SERVICE INFORMATION

CS-310ES 9

2-3 Adjusting carburettor

1. Start and warm engine for 1 minute alternat-

ing engine speed between WOT and idle every 5

seconds. Turn H mixture needle anticlockwise until

engine speed drops to approx. 12,500 r/min at

WOT.

NOTE : Do not run engine at high speed without

load longer than 10 seconds, or engine damage

may occur.

2. Adjust L mixture needle using 2.5mm blade

screwdriver to reach maximum engine r/min just

before lean r/min drop off.

3. Set idle speed to 3,700 r/min by turning Idle

adjust screw. Engine speed should be stable

at 3,700 +/- 50 r/min after idle adjust screw

adjustment.

4. Turn L mixture needle anticlockwise reducing engine idle speed 500 r/min to set idle speed at 3,200

r/min. The idle speed range is 3,100 - 3,300 r/min.

NOTE : Engine speed must be allowed to stabilize a minimum of 20 seconds after each adjustment of L

mixture needle to assure accurate tachometer readings.

5. Before adjustment, WOT engine speed should be less than or equal to 12,500 r/min. If r/min is higher,

turn H mixture needle anticlockwise until 12,500 r/min is achieved. To make the final WOT engine speed

adjustment, turn the H mixture needle clockwise in 1/8 turn increments with the engine at idle. After each

adjustment, accelerate to WOT, and check r/min. The final r/min should fall within 12,750 - 12,950 r/min.

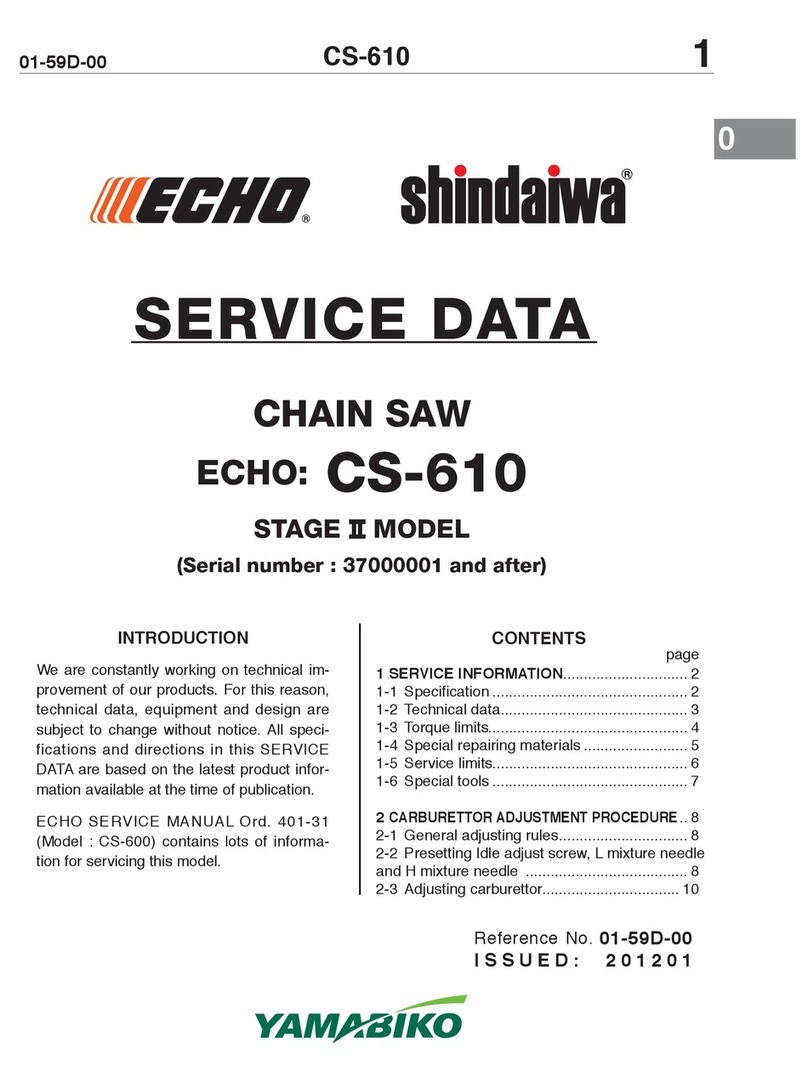

6. After adjusting carburettor, put new limiter cap

on the other side (c) of limiter cap tool (C) as

shown, and press the limiter caps to the bottoms

on L and H mixture needles respectively.

NOTE : Align the limiter cap’s tabs (A) with locat-

ing slots (B) in extended housing of carburettor.

IMPORTANT : The limiter caps must be properly installed on L and H mixture needles to comply

with Emission Directive.

7. Start engine, and verify engine idle speed ranges from 2,800 to 3,600 r/min, and WOT engine speed

ranges from 12,000 to 13,000 r/min. Make sure the chain does not rotate when engine is idling. When

final adjustment is completed, the engine should idle, accelerate smoothly, and attain WOT per above

specifications.

NOTE : The initial carburettor settings for Idle adjust screw, Idle and Hi speed mixture needles are intend-

ed to start and run the engine before final carburettor adjustments are made to conform the unit to meet

Emission Directive. The actual number of turns needed for engine operation may vary.

Idle adjust screw

L mixture needle H mixture needle

C

A

B

A

B

c