Ecodan EHPT18X-UKHLDWB Guide

UNVENTED MAINS PRESSURE WATER HEATER

WITH FTC6 CONTROL SYSTEM. FOR USE WITH

ECODAN PUZ-(H)WM AIR SOURCE HEAT PUMP

RANGE.

IMPORTANT: PLEASE READ AND UNDERSTAND THESE INSTRUCTIONS

BEFORE COMMENCING INSTALLATION , OPERATING THE UNIT OR

PERFORMING ANY MAINTENANCE.

PLEASE LEAVE THIS MANUAL WITH THE CUSTOMER FOR FUTURE REFERENCE.

Installation, Operation, Service & Parts Manual

Renewable Heating Technology

July 2023

Doc. No. 685702

EDITION-1

EHPT18X-UKHLDWB

EHPT21X-UKHLDWB

EHPT21X-UKHDWB

EHPT25X-UKHDWB

EHPT30X-UKHDWB

2

Contents

Abbreviations and Glossary 2

Safety Precautions 3

Introduction 5

6

Product Diagrams 7

Fiche Performance Data 7

Preparing to Install the Cylinder 8

Installation Instructions 9

Wiring Diagram 15

Electrical Work 16

System Set Up 19

Operator and owner info 30

Commissioning 37

Servicing 38

Annual Maintenance Log Book 39

Servicing 40

Troubleshooting 59

Test Plot Diagram 72

Disassembly / Decommissioning Procedure 73

Service & Maintenance 76

Parts List 79

No. Abbreviations/Word Description

1 Compensation curve mode Space heating incorporating outdoor ambient temperature compensation

2 COP

3 Cylinder unit Indoor unvented DHW tank and component plumbing parts

4 DHW mode Domestic hot water heating mode for showers, sinks etc.

5 Flow temperature Temperature at which water is delivered to the primary circuit

6 Freeze stat. function Heating control routine to prevent water pipes freezing

7 FTC Flow temperature controller, the circuit board in charge of controlling the system

8 Heating mode

9 Legionella Bacteria potentially found in plumbing, showers and water tanks that may cause Legionnaires' disease

10 LP mode Legionella prevention mode – a function on systems with water tanks to prevent the growth of Legionella bacteria

11 Packaged model Plate heat exchanger (Refrigerant - Water) in the outdoor heat pump unit

12 PRV Pressure relief valve

13 Return temperature Temperature at which water is delivered from the primary circuit

14 Split model Plate heat exchanger (Refrigerant - Water) in the indoor unit

15 TRV Thermostatic radiator valve – a valve on the entrance or exit of the radiator panel to control the heat output

16 Cooling mode

Abbreviations and Glossary

3

Safety Precaution

WARNING:

Precautions that must be observed to prevent injuries or death. CAUTION:

Precautions that must be observed to prevent damage to unit.

Please read the following safety precautions carefully.

• Be sure to perform periodical maintenance.

• Be sure to follow your local regulations.

• Be sure to follow the instructions provided in this manual.

MEANINGS OF SYMBOLS DISPLAYED ON THE UNIT

WARNING

This mark is for R32 refrigerant only. Refrigerant type is written on nameplate of outdoor unit.

Read the OPERATION MANUAL carefully before operation.

Service personnel are required to carefully read the OPERATION MANUAL and INSTALLATION MANUAL before operation.

Further information is available in the OPERATION MANUAL, INSTALLATION MANUAL, and the like.

WARNING

Mechanical

The cylinder unit and outdoor unit must not be installed, disassembled, relocated, altered or repaired by the user. Ask an authorised installer or technician. If the unit is installed improperly

Do not position furniture or electrical appliances below the outdoor unit or cylinder unit.

The discharge pipework from the emergency devices of the cylinder unit should be installed according to local law.

Electrical

The units must be powered by a dedicated power supply and the correct voltage and circuit breakers must be used.

Wiring should be in accordance with national wiring regulations. Connections must be made securely and without tension on the terminals.

Earth unit correctly.

Discharge the condenser before the work involving the electric parts.

General

Keep children and pets away from both the cylinder unit and outdoor units.

Do not use the hot water produced by the heat pump directly for drinking or cooking. This could cause illness to the user.

Do not stand on the units.

Do not touch switches with wet hands.

Do not place any heavy items on top of the cylinder unit.

allow air to remain in the lines. If air is mixed with refrigerant, then it can be the cause of abnormal high pressure in the refrigerant line, and may result in an explosion and other hazards.

impediment to securing product safety.

Do not use means to accelerate the defrosting process or to clean, other than those recommended by the manufacturer.

Do not pierce or burn.

Be aware that refrigerants may not contain an odour.

Pipework shall be protected from physical damage.

The installation of pipework shall be kept to a minimum.

Compliance with national gas regulations shall be observed.

Keep any required ventilation openings clear of obstruction.

Do not use low temperature solder alloy in the case of brazing the refrigerant pipes.

In the case of a refrigeration leak, stop the operation of the unit, thoroughly ventilate the room and contact the installer.

4

CAUTION

Use clean water that meets local quality standards on the primary circuit.

The cylinder unit should be located inside to minimise heat loss.

Water pipe-runs on the primary circuit between outdoor and indoor unit should be kept to a minimum to reduce heat loss.

Ensure condensate from outdoor unit is piped away from the base to avoid puddles of water.

Remove as much air as possible from the primary and DHW circuits.

Be sure to wrap insulation around the piping. Direct contact with the bare piping may result in burns or frostbite.

Never put batteries in your mouth for any reason to avoid accidental ingestion.

Battery ingestion may cause choking and/or poisoning.

Install the unit on a rigid structure to prevent excessive sound or vibration during operation.

Do not transport the cylinder unit with water inside the DHW tank. This could cause damage to the unit.

Preventative measures should be taken against water hammer, such as installing a Water HammerArrestor on the primary water circuit, as directed by the

manufacturer.

As for the handling of refrigerant, refer to the outdoor unit installation manual.

[1] Cautions for service

(1) Perform service after recovering the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(4) If moisture or foreign matter might have entered the refrigerant piping during service, ensure to remove them.

[2] Additional refrigerant charge

When charging directly from refrigerant cylinder

(1) Check that cylinder for R410Aor R32 on the market is syphon type.

(2) Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

[3] Service tools

Use the service tools below as exclusive tools for R410A or R32 refrigerant.

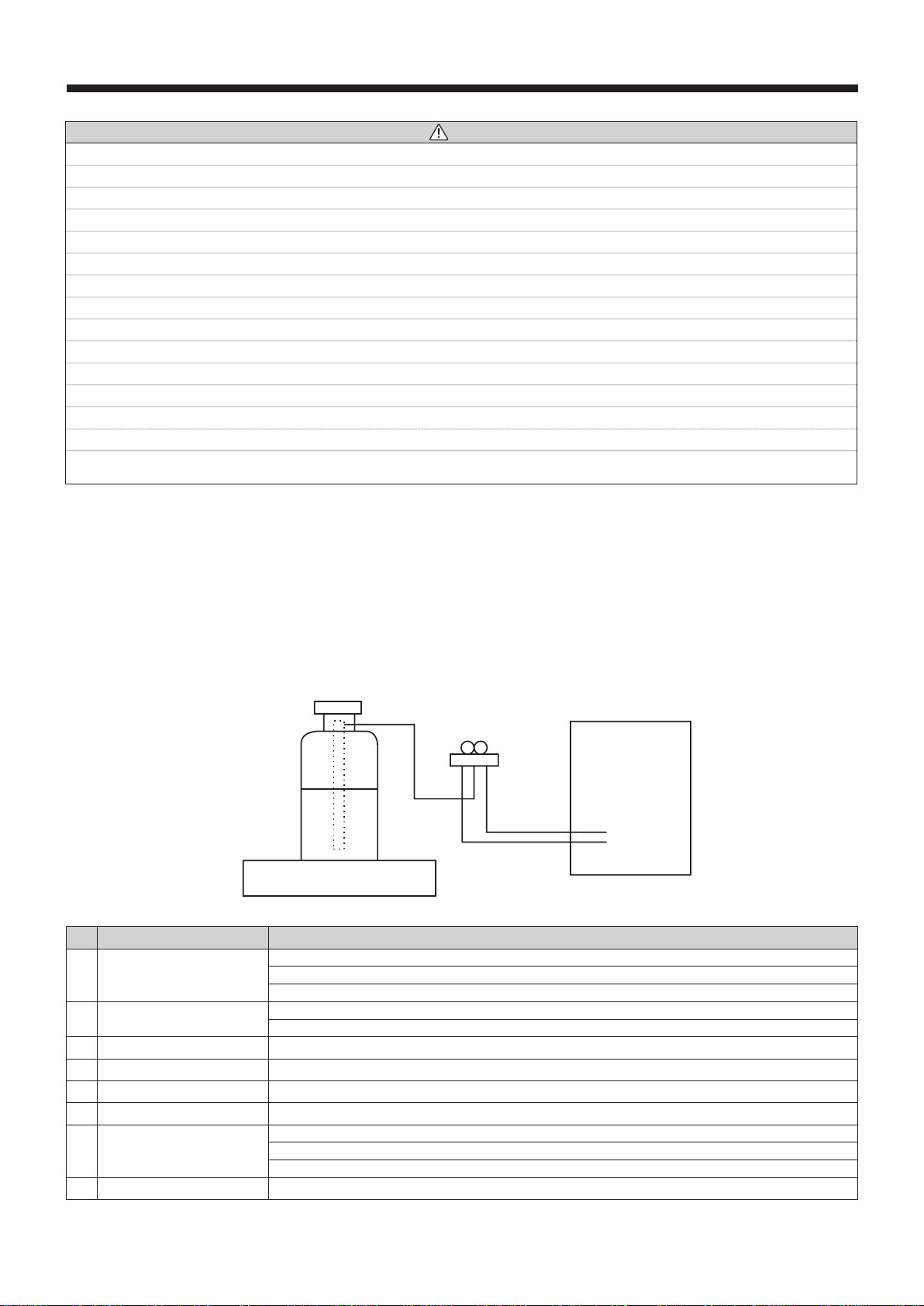

No. Tool name Specications

1Gauge manifold R410A or R32

Use high-tension side pressure of 5.3 MPa·G or over.

2Charge hose R410A or R32

Use pressure performance of 5.09 MPa·G or over.

3Electronic weighing scale —

4Gas leak detector Use the detector for R134a, R407C, R410A or R32.

5 Attach on vacuum pump.

6Refrigerant charge base —

7Refrigerant cylinder R410A or R32

Top of cylinder (Pink)

Cylinder with syphon

8 Refrigerant recovery equipment —

Electronic weighing scale

Unit

5

CAUTION

• Do not use sharp objects to press the buttons of the main remote controller as this will cause damage to the buttons.

Disposal of the Unit

Note: This symbol mark is for EU countries only. This

symbol mark is according to the directive 2012/19/EU

Article 14 Information for users and Annex IX, and/or

to the directive 2006/66/EC Article 20 Information for

end-users and Annex II.

This symbol indicates that this product must not be disposed of with

general household waste, to prevent damage to the environment and

risk to personal health.

Instead, it is your responsibility to ensure the product is

decommissioned and disposed of safely by isolating the electricity

supply to the immersion heater and heat pump, before draining

must then dispose of the cylinder by handing it over to a designated

recycling centre for domestic waste electrical equipment. Contact your

or to arrange a collection.

Introduction

hot water expansion vessel, cold water combination valve, tundish, Wi-Fi adapter harness and Mitsubishi main remote control.

IMPORTANT NOTE TO THE INSTALLER

You must ensure the installation complies with the current Building Regulations and/or Technical Standards Documents for England,

Scotland or Wales.

IMPORTANT NOTE

All goods are sold subject to Mitsubishi Electric’s Terms and Conditions of Sale.

