Echo Mountain Audio JBL 4425 User manual

JBL Model 4425

Charge-Coupled Crossover

User Manual

echomountainaudio.com

echo mountain audio

altadena, california

2

INTRODUCTION 2

THE CHARGE-COUPLED TOPOLOGY 3

WHAT YOU’LL NEED 3

OVERVIEW 4

PARTS INFORMATION 6

REMOVING CROSSOVER FROM SPEAKER 7

REMOVING FACTORY PCB FROM CROSSOVER UNIT 7

PCB ASSEMBLY 8

INSTALLATION OF PCBS INTO CROSSOVER ASSEMBLY 10

INSTALLATION OF COMPLETED CROSSOVER ASSEMBLIES 11

APPENDIX A: PARTS LIST 13

APPENDIX B: MEASURED FREQUENCY RESPONSE 14

Introduction

Thank you for your purchase of Echo Mountain Audio’s charge-coupled crossover boards for the

JBL Model 4425 Studio Monitor. The set of bare boards you have received are intended for DIY

build and “plug-and-play” integration into your existing 4425 monitor system.

The scope of this user manual is to, as succinctly as possible, guide the assembly of the PCBs

and integration into the existing crossover unit.

Any comments, questions, technical support requests, etc. are welcomed and encouraged, and

3

The Charge-Coupled Topology

The “charge-coupling” technique was first employed on JBL’s K2 S5500 loudspeaker system by

Chief Engineer Greg Timbers and was used subsequently on all high-end JBL Synthesis models,

including the top-of-the-line Everest DD66000. The technique involves replacing a given capacitor

in a crossover topology with two series capacitors of twice that value (this series combination is

equivalent to the original value), with a DC bias injected between the two capacitors through a

large value resistor. This DC-biased topology mitigates the effects of dielectric absorption and

the distortion associated with a change in the direction of current as the input signal transitions

from positive to negative (i.e., zero crossing). The theory of operation is explained in detail in the

following excerpts from the K2 S5500 product overview:

http://www.lansingheritage.org/images/jbl/specs/home-speakers/1993-k2-s5500/page10.jpg

http://www.lansingheritage.org/images/jbl/specs/home-speakers/1993-k2-s5500/page11.jpg

http://www.lansingheritage.org/images/jbl/specs/home-speakers/1993-k2-s5500/page12.jpg

What You’ll Need

To complete the project build, you’ll need the items listed below. Links for each item are

provided to the recommended items/brands we’ve used in our own builds, but feel free to use

what works best for you.

• (2) Echo Mountain Audio Model 4425 Crossover boards

• 4425 Charge-Coupled parts kit for Model 4425 from Solen (see Parts Information

section and Appendix A for more details)

• (2) 9V batteries

• (2) 9V battery holder clips

• (2) 9V battery connectors with flying leads

• Zip ties

• Soldering iron – The PACE ADS200 is excellent, made in the USA, and what we use

• Small, smooth-jaw (non-marring) pliers

• Wire cutters

• Wire strippers

• Eutectic (Sn63/Pb37) flux-core solder – not lead-free! We use Cardas solder.

• De-soldering pump

• Adhesive for staking large components (capacitors and inductors) to the PCB – we

