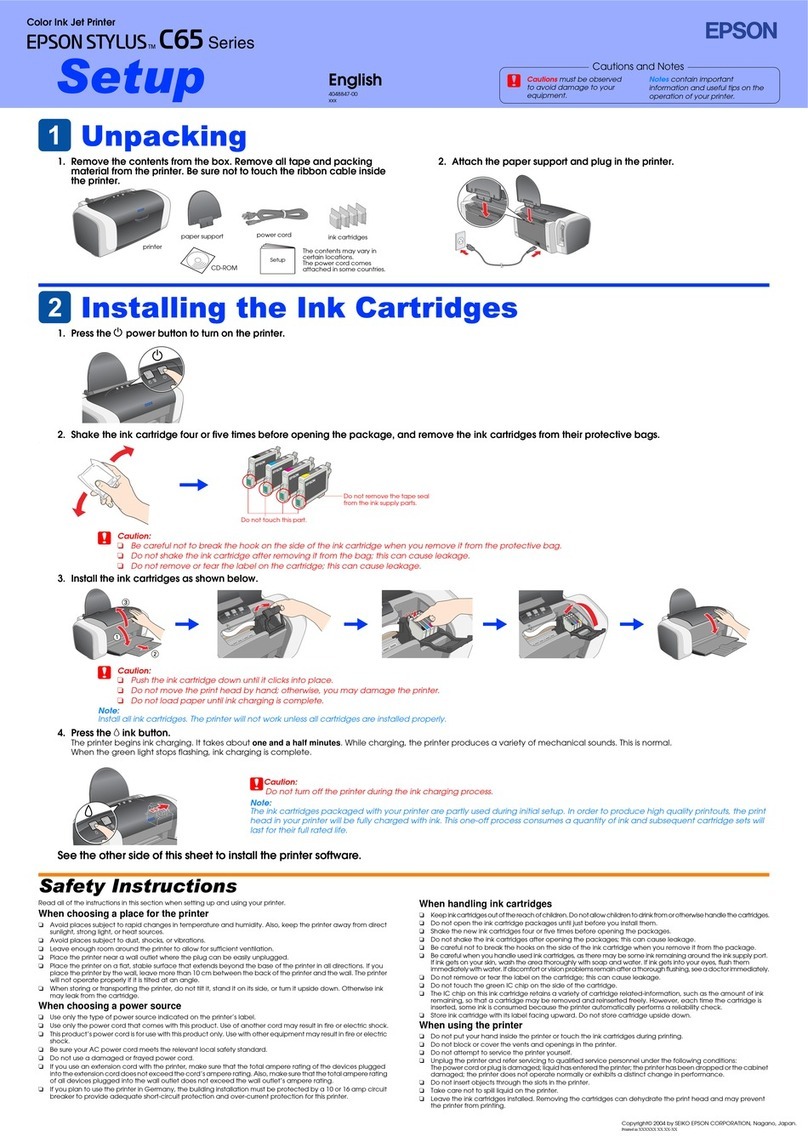

1.1 Warnings and Cautions

At appropriate points within the text of this manual, additional safety statements will be displayed. These

are designed to alert your attention to hazards and important information that assists you in carrying out

your activities on this printer safely and efficiently. Each safety statement has a separate meaning so that

you can identify the importance of the information provided. Examples and descriptions of safety

statements have been provided as follows:

WARNING: A WARNING ALERTS YOU TO HARMFUL OR POTENTIALLY LETHAL

ACTIVITIES. A DESCRIPTION OF THE HAZARD IS GIVEN AND THE

CONSEQUENCES OF IGNORING THEM. A WARNING CAN ALSO BE SHOWN AS A

SPECIFIC HAZARD, FOR EXAMPLE, EYEROTECTION (SEE BELOW).

THE EYE PROTECTION WARNING ICON IS SHOWN THROUGHOUT THE MANUAL

TO INDICATE. THAT APPROVED EYE PROTECTION, WHICH CONFORMS TO

EUROPEAN AND INTERNATIONAL SAFETY STANDARDS, MUST BE WORN WHEN

CARRYING OUT INK OR SOLVENT RELATED

ACTIVITIES.