Important Note:

Included with the Ecodan product is information about how to register the Mitsubishi Electric user guarantee. Please direct the end user

and any cylinder or interfacing equipment purchased from Mitsubishi Electric by you as installer.

The guarantee applies where the installation address is in England, Scotland or Wales only and for domestic use. This registration

should be completed only by the end user/system owner so please ensure that the information about how to register the Mitsubishi

Electric user guarantee reaches them. There are various options to register the guarantee and details can be found online at

https://les.mitsubishielectric.co.uk. The registration is logged by our warranty department. In the unlikely event of failure of the Ecodan

heat pump or any such cylinder or interfacing equipment purchased from Mitsubishi Electric, registration of the guarantee ensures

contact details on back page).

Please Note:

If you do not register the Mitsubishi Electric user guarantee then the product will only be guaranteed to the user by Mitsubishi Electric

consumer rights under applicable national legislation.

6

Specication Details

The unvented cylinders are made from Duplex stainless steel

for corrosion resistance, are encased in a strong rust-proofed

steel case and are highly insulated with environmentally-

friendly foam. Further details are below.

Materials

• Inner shell – Duplex stainless steel

• Coil – 22mm diameter stainless steel

28mm diameter stainless steel

• Bosses – stainless steel

• Polyurethane CFC- and HCFC-free foam insulation. This

insulation has an Ozone Depletion Potential of Zero and

a Global Warming Potential of 1

• Anode – none required

All cylinders are welded using a controlled oxygen purged

process to maximise the corrosion resistant qualities of the

high-grade Duplex stainless steel. Every cylinder is checked

using 15 bar pressure testing.

Immersion heater

• 1 ¾” BSP parallel threaded head

• Titanium long life low noise element

• Brazed construction

• Safety cut-out

• Element rating 3kW at 230-240 Volt A/C

Flow rates

The graph below illustrates the speed at which hot water can

be distributed reliably throughout the home.

Coil Presure Drop

Slimline Cylinders

Standard Cylinders

Pressure specications - The Unvented Cylinder

Maximum Inlet Water Pressure 12.0 bar

Operating Pressure/Maximum Design Pressure 3.0 bar

Expansion Valve Opening Pressure 6.0 bar

Expansion Vessel Charge Pressure 3.0 bar

Maximum Operating Pressure 3.0 bar

Opening Pressure of T & P Valve 7.0 bar

Opening Temperature of T & P Valve

Maximum Coil Pressure 3.5 bar

Immersion Element specications

Element Rating 3kW 230-240 Volt

Thread Type 1¾” BSP

Fuse Requirement (Via FTC6) 16A

Control Thermostat (Via FTC6)

High Limit Thermostat Set Point

0

0.1

0.2

0.3

0.4

0.5

0.6

0

5

10

15

20

25

30

Pressure drop (Bar)

Flow rate (LPM)

0

0.05

0.1

0.15

0.2

0.25

0.3

0

5

10

15

20

25

30

Flow rate (LPM)

Pressure drop (Bar)

0

10

20

30

40

50

60

70

80

90

2 2.5 3 3.5

Water Pressure (Bar)

Flow Rate (LPM)

4 4.5 5

7

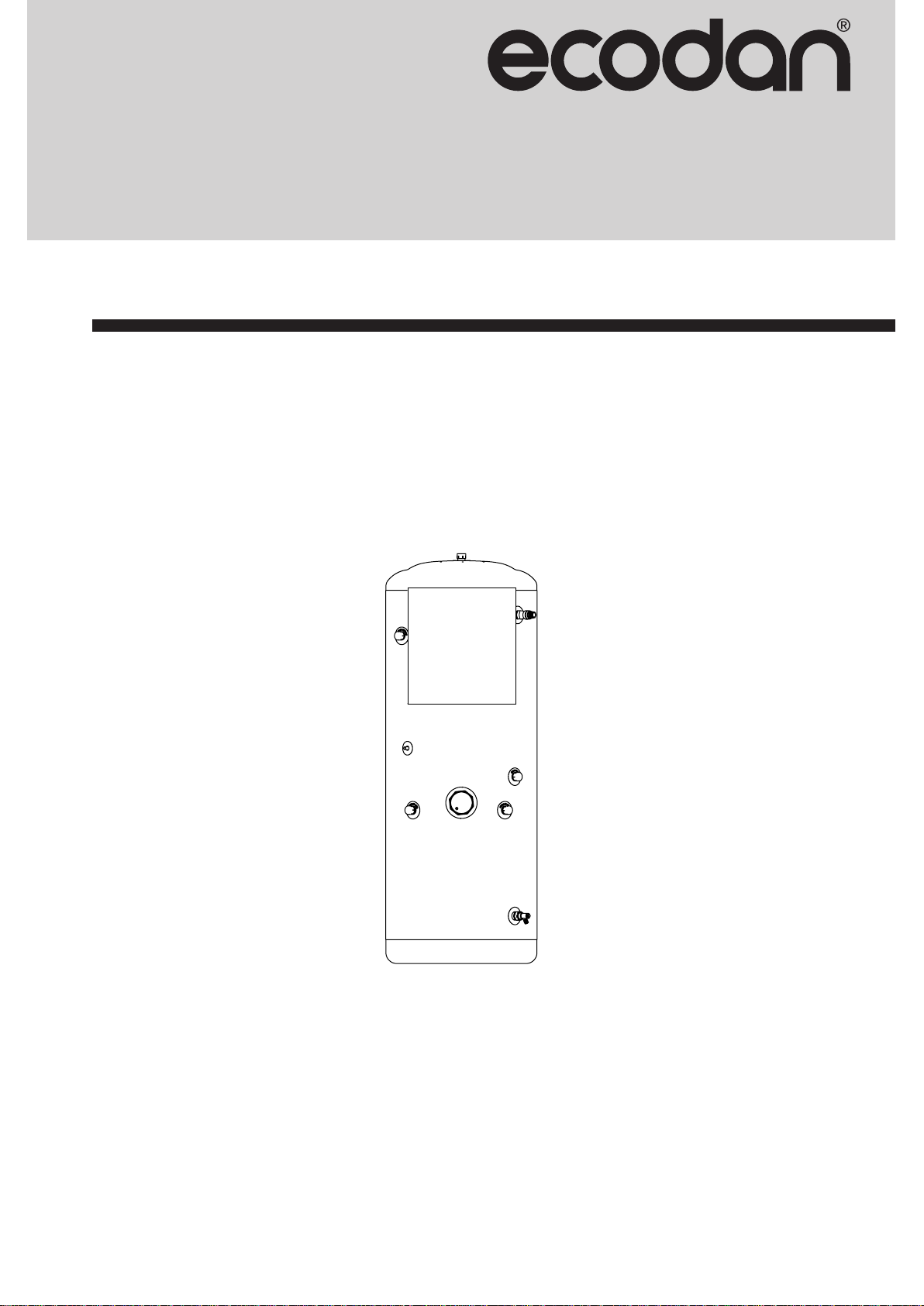

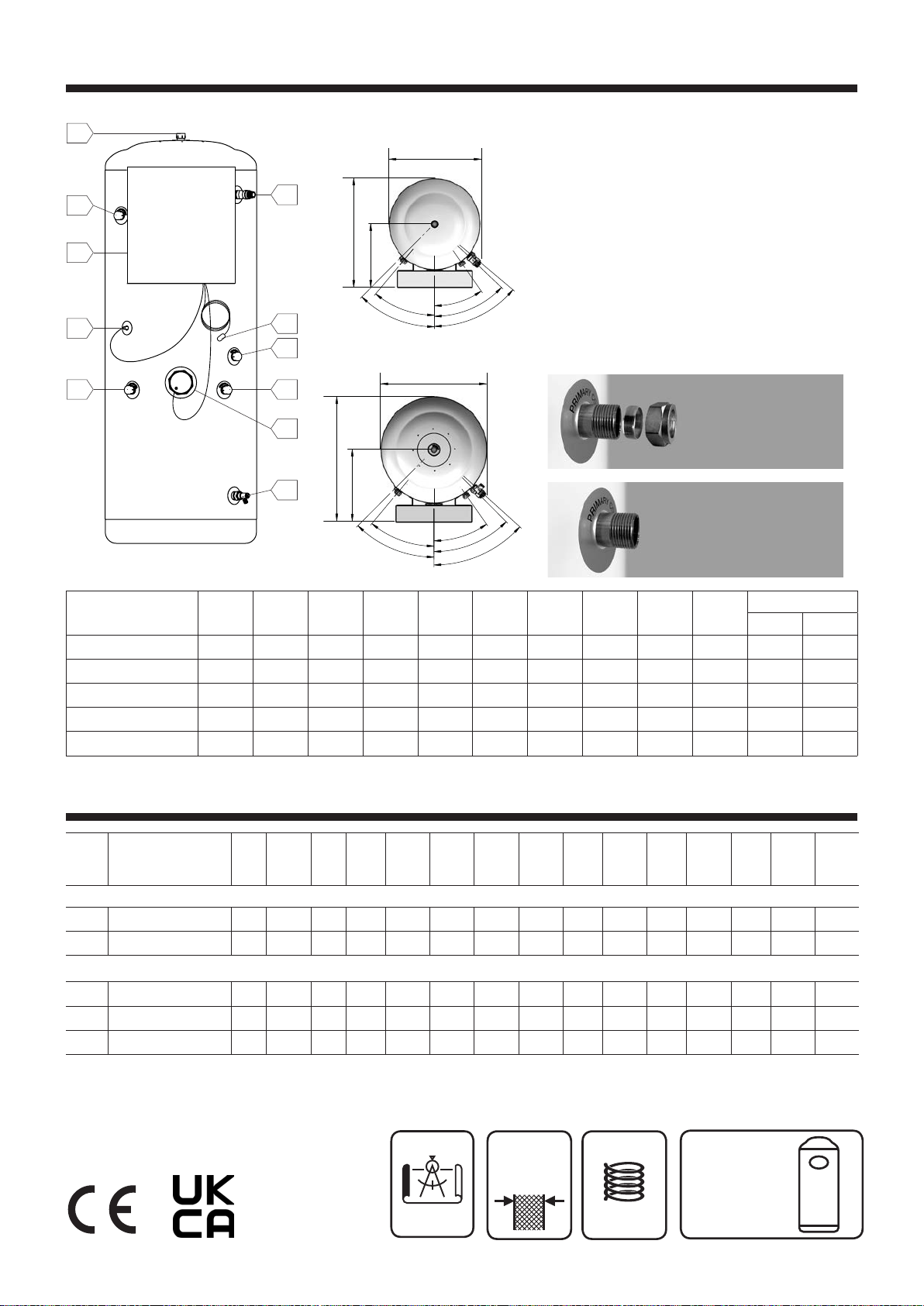

Product Diagrams

A

J

H

C

G

I

B

F

DD

E

Slimline

Standard

Connections

A Cold feed - 22mm / ¾" BSP

B Hot water outlet - 22mm / ¾" BSP

C 3kW 14" Immersion heater - 1¾" BSP

D Heat pump coil connections - 22mm / ¾" BSP

- ½”NPT x 15mm

F Secondary return - 22mm / ¾" BSP

(Excluding EHPT18X-UKHLDWB)

G Dry stat pocket - 10mm

H Drain cock

I FTC6 Controller

J Wi-Fi Adaptor (installer to locate and mount)

Product

Codes

Total

Height

(mm)