highly recommend Eclectic Products E6000 Clear adhesive

• Heavy duty double-sided tape

4

Overview

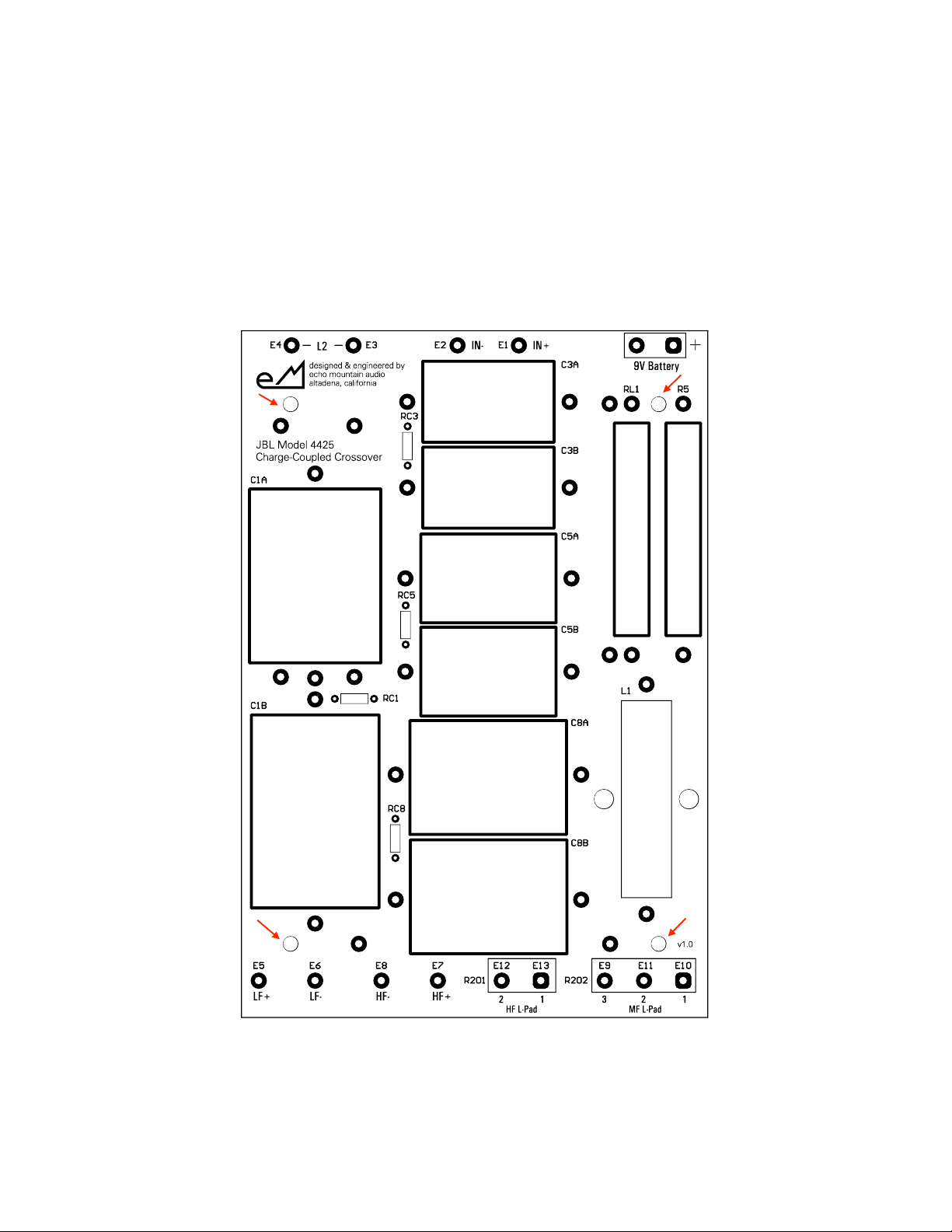

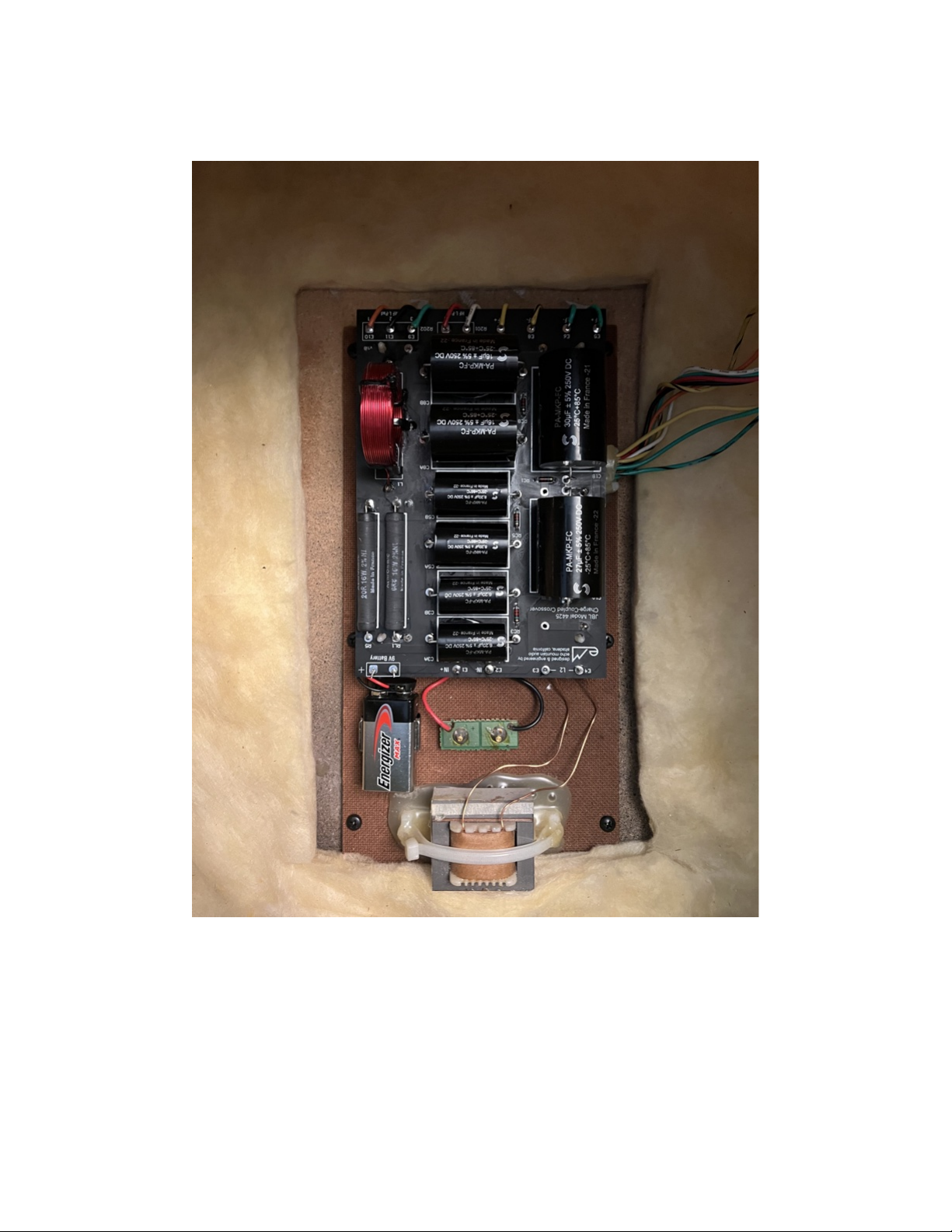

The JBL 4425 Charge-Coupled Crossover PCB is shown in Figure 1 (top side) and Figure 2