CAUTION: A CAUTION ALERTS THE USER TO ACTIVITIES THAT MAY CAUSE

DAMAGE TO EQUIPMENT OR REDUCE ITS OPERATING EFFICIENCY, BUT IS

NOT DIRECTLY HAZARDOUS TO PERSONNEL.

NOTE: A Note provides important additional information but is not safety related. The hand icon may not

always be shown depending on the importance of the Note. A Note with a hand icon indicates that you

should take particular notice of the information provided.

1.2 Lethal Voltages

WARNING: LETHAL VOLTAGE. DANGEROUS VOLTAGES ARE PRESENT IN THIS

EQUIPMENT WHEN ELECTRICAL POWER IS APPLIED. THERE IS A DANGER OF

DEATH OR INJURY FROM ELECTRIC SHOCK.

UNDER NO CIRCUMSTANCES ARE YOU TO ATTEMPT TO OPEN THE SCREEN

DOOR OR THE BACK ACCESS DOOR AND REMOVE OR ADJUST ANY

COMPONENTS FITTED WITHIN THE PRINTER.

ONLY FULLY TRAINED OPERATORS OR APPROVED SERVICE ENGINEERS ARE

QUALIFIED TO OPEN THE FRONT INKSYSTEM DOOR WHEN ADDING INK OR

SOLVENT,ONLY FULLY TRAINED EC-JET APPROVED ERVICE ENGINEERS

ARE QUALIFIED TO OPEN THE THE SCREEN DOOR OR THE BACK ACCESS

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

9

DOOR TO MAINTAIN OR ADJUST THE INTERNAL PARTS.

1.3 Operation

All users operating the printer must be aware of the following hazards associated with ink jet printers.

The following safety information should be made available to all personnel and is applicable to anybody

in the printer’s operating environment. Only fully trained and competent personnel should operate or

maintain EC-JET printers. If you are in any doubt as to your ability to operate or maintain the printer, did

not hesitate to consult your supervisor for guidance or contact your local EC-JET distributor who will be

happy to advise you.

1. Don’t smoke or use naked flames in the vicinity of the printer. The printer contains flammable inks

and solvents.

2. Always ensure that the printer electrical supply is isolated prior to performing cleaning or

maintenance activities. Lethal voltages are present in the printer cabinet and printhead when

mains power is applied which can cause death or serious injury if the correct electrical procedures

are not observed. When a main operated external alarm is connected to the external alarm socket,

this must be disconnected before any maintenance activities are carried out.

3. Only the fully trained operators or service engineers qualified to open the front ink system door to

add the ink or solvent. Only fully trained EC-JET approved service engineers qualified to open the

screen door or the back access door

4. Always check that all covers are correctly fitted and all doors are closed before you use it. If you

are not sure, ask your supervisor for guidance. Covers act as safety barriers and also ensure the

printer retains its electromagnetic compatibility.

5. It is recommended that the printer is situated at least 600 mm from floor level for your comfort.

1.4 Inks and Solvents

Whenever inks and solvents are used, safety eyeglasses to the appropriate European and International

Directives must be worn. Solvent resistant gloves must be worn when contact with inks or solvents is

likely.

The effects of solvents and inks are potentially harmful. Prior to use, ensure the printing area is properly

ventilated and the Material Safety Data Sheets have been read and fully understood. If you are unsure,

contact your supervisor for guidance.

If the Material Safety Data Sheets have not been supplied or are not available, please contact your local

EC-JET distributor. Always refer to the Material Data Safety Sheets before working with inks and

solvents.

Store all inks and solvents in original containers, in a well- ventilated cabinet and away from heat sources.

Ensure all spilt ink or ink deposits are removed immediately using the correct solvent for the ink used.