Diameter

(mm) A

(mm) B

(mm) C

(mm) D

(mm) E

(mm) F

(mm) G

(mm) HFTC6 Controller

Bottom Top

EHPT18X-UKHLDWB 1712 475 726 1712 756 668 1479 N/A 864 158 1156 1578

EHPT21X- UKHLDWB 2025 475 726 2025 769 668 1795 1615 1020 158 1156 1578

EHPT21X-UKHDWB 1495 550 680 1495 584 558 1273 1150 768 173 1018 1440

EHPT25X-UKHDWB 1745 550 680 1745 654 558 1523 1400 893 173 1156 1578

EHPT30X-UKHDWB 2058 550 680 2058 654 558 1836 1600 1050 173 1156 1578

376

40°

45°

35°

45°

48°

40°

46.5°

35°

50°

45°

332

651

550

570

475

376

40°

45°

35°

45°

48°

40°

46.5°

35°

50°

45°

332

651

550

570

475

¾" BSP parallel male thread

connections without

nut & olive

22mm compression

connections when using

the nut & olive

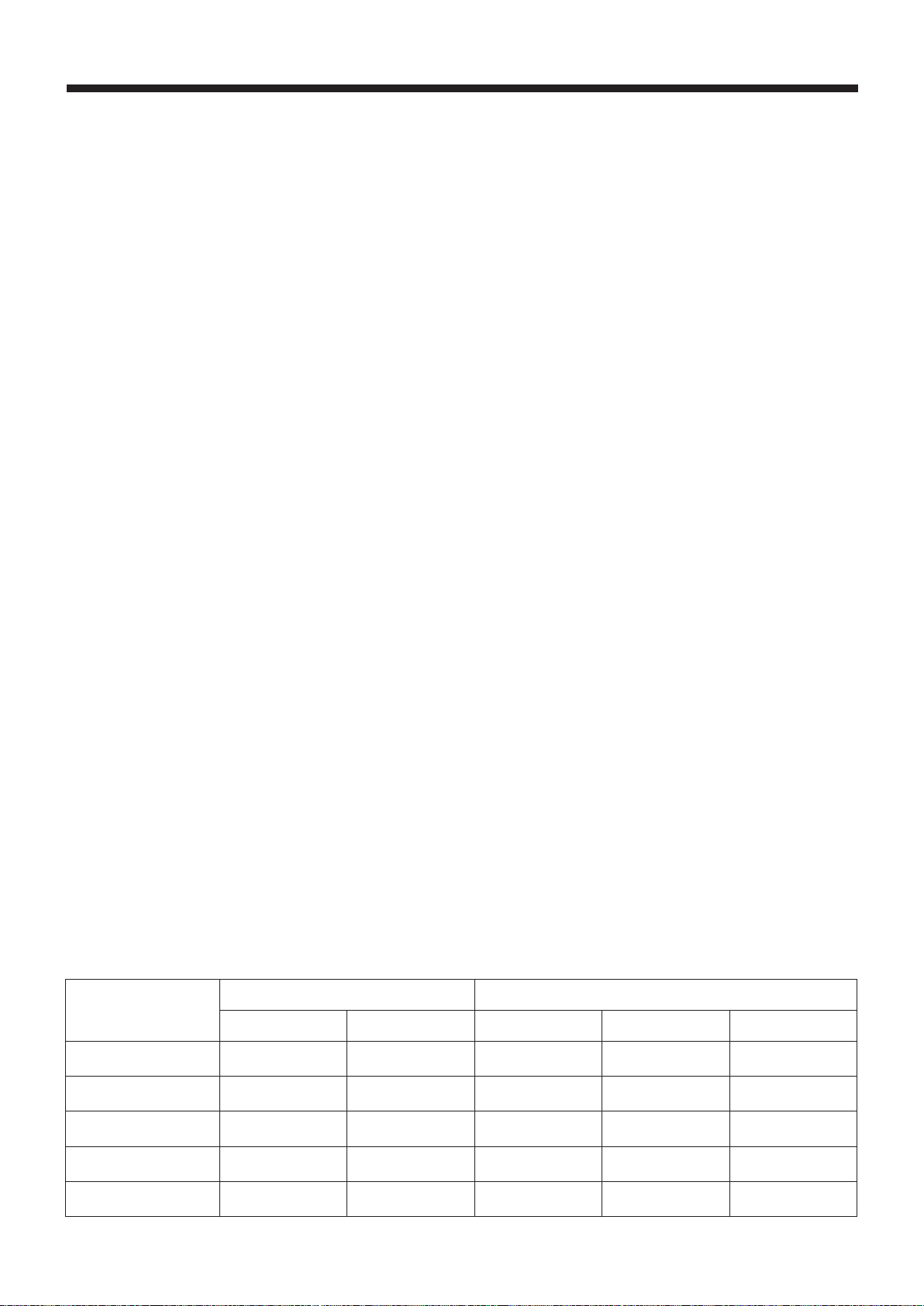

Fiche - Technical Performance Data

Nominal

Capacity

(Litre)

Product

Codes Energy

Rating

Standing

Loss

(W)

Total

Height

(mm)

Diameter

(mm)

Weight

Empty

(kg)

Weight

Full

(kg)

Actual

Cylinder

Capacity

(Litre)

Expansion

Vessel

(Litre)

Heat-up

Time

(Min.)

Heat

Loss

(kW/24Hr)

Coil

Primary

Flow

(L.P.M.)

Coil

Pressure

Drop

(Bar)

Coil

Surface

Area

(m2)

Coil

Capacity

(Litre)

Coil

(kW

Rating)

Heat pump slimline unvented hot water cylinders

180 EHPT18X-UKHLDWB C 72 1712 475 45 218 173

19

20 1.72 15 0.14 1.7 8.0 32

210 EHPT21X-UKHLDWB C 87 2025 475 51 259 208

19

24 2.08 15 0.14 1.7 8.0 32

Heat pump unvented hot water cylinders

210 EHPT21X-UKHDWB C 75 1495 550 48 242 195

19

24 1.79 15 0.08 2.3 14.3 32

250 EHPT25X-UKHDWB C 84 1745 550 53 288 235

24

29 2.02 15 0.08 2.3 14.3 32

300 EHPT30X-UKHDWB C 93 2058 550 60 345 285

24

34 2.24 15 0.08 2.3 14.3 32

3 Bar

Max design

pressure (DHW)

Insulation

Thickness

50mm

3.5 Bar

Max primary

coil pressure

Recommended

Minimum Input

25 L.P.M.

@

1.5 Bar

Tested in accordance with BS EN 12897:2016+A1:2020

(closed) storage water heaters.

8

Preparing To Install the Cylinder

Storage prior to installation

The unvented cylinder should be stored in its original

packaging in an upright position in a dry, frost-free

environment.

Handling product

The unvented cylinder should be carried upright where

possible. Assessments of risks for carrying the unit should

be conducted. Use more than one person for carrying where

components such as the T&P valve or immersion heater.

Always follow latest guidelines for lifting techniques to avoid

injury or damage to the product.

Water supply

The unvented cylinder operates at 3 bar (controlled by the

cold water combination valve) and is capable of delivering

over 50 litres per minute. The cold water combination valve

available, however the performance of any unvented system

is only as good as the mains water supply. The maximum

possible water demand should be assessed, taking into

consideration that both hot and cold services are supplied

simultaneously from the mains.

The water supply should be checked to ensure it can

meet these requirements. If necessary, consult the local

availability.

If measuring the water pressure, note that a high static (no

In a domestic installation 1.5 bar and 25 L/min. should be

regarded as the minimum. The maximum mains pressure that

the cold water combination valve can accept is 12 bar.

Consideration should be given to upgrading existing

½" (15mm) cold mains pipework to a larger size if the

achieved.

Note: the system must be fed from domestic mains water

supply compliant with Water Regulations 2000 and the use

of well water or a private borehole will void the cylinder’s

Warranty.

Siting the unit

The unvented cylinder can supply outlets above it or at

some distance from it. Site the unit to minimise “dead

leg” distances, especially to the point of most frequent

use. Outlets above the unvented cylinder will reduce the

outlet pressure available by 0.1 bar for every 1m of height

The unvented cylinder must be installed indoors in a frost-free

environment and all exposed pipework should be insulated.

The units must be installed in the correct orientation, i.e.

the cylinder when full. See the illustration and table for the

minimum recommended cupboard size; take care to ensure

the discharge pipe(s) from its safety valves can be correctly

installed - see discharge arrangement on page 13 & 14.

Model Cylinder

ø

mm

Airing Cupboard Size

Width

mm Depth

mm Height

mm

EHPT18X-UKHLDWB 475 675 675 1832

EHPT21X-UKHLDWB 475 675 675 2145

EHPT21X-UKHDWB 550 750 750 1615

EHPT25X-UKHDWB 550 750 750 1865

EHPT30X-UKHDWB 550 750 750 2178

50mm

410mm

100mm 100mm

120mm

H

Ceiling or similar

flat surface capable of supporting the weight when full

50mm

410mm

100mm 100mm

120mm

H

Ceiling or similar

flat surface capable of supporting the weight when full

9

Preparing To Install the Cylinder

Access

Consideration should be given to the position of discharge

pipes (tundish) drain valves. Avoid positioning these too close

space so that the cylinder can be inspected, maintained and

serviced in the future.

The immersion heaters are 410mm long and care should

be taken to ensure that they can be withdrawn, enabling the

immersion heater to be replaced at the end of its working life

and providing inspection access to the interior of the cylinder

in servicing if required. The discharge pipework from the

safety valves should fall continuously and terminate safely.

AAV’s

Additional automatic air vents (AAV) (not supplied) may be

required at high points in the primary system where pipework

system (primary circuit), release all trapped air using air vents

during and following heating period and top up with water as

necessary. After removing the air, automatic air vent(s) MUST

be closed.

Flushing the heating system

(Retrot installations)

Part L of the 2022 Building Regulations require that all central

heating systems are cleaned and dosed with protective

as the heat pump, to protect the equipment from damage.

Ecodan heat pumps also require anti-freeze protection.

Failure to do so will put the product Warranty at risk.

Turn to test

Cold water combination valve Cold

Mains In

Expansion Relief

to Tundish

Balanced Cold

Connection

Outlet to Cylinder

Cold mains pipework

Option 1: Run the cold mains through the building to the place

where the unvented cylinder is to be installed.

Option 2. Where local Building Regulations do not permit

the cylinder to be connected directly to mains supply, run the

cold feed from a cold feed break tank using a suitable pump

to boost pressure. The pump MUST be used in conjunction

with a sensor in the feed tank to ensure tank does not drain

empty and pull air. Take care to prevent heat pick-up by not

running the cold pipe near hot water or heating pipework. This

(not supplied). We recommend using a full bore quarter turn

ball valve; alternatively a stopcock can be used, however this

similar service valve.

Make the connection to the cold feed of the cylinder with

the cold water combination valve positioned above the

Temperature & Pressure Relief Valve (TPRV) mounted on

the side of the cylinder. This ensures that the cylinder does

not have to be drained down in order to service the cold

water combination valve. Ensure that the arrow points in the

Select a suitable position for the potable water expansion

vessel. Mount it to the wall using the bracket attached to the

weight (and with appropriate consideration to wall material).

Connect the expansion vessel to the cold feed pipework

between the cold water combination valve and the cold inlet

on the cylinder. Ensure that the top of the vessel is accessible

for servicing.

Cylinder connections

The cylinder should be plumbed in using BS EN1057-R250

copper tube. Cut the tube square using a rotary tube cutter

and ensure no sharp edges or burrs protrude. Slide both

gland nut and olive onto the tube and push tube fully home

into the connection, ensuring the tube end fully bottoms on

the connection recess. Smear the outer wall of the olive with

plumbing paste and tighten the gland nut in the prescribed

manner.

Alternatively, if you are using imperial pipework, you may

the BSP thread on the cylinder boss.

completely watertight, including bosses and any pre-plumbed

components.

the expansion relief valve and the storage cylinder. The relief

valve connections should not be used for any other purpose.