(bottom side). The board is designed to fit into the existing crossover housing, and the mounting

holes, denoted with red arrows in Figure 1, are sized to make use of the existing snap-lock PCB

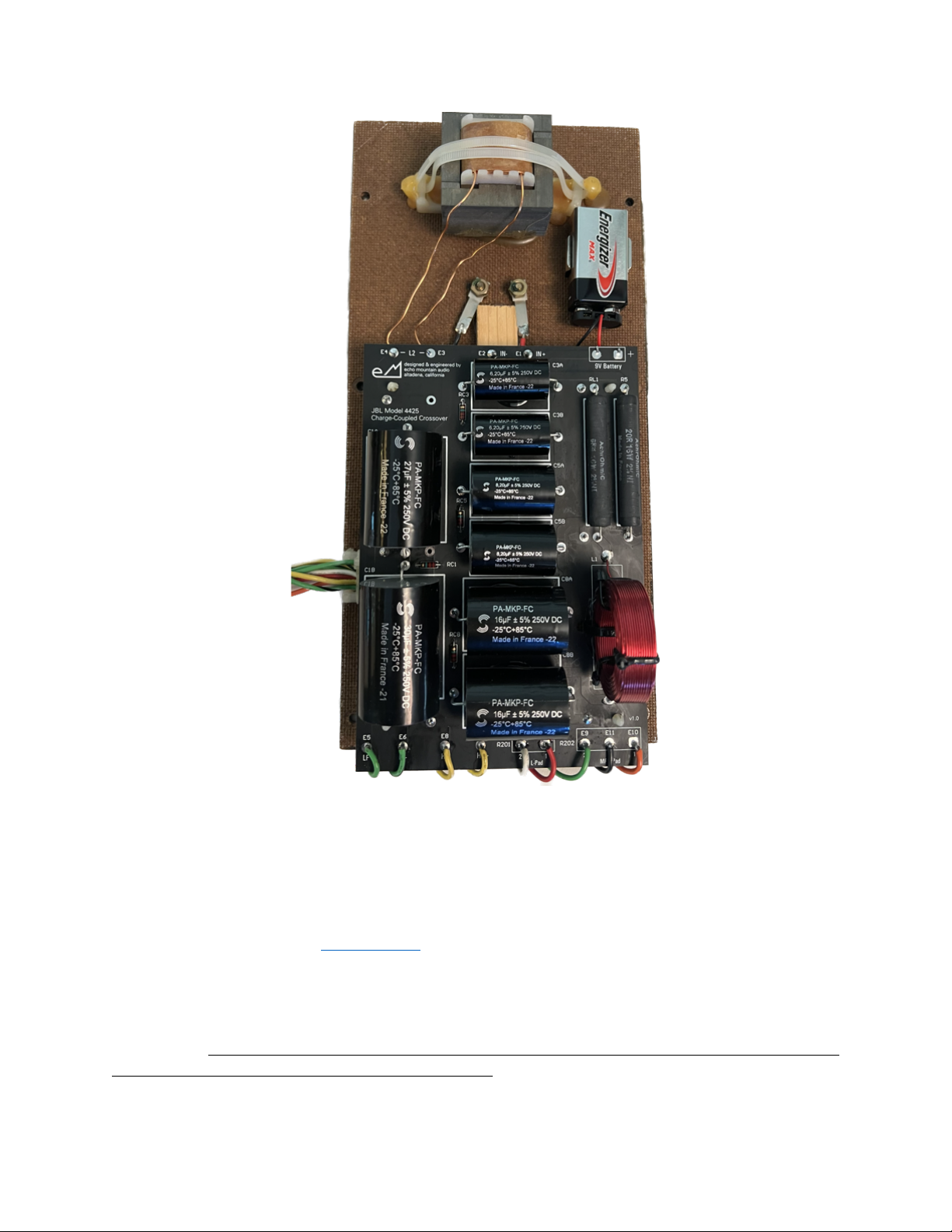

clips. An example of a completed crossover, installed in the factory crossover housing, is shown

in Figure 3. Note that the default configuration uses the factory inductor for the woofer low-pass

filter. If you are building a custom crossover for the 4425, do not have access to a factory

crossover unit, and/or want to use a different inductor, please see the Parts Information section.

