Eco Heating Systems CB 85 HW Manual

E93.1803.901

Original Manual

Installation, service and user manual

Wall hung high efficiency water heater

CB 85 HW

CB 105 HW

CB 125 HW

CB 155 HW

E93.1803.901 HW

3

TABLE OF CONTENTS

1INTRODUCTION................................................................................................................................... 7

ABBREVIATIONS........................................................................................................................... 7

2SAFETY GUIDELINES ......................................................................................................................... 7

IMPORTANT TECHNICAL WARNINGS AND GUIDELINES ...................................................................... 8

SAFETY VALVE........................................................................................................................... 10

3TECHNICAL DATA HW WATER HEATERS..................................................................................... 11

FUNCTIONAL INTRODUCTION....................................................................................................... 11

LOCATION OF VERSION NUMBERS................................................................................................ 11

TECHNICAL SPECIFICATIONS DATASHEET..................................................................................... 12

TABLE TECHNICAL SPECIFICATIONS ERP..................................................................................... 14

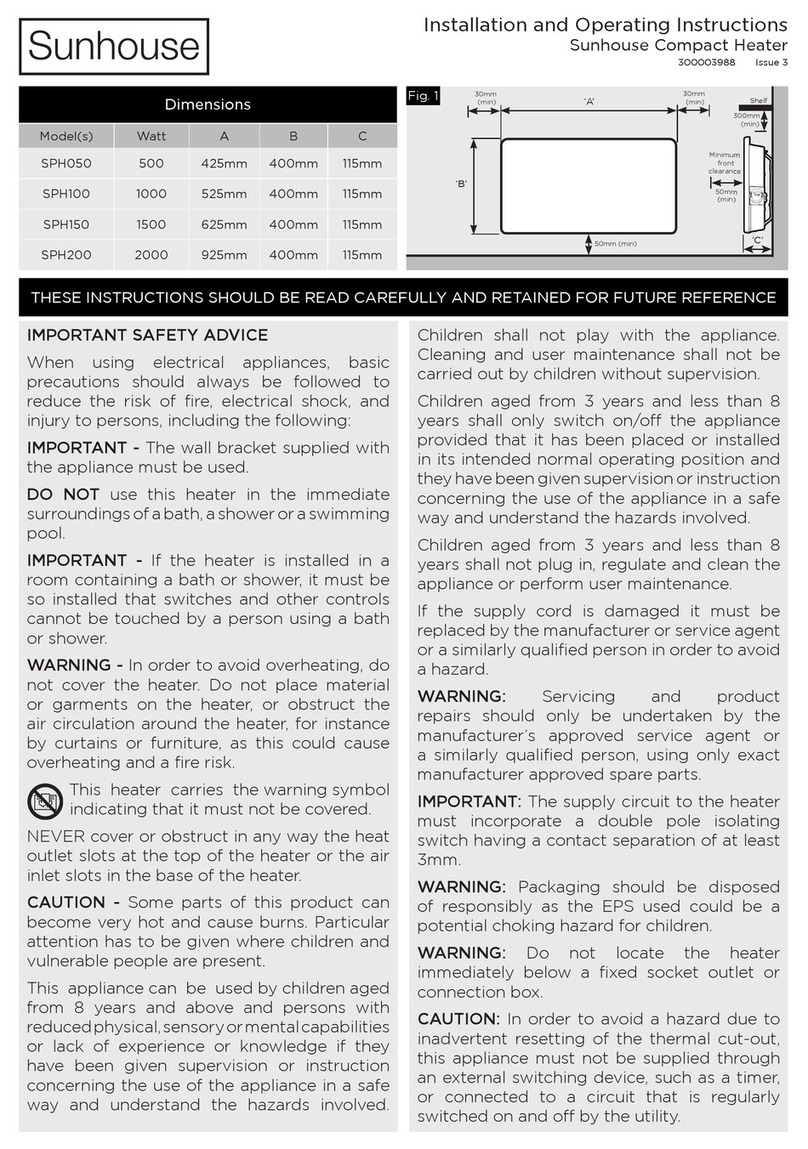

4DIMENSIONS & CONNECTIONS ...................................................................................................... 15

CB 85 HW &CB 105 HWTWIN PIPE.......................................................................................... 15

CB 85 HW &CB 105 HWCONCENTRIC..................................................................................... 16

CB-125-HW TWIN PIPE ............................................................................................................. 17

CB 125 HWCONCENTRIC.......................................................................................................... 18

CB-155-HW TWIN PIPE ............................................................................................................. 19

TANKS EWD300 -EWD500 -EWD750..................................................................................... 20

ERP SPECIFICATIONS ECOHS TANKS........................................................................................... 22

TANK CONNECTIONS AND SIZES................................................................................................... 22

CASCADE FRAMES...................................................................................................................... 23

4.9.1 Cascade frames dimensions ...................................................................................... 24

5ACCESSORIES AND UNPACKING................................................................................................... 25