Installation Instructions - Unvented Cylinders

10

Installation Instructions - Unvented Cylinders

Balanced connections

A balanced hot and cold supply is necessary to stop one

from overpressurisation of the other. This can be achieved

by feeding all cold outlets from the 22mm balanced cold

connection featured on the cold water combination valve. If

you are not using this balanced cold connection and using an

cold water combination valve’s balanced cold connection.

Where there are showers, bidets or monobloc mixing taps

in the installation, these need to be installed to comply with

the Water Supply (Water Fittings) Regulations 1999. If these

devices have unbalanced supplies, there must be single

check valves installed at both inlets.

Hot water pipework

Run

suit the type of tap for example. You should aim to keep the run

length of any hot water pipework from the cylinder to outlet to a

practical minimum so the time taken for the hot water to reach

the outlet is as quick as possible. Then connect the hot water

the diagram on page 7).

Connections - heat pump coil

The cylinders are suitable for use with Ecodan PUZ-(H)WM

Air Source heat pumps; see compatibility table bellow.

be pumped. Gravity circulation is not suitable.

The heat pump cannot be vented through the cylinder.

Solid fuel boilers or any other boiler in which the energy input

and appropriate safety measures are installed, should NOT

be used. The primary circuit must be a sealed system type,

sized expansion vessel for the size of the heating system.

Ecodan R32 heat pumps include an integral 3 bar PRV. No

additional PRV’s should be added to the circuit.

heating of the cylinder.

Water Quality and System Preparation

General

The water in both primary and sanitary circuit should be clean

and with pH value of 6.5-8.0.

The following are the maximum values:

• Calcium: 100 mg/L, Ca hardness: 250 mg/L, Chloride:

100 mg/L, Copper: 0.3 mg/L

• Other constituents should be to European Directive

98/83 EC standards.

• In known hard water areas, to prevent/minimise scaling, it

Anti-freeze

Anti-freeze solutions MUST use propylene glycol with a

toxicity rating of Class 1 as listed in Clinical Toxicology of

Commercial Products, 5th Edition.

Notes:

1) Ethylene glycol is toxic and MUST NOT be used in the

primary water circuit in case of any cross-contamination of

the potable circuit.

2) For 2-zone valve ON/OFF control, propylene glycol MUST

be used.

New and existing installations (primary water circuit)

Before connecting outdoor unit, thoroughly cleanse pipework

of building debris, solder etc. using a suitable chemical

cleansing agent.

Flush the system to remove chemical cleanser.

Add a combined inhibitor and anti-freeze solution to prevent

damage to the pipework and system components.

Corrosion inhibitor should always be used.

When using chemical cleansers and inhibitors always follow

the manufacturer’s instructions and ensure the product is

appropriate for the materials used in the water circuit.

Slimline Standard

EHPT18X-UKHLDWB EHPT21X-UKHLDWB EHPT21X-UKHDWB EHPT25X-UKHDWB EHPT30X-UKHDWB

PUZ-WM50 VHA(-BS) •••

PUZ-WM60 VAA(-BS) •••••

PUZ-WM85 (V-Y)AA(-BS) •••••

PUZ-WM112 (V-Y)AA(-BS) •••••

PUZ-HWM140(V-Y)HA •••••

Heat Pump to Cylinder Compatibility

11

Installation Instructions - Unvented Cylinders

Minimum required water volume and required

primary ow rates

Outdoor heat pump unit Min. water

volume Required

ow rate

PUZ-WM50VHA 7L 14.3L/min

PUZ-WM60VAA 9L 17.2L/min

PUZ-WM85(V-Y)AA 12L 24.4L/min

PUZ-WM112(V-Y)AA 16L 32.1L/min

PUZ-HWM140(V-Y)HA 20L 40.1L/min

If the interlock operation of primary and secondary pump is

not available, ensure required additional water in only primary

circuit. If the interlock operation of primary and secondary

pump is available, ensure total water amount in primary and

secondary circuit. In the case of shortage of required water

Secondary circulation connection

The cylinders can be used with secondary circulation if

required. Use an appropriate WRAS approved bronze

or stainless steel circulator in conjunction with a WRAS

secondary circulation systems it may be necessary to

incorporate an extra expansion vessel into the circuit to

accommodate the increased system water volume.

Important: Immersion to be wired via FTC6. For full

to diagram opertit.

Electrical supply to the immersion heater

The unvented cylinder requires 230-240 Volt electrical

supply for the immersion element. The electrical supply to

the immersion heater must be fused at 16A via a double

pole isolating switch that meets the current BS Standards. A

breaker with at least 3.0mm contact separation in each pole

shall be provided. Use an earth leakage breaker (NV). The

breaker shall be provided to ensure the disconnection of all

active phase conductors of the supply. The cable must be

at least 2.5mm2

complying to the current BS Standards.

Electrical supply to the 3-way diverter valve

The 3-way diverter valve uses 230-240 Volt electrical supply.

connecting via FTC box.

Do not grip the valve head while tightening or adjusting

plumbing connections. Flow from the heat pump must be

MUST

NOT be mounted below horizontal level of pipework.

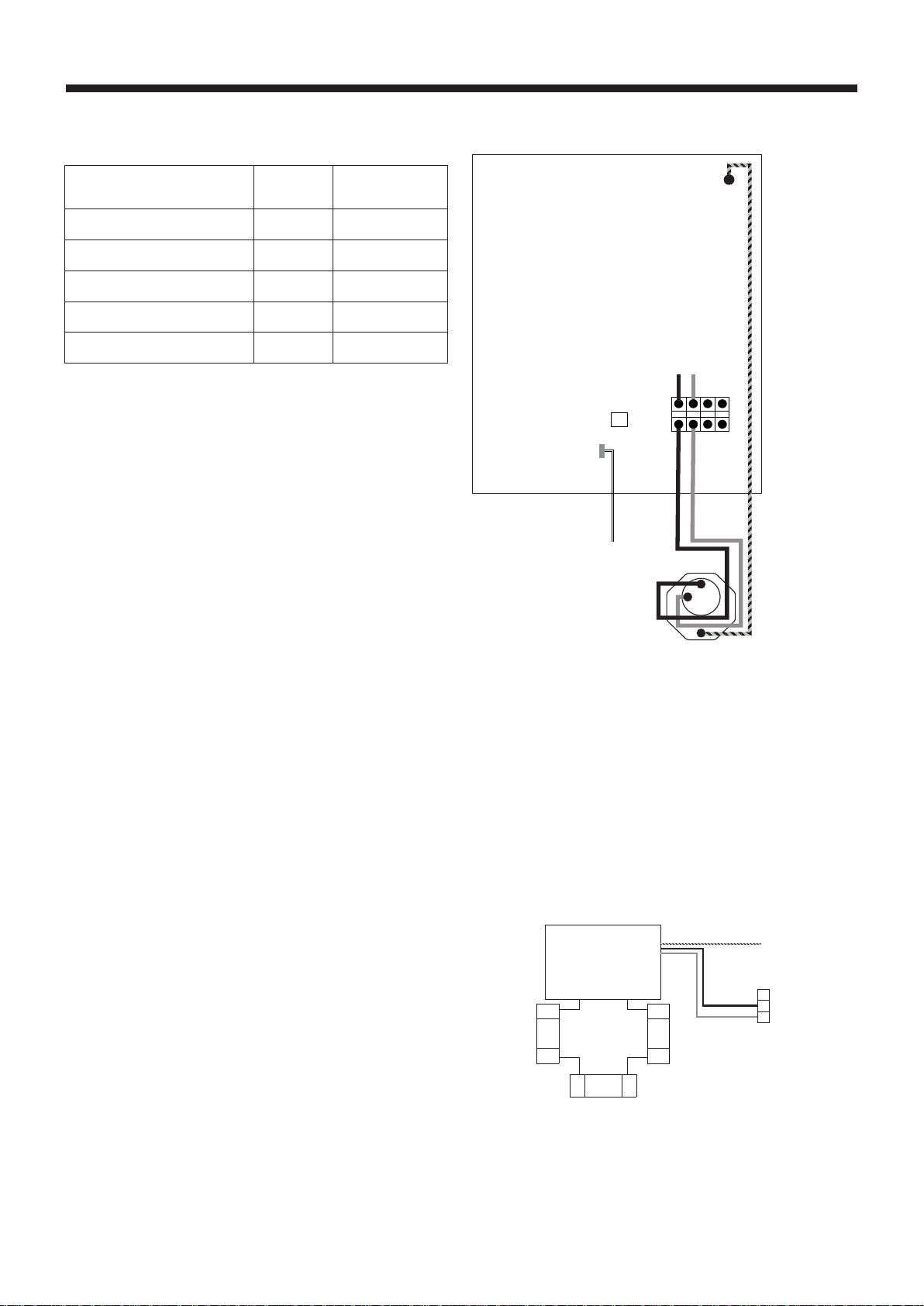

Immersion Heater

To

Thermostat

SD

Live

(Brown) Neutral

(Blue) Earth (Yellow/Green)

Immersion Heater Wiring

2/T1

1/L1 3/L2

4/T2 5/L3

5/T3 A1

A2

IHC

CNW5

CN108

A

B

4

5

6

Live (Brown)

Neutral (Blue)

Earth (Yellow/Green)

A

AB

B

To Heating

To Hot Water

OUT 4 TBO.2 4-6

Flow from

Heat Pump

3-way Diverter valve

Immersion Heater Wiring

12

Installation Instructions - Unvented Cylinders (cont.)