Figure 1: PCB top side view (mounting holes denoted with red arrows)

5

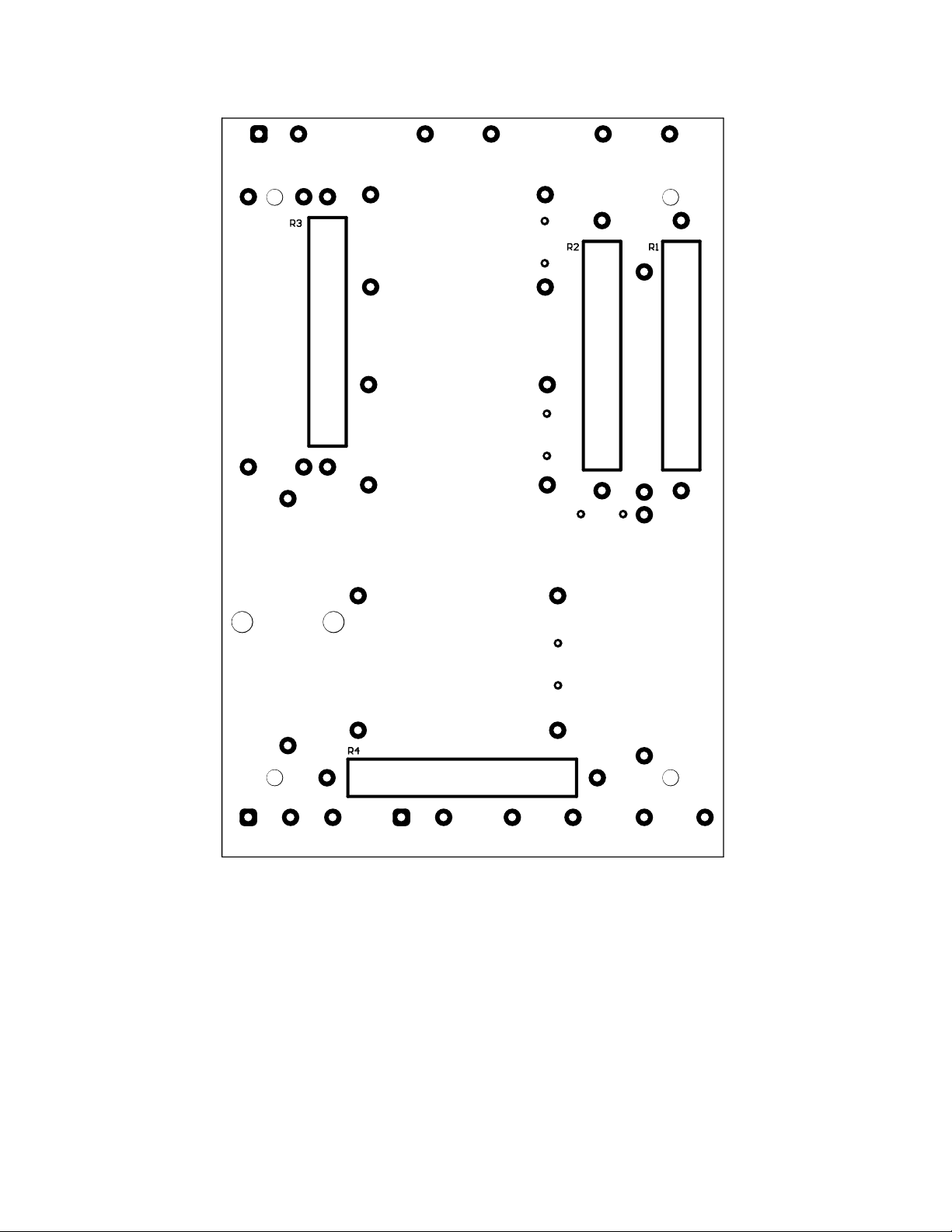

Figure 2: PCB bottom side view

6

Figure 3: Completed crossover unit with 9V battery installed

Parts Information

The footprints on the boards have been sized to accommodate the components in the official

parts kit from Solen in Canada. The contents of the parts kit are detailed in the Parts List in

Appendix A and on Solen’s product page.

Components of the same type and rating from other manufacturers may be substituted at the

user’s discretion, but it is the responsibility of the user to measure the board footprints and

ensure a proper fit, as well as ensuring that any user-substituted parts are properly rated for the

application. Echo Mountain Audio does not support or provide specific info on custom or user-

selected parts that are not on the official parts list.

7

Removing Crossover from Speaker

1. Lie the speaker on its back and remove the woofer by carefully loosening the screws

(don’t let the screwdriver slip and damage your cone or surround!) and lifting it gently out

of the cabinet.

2. Disconnect the two wires (green and green/black stripe) from the woofer and place the

woofer off to the side in a safe location.

3. You will now be able to see the stock crossover unit mounted to the rear wall of the

speaker. Now is a good time to take a picture of the stock units, wire orientation, etc., in

case you ever want to return the speaker to its stock configuration. Your new Echo

Mountain boards use the same pad numbering convention (E1, E2, E3, etc.) as the factory

boards for simplicity and ease of rework.

4. Unscrew the six Philips head screws that secure the mounting plate to the rear wall of

the speaker and set them aside in a safe place.

5. At this point, you’ll need to disconnect the wires going to the crossover unit in order to

be able to remove it from the cabinet. There are two options for this: de-soldering the

wires at the PCB (difficult because of the limited access through the woofer cutout), or

snipping the wires at the PCB (and then de-soldering the small bits of remaining wire once

the unit is removed). We strongly recommend the latter method, as it’s much easier, and

there is enough slack in the wires to allow for this. Snip the wires as close to the PCB as

possible (they should all be accessible from the top side of the board).

6. Once the wires are de-soldered or cut from the PCB, you will need to remove them from

the strain relief “clamp” that is adhered to the crossover mounting plate. This strain relief

apparatus doesn’t look the same on every model, but usually consists of adhesive, a zip

tie, or both. The adhesive is brittle enough due to years of age that it can be easily broken

and removed. Don’t worry about damaging the strain relief clamp, as you’ll be replacing

it later with an adhesive-backed zip tie mount and zip tie, but do take care not to damage

the wires.