ACCESSORIES............................................................................................................................ 25

UNPACKING ............................................................................................................................... 25

6INSTALLATION LOCATION OF THE HW......................................................................................... 26

INSTALLATION CLEARANCES ....................................................................................................... 26

WATER HEATER INSTALLATION LOCATION REQUIREMENTS:.......................................................... 26

MOUNTING THE WATER HEATER .................................................................................................. 27

7CONNECTIONS.................................................................................................................................. 28

TANK POSITIONING..................................................................................................................... 28

WATER HEATER CONNECTIONS................................................................................................... 28

CONDENSATE DRAIN CONNECTION .............................................................................................. 28

NON RETURN VALVE................................................................................................................... 29

PUMP FUNCTIONALITY ................................................................................................................ 29

FROST PROTECTION................................................................................................................... 29

WATER QUALITY......................................................................................................................... 30

FLUSH THE SYSTEM WITH FRESH WATER...................................................................................... 30

DE-AIR SEQUENCE..................................................................................................................... 30

WATER PRESSURE..................................................................................................................... 31

8THE HW SANITAIRY SYSTEM: INSTALLATION INSTRUCTIONS................................................. 32

THE HW SYSTEM ....................................................................................................................... 32

8.1.1 Stand-alone set-up...................................................................................................... 32

8.1.2 Stand-alone configuration........................................................................................... 33

8.1.3 CB-HW setup with EWD tank ..................................................................................... 33

8.1.4 CB-HW setup with one NON-EWD tank..................................................................... 34

8.1.5 Cascade set-up........................................................................................................... 35

8.1.6 Cascade calculations.................................................................................................. 36

8.1.7 Elaborated examples .................................................................................................. 40

8.1.8 One CB 125 HW heater with one EWD500 tank........................................................ 40

8.1.9 Two CB 105 HW water heaters with two EWD500 tanks........................................... 41

8.1.10 Pump control............................................................................................................... 42

8.1.11 Tank sensor ................................................................................................................ 42

8.1.12 System Sensor............................................................................................................ 42

8.1.13 Return and Supply piping of a non EWD Tank........................................................... 42

E93.1803.901 HW

4

9HEATEXCHANGER RESISTANCE GRAPHS................................................................................... 43

9.1.1 Resistance graph CB 85 HW...................................................................................... 43

9.1.2 Resistance graph CB 105 HW.................................................................................... 43

9.1.3 Resistance graph CB 125 HW.................................................................................... 44

9.1.4 Resistance graph CB 155 HW.................................................................................... 44

MINIMUM REQUIRED PUMP HEAD................................................................................................. 45

PUMP:MAXIMUM ELECTRIC POWER ............................................................................................. 45

10 FLUE GAS AND AIR SUPPLY SYSTEM........................................................................................... 46

GENERAL................................................................................................................................... 46

POLYPROPYLENE....................................................................................................................... 47

10.2.1 Flexible polypropylene ................................................................................................ 47

STAINLESS STEEL VENT.............................................................................................................. 47

AIR SUPPLY ............................................................................................................................... 47

10.4.1 Combustion air quality ................................................................................................ 48

10.4.2 Air supply through humid areas.................................................................................. 48

10.4.3 Air inlet pipe materials................................................................................................. 48

ROOM AIR.................................................................................................................................. 48

10.5.1 Air contamination ........................................................................................................ 48

PROPER VENT INSTALLATION AND TYPE OF GAS VENT OR VENT CONNECTOR.................................. 49

WATER HEATER CATEGORIES -TYPES OF FLUE GAS SYSTEMS....................................................... 50

C63 CERTIFIED .......................................................................................................................... 55

PIPE HEIGHTS AND MUTUAL DISTANCES ON A FLAT ROOF .............................................................. 55

FLUE GAS AND AIR SUPPLY RESISTANCE TABLE............................................................................ 56

TYPICAL EXAMPLES.................................................................................................................... 57

10.11.1 Example A: Twin pipe system with separate pipes for flue outlet and air supply....... 57

10.11.2 Example B: Twin pipe system with concentric roof terminal....................................... 58

10.11.3 Example C: Single flue gas outlet. Air supply from water heater room ...................... 60

10.11.4 Example D: Concentric flue gas/air supply pipe (roof-mounted)................................ 61

10.11.5 Example E: Concentric system Wall outlet C13 (wall-mounted) ................................ 61

10.11.6 Example F: Separate air supply duct & flue duct in different pressure zone (C53).... 63

11 COMMON FLUE CASCADING .......................................................................................................... 64

SAFETY MEASURES COMMON FLUE SYSTEMS.............................................................................. 64

EXISTING COMMON VENTING GUIDELINES..................................................................................... 66

12 ELECTRICAL INSTALLATION .......................................................................................................... 67

GENERAL................................................................................................................................... 67

CONNECTION MAINS SUPPLY....................................................................................................... 67

ELECTRICAL CONNECTIONS ........................................................................................................ 67

EXPLANATION OF THE LOW VOLTAGE CONNECTIONS..................................................................... 68

EXPLANATION OF THE MAINS VOLTAGE CONNECTIONS.................................................................. 69

ELECTRICAL SCHEMATIC............................................................................................................. 70

LADDER/LOGIC DIAGRAM....................................................FOUT!BLADWIJZER NIET GEDEFINIEERD.