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

10

1.5 First Aid

Ensure that first aid information is readily available in the event of ingestion, inhalation, or contact with the

skin or eyes. Ideally all operators should be trained in First Aid and should be aware of the effects of

working with flammable and toxic substances. All operators should have access to the ink and solvent

Material Safety Data Sheets, which explain the hazards and medical action to be taken if first aid is

necessary.

1.5.1 Eye Contact

Flush eyes using clean running water for a minimum of 10 minutes. Obtain immediate medical attention.

1.5.2 Skin Contact

Remove any contaminated clothing and wash the affected skin area thoroughly with proprietary cleaner.

Do NOT attempt to use solvents to remove ink from skin.

1.5.3 Inhalation

Evacuate the person into a fresh air environment. If the person experiences any difficulty in breathing,

obtain immediate medical attention.

1.5.4 Ingestion

Do not induce vomiting; obtain immediate medical attention and give the casualty half a litre of water to

drink.

1.6 In Case of Emergency

If the printer needs to be stopped quickly due to an emergency, press the red [stop] key on the printer to stop the

printing and switch the printer power switch on the rear panel of the printer to the ‘O’ (off) position. Call for

medical assistance as required.

1.7 Noise Emissions

The noise emission level from this printer does not exceed 70 dBA. This means that there is no hazard to

hearing and, therefore, no legal requirement for ear protection to be worn when working in the vicinity of

this printer.

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

11

2. Introduction

A Safety section has been provided at the front of this manual for your use. You are strongly advised to

read the Safety section carefully before attempting to use the EC-JET printer.

2.1 Printer System Overview

The EC-JET printers provide a means of application of printed information onto a wide range of products.

This information would typically be the date, production codes, consumer information, product or

corporate identification, product traceability, and many others. It can be widely used in pharmaceutical,

chemical, food, construction materials, tobacco, ceramics, electronics and other industries.

The printer is normally fixed to a production line in such a way that printing takes place as the product

passes the print head. The presence of the product and printing can be synchronized using a product

detecting sensor.

The printer consists of a cabinet and a print head. The cabinet houses the electronics module, the ink

system, a power supply and a message screen display. The print head is attached to the rear of the

cabinet via a flexible conduit.

The print head is supplied with ink by the ink system which the print head forms into a continuous stream

of ink drops which recycle to the ink system. When printing is required, drops of ink for printing the

message are deflected from the stream out of the print head onto the product, providing a non-contact

method of printing. The process is controlled by the electronics module which also stores the messages

to be printed. The message is programmed using the touch screen.