7. At this point, the crossover assembly should be free of the speaker, and you should be

able to remove it through the woofer cutout.

8. Repeat steps 1-7 above for the other speaker.

Removing Factory PCB from Crossover Unit

1. Place the crossover unit on your workbench, and carefully release the PCB from the four

snap-lock plastic terminals by gently (gently!) pinching on the tabs with a pair of non-

marring pliers or your fingers. Do this to one corner at a time.

2. Once the PCB is free of the clips, locate the red and black wires connected between the

crossover binding posts and the PCB, and de-solder these wires from the PCB (leaving

them connected at the binding posts).

3. Locate the two wires coming from the inductor mounted on the crossover plate to the

PCB, and de-solder these wires from the PCB.

4. The factory PCB should now be free of the rest of the crossover assembly; set it aside.

5. Repeat steps 1 through 4 above for the other crossover unit.

8

PCB Assembly

For ease of assembly and to allow for unobstructed two-handed access to ensure that one makes

good solder joints, it is recommended to follow the steps in the order they are presented. Since

there are gluing and curing steps involved on the large components (capacitors and air core

inductor), we recommend doing each phase of the assembly in parallel on both boards before

moving on to the next phase, to minimize time spent waiting for the adhesive to cure. You’ll

notice that there is a mention of cleaning flux residue after each individual step – this is

intentional. As the board get populated with more components, it becomes more difficult to

clean off the flux residue in tight spaces, so do yourself a favor and clean it off after soldering

each component, before moving on to the next.

Note that because these PCBs contain plated through holes with annular rings on both sides of

the board, you are free to solder from either the top or bottom of the board. We recommend

soldering on the same side on which you are installing the component in question – it makes

things much easier.

It can also be helpful to install standoffs into the four mounting holes on the PCB to keep the

board stable while soldering. The standoffs can then be removed prior to installing the assembled

PCB back into the crossover unit.

Phase 1: Resistors

1. Insert and solder power resistors R1, R3, and R4 on the bottom side of the board. Note

that R2 will not be populated. Clean off any residual flux residue with a swab and

isopropyl alcohol.

2. Insert and solder the small 0.25W resistors RC1, RC3, RC5, RC8 on the top side of the

board. Clean off any residual flux residue with a swab and isopropyl alcohol.

3. Insert and solder power resistors RL1 and R5 on the top side of the board. Clean off any

residual flux residue with a swab and isopropyl alcohol.

Phase 2: Capacitors in the center of the board

In this phase, you will only install capacitors C3A, C3B, C5A, C5B, C8A, and C8B. These are the

six capacitors aligned vertically in the center of the board. Use the parts list in Appendix A to

locate the proper components for this section of the procedure.

1. Bend the leads of the capacitors using the plated through holes on the board as a sizing

guide and do a preliminary fit check of the capacitors in their footprints, adjusting your

lead bending as needed. Remove all the capacitors from the through holes once you’ve

done this.

2. Place a dab of adhesive in the center of the first PCB footprint (C3A). The general rule of

thumb is that less is more; you want enough adhesive to cover the entire surface area

where the capacitor touches the PCB, but be mindful that the adhesive will squeeze out

from under the component once you press it into place (we want this for mechanical

strength and vibration resistance), and you don’t want it getting all over the board or

squeezing into the adjacent footprints. See component C3A in the picture of the

completed assembly in Figure 3 for a reference of how much squeeze-out you’ll want.

3. After the adhesive has been applied, place capacitor C3A on the board with its leads

through the plated through holes and press down gently (don’t need much pressure) from

9

the top for a few seconds to allow the adhesive to spread underneath the part. The

component will have some play in the plated through holes, allowing it to rock and back

and forth slightly; adjust it so that it’s sitting upright and not tilted to one side.

4. Repeat steps 2 and 3 for the other five capacitor footprints (C3B, C5A, C5B, C8A, C8B).

Note that you’ll need a little more adhesive as the components get larger.

5. Now that all six of these capacitors are placed on the board, take a break and let the

adhesive cure for a while before proceeding to solder them all in. If you are using the

E6000 adhesive we recommended earlier in this manual, the advertised cure time is 24

hours for a full cure, but depending on the temperature in your work area, one hour or

slightly more should allow for a sufficiently stable bond to start soldering.

6. Solder the leads for the six capacitors you’ve installed so far and clean off all the flux

residue when you are done.

Phase 3: Capacitors C1A and C1B

1. Locate the 27µF and 30µF capacitors for positions C1A and C1B.

2. Follow the same procedure from steps 1 through 3 in Phase 2 to install these capacitors.

Phase 4: Inductor L1

1. Locate the 1.0mH air core inductor for position L1.

2. Start by doing a fit check -arrange the leads to fit through the plated through holes, while

positioning the inductor so that it sits flat on the board (see Figure 3 for reference). The

leads will be much longer than required for the given footprint, so trim off the excess

length, leaving enough to pass through the board and allow for a solder fillet on both

sides.