SENSOR AVAILABILITY................................................................................................................. 73

NTC SENSOR CURVE.................................................................................................................. 73

PROGRAMMABLE IN-AND OUTPUTS ............................................................................................. 74

13 WATER HEATER CONTROLLER AND DISPLAY............................................................................ 75

DISPLAY AND SETTINGS.............................................................................................................. 76

13.1.1 Set Actual DHW setpoint directly via the Status overview.......................................... 77

13.1.2 Entering the menu....................................................................................................... 77

13.1.3 Protected menu items................................................................................................. 78

13.1.4 De-aeration Sequence................................................................................................ 78

13.1.5 Language settings....................................................................................................... 78

13.1.6 Change language via the menu.................................................................................. 79

13.1.7 Change the language via the menu Icons .................................................................. 79

WATER HEATER HISTORY............................................................................................................ 79

ERROR LOGGING........................................................................................................................ 80

SERVICE REMINDER.................................................................................................................... 80

13.4.1 Service overdue logging ............................................................................................. 80

13.4.2 Service reminder implementations ............................................................................. 81

13.4.3 Reset the service reminder......................................................................................... 81

13.4.4 Menu’s and parameters .............................................................................................. 81

E93.1803.901 HW

5

GENERAL................................................................................................................................... 82

13.5.1 Pump start exercise every 24 hours ........................................................................... 82

13.5.2 Frost protection........................................................................................................... 82

IGNITION CYCLE ......................................................................................................................... 83

13.6.1 Control functions......................................................................................................... 84

13.6.2 On board HMI and LED colors.................................................................................... 85

13.6.3 Flame detection .......................................................................................................... 85

13.6.4 Flame recovery ........................................................................................................... 85

DEMAND FOR DOMESTIC HOT WATER.......................................................................................... 86

13.7.1 DHW Storage with bulb and strap-on sensor; DHW mode 1...................................... 86

13.7.2 Anti-legionella protection............................................................................................. 87

DISPLAY MENU STRUCTURE SUMMARY......................................................................................... 89

14 TEMPERATURE PROTECTION ........................................................................................................ 97

15 ERROR INFORMATION..................................................................................................................... 97

WATER HEATER HISTORY............................................................................................................ 97

LOCKOUT CODES........................................................................................................................ 98

BLOCKING CODES .................................................................................................................... 100

WARNINGS .............................................................................................................................. 102

16 CASCADING..................................................................................................................................... 103

SYSTEM SETUP ........................................................................................................................ 103

QUICK-GUIDE CASCADE SET-UP ................................................................................................ 104

WATER HEATER CASCADE COMMUNICATION SETUP.................................................................... 104

16.3.1 Setting the water heater address.............................................................................. 105

16.3.2 Setting of the cascade parameters........................................................................... 105

16.3.3 Cascade –Heating only Managing water heater...................................................... 106

16.3.4 Cascade –Domestic Hot Water Settings ................................................................. 106

16.3.5 Cascade –Power balance mode.............................................................................. 107

CASCADE –WATER HEATER ROTATION ..................................................................................... 107

16.4.1 Next depending to start selection ............................................................................. 107

CASCADE ERROR HANDLING .................................................................................................... 107

16.5.1 Cascade Frost protection.......................................................................................... 107

16.5.2 Emergency mode...................................................................................................... 108

16.5.3 Loss of cascade communication............................................................................... 108

16.5.4 Managing water heater error..................................................................................... 108

17 SYSTEM TEST.................................................................................................................................. 109

18 COMMISSIONING THE WATER HEATER...................................................................................... 110

FIRST:FLUSHING THE WATER HEATER WITH WATER.................................................................... 110

SECOND:FILLING &VENTING THE WATER HEATER AND THE SYSTEM............................................ 110

THIRD:CHECK THE WATER FLOW............................................................................................... 110

MOUNTING CONDENSATE TRAP ................................................................................................ 110

CHECKING GAS PRESSURE........................................................................................................ 111

FIRING FOR THE FIRST TIME ...................................................................................................... 111

19 ADJUSTING AND SETTING THE WATER HEATER...................................................................... 112

INTRODUCTION......................................................................................................................... 112

19.1.1 Combustion table...................................................................................................... 112

19.1.2 Setting screws venturi- and gas valves: drawings.................................................... 113

ADJUSTMENT PROCEDURES...................................................................................................... 114

VENTURI REPLACEMENT ADJUSTMENT...................................................................................... 114

CONVERSION FROM NATURAL GAS TO PROPANE......................................................................... 115

START UP CHECKLIST .............................................................................................................. 117