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

12

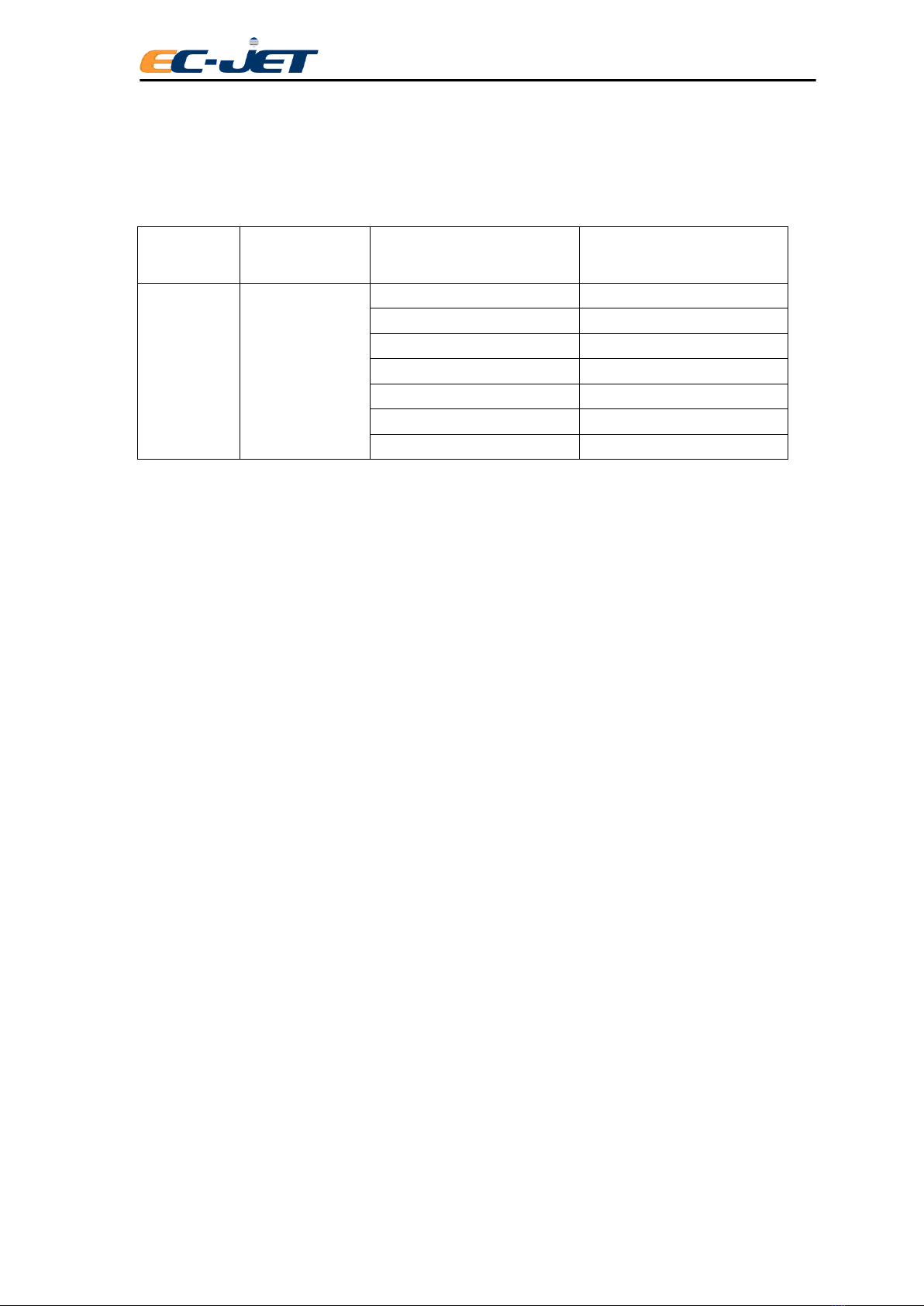

2.2 System Description

The EC-JET printers are designed to provide versatile, uninterrupted operation in factory environments.

The models available, together with available raster types and compatible print heads are as follows:

PRINTER

MODEL

PRINTERHEAD

TYPE

RASTER TYPE

CHARACTERS

EC-JET

1000Pro

60µm

7 Dot Standard Speed

5、7

9 Dot Standard Speed

5、7、9

12 Dot Standard Speed

5、7、9、12

16 Dot Standard Speed

5、7、9、12、16

24 Dot Standard Speed

5、7、9、12、16、24

24 Dot High Quality

5、7、9、12、16、24

25 Dot Standard Speed

5、7、9、12、16、24

2.2.1 Operating Simplicity

Easy start-up and shutdown requires minimal operator intervention. Messages are easily created using

the built-in QWERTY keyboard, and the printer offers print adjustment and message editing facilities.

2.2.2 Diagnostics

A comprehensive diagnostics package is built into the printer to enable problems to be identified and

rectified quickly.

2.2.3 Print head Design

The print head is robustly designed for industrial environments. It is hermetically sealed and is

permanently attached to the printer itself by a 2 metres length of conduit.

2.2.4 Printing Drops

To form a printed pattern, each drop must be directed to a different place on the product being printed.

To achieve this, the drops pass through a charge electrode (within the print head), which applies a

different charge to each drop. This causes the flight path of the drops to differ as they travel between

two deflector plates. When the drops reach the product, they form one line of drops called a raster. As the

product passes under the print head, rasters are laid down side by side to form the printed message.