3. Now that you’ve trimmed off the excess leads to the desired length, you’ll need to

remove the enamel coating at the ends of the wire and tin the wire, so that it will solder

properly to the pads. This YouTube video provides a great tutorial on how to do this.

4. With the inductor removed from the board, thread a zip tie through the two holes on the

inductor footprint such that the zip tie is looped through the bottom of the board, and both

ends of the zip tie are pointing upwards. Leave the zip tie open for now.

5. As you did with the capacitors previously, place a dab of adhesive on the inductor

footprint, big enough that it will cover the mounting surface of the inductor with the

squeeze out, but not big enough that it will make a mess.

6. Place the inductor onto the footprint, with the leads inserted into the plated through holes,

and press down gently in the center to seat it in the adhesive. Carefully fasten the zip tie

so that it will clamp around the lower portion of the coil that is resting flush against the

board, tighten the zip tie, and snip off the excess. Allow the adhesive to cure for about

an hour before proceeding to the next step.

7. Solder the two inductor leads to the PCB.

At this point, you should now have two fully assembled boards with all capacitors and inductors

soldered and adhered to the board. Walk away, take a well-earned break, have an adult beverage,

etc., and allow all of the adhesive to cure for the full recommended cure time overnight before

proceeding to install the boards into the crossover assemblies.

10

Installation of PCBs Into Crossover Assembly

After allowing the boards to cure overnight, you’re now ready to install the new PCBs into the

factory crossover assembly.

1. Align the PCB mounting holes with the four snap-lock board mounts on the crossover

board, and gently snap each corner into place, one at a time. The board orientation should

match that shown in Figure 3.

2. Insert the stripped ends of the black and red wires from the binding posts into the plated

through holes E1 (IN+, red wire) and E2 (IN-, black wire). Solder both wires to the PCB.

3. Insert the tinned ends of the two wires from the inductor mounted on the crossover

assembly to pads E3 and E4 (also denoted by “L2” on the PCB silkscreen). Solder both

wires to the PCB.

4. Obtain one of the 9V battery connectors with flying leads. Cut the leads down to about

1-1.5 inches in length, strip the ends, and insert the red wire into the PCB pad marked 9V

battery “+” (upper right corner of the PCB). Insert the black wire into the PCB pad to the

left of that. Solder both wires to the PCB.

5. Obtain one of the 9V battery clips and the double-sided tape and cut a piece of tape to fit

to the bottom surface of the mounting clip. Affix one side of the tape to the bottom of

the clip and press down to adhere.

6. Place a 9V battery in the clip, center it, and then remove the protective layer on the

exposed side of double-sided tape. Place the battery and clip down on the right side of

the crossover assembly mounting plate, choosing the location such that there is enough

room to remove/install the battery, and enough room to attach the battery connector and

wires. Use Figure 3 as a guide on placement. Remove the battery from the clip while

holding the clip down to the surface (you don’t want to lift the tape up inadvertently).

Press down firmly on the bottom of the clip to increase the adhesion of the tape. If the

tape accidentally lifts from the crossover, start over with a fresh piece of tape, as it will

take small debris from the fiberboard with it, and won’t adhere as well on the next

attempt. This may sound complicated from the detailed description, but it’s quite simple.

Note that the battery can slide back and forth in the clip, so the exact placement of the

clip is not critical.

7. If remnants of the old strain relief clamp (refer to Step 6 of the “Removing Crossover

from Speaker” section) are still in place, remove them carefully with a putty knife or other

tool (the old, brittle adhesive should chip away easily). If this is proving difficult, leave it

there and move to the next step.

8. In the location of the old strain relief clamp (or adjacent to it, if you couldn’t get it fully

removed), place an adhesive-backed zip tie mount and press down to adhere.

9. Repeat steps 1 through 8 for the other PCB and crossover assembly.

11

Installation of Completed Crossover Assemblies

1. Inside the speaker cabinet, strip the ends of the L-pad and driver wires that were

previously snipped away from the factory PCB, twist the strands together, and tin the

ends of the wires with solder.

2. Solder the wires inside the cabinet to their proper PCB pads according to the table below.

The wire color codes shown in the table are consistent both with the 4425 speakers

we’ve tested and the original 4425 technical manual from JBL. Route the wires along the

bottom side of the board, bring them up and around the bottom edge of the PCB, and

Insert the wires into the PCB pads from the top side of the board – this will offer strain

relief of these connections (again, use Figure 3 as an example of how it should look).

Double check the wiring against the table below, and then solder the wires to the PCB.

3. Thread a zip tie through the zip tie mount you adhered to the assembly in the previous

section, so that it’s facing up. Bundle the wires from the bottom side of the PCB together

and use the zip tie to secure the bundle. Before tightening it fully, make sure there is no

excessive strain on the connections to the PCB, nor excess slack in the wire routing

underneath the PCB. You can push/pull the wires through your semi-tightened zip tie

loop until you have everything dressed properly, and then tighten it fully and snip off the

excess length.

4. Align the assembly mounting holes with their mounting points on the back wall of the

speaker and use the six original Philips head screws to securely mount the assembly to

the cabinet. An example of a finished, mounted assembly is shown in Figure 4.

5. Connect the green wire from the crossover to the red (+) terminal on the woofer and

connect the green/black striped wire to the black (-) terminal on the woofer.