20 INSPECTION, MAINTENANCE AND SERVICE.............................................................................. 119

GENERAL................................................................................................................................. 119

INSPECTION,MAINTENANCE AND SERVICE.................................................................................. 119

20.2.1 Decalcifying of the Heat exchanger.......................................................................... 125

20.2.2 Mounting the burner door.......................................................................................... 126

INSTRUCTIONS FOR THE USER................................................................................................... 126

21 MAINTENANCE CHECKLIST .......................................................................................................... 127

E93.1803.901 HW

6

22 SPARE PARTS................................................................................................................................. 128

CB-85-HW AND CB-105-HW EXPLODED VIEW......................................................................... 128

CB-125-HW EXPLODED VIEW.............................................FOUT!BLADWIJZER NIET GEDEFINIEERD.

CB-155-HW EXPLODED VIEW................................................................................................... 130

LIST OF PARTNUMBERS CB 85 –CB 155........................................................................... 132

23 USER’S PART .................................................................................................................................. 135

ABBREVIATIONS....................................................................................................................... 135

SAFETY GUIDELINES................................................................................................................. 135

TO TURN OFF GAS TO THE APPLIANCE........................................................................................ 136

MAINTENANCE AND INSPECTION................................................................................................ 136

DISPLAY AND BUTTONS............................................................................................................. 137

SCREENS AND SETTINGS .......................................................................................................... 138

STARTING THE WATER HEATER. ................................................................................................ 139

23.7.1 Entering the menu..................................................................................................... 139

CHANGING THE SETPOINT DHW............................................................................................... 140

23.8.1 Set Actual setpoint/DHW setpoint directly via the Status overview.......................... 140

23.8.2 Changing the DHW setpoint directly......................................................................... 140

PASSWORD.............................................................................................................................. 141

AVAILABLE MENU ITEMS ........................................................................................................... 142

23.10.1 Central Heating (CH), Do not use or change these settings ................................... 142

23.10.2 Domestic Hot Water (DHW)...................................................................................... 142

23.10.3 Information................................................................................................................ 142

23.10.4 Software Versions..................................................................................................... 142

23.10.5 Water heater Status.................................................................................................. 142

23.10.6 Water heater History................................................................................................. 143

23.10.7 Error log .................................................................................................................... 143

23.10.8 Service...................................................................................................................... 143

23.10.9 Settings..................................................................................................................... 143

23.10.10 General Settings ....................................................................................................... 143

23.10.11 Language.................................................................................................................. 143

23.10.12 Unit Type................................................................................................................... 143

23.10.13 Date & Time.............................................................................................................. 143

23.10.14 Time zone settings.................................................................................................... 144

23.10.15 Display settings......................................................................................................... 144

23.10.16 Cascade mode.......................................................................................................... 144

23.10.17 Other Settings........................................................................................................... 144

23.10.18 Boiler settings ........................................................................................................... 144

BOILER HISTORY...................................................................................................................... 144

ERROR LOGGING...................................................................................................................... 145

SERVICE REMINDER.................................................................................................................. 145

E93.1803.901 HW

7

1 INTRODUCTION

This manual is written for:

▪the installer

▪system design engineer ▪the service engineer

▪the user

Eco Heating Systems Groningen B.V. is not accountable for any damage caused by following these instructions

incorrectly. Use only original Eco Heating Systems Groningen B.V. spare parts for service and repair purposes.

All documentation produced by the manufacturer is subject to copyright law.

Abbreviations.

CB = Condensing Boiler

HW = Hot Water Boiler for Hot Water (drinking water) usage only.

BCU = burner control unit

PB = display board/ control panel (Pixel Button)

85/105/125/155 = Model number of the water heater.

2 SAFETY GUIDELINES

“FOR YOUR SAFETY READ BEFORE OPERATING”

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause property

damage or personal injury. Installation and service must be performed by a qualified in-

staller or service agency (who must read and follow the supplied instructions before in-

stalling, servicing, or removing this water heater).

“A. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the burner.

Do not try to light the burner by hand.”

“B. BEFORE OPERATING smell all around the appliance area for gas. Be sure to smell close to the floor because

some gas is heavier than air and will settle on the floor.”

“C. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the control system and any gas control which has been under

water.”

Without written approval of the manufacturer the internals of the water heater may not be changed. When these

changes are executed without approval, the water heater certification is invalid.

WARNING: Water temperatures over 52 °C can cause severe burns in-

stantly from scalding. The water temperature is factory set at 60 °C be-

cause of legionella prevention. Before bathing or showering always check

the water temperature.

When this heater is supplying general purpose hot water requirements

for use by individuals, a thermostatically controlled mixing valve for

reducing point of use water temperature is recommended to reduce the

risk of scald injury.

Contact a licensed plumber or the local plumbing

authority for further information.