2.2.5 Leaving Gaps

Unprinted drops in a raster carry no charge and are therefore not deflected. These drops are captured by

a gutter in the print head, and returned to the ink tank. Gaps between raster (perhaps to separate

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

13

readable characters) are created by the printer simply not printing a raster as the product continues to

move past the printhead.

2.2.6 Detecting Products

A photocell or product detecting sensor is used to inform the printer when the product has been detected.

After a predefined delay, the first raster of the pattern will be printed, followed by the remaining rasters of

the pattern, as described above.

2.2.7 Conveyor Speed

For production setups using a conveyor, variation in conveyor speed can produce variation in the

appearance of the printed message. If the product is moving very slowly, the rasters could be printed

too close together and the characters formed would be too thin. Conversely, if the product is moving

very fast, the rasters could be printed too far apart, resulting in unprinted gaps between the rasters.

This problem is overcome by either varying the print width (through a user menu option) to match the

production of rasters with the conveyor speed, or by using a shaft encoder to control the rate at which

each raster is printed in relation to the conveyor movement.

2.2.8 Ink Blockage Prevention

It is essential to use the correct solvent for the ink being used, i.e. the solvent used in the ink

base: MEK solvent for MEK based ink, ETHANOL solvent for ETHANOL based ink, etc.

The principle of continuous ink jet printing has proved to be the most effective means

of printing with an ink which is required to dry instantly, within a second, on almost any

surface.

2.2.9 Blockages

If ink is required to dry on the product it will also have a tendency to dry in the printer, with a possibility of

causing a blockage.

The continuous ink jet printer overcomes this problem by continuously producing the print drops in

operation. Although the ink is evaporating quickly during this process, it does not cause a nozzle

blockage, as there is a constant replacement of ink in the nozzle.

2.2.10 Automatic Cleaning at Shutdown

A potential problem arises on shutdown when ink is left in the nozzle; as it is fast drying it will soon dry

and clog up the nozzle. To overcome this, special procedures to clear the nozzle are necessary.

With EC-JET printers the clean-up procedures at shutdown are achieved by an automatic flushing

system.On shutdown, the ink is removed from the ink nozzle assembly by suction through a purge line.

Just prior to shutdown, a solvent flush system introduces solvent into the printhead, and runs solvent

through the nozzle and gutter, thus clearing ink from these vital components. This automatic procedure

makes it unnecessary to clean the printhead for shutdown.

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

14

2.2.11 Velocity of Drop

Ink velocity can impose a minor change in the mass of a drop, which will affect the final printing position

of the drop. However, precise placement of drops is more dependent on the speed of the drops as they

travel through the deflector plates;.

For this reason, the velocity of drop (VOD) is constantly monitored and compared with the optimum (VOD

reference) value printed on the print head conduit. A “feedback loop” is used to increase or decrease

ink pressure, thus maintaining the correct speed of drops for accurate placement and therefore quality of

print. The following illustrates principle:

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

15

2.3 Principles of Operation

A conducting ink is supplied under pressure to an ink gun and forced out through a small nozzle of

typically 40 to 70 micro diameters. As it passes through the nozzle the liquid is piezo-electrically pulsed

(modulated) and the stream breaks up into a continuous series of drops which are equally spread and are

of the same size.

Surrounding the jet at the point where the drops

separate from the liquid stream is a charge

electrode. A voltage is applied between the

charge electrode and the drop stream. When the

drop breaks off from the stream it carries a

charge proportional to the applied voltage at the

instant at which it breaks off. By varying the

charge electrode voltages at the same rate as

the drops are produced, it is possible to charge

every drop to a predetermined level.

The drop stream continues its flight and passes

between two deflector plates which are

maintained at a constant potential, typically plus

and minus 5 kilovolts. In the presence of this field

a drop is deflected towards one of the plates by

an amount proportional to the charge carried.

Drops which are uncharged are unelected and

are collected by a gutter to be recycled into the

ink tank. Those drops which are charged, and,

therefore, deflected, are printed on the substrate,

which is travelling at a certain degree and speed

to the direction of the drop deflection.