6. Lower the woofer in to the cabinet, align the holes on the woofer with the holes on the

baffle, and use the original mounting screws to secure it.

7. Repeat steps 1 through 6 for the other crossover assembly and speaker cabinet.

8. You’re all done! Fire up some tunes and enjoy the upgraded sonic experience!

PCB Pad

Designator

Connection

E1 Red wire to speaker input +

E2 Black wire to speaker input -

E3 Enameled wire from stock inductor

E4 Enameled wire from stock inductor

E5 Green wire to LF driver red terminal

E6 Green/black wire to LF driver black terminal

E7 Yellow wire to HF driver red terminal

E8 Yellow/black wire to HF driver black terminal

E9 Green wire to L-Pad R202 pin 3

E10 Orange wire to L-Pad R202 pin 1

E11 Black wire to L-Pad R202 pin 2

E12 White wire to L-Pad R201 pin 2

E13 Red wire to L-Pad R201 pin 1

12

Figure 4: Completed crossover installed in speaker cabinet, as viewed through woofer cutout (top of image points

towards top of speaker)

13

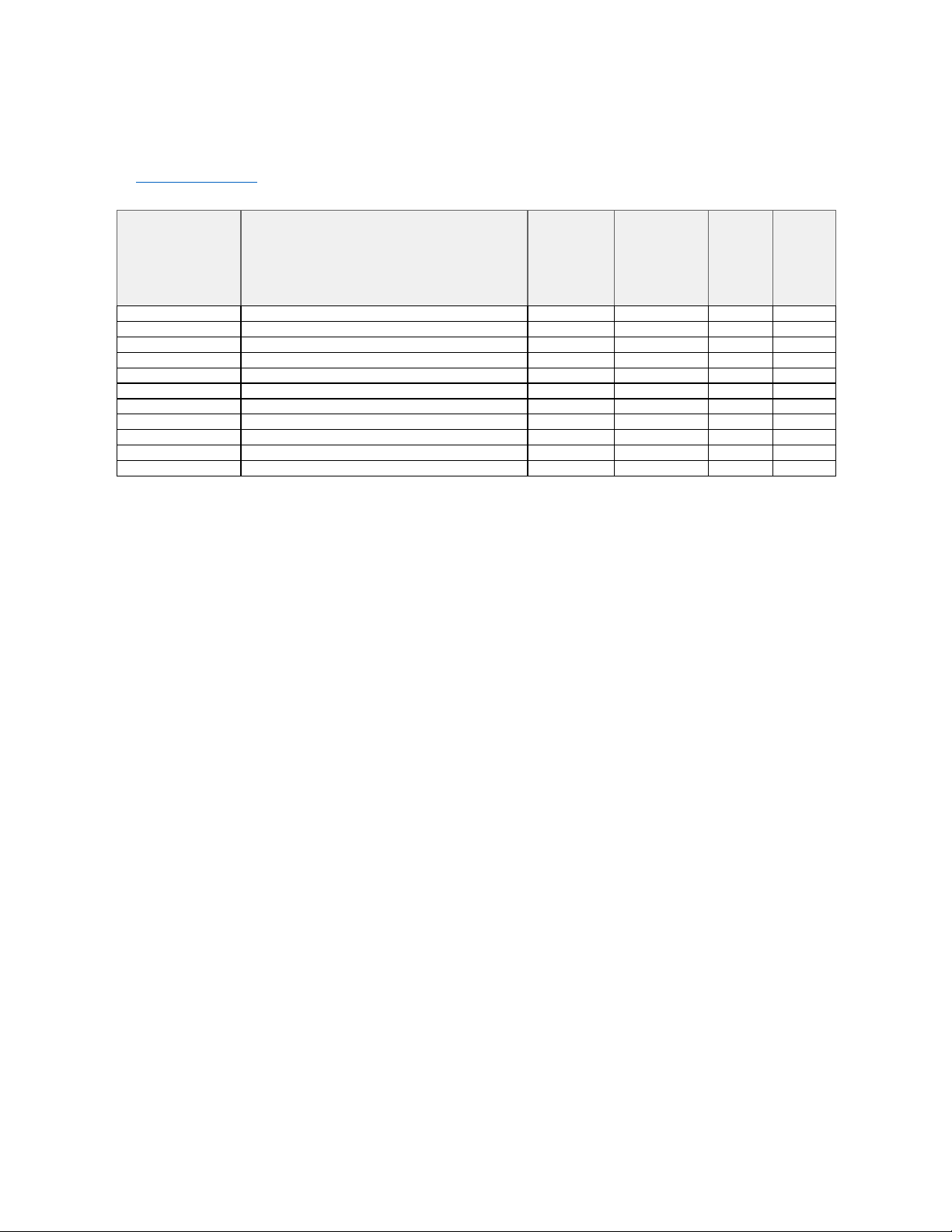

Appendix A: Parts List

The table below shows the parts list included in the official parts kit from Solen (sold separately

on Solen’s website).

Designator Description Manufacturer

Manufacturer

Part No.