This water heater is equipped with a flue pressure switch in the event of a

blocked vent the water heater will lockout. No attempt by the user/owner

should be made to put the water heater back into operation. A qualified

service technician should be notified of the issue. The water heater should only be reset by a qualified service

technician after they have diagnosed and corrected the issue that caused the safety lockout of the water heater.

Eco Heating Systems recommends the installation of a carbon monoxide detector in the water heater room for all

installations.

E93.1803.901 HW

8

What to do if you smell gas:

▪Don't use any electrical equipment.

▪Don't press any switches.

▪Close the gas supply.

▪Ventilate the room (open the windows and/or outdoor water heater room doors).

▪Immediately warn the installer.

The manufacturer/supplier is not liable for any damage caused by inaccurately following of

these mounting instructions. Only original parts may be used when carrying out any repair or

service works.

This appliance can be used by children aged from 8 years and above and persons with re-

duced physical, sensory or mental capabilities or lack of experience and knowledge if they

have been given supervision or instruction concerning use of the appliance in a safe way and

understand the hazards involved.

The protection class for gas appliance type B23(P) is IP20.

Only with the special air inlet (see § 5.1 "Accessories"), the protection class is IPX4D.

Important technical warnings and guidelines

Visually inspect the venting system for proper size and horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deficiencies which could cause an unsafe condition.

Maintenance and inspection of the water heater should be carried out at the following conditions:

•When a number of similar error codes and/or lock-outs appear.

•At least every 12 months maintenance must be done to ensure safe and efficient operation.

Damage caused by lack of maintenance will not be covered under warranty

The Eco Heating Systems Hot Water systems will, for a long period, comfortably meet your requirement of hot

water of the right temperature at the right hour, provided that a few important conditions have been fulfilled regard-

ing the installation.

Please follow all instructions and recommendations presented in this manual by Eco Heating Systems, especially

the ones concerning the next important topics:

- Water quality (also see § 8.1)

A first necessary condition is the quality of the water to be heated in the water heater.

Only potable water can be used with this water heater. Do not introduce pool or spa water, or any chemically

treated water into the water heater.

Three values matter: hardness, total amount of dissolved solids and acidity. If water quality does NOT meet

the requirements the system may be seriously damaged in time!

Hardness should not exceed 196 PPM CaCO3(11 °dH). If the waterflow is enlarged, a water hardness up

to 250 PPM (14 °dH) is acceptable.

Water hardness leads to scale formation and may affect/damage the water heater. Hard water scaling

must be avoided or controlled by proper water treatment.

TDS (Total Dissolved Solids) should not exceed 450 PPM

Hardness and TDS together should not exceed 450 PPM

pH value should be between 6,5 and 7,5, measured cold.

The actual values can be retrieved at your local water supplier.

If water quality doesn’t meet the above mentioned requirements, a water treatment installation shall be in-

stalled to improve water quality to the required levels.

- Water flow velocity and pump selection

For a given combination of water heaters and tanks, pump selection is very important with respect to the

required flow velocity. Use the water heater exchanger resistance graphs to calculate the pump needed.

E93.1803.901 HW

9

- Water flow velocity and pipe diameters and lengths

The arguments that hold for pump selection, hold for piping design as well: all piping components added up

are giving a certain total resistance which should not exceed a critical value at which the pump cannot realize

the required flow velocity anymore.

Following the instructions and recommendations given in the referred paragraphs will highly improve the function-

ing and considerably lengthen the life time of your HW system.

Furthermore, for all Eco Heating Systems appliances the next instructions and recommendations apply:

!Never use aluminum or aluminum containing flue gas outlet parts.

!Always fill the siphon before commissioning the water heater

!Always set the gas valve during commissioning of the water heater, for the first time and after maintenance

and/or installation changes

!Never place a (ball) valve between the safety valve and the water heater

!In a log, keep track of all situations regarding the appliance:

what, when, by whom, what actions and/or changes, what communication has been performed

Eco Heating Systems is not liable for any damage caused by inaccurately following these instructions. Only Eco

Heating Systems parts may be used when carrying out any repair or service works.

Do not use chlorine based products for brazing. When commissioning the water heater, the running of the water

heater pump must be checked before leaving the installation.

Firing the water heater without water flow (but filled with water) will cause a boiling noise and can damage the heat

exchanger.

The Outlet and Inlet temperature are checked continuously. The temperature difference may not exceed the pro-

grammed value belonging to the actual power mode. If it does, the water heater will go in a lock-out.

The applied DHW pump must be controlled only by the HW water heater control. If, for any reason, an

external pump control is applied without written approval of Eco Heating Systems, the complete war-

ranty on the HW water heater and all supplied parts will become invalid.

Minimum water pressure 1 bar.

Fuel used should have sulfur rates that comply with the next values: a maximum annual peak over a short period

of time of 150 mg/m3and an annual average of 30 mg/m3 maximum.

Combustion air must be free of contents of chlorine, ammonia and alkali agents. The air near a swimming pool, a

washing machine or a laundry is containing these ammonia contents.