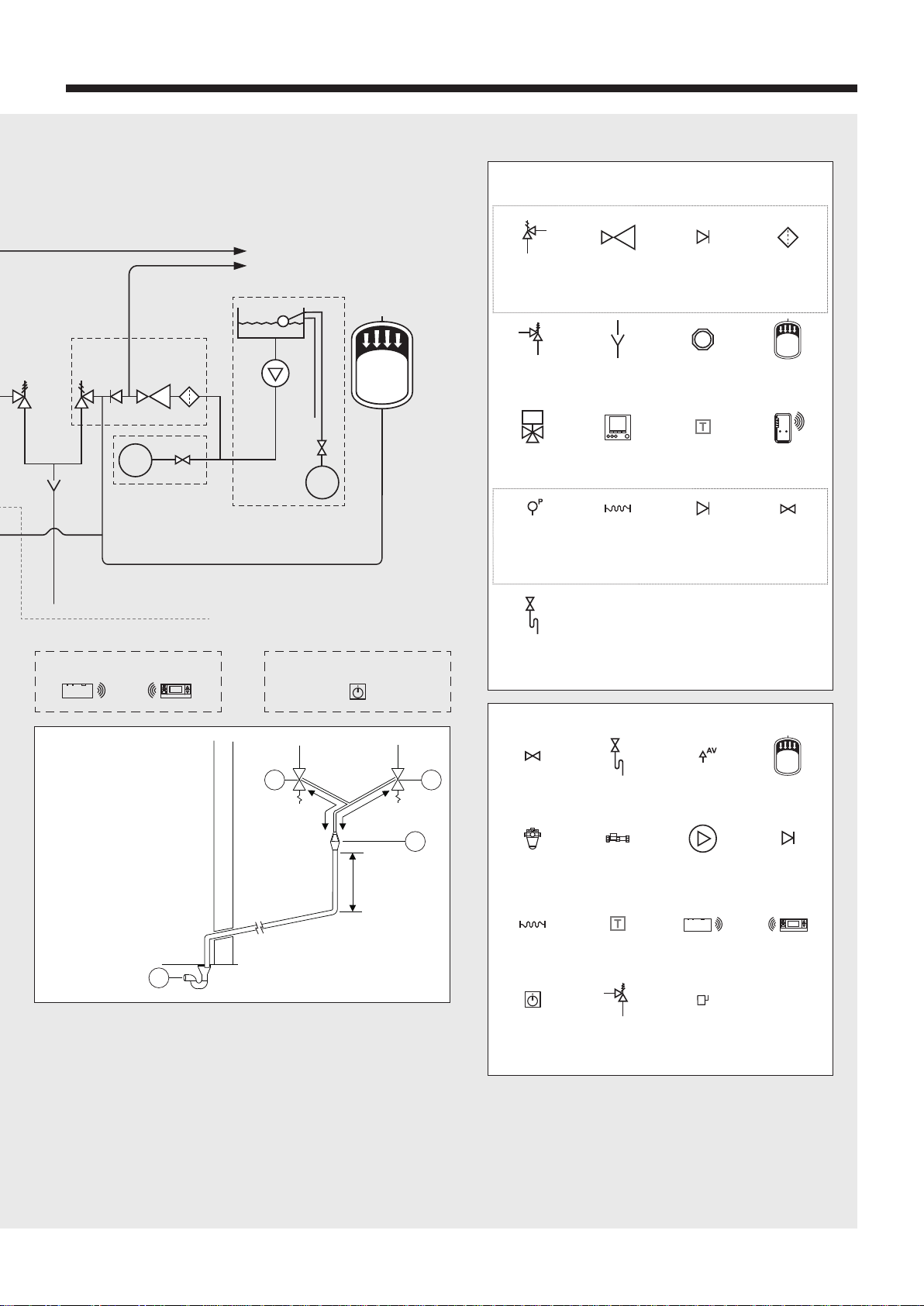

T

System Schematic

DRAIN

DRAIN

COLD

MAIN

BALANCED

COLD

To cold water outlets

To hot water outlets

OVERFLOW

Cold water

combination

valve POTABLE

WATER

EXPANSION

VESSEL

COLD

MAIN

COLD

MAIN

Filling Loop, disconnect

when not in use

Opt 2.

Connection via breaker tank

Immersion

230V|SP+N|50Hz

FIC6 Board

230V|SP+N|50Hz

Wi-Fi

Adaptor

Main

Controller

Wireless Transmitter

Rads/FC (Option)

Wireless Receiver

(Option) Room Thermostat / UFH Wiring Centre

(Local Supply)

Zone 1 Heating

Rads/UFH/FC

Zone 1

Call for heating

OR

Flow to heating system

Return from heating system

12V DC

(2 x 0.3mm2)

Refer to detail

on discharge

pipework

System Schematic

Main

Controller

Flushing Bypass

XP+N|50Hz

T

T

AV

HEATING

EXPANSION

VESSEL

SECONDARY RETURN CIRCUIT

(210, 250 & 300L SIZES)

P

FTC6

Opt 1.

Direct mains connection

Detailed Discharge Pipework

Arrangement

1 2

600mm

MAXIMUM

600mm

MAXIMUM

300mm

MINIMUM

3

4

Metal discharge pipe

(D1) from both safety

valves to tundish

Discharge pipe (D2)

from tundish, with

continuous fall.

See Building Regulations

G3 section 3.56,

Table 4 & worked example

Discharge below fixed grating

(Building Regulations G3 section 3.61

gives alternative points of discharge)

1) Expansion relief valve on cold

water combination valve

2) Temperature & pressure relief

valve on cylinder

3) Tundish

4) Drain with fixed grating

13

Installation Instructions - Unvented Cylinders (cont.)

T

System Schematic

DRAIN

DRAIN

COLD

MAIN

BALANCED

COLD

To cold water outlets

To hot water outlets

OVERFLOW

Cold water

combination

valve POTABLE

WATER

EXPANSION

VESSEL

COLD

MAIN

COLD

MAIN

Filling Loop, disconnect

when not in use

Opt 2.

Connection via breaker tank

Immersion

230V|SP+N|50Hz

FIC6 Board

230V|SP+N|50Hz

Wi-Fi

Adaptor

Main

Controller

Wireless Transmitter

Rads/FC (Option)

Wireless Receiver

(Option) Room Thermostat / UFH Wiring Centre

(Local Supply)

Zone 1 Heating

Rads/UFH/FC

Zone 1

Call for heating

OR

Flow to heating system

Return from heating system

12V DC

(2 x 0.3mm2)

Refer to detail

on discharge

pipework

System Schematic

Main

Controller

Flushing Bypass

XP+N|50Hz

T

T

AV

HEATING

EXPANSION

VESSEL

SECONDARY RETURN CIRCUIT

(210, 250 & 300L SIZES)

P

FTC6

Opt 1.

Direct mains connection

Detailed Discharge Pipework

Arrangement

1 2

600mm

MAXIMUM

600mm

MAXIMUM

300mm

MINIMUM

3

4

Metal discharge pipe

(D1) from both safety

valves to tundish

Discharge pipe (D2)

from tundish, with

continuous fall.

See Building Regulations

G3 section 3.56,

Table 4 & worked example

Discharge below fixed grating

(Building Regulations G3 section 3.61

gives alternative points of discharge)

1) Expansion relief valve on cold

water combination valve

2) Temperature & pressure relief

valve on cylinder

3) Tundish

4) Drain with fixed grating

Key:

Items supplied with cylinder

Other items

Pressure

reducing valve

Flexihose

3-way diverter

valve Thermostat

(cylinder)

Drain cock

Flow

sensor

Thermostat

Pressure and

temperature

relief valve

Pressure

relief valve

Pressure

gauge

Pressure and

temperature

relief valve

Main

controller

Full bore

isolating valve

Magnetic

Flexihose

Room

thermostat/UFH

wiring centre

1 x Draincock

(cylinder)

Check

valve

Check

valve

Anti-splash

tundish

Wi-Fi

adaptor

Air vent

valve

Circulation

pump

Wireless

receiver

FTC6

Connector

block

Potable water

expansion

vessel

Expansion

vessel

Check

valve

Wireless

transmitter

Inline

strainer

2x DN15

isolation valve

3kW Titanium

immersion

heater

1 x Cold water combination valve

1 x Filling loop

14

Discharge arrangement

You will need to position the inlet control group so that the

discharge from both safety valves can be joined together via

a 15mm tee (see diagram on page 13). Connect the tundish

and then connect and route the discharge pipe.

Ensure all pipes to and from the tundish are cut square,

vertically.

The discharge pipework must be routed in accordance with

Part G3 of schedule 1 of the Building Regulations.

The information that follows is not exhaustive and if you are in

doubt you should seek advice.

Note: The discharge will consist of scalding water and steam.

damaged by such discharges.

Note: Although Building Regulations now permit the

D2 pipe from the tundish to be installed in soil stacks within

premises, we do not recommend this, as discharge from

the temperature and pressure valve may continue for long

periods of time. It is the installer’s responsibility to ensure

the discharge pipework can support the discharge for

prolonged periods. If used, follow the guidance given in the

G3 Building Regulations (mechanical seal without water trap).

pipework is also not recommended.

The two safety valves will only discharge water under fault

conditions. When operating normally water will not be

discharged. The tundish should be located in the same space

close as possible to, and lower than, the safety device, with

no more than 600mm of pipe between the valve outlet and

the tundish. The tundish should be positioned away from

electrical devices.

Any discharge should be visible at the tundish. The tundish

should be located such that any discharge is visible. In

addition, where discharges from safety devices may not

be apparent, extra consideration should be given, e.g. for

people with impaired vision or mobility. This could be via the

installation of a suitable electronically operated or other safety

device to warn when discharge takes place.

The discharge pipe (D2) from the tundish should:

A Have a vertical section of pipe at least 300mm long, below

the tundish before any elbows or bends in the pipework.

B Be installed with a continuous fall of at least 1 in 200

thereafter.

The discharge pipe (D2) from the tundish should be of metal

or other material that has been demonstrated to be capable of

withstanding temperatures of the water discharged.

The discharge pipe (D2) should be at least one pipe size

larger than the nominal outlet size of the safety device, unless

its total equivalent hydraulic resistance exceeds that of a

straight pipe 9m long. Therefore, discharge pipes between

9m and 18m equivalent resistance length should be at least

two sizes larger than the nominal outlet size of the safety

device; between 18 and 27m at least three sizes larger. Bends

Refer to the diagram, Table 2 and the worked example.

An alternative approach for sizing discharge pipes would be

testing and maintenance of services supplying water for

domestic use within buildings and their curtilages.

The discharge pipe (D2) should terminate in a safe place

where there is no risk to persons in the vicinity of the

discharge. Examples of acceptable discharge arrangements

are:

grating and above the water seal.

B Downward discharges at a low level; i.e. up to 100mm

above external surfaces such as car parks, hard

standings, grassed areas etc. are acceptable, providing

that – where children play or otherwise could come into

contact with discharges – a visible wire cage or similar

guard is positioned to prevent contact.

C Discharges at a high level; e.g. into a metal hopper and

metal down pipe with the end of the discharge pipe

clearly visible; or onto a roof capable of withstanding high

temperature discharges of water and 3m from any plastic

guttering systems that would collect such discharges.

D Device to warn when discharge takes place.

Discharge worked example

The example below is for G1/2 temperature relief valve with

a discharge pipe (D2) having four elbows and a length of 7m

from the tundish to the point of discharge.

Maximum resistance allowed for a straight length of 22mm

copper discharge pipe (D2) from a G1/2 temperature relief

valve is: 9.0m.

Subtract the resistance for four 22mm elbows at 0.8m each =

3.2m.

Therefore the maximum permitted length equates to: 5.8m.

5.8m is less than the actual length of 7m, therefore calculate

the next largest size.

Maximum resistance allowed for a straight length of 28mm

pipe (D2) from a G1/2 temperature relief valve equates to:

14m.

As the actual length is 7m, a 28mm (D2) copper pipe will be

satisfactory.

Table 2: Sizing of copper discharge pipe ‘D2’ for a

temperature relief valve with a G1/2 outlet size (as supplied).

Size of

discharge

pipework

Maximum length

of straight pipe

(no bends or

elbows)

Deduct the gure

below from the

maximum length for

each bend or elbow in

the discharge pipe

22mm Up to 9m 0.8m

28mm Up to 18m 1.0m

35mm Up to 27m 1.4m

Installation Instructions - Unvented Cylinders (cont.)