Quantity

per board

Total

Quantity

per

project

C1A Capacitor, 27 uF, PA Series, 250V Solen PA2700 1 2

C1B Capacitor, 30 uF, PA Series, 250V Solen PA3000 1 2

C3A, C3B Capacitor, 6.2 uF, PA Series, 250V Solen PA620 2 4

C5A, C5B Capacitor, 8.2 uF, PA Series, 250V Solen PA820 2 4

C8A, C8B Capacitor, 16 uF, PA Series, 250V Solen PA1600 2 4

L1 Inductor, 1.0 mH, Air Core Solen S201.0 1 2

R1 Resistor, 51 ohm, 16W, Non-inductive wirewound AchrOhmiC AOC1600G51R 1 2

R3 Resistor, 3.9 ohm, 16W, Non-inductive wirewound AchrOhmiC AOC1600G3R9 1 2

R4, R5 Resistor, 20 ohm, 16W, Non-inductive wirewound AchrOhmiC AOC1600G20R 2 4

RC1, RC3, RC5, RC8 Resistor, 2.2 Mohm, 0.25W, Carbon film Solen RCC025225J 4 8

RL1 Resistor, 6.8 ohm, 16W, Non-inductive wirewound AchrOhmic AOC1600G6R8 1 2

14

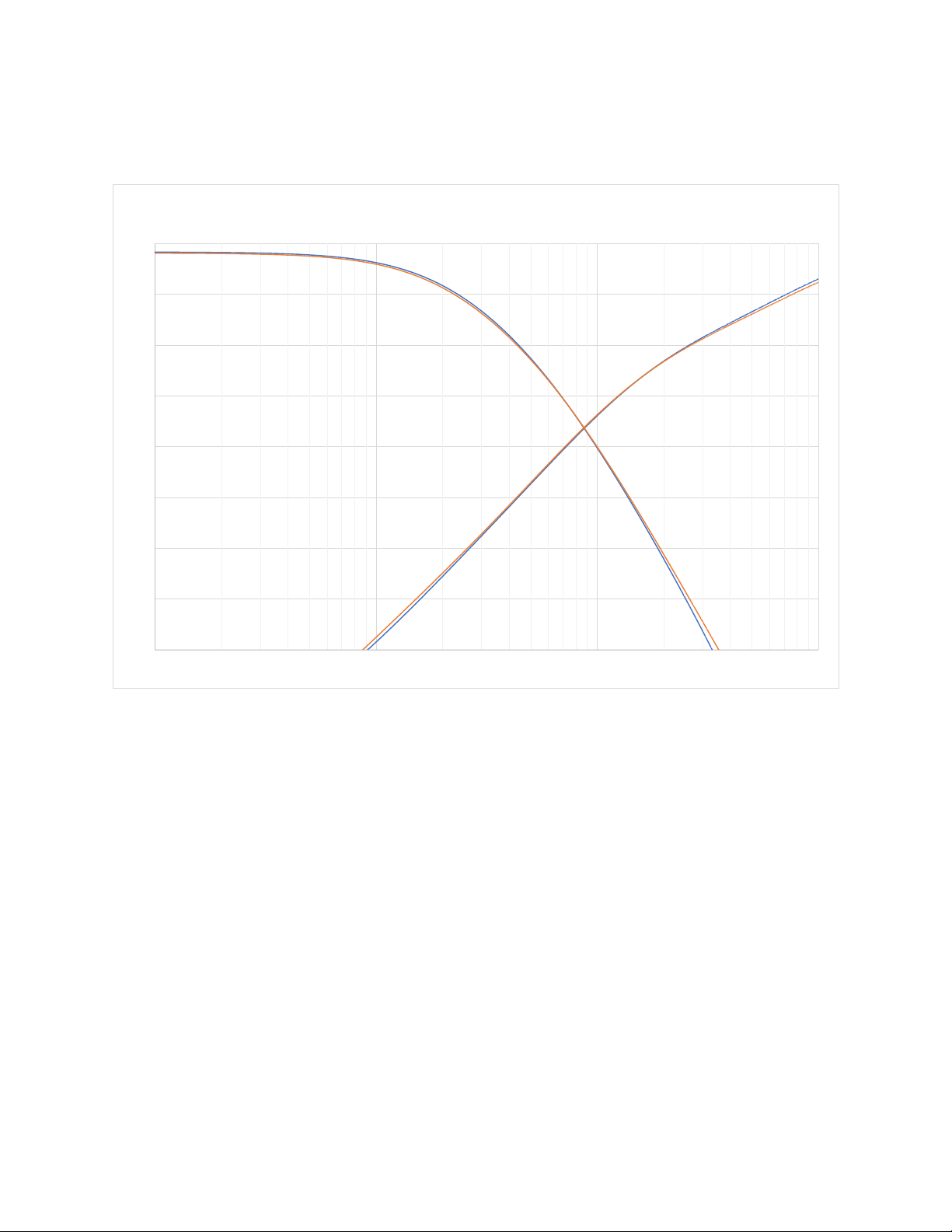

Appendix B: Measured Frequency Response

Measured response for the 4425 factory crossover (orange curves) and the Echo Mountain

Charge-Coupled Crossover (blue curves) was obtained using 8 ohm dummy loads with an RME

ADI-2 Pro FS R BE audio interface and REW software.

-40

-35

-30

-25

-20

-15

-10

-5

0

20 200 2000 20000

Magnitude (dB)

Frequency (Hz)

Model 4425 Crossover

Stock (Orange) vs. Echo Mountain Charge-Coupled Equivalent (Blue)

Both L-Pads at Max

Table of contents