By varying the charge on the individual drops,

whatever pattern is required (including

alphanumeric characters) may be printed. A

series of

drops deflected across the substrate is known as

a raster.

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

16

3. Controls and Indicators

3.1 Getting Started

This section of the manual is intended to help you understand the setting-up of the printer and tells you

how to switch it on, program a simple message, start the printer jet, print the message and stop the

printer.

Apart from familiarizing you with the machine and some of the most frequently used software, it will

enable you to verify that all is well and the printer and accessories have reached you in good condition.

3.2 Installation

The printer should always be installed by a fully trained, EC-JET approved, service engineer. Guarding

and safety interlocks should all be in place and working correctly. EC-JET can accept no liability for

damage to either machine or personnel in the event of the printer being installed, moved or maintained by

unauthorized and/or untrained personnel.

If the printer is relocated or changes to the production line are made, information on how to install and set

up the printer can be found in “Appendix 1: Installation and Setting Up”.

EC-JET printers can be fit to a single-phase 50/60 Hz AC power supply of 115V or 230 V.

Switch on the right voltage before power on, the shift button can be found as the picture shows:

There are two types of power supply:

115V for the range of 85-132Vac, 50/60Hz

230V for the range of 170-264Vac, 50/60Hz

NOTE: Disconnect the power supply plug before your switch on. Use a flat screwdriver to

switch.(the figures shown on the PSU value )

Input current: < 2.00A@115Vac,< 1.20A @ 230Vac

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

17

3.3 Connection

Before connecting to the power supply, make sure the ON/OFF switch is in the OFF position. The wires

in this electrical supply lead are colorized in accordance with the following code:

GREEN-YELLOW EARTH (E)

BLUE NEUTRAL (N)

BROWN LIVE (L)

WARNING: THIS PRINTER MUST BE EARTHED. THIS PRINTER MUST ONLY BE

WIRED BY A QUALIFIED ELECTRICIAN. EC-JET CAN ACCEPT NO

RESPONSIBILITY FOR ANY DAMAGE CAUSED TO EITHER MACHINE OR

PERSONNEL DUE TO INCORRECT OR FAULTY WIRING.

3.3.1 Switch on the printer

Plug the printer into a suitable supply and switch the printer power switch at the rear right of the

machine to on.

The following screen is displayed when power is switched on:

There will be a delay of a few seconds while the computer logic carries out internal checks. When these

checks are complete, the following display will be seen:

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

18

3.3.2 Start and Stop keys

Start Key

This initiates the start-up sequence which is responsible for carrying out internal checks and regulating

the ink flow until it is ready for printing.

Stop Key

This initiates the shutdown sequence which purges the nozzle of ink and automatically carries out

procedures to clean the nozzle. This prevents a potentially serious blockage of the nozzle caused by

dried ink. Simply press the [stop] key and the printer will initiate the shutdown sequence, which takes

approximately 3 minutes. While the machine is shutting down, the following message will appear in the

status line of the screen:

When the printer has finished the shutdown sequence, the following message will appear in the status

line of the screen:

The machine may now be switched off by the power switch at the rear of the printer.

CAUTION: Never switch off until the printer tells you to do so when it displays: “Jet Stopped: You may

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

19

now switch off”, in the status line of the screen. Whenever the Start or Stop keys are pressed, the

CURRENT MESSAGE screen is displayed.

3.4 Screen Display

Message Display

This part of the display area is used for displaying, creating and editing messages to be printed.

Operation Menu Display

This is used to display the operation message.

Appearance Line

This is used to display valve of VOD, pressure and phase.

Status Line

The status line is present in all menu displays. It is used to convey warning messages and print

failure conditions, to the operator.

Time / Date Display

This displays time and date.

Guangzhou EC-PACK Packaging Equipment Co., Ltd.

EC-JET 1000Pro Continuous Inkjet Printer

20

3.4.1 Display Brief Introduction

This button is to shift the functions and data shown in the OPERATION MENU. As below

pictures:

Table of contents

Other EC-PACK Printer manuals