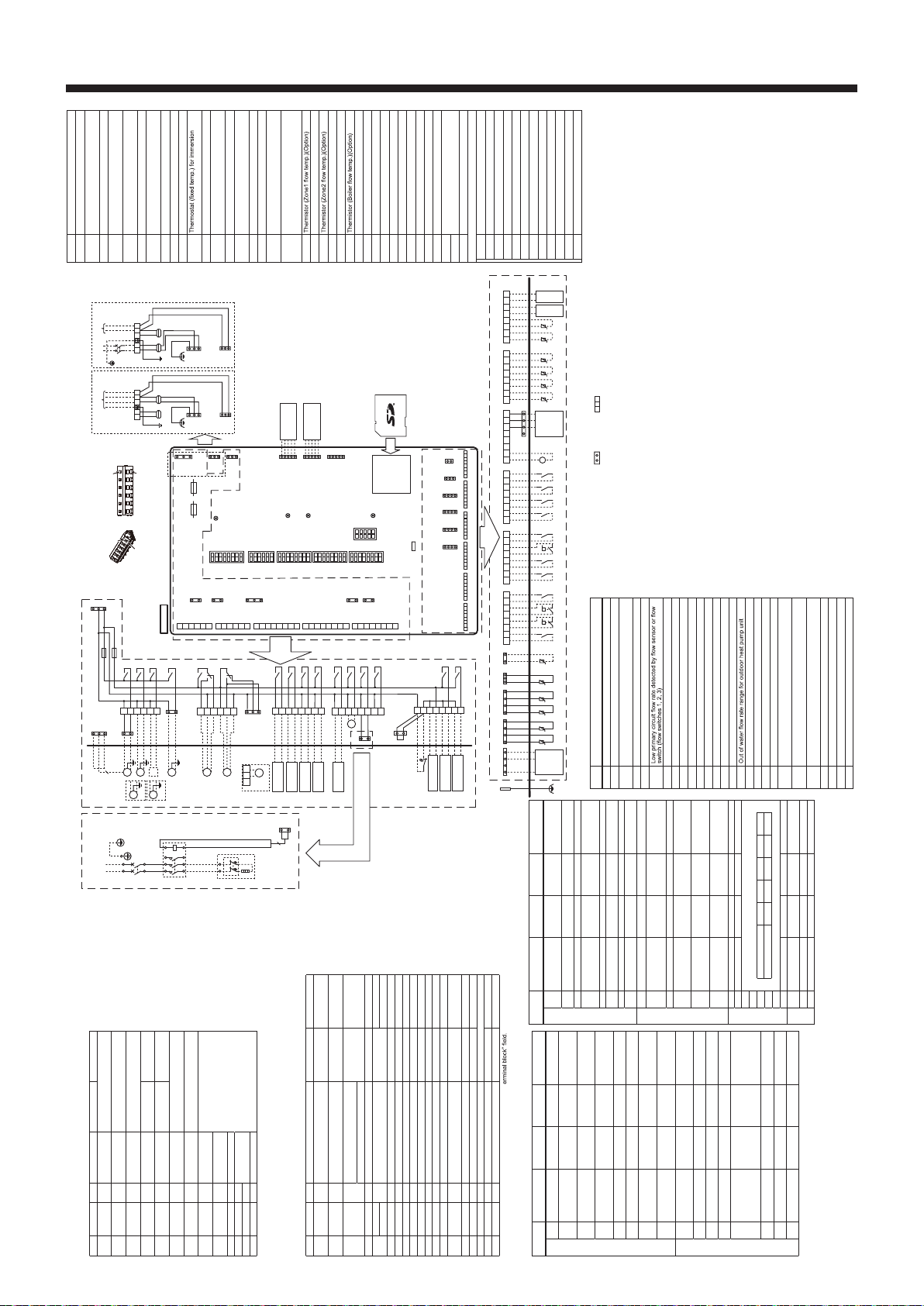

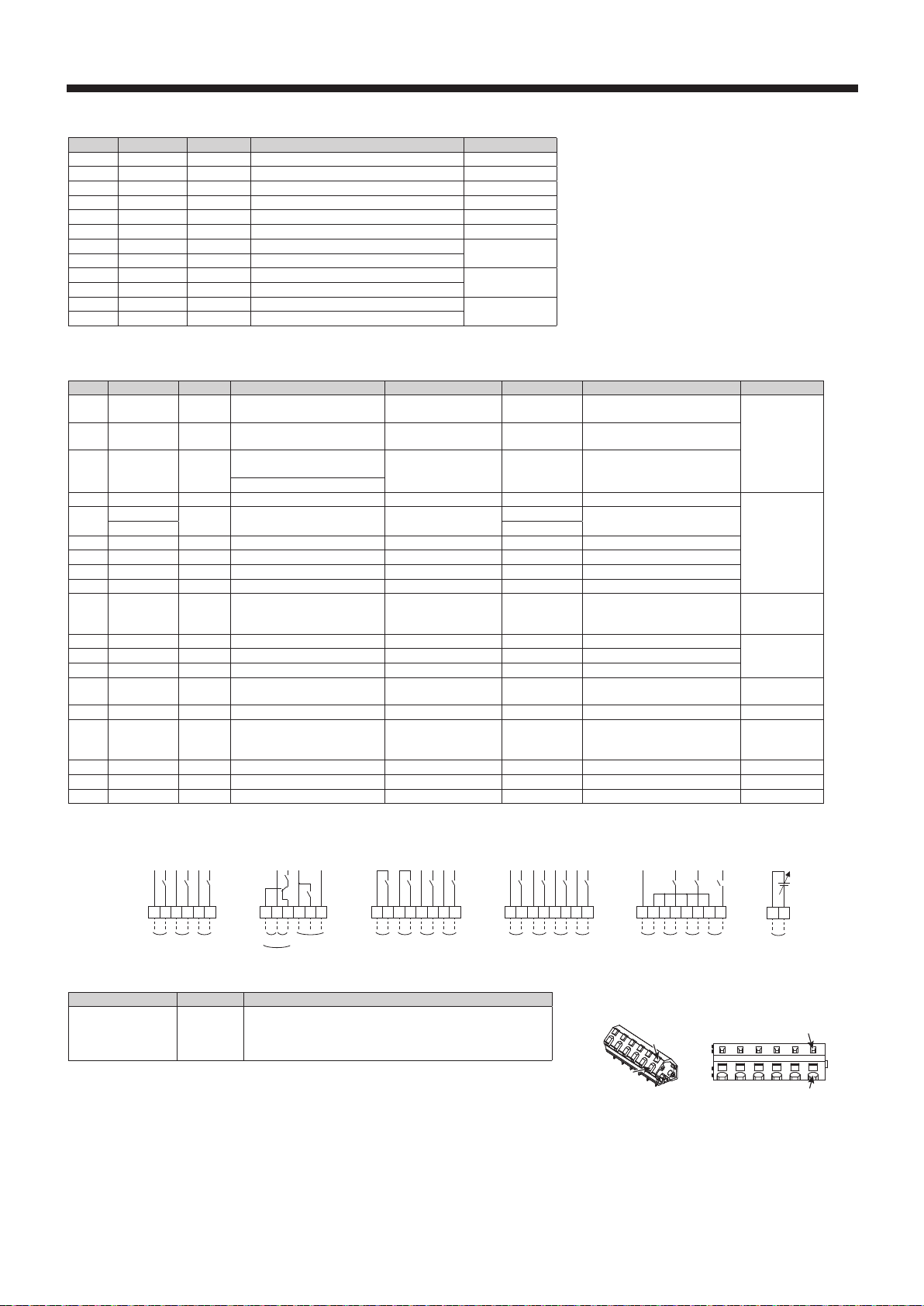

FTC WIRING DIAGRAM <PAC-IF07*B-E> Symbol Name

TB1 Terminal block <Power supply, Outdoor unit>

ECB2

Earth leakage circuit breaker for immersion heater

(Except PAC-IF071B-E)

MP1

Water circulation pump 1(Space heating & DHW)

MP2 Water circulation pump 2

(Space heating for Zone1)(Local supply)

MP3 Water circulation pump 3

(Space heating for Zone2)(Local supply)

MP4

Water circulation pump 4 (DHW)(Local supply)

3WV

(2WV1) 3-way valve (2-way valve 1)(Local supply)

2WV2a 2-way valve (For Zone 1)(Local supply)

2WV2b 2-way valve (For Zone 2)(Local supply)

MXV Mixing valve (Local supply)

IHT heater(Except PAC-IF071B-E)

IH Immersion heater(Except PAC-IF071B-E)

IHC Contactor for immersion heater

(Except PAC-IF071B-E)

TH1 Thermistor (Room temp.)(Option)

TH2 Thermistor (Ref. liquid temp.)

(Included in PAC-IF071B-E)

THW1 Thermistor (Flow water temp.)

THW2 Thermistor (Return water temp.)

THW5A Thermistor (DHW tank upper water temp.)

(Included in PAC-IF073B-E)

THW5B Thermistor (DHW tank lower water temp.)

(Included in PAC-IF073B-E)

(Option for PAC-IF071/072B-E)

THW6

THW7 Thermistor (Zone1 return temp.)(Option)

THW8

THW9 Thermistor (Zone2 return temp.)(Option)

THW10 Thermistor (Mixing tank temp.)(Option)

THWB1

IN1 Room thermostat 1 (Local supply)

IN2 Flow switch 1 (Local supply)

IN3 Flow switch 2 (Local supply)

IN4 Demand control (Local supply)

IN5 Outdoor thermostat (Local supply)

IN6 Room thermostat 2 (Local supply)

IN7 Flow switch 3 (Local supply)

IN8 Electric energy meter 1 (Local supply)

IN9 Electric energy meter 2 (Local supply)

IN10 Heat meter (Local supply)

IN11 Smart grid ready input (Local supply)

IN12

INA1 Flow sensor (Option)

FLOW TEMP. CONTROLLER (FTC)

TBO.1-5

Terminal block <Outputs>

TBI.1-6 Terminal block <Signal Inputs, Thermistor>

F1 Fuse (IEC T10AL250V)

F2 Fuse (IEC T6.3AL250V)

SW1-6 DIP switch *See Table 3

X1-16 Relay

LED1 Power supply (FTC)

LED2 Power supply (Main remote controller)

LED3 Communication (FTC-Outdoor unit)

LED4 Reading or writing data to SD card

CNPWM

Pump speed control signal for MP1

CN108 SD card connector

1. Symbols used in wiring diagram are, : connector, : terminal block. Function with asterisk (*) may not be available depending on model types.

2. Indoor unit and outdoor unit connecting wires have polarities, make sure to match terminal numbers (S1, S2, S3) for correct wirings.

3. Since the outdoor unit side electric wiring may change, be sure to check the outdoor unit electric wiring diagram for service.

4. When connecting a booster heater, the wiring method is different according to the type of built-in thermostat.

Please refer to the installation manual for details.

Table 4 Error Codes

Code Error

L3 Circulation water temperature overheat protection

L4 DHW tank water temperature overheat protection

L5 Indoor unit temperature thermistor (THW1, THW2, THW5B,

THW6, THW7, THW8, THW9) failure

L6 Circulation water freeze protection

L8 Heating operation error

L9

LA Pressure sensor failure

LB High pressure protection

LC Boiler circulation water temperature overheat protection

LD

Boiler temperature thermistor (THWB1) failure

LE Boiler operation error

LF Flow sensor failure

LH Boiler circulation water freeze protection

LJ DHW operation error (type of external plate HEX)

LL Setting errors of DIP switches on FTC control board

LP

P1 Thermistor (Room temp.) (TH1) failure

P2 Thermistor (Ref. liquid temp.) (TH2) failure

P6 Anti-freeze protection of plate heat exchanger

J0 Communication failure between FTC and wireless receiver

J1 - J8

Communication failure between wireless receiver and

wireless remote controller

J9

Communication failure between FTC (Master) and FTC

(Slave)

E0 - E5 Communication failure between main remote controller and

FTC

E6 - EF

Communication failure between FTC and outdoor unit

E9 Outdoor unit receives no signal from indoor unit.

EE Outdoor unit incorrect connection

U*, F*,A*

Outdoor unit failure

Table 1 Signal Inputs

Name

Terminal block

Connector

Item OFF (Open) ON (Short)

IN1 TBI.1 7-8 — Room thermostat

1 input *1 Refer to SW2-1 in

<Table 3 DIP Switch Functions>.

IN2 TBI.1 5-6 — Flow switch 1

input Refer to SW2-2 in

<Table 3 DIP Switch Functions>.

IN3 TBI.1 3-4 — Flow switch 2

input (Zone1) Refer to SW3-2 in

<Table 3 DIP Switch Functions>.

IN4 TBI.1 1-2 — Demand control

input Normal Heat source OFF/

Boiler operation *3

IN5 TBI.2 7-8 — Outdoor thermo-

stat input *2 Standard opera-

tion Heater operation/

Boiler operation *3

IN6 TBI.2 5-6 — Room thermostat

2 input *1 Refer to SW3-1 in

<Table 3 DIP Switch Functions>.

IN7 TBI.2 3-4 — Flow switch 3

input (Zone2) Refer to SW3-2 in

<Table 3 DIP Switch Functions>.

IN8 TBI.3 7-8 — Electric energy

meter 1

Refer to installation manual.