If the water heater is used in combination with a hot water tank without any other heat exchanger; the water heater

should be equipped with a safety relief valve. In some cases also the tank should be equipped with a T&P relief

valve. Always apply all applicable installation standards and regulations.

At first installation, the built-in automatic air vent should be open.

LEGIONNAIRES’ DISEASE

An anti-Legionella function is present in the software and is default turned ON. See this manual for the program-

ming options.

E93.1803.901 HW

10

Safety valve

DO NOT apply a closing valve or any other form of narrowing between the water heater and the safety valve,

because this might disturb the correct functioning of the safety valve.

The right safety valve has been supplied with the CB xxx HW water heater.

Water heater

Safety valves

Part number

HW 85-125

27112 Prescor B ¾ - 10 bar - 150 kW

E04.015.090

HW 155

29007 Prescor B 1 - 10 bar - 250 kW

E04.015.091

The HW water heater and tank should be installed by a skilled installer according to all applicable standards and

regulations for tap water installations. Use the next scheme as guideline. When multiple water heaters and tanks

are applied, every combination has to be equipped with its own safety valve.

Hot water could be released when the safety valve is opened. This can result in severe

personal injury. Before operating the safety valve manually, check that it will discharge in a

safe place. If water does not flow freely from the end of the discharge pipe, turn the gas

supply and power OFF and call a qualified person to determine the cause. Refer to the

safety valve manufacturer's instructions for inspection and maintenance requirements.

A) Potable water inlet

B) Hot water supply (circulation if appli-

cable)

C) Circulation return

1) Pressure regulating valve (manda-

tory in case service water pressure is

too high)

2) Inlet combination with valve (manda-

tory)

3) Apply filter if necessary (recom-

mended)

4) A suitable safety valve must be

mounted near the water heater

(mandatory) This safety valve may

never be isolated from the water

heater by means of a closing valve

5) Remote tank sensor (necessary)

6) Drain valve (recommended)

7) Hot and cold-water mixers

8) Strap-on temperature sensor

If the installation is constructed in such a way that underpressure (Pabs<1 bar;

Patm<0 bar) can occur in the tank, an aerator must be installed between the inlet

combination and the tank, without any valve".

SAFETY COMPONENTS

The picture shows an example of a functional installation. The safety components as shown in

the picture are NOT necessarily conform all applicable standards and regulations.

ALWAYS have the system installed by a skilled installer. Safety components must be added

according to all applicable standards and regulations.

WARNING

PUMP

NON- RETURN VALVE

VALVE

SAFETY VALVE

AUTOMATIC VENT

FILTER

INLET COMBINATION

- Overflow

- Non return valve

- Valve

PRESSURE REGULATING

VALVE

WARNING

NOTICE

E93.1803.901 HW

11

3 TECHNICAL DATA HW WATER HEATERS

Functional introduction

The HW water heaters are water heaters with a maximum high efficiency. Such a performance can be reached

by, amongst other things, using a special heat exchanger made of stainless steel. This allows the flue gases to

cool down below the condensation point, and so release extra heat. This has an immediate positive impact on the

efficiency.

The water heater is set for Natural gas.

Fuel used should have Sulphur rates with a maximum annual peak over a short period of time of 150 mg/m3(110

ppm average) and an annual average of 30 mg/m3 . (22 ppm average)

Water heater control includes:

▪Cascade control for up to sixteen water heaters

▪Remote operation and heat demand indication from each water heater

▪Anti-Legionnaires’ disease function.

Connections for:

▪Water heater pump

▪PWM control for external water heater pump.

▪System pump

▪External flow switch or external safety device.

▪Modbus

▪External system sensor

▪DHW sensor.

▪External Ignition coil

Location of version numbers

Parameter Version

- To be found on the small sticker on the side of the

burner controller.

v.A = “Version A” e.g

Burner Controller Hardware Version

–To be found on the second line of the white sticker

on the side of the burner controller.

e.g. 957MN25_3Rh4b

Burner Controller Software Versions

–Press the menu button , go to Information and then to Software Versions.

Information

Software Versions

Boiler Status

Boiler History

Error Log

i

Software Versions

Display [63EF 83BC]

Boiler [5C79 14A9]

Device Group 900MN

E93.1803.901 HW

12

Technical specifications datasheet

GENERAL

Product identification number:

0063CT3633

Gas Appliance Type

-

B23(P), C13, C33, C43,C53, C63,C83, C93, C(10)3,

C(11)3, C(12)3, C(13)3, C(14)3, C(15)3

Type boiler

CB 85 HW

CB 105 HW

CB 125 HW

CB 155 HW

Classification Netherlands (NL)

II2EK3P

II2EK3P

II2EK3P

II2EK3P

Classification UK (GB)

II2H3P

II2H3P

II2H3P

II2H3P

Classification Germany (DE)

II2E3P

II2E3P

II2E3P

II2ELL3P

Classification France (FR)

II2Esi3P

II2Esi3P

II2Esi3P

II2Esi3P

Classification Belgium (BE)

II2E(S)3P

II2E(S)3P

II2E(S)3P

II2E(S)3P

Classification Italy (IT)

II2H3P

II2H3P

II2H3P

II2H3P

Classification Turkey (TR)

I2H

I2H

I2H

I2H

Classification Ireland (IE)

II2H3P

II2H3P

II2H3P

II2H3P

Dimensions (h x w x d)

mm

845 x 440 x 530

Water content estimated

liter

5.0

6.5

8.3

10.4

Weight (empty)

Kg

77

79

83

86

Flow/return connection (boiler)

Inch

R 1”

R 1”

R 1”

R 1¼”

Gas connection

Inch

R ¾”

R ¾”

R ¾”

R 1”

Flue connection twin pipe

Mm

100

100

100

150

Flue connection concentric pipe

Mm

100/150

100/150

100/150

N.A.

HEATING

Values min-max:

Nominal input (gross) (G20)

kW

17.1 - 90.7

20.7 - 108.1

26.2 - 132.6

38.9 - 161.4

Nominal input (net) (G20)

kW

15.4 - 81.7

18.6 - 97.3

23.6 - 119.4

35.0 - 145.3

Nominal input (gross) (G25.3)

kW

17.4 - 88.6

20.8 - 105.7

26.4 - 129.7

39.3 - 158.0

Nominal input (net) (G25.3)

kW

15.7 - 79.7

18.7 - 95.2

23.8 - 116.9

35.4 - 142.2

Nominal input (gross) (G31)

kW

17.4 - 87.4

20.6 - 103.4

26.2 - 131.2

42.7 - 154.4

Nominal input (net) (G31)

kW

16.0 - 80.5

19.0 - 95.2

24.1 - 120.8

39.3 - 142.2

Nominal output 80/60 °C (G20)

kW

14.9 - 79.1

18.0 - 94.2

22.9 - 115.7

33.9 - 140.9

Nominal output 50/30 °C (G20)

kW

16.0 - 85.1

19.5 - 101.8

24.7 - 124.7

36.4 - 151.0

Nominal output 37/30 °C (G20)

kW

16.6 - 88.4

20.2 - 105.5

25.6 - 129.4

38.0 - 157.8

Nominal output 80/60 °C (G25.3)

kW

15.2 - 77.0

18.1 - 92.3

23.1 - 113.4

34.3 - 137.9

Nominal output 50/30 °C (G25.3)

kW

16.4 - 83.0

19.6 - 99.6

24.9 - 121.1

36.8 - 147.7

Nominal output 37/30 °C (G25.3)

kW

17.0 - 88.4

20.3 - 105.5

25.8 - 129.4

38.4 - 157.8

Efficiency (input 30%, return tem-

perature 30 °C)

%

108.2%

108.4%

108.4%

108.6%

GAS CONSUMPTION Values min-max:

Natural gas (G20)

m3/h

1.6 –8.5

1.9 –10.2

2.5 –12.5

3.7 –15.3

Natural gas (G25.3) 7

m3/h

1.8 –9.2

2.2 –11.6

2.8 –14.2

4.1 –16.3

Propane (G31) 1

m3/h

0.6 –3.2

0.8 –3.9

1.0 –4.8

1.6 –5.7

Gas supply pressure

nominal 2

G20

mbar

20

G25.3 7

mbar

25

G31

mbar

37

E93.1803.901 HW

13

Type boiler

CB 85 HW

CB 105 HW

CB 125 HW

CB 155 HW

EMISSION Values min-max:

CO2flue gas 3

G20

%

7.9 –8.4

7.9 –8.4

7.9 –8.4

7.9 –8.4

G25.3 7)

%

8.4 –8.2

8.4 –8.2

8.4 –8.2

8.4 –8.2

G31

%

10.5 –9.3

10.3 –9.3

10.3 –9.5

10.3 –9.5

O2flue gas 3

G20

%

6.9 - 6.0

6.9 - 6.0

6.9 - 6.0

6.9 - 6.0

G25.3 7)

%

5.7 - 6.1

5.7 - 6.1

5.7 - 6.1

5.7 - 6.1

G31

%

4.9 –6.7

5.2 - 6.7

5.2 –6.4

5.2 –6.4

NOx class

-

6

6

6

6

Flue gas temperature at combustion air

temperature = 20 °C

°C

60 - 90

Mass flow flue gas (min/max)

g/s

8.0 - 42

10 - 51

12 - 62

15 - 76

Available pressure for the flue system 4

Pa

200

INSTALLATION

Resistance water heater

T = 12.5 K

m.W.C

9.00

9.50

9.56

8.53

T = 16.5 K

5.45

5.65

5.54

5.14

Pressure water heater max.

bar

8.0

Max. water temperature

°C

85

Pressure relief valve max. pressure

bar

10

ELECTRIC

Maximum power consumption 5

W

190

280

280

280

Power supply

V/Hz

230 / 50

Protection class 6

-

IPX4D

NOTES

1Using propane, a restriction needs to be placed and the maximum and minimum fan speed needs to be

changed

2Min. and max. gas supply pressures:

p nom [mbar]

p min [mbar]

p max [mbar]

G20

20

17

25

G25.3

25

20

30

G31

37

25

57.5

3O2/ CO2of the unit measured/set without the water heater front panel in place

4Maximum allowed combined resistance of flue gas and air supply piping at high fire

5Power consumption is measured without circulation pump

6For gas appliance type B23(P) only class IPX4D with special air inlet (see § 5.1 "Accessories"), otherwise

the protection class is IP20.

7 Only applicable to the Dutch manual.

E93.1803.901 HW

14

Table technical specifications ERP

Type water heater:

CB 85

CB 105

CB 125

CB 155

Load profile

XXL

XXL

3XL

3XL

Unit

Water heating energy efficiency (ηwh)

%

85.9

85.6

89.6

89.1

Daily fuel consumption (Qfuel)

kWh

27.840

27.800

51.540

51,730

Daily electricity consumption (Qelec)

kWh

0.292

0.346

0.260

0.289

Emissions of nitrogen oxides

(EN15502-1:2012+A1:2015)

mg/kWh

23.1

21.3

23.9

20.1

Sound power level, indoors (LWA)

(EN 15036-1:2006)

dB(A)

65.8

68.0

67.8

73.0

A water tank is needed when applying a CB-HW water heater appliance.

The efficiency of the complete installation depends on:

• type of water tank.

• volume of the water tank.

• number of tanks

• number of water heaters

• type of circulation pump.

• length of the connecting pipes.

• insulation of the connecting pipes.

The load profile might be higher depending on the applied tank volume,.

Boiler is IP20 applying a

dust filter or bird screen only

Boiler is IPX4D applying a dust fil-

ter or bird screen with two elbows

and if necessary, a short straight

pipe.

E93.1803.901 HW

15

4 DIMENSIONS & CONNECTIONS

CB 85 HW & CB 105 HW Twin pipe

Connections

Twin Pipe CB 85 &105

A

Hot water Outlet

BSP 1”

B

Cold water Inlet

BSP 1”

C

Condensate

Flexible hose Ø 25/21 mm

D

Gas

BSP ¾”

E / F

Flue gas / Air inlet

100 / 100 mm

EHS.T0200.5034

E93.1803.901 HW

16

CB 85 HW & CB 105 HW Concentric

Connections

Concentric CB 85 & 105

A

Hot water Outlet

BSP 1”

B

Cold water Inlet

BSP 1”

C

Condensate

Flexible hose Ø 25/21 mm

D

Gas

BSP ¾”

E /

F

Flue gas / Air inlet

100 /150 mm

EHS.T0200.5035

E93.1803.901 HW

17

CB-125-HW Twin pipe

Connections

Twin Pipe CB 125

A

Hot water Outlet

BSP 1”

B

Cold water Inlet

BSP 1”

C

Condensate

Flexible hose Ø 25/21

mm

D

Gas

BSP ¾”

E / F

Flue gas / Air inlet

100 / 100 mm

EHS.T0200.5025

E93.1803.901 HW

18

CB 125 HW Concentric

Connections

Concentric CB 125

A

Hot water Outlet

BSP 1”

B

Cold water Inlet

BSP 1”

C

Condensate

Flexible hose Ø 25/21

mm

D

Gas

BSP ¾”

E / F

Flue gas / Air inlet

100 /150 mm

EHS.T0200.5026

E93.1803.901 HW

19

CB-155-HW Twin pipe

Connections

Twin Pipe CB 155

A

Hot water Outlet

BSP 1¼”

B

Cold water Inlet

BSP 1¼”

C

Condensate

Flexible hose Ø 25/21

mm

D

Gas

BSP 1”

E / F

Flue gas / Air inlet

150 / 150 mm

EHS.T0200.5014

E93.1803.901 HW

20

Tanks EWD300 - EWD500 - EWD750

For the connections marked A-H see § 4.8.

EWD300 EWD500

The EWD300, EWD500 and EWD750 are supplied including an

already assembled slice sensor (directly glued to the tank behind

the insulation) The sensor has an cable with a length of 5 meter.

E93.1803.901 HW

21

EWD750

For the connections marked A-H see § 4.8.

The EWD300, EWD500 and EWD750 are supplied including an

already assembled slice sensor (directly glued to the tank behind

the insulation) The sensor has an cable with a length of 5 meter.

This manual suits for next models

3

Table of contents

Popular Heater manuals by other brands

Coopers

Coopers OPA-60 Instructions for use

Alpina

Alpina SF-9381 Instructions for use

Pro-Elec

Pro-Elec PEL00941 Important safety information

Sunhouse

Sunhouse SPH050 Installation and operating instructions

UNITED

UNITED UHH-812 operating instructions

Aqua-Hot

Aqua-Hot WORK READY WR4000 installation instructions