IN9 TBI.3 5-6 — Electric energy

meter 2

IN10

TBI.2 1-2 — Heat meter

IN11

TBI.3 3-4 — Smart grid ready

input

IN12

TBI.3 1-2 —

INA1

TBI.4 1-3 CN1A Flow sensor

*1. Set the ON/OFF cycle time of the room thermostat for 10 minutes or more;

otherwise the compressor may be damaged.

*2. If using outdoor thermostat for controlling operation of heaters, the lifetime of the

heaters and related parts may be reduced.

*3. To turn on the boiler operation, use the main remote controller to select “Boiler” in

“External input setting” screen in the service menu.

Table 2 Outputs

Name

Terminal block

Connector

Item OFF ON

OUT1

TBO.1 1-2 CNP1 Water circulation pump 1 output

(Space heating/cooling & DHW) OFF ON

OUT2

TBO.1 3-4 — Water circulation pump 2 output

(Space heating/cooling for Zone1) OFF ON

OUT3

TBO.1 5-6 — Water circulation pump 3 output

(Space heating/cooling for Zone2) *1 OFF ON

2-way valve 2b output *2

OUT4

TBO.2 4-6 CNV1 3-way valve (2-way valve) output Heating DHW

OUT5

TBO.2 1-2 — Mixing valve output *1 Stop Close

TBO.2 2-3 Open

OUT6

TBO.5 5-6 — Booster heater 1 output OFF ON

OUT7

TBO.5 7-8 — Booster heater 2 output OFF ON

OUT8

TBO.4 7-8 — Cooling signal output OFF ON

OUT9

TBO.4 5-6 CNIH Immersion heater output OFF ON

OUT10

TBO.3 1-2 — Boiler output OFF ON

OUT11

TBO.3 5-6 — Error output Normal Error

OUT12

TBO.3 7-8 — Defrost output Normal Defrost

OUT13

TBO.4 3-4 — 2-way valve 2a output *2 OFF ON

OUT14

— CNP4 Water circulation pump 4 output

(DHW) OFF ON

OUT15

TBO.4 1-2 — Comp. ON signal OFF ON

OUT16

TBO.3 3-4 — Thermo ON signal OFF ON

OUTA1

TBI.4 7-8 — Analog output 0V-10V

BC

TBO.5 3-4 — Booster heater protection output

OFF(BHT Open) ON(BHT Short)

BHT

TBO.5 1-2

CNBHT

Thermostat for booster heater

Thermostat normal: Short High temp. open

Do not connect to the terminals that are indicated as “—” in the “T

*1. For 2-zone temperature control.

*2. For 2-zone valve ON/OFF control.

CN108

CN01

(BK)

1

3

CN3C

(BU)

1

3

CNPWM

(WH)

1

5

CNRF

(WH) Wireless receiver

(Option)

1

5

CN105

(RD) WiFi adapter

(Option)

1

5

CNIT

(BU)

1

2

CN20

(RD)

1

3

CN21

(YE)

1

4

CNW12

(RD)

CNW5

(BU)

1

4

CN1A

(WH)

TBI.1

LED1

LED2

LED3

LED4

TAB1

1

8

1

8

1

8

1

8

1

6

SW1

SW2

SW3

SW4

SW5

F1

IEC T10AL250V

F2

IEC T6.3AL250V

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

3

1

3

CNBHT

(BK)

CNIH

(OG)

CNV1

(WH)

CNP4

(RD)

CNP1

(WH)

TBO.1

TBO.2

TBO.3

TBO.4

1

2

3

4

5

6

7

8

TBO.5

1

3

5

1

3

CNP4

(RD)

F1

F2

CN01

(BK)

TBO.1 X1

X2

X3

X14

1

3

3

CNPWM

(WH)

CNP1

(WH)1

3

M

1~

2WV2b

MP3

MP4

1

2

3

4

5

6

TBO.2

1

3

5

CNV1

(WH)

3WV

1

2

3

4

5

6

7

8

TBO.3

X4

X10

X16

X11

X12

TBO.4

1

2

3

4

5

6

7

8

TBO.5

X15

X13

X9

X8

Signal output

(Boiler)

Signal output

(thermo on)

Signal output

(Error)

Signal output

(Defrost)

Signal output

(Comp. on)

CNIH

(OG) 2WV2a

1

3

X6

X7

N

(3)

L

(1)

42

BU

RD

315

A1

426

A2

IHT

IH

BA

BU

RD

1

3

2CNIH

(OG)

OG

OG

Power supply

to Immersion heater

(Except PAC-IF071B-E)

~/N 230V 50Hz

ECB2

IHC

1

5

3

1

5

3

1

3

1

3

FTC board

X5B

X5A

MXV

Close

N

Open

MP2

MP1

M

1~

M

1~

TBI.2 TBI.3 TBI.4 TBI.5 TBI.6

1234567812345678123456781234567812345678 12345678

1

2

3

4

5

6

1

4

t° t° t°

12345678

IN4IN3IN2IN1

12345678

IN10IN7IN6IN5

12345678

IN12IN9IN8 IN11

12345678

OUTA1

Flow

Sensor

12345678

t°

THW6 THW7 THW8 THW9

t° t°

12345678

THWB1 THW10

Main remote

controller

FTC

(Slave)

TBI.1 TBI.2 TBI.3 TBI.4 TBI.5 TBI.6

CN20

(RD)

t°

CN21

(YE)

13

12

CNW12

(RD)

14

CNW5

(BU)

t°

TAB1

THTH1TH2 *

THW5B *

-+ +-

V

-+-+

14

t° t°t°

THW2THW1

1

5

SW6

M

1~

M

1~

M

1~

M

1~

M

1~

NL

S3S2S1

NL

S3S2S1

To outdoor

unit

TB1

OG OG

YE

YE

GNYE

To outdoor

unit

Power supply

~/N 230V 50Hz

TB1

OG

BU

RD

BU

RD

YE

GNYE

1

3

1

3

OG

BN OG

BN

Indoor unit powered

by independent source

Indoor unit powered

via outdoor unit

CIRCUIT

BREAKER

1

3

5

CN3C

(BU)

CN3C

(BU)

CN01

(BK)

OG

YE

1

3

5

CN01

(BK)

2WV1

M

1~

4 5 6

TBO.2

1

2

3

4

5

6

7

8

Signal output for booster

heater protection

Signal output

(booster heater 1)

Signal output

(booster heater 2)

CN1A

(WH)

14

<How to useTBO.1 to 5>

14

Pressre

Sensor *

CN401

(WH)

1

4

CN401

(WH)

t°

THW5A *

1

BHT

CNBHT

(BK)

3

Tool Tool

Conductor Conductor

Outline view Top view

Connect them using either way as shown below.

*1. External output (OUT11) will be available. For safety reasons, this function is not available for certain errors. (In that case, system operation must be stopped and only the

water circulation pump keeps running.)

*2. This switch functions only when the FTC unit is connected with a PUHZ-FRP outdoor unit. When another type of outdoor unit is connected, the heating mode function is

active regardless of the fact that this switch is ON or OFF.

*3. Space heating and DHW can be operated only in indoor unit, like an electric heater.

*4. If emergency mode is no longer required, return the switch to OFF position.

*5. Active only when SW3-6 is set to OFF.

*6. Active only when SW4-1 is set to ON.

Table 3 DIP switch functions

DIP switch Function OFF ON Default settings:

Indoor unit model

SW1

SW1-1

Boiler WITHOUT

Boiler WITH Boiler OFF

SW1-2

Heat pump maxi-

mum outlet water

temperature 55ºC 60ºC ON

SW1-3

DHW tank WITHOUT

DHW tank WITH DHW

tank

OFF : PAC-IF071B-E

ON : Except

: PAC-IF071B-E

SW1-4

Immersion heater WITHOUT Im-

mersion heater WITH Immer-

sion heater

OFF : PAC-IF071B-E

ON : Except

: PAC-IF071B-E

SW1-5

Booster heater WITHOUT

Booster heater WITH Booster

heater

OFF

SW1-6

Booster heater

function For heating

only For heating

and DHW

OFF

SW1-7

Outdoor unit type Split type Packaged type

OFF : PAC-IF071B-E

ON : Except

: PAC-IF071B-E

SW1-8

Wireless remote

controller WITHOUT

Wireless re-

mote controller

WITH Wireless

remote control-

ler OFF

SW2

SW2-1

Room thermostat 1

input (IN1) logic

change

Zone1 opera-

tion stop at ther-

mostat short

Zone1 opera-

tion stop at ther-

mostat open

OFF

SW2-2

Flow switch 1 input

(IN2) logic change Failure detec-

tion at short Failure detec-

tion at open OFF

SW2-3

Booster heater

capacity restriction Inactive Active OFF

SW2-4

Cooling mode func-

tion Inactive Active OFF

SW2-5

Automatic switch to

backup heat source

operation (When

outdoor unit stops

by error)

Inactive Active *1 OFF

SW2-6

Mixing tank WITHOUT Mix-

ing tank WITH Mixing

tank OFF

SW2-7

2-zone temperature

control Inactive Active *5 OFF

SW2-8

Flow sensor WITHOUT

Flow sensor WITH Flow

sensor OFF

DIP switch Function OFF ON Default settings:

Indoor unit model

SW3

SW3-1

Room thermostat

2 input (IN6) logic

change

Zone2 opera-

tion stop at ther-

mostat short

Zone2 opera-

tion stop at ther-

mostat open

OFF

SW3-2

Flow switch 2 and 3

input logic change Failure detec-

tion at short Failure detec-

tion at open OFF

SW3-3

— — — OFF

SW3-4

Electric energy

meter WITHOUT

Electric energy

meter WITH Electric

energy meter OFF

SW3-5

Heating mode function *2

Inactive Active ON

SW3-6

2-zone valve ON/

OFF control Inactive Active OFF

SW3-7

Heat exchanger for DHW

Coil in tank

External plate HEX

OFF

SW3-8

Heat meter WITHOUT

Heat meter WITH Heat

meter OFF

SW4

SW4-1

Multiple outdoor control

Inactive Active OFF

SW4-2

Position of multiple

outdoor units

control *6 Slave Master OFF

SW4-3

— — — OFF

SW4-4

Indoor unit only

operation (during

installation work) *3 Inactive Active OFF

SW4-5

Emergency mode

(Heater only opera-

tion) Normal

Emergency mode

(Heater only

operation)

OFF *4

SW4-6

Emergency mode

(Boiler operation) Normal Emergency

mode

(Boiler operation)

OFF *4

SW5

SW5-1

— — — OFF

SW5-2

Advanced auto adaptation

Inactive Active ON

SW5-3

Capacity code

SW5-3 SW5-4 SW5-5 SW5-6 SW5-7

PAC-IF07*B-E OFF OFF OFF OFF OFF

SW5-4

SW5-5

SW5-6

SW5-7

SW5-8

— — — OFF

SW6

SW6-1

— ——

OFF : PAC-IF071/072B-E

ON : PAC-IF073B-E

SW6-3

Pressure sensor Inactive Active OFF

SW6-4

Analog output Inactive Active OFF

15

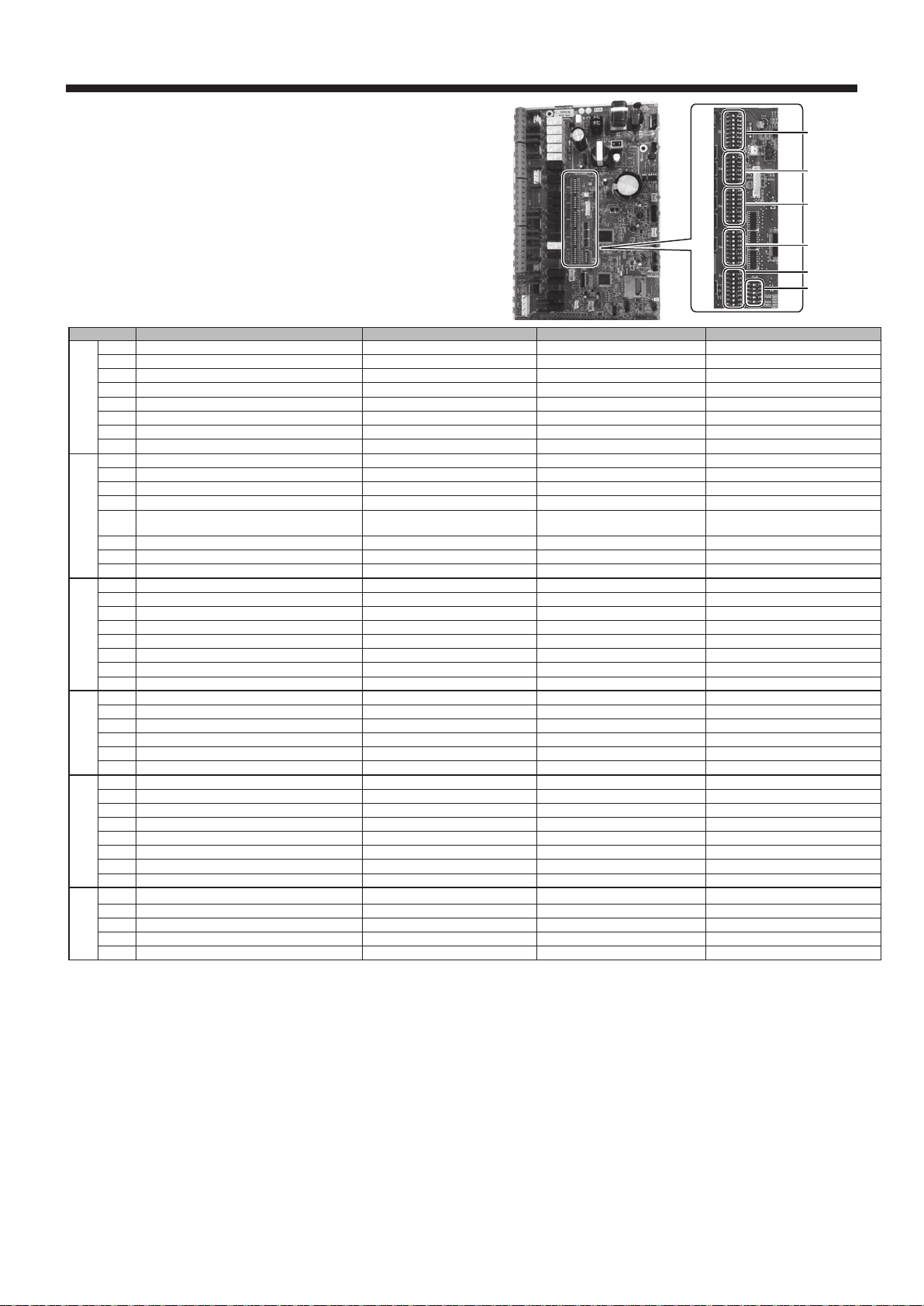

Wiring Diagram

FTC WIRING DIAGRAM <PAC-IF07*B-E> Symbol Name

TB1 Terminal block <Power supply, Outdoor unit>

ECB2

Earth leakage circuit breaker for immersion heater

(Except PAC-IF071B-E)

MP1

Water circulation pump 1(Space heating & DHW)

MP2 Water circulation pump 2

(Space heating for Zone1)(Local supply)

MP3 Water circulation pump 3

(Space heating for Zone2)(Local supply)

MP4

Water circulation pump 4 (DHW)(Local supply)

3WV

(2WV1) 3-way valve (2-way valve 1)(Local supply)

2WV2a 2-way valve (For Zone 1)(Local supply)

2WV2b 2-way valve (For Zone 2)(Local supply)

MXV Mixing valve (Local supply)

IHT heater(Except PAC-IF071B-E)

IH Immersion heater(Except PAC-IF071B-E)

IHC Contactor for immersion heater

(Except PAC-IF071B-E)

TH1 Thermistor (Room temp.)(Option)

TH2 Thermistor (Ref. liquid temp.)

(Included in PAC-IF071B-E)

THW1 Thermistor (Flow water temp.)

THW2 Thermistor (Return water temp.)

THW5A Thermistor (DHW tank upper water temp.)

(Included in PAC-IF073B-E)

THW5B Thermistor (DHW tank lower water temp.)

(Included in PAC-IF073B-E)

(Option for PAC-IF071/072B-E)

THW6

THW7 Thermistor (Zone1 return temp.)(Option)

THW8

THW9 Thermistor (Zone2 return temp.)(Option)

THW10 Thermistor (Mixing tank temp.)(Option)

THWB1

IN1 Room thermostat 1 (Local supply)

IN2 Flow switch 1 (Local supply)

IN3 Flow switch 2 (Local supply)

IN4 Demand control (Local supply)

IN5 Outdoor thermostat (Local supply)

IN6 Room thermostat 2 (Local supply)

IN7 Flow switch 3 (Local supply)

IN8 Electric energy meter 1 (Local supply)

IN9 Electric energy meter 2 (Local supply)

IN10 Heat meter (Local supply)

IN11 Smart grid ready input (Local supply)

IN12

INA1 Flow sensor (Option)

FLOW TEMP. CONTROLLER (FTC)

TBO.1-5

Terminal block <Outputs>

TBI.1-6 Terminal block <Signal Inputs, Thermistor>

F1 Fuse (IEC T10AL250V)

F2 Fuse (IEC T6.3AL250V)

SW1-6 DIP switch *See Table 3

X1-16 Relay

LED1 Power supply (FTC)

LED2 Power supply (Main remote controller)

LED3 Communication (FTC-Outdoor unit)

LED4 Reading or writing data to SD card

CNPWM

Pump speed control signal for MP1

CN108 SD card connector

1. Symbols used in wiring diagram are, : connector, : terminal block. Function with asterisk (*) may not be available depending on model types.

2. Indoor unit and outdoor unit connecting wires have polarities, make sure to match terminal numbers (S1, S2, S3) for correct wirings.

3. Since the outdoor unit side electric wiring may change, be sure to check the outdoor unit electric wiring diagram for service.

4. When connecting a booster heater, the wiring method is different according to the type of built-in thermostat.

Please refer to the installation manual for details.

Table 4 Error Codes

Code Error

L3 Circulation water temperature overheat protection

L4 DHW tank water temperature overheat protection

L5 Indoor unit temperature thermistor (THW1, THW2, THW5B,

THW6, THW7, THW8, THW9) failure

L6 Circulation water freeze protection

L8 Heating operation error

L9

LA Pressure sensor failure

LB High pressure protection

LC Boiler circulation water temperature overheat protection

LD

Boiler temperature thermistor (THWB1) failure

LE Boiler operation error

LF Flow sensor failure

LH Boiler circulation water freeze protection

LJ DHW operation error (type of external plate HEX)

LL Setting errors of DIP switches on FTC control board

LP

P1 Thermistor (Room temp.) (TH1) failure

P2 Thermistor (Ref. liquid temp.) (TH2) failure

P6 Anti-freeze protection of plate heat exchanger

J0 Communication failure between FTC and wireless receiver

J1 - J8

Communication failure between wireless receiver and

wireless remote controller

J9

Communication failure between FTC (Master) and FTC

(Slave)

E0 - E5 Communication failure between main remote controller and

FTC

E6 - EF

Communication failure between FTC and outdoor unit

E9 Outdoor unit receives no signal from indoor unit.

EE Outdoor unit incorrect connection

U*, F*,A*

Outdoor unit failure

Table 1 Signal Inputs

Name

Terminal block

Connector

Item OFF (Open) ON (Short)

IN1 TBI.1 7-8 — Room thermostat

1 input *1 Refer to SW2-1 in

<Table 3 DIP Switch Functions>.

IN2 TBI.1 5-6 — Flow switch 1

input Refer to SW2-2 in

<Table 3 DIP Switch Functions>.

IN3 TBI.1 3-4 — Flow switch 2

input (Zone1) Refer to SW3-2 in

<Table 3 DIP Switch Functions>.

IN4 TBI.1 1-2 — Demand control

input Normal Heat source OFF/

Boiler operation *3

IN5 TBI.2 7-8 — Outdoor thermo-

stat input *2 Standard opera-

tion Heater operation/

Boiler operation *3

IN6 TBI.2 5-6 — Room thermostat

2 input *1 Refer to SW3-1 in

<Table 3 DIP Switch Functions>.

IN7 TBI.2 3-4 — Flow switch 3

input (Zone2) Refer to SW3-2 in

<Table 3 DIP Switch Functions>.

IN8 TBI.3 7-8 — Electric energy

meter 1

Refer to installation manual.

IN9 TBI.3 5-6 — Electric energy

meter 2

IN10

TBI.2 1-2 — Heat meter

IN11

TBI.3 3-4 — Smart grid ready

input

IN12

TBI.3 1-2 —

INA1

TBI.4 1-3 CN1A Flow sensor

*1. Set the ON/OFF cycle time of the room thermostat for 10 minutes or more;

otherwise the compressor may be damaged.

*2. If using outdoor thermostat for controlling operation of heaters, the lifetime of the

heaters and related parts may be reduced.

*3. To turn on the boiler operation, use the main remote controller to select “Boiler” in

“External input setting” screen in the service menu.

Table 2 Outputs

Name

Terminal block

Connector

Item OFF ON

OUT1

TBO.1 1-2 CNP1 Water circulation pump 1 output

(Space heating/cooling & DHW) OFF ON

OUT2

TBO.1 3-4 — Water circulation pump 2 output

(Space heating/cooling for Zone1) OFF ON

OUT3

TBO.1 5-6 — Water circulation pump 3 output

(Space heating/cooling for Zone2) *1 OFF ON

2-way valve 2b output *2

OUT4

TBO.2 4-6 CNV1 3-way valve (2-way valve) output Heating DHW

OUT5

TBO.2 1-2 — Mixing valve output *1 Stop Close

TBO.2 2-3 Open

OUT6

TBO.5 5-6 — Booster heater 1 output OFF ON

OUT7

TBO.5 7-8 — Booster heater 2 output OFF ON

OUT8

TBO.4 7-8 — Cooling signal output OFF ON

OUT9

TBO.4 5-6 CNIH Immersion heater output OFF ON

OUT10

TBO.3 1-2 — Boiler output OFF ON

OUT11

TBO.3 5-6 — Error output Normal Error

OUT12

TBO.3 7-8 — Defrost output Normal Defrost

OUT13

TBO.4 3-4 — 2-way valve 2a output *2 OFF ON

OUT14

— CNP4 Water circulation pump 4 output

(DHW) OFF ON

OUT15

TBO.4 1-2 — Comp. ON signal OFF ON

OUT16

TBO.3 3-4 — Thermo ON signal OFF ON

OUTA1

TBI.4 7-8 — Analog output 0V-10V

BC

TBO.5 3-4 — Booster heater protection output

OFF(BHT Open) ON(BHT Short)

BHT

TBO.5 1-2

CNBHT

Thermostat for booster heater

Thermostat normal: Short High temp. open

Do not connect to the terminals that are indicated as “—” in the “T

*1. For 2-zone temperature control.

*2. For 2-zone valve ON/OFF control.

CN108

CN01

(BK)

1

3

CN3C

(BU)

1

3

CNPWM

(WH)

1

5

CNRF

(WH) Wireless receiver

(Option)

1

5

CN105

(RD) WiFi adapter

(Option)

1

5

CNIT

(BU)

1

2

CN20

(RD)

1

3

CN21

(YE)

1

4

CNW12

(RD)

CNW5

(BU)

1

4

CN1A

(WH)

TBI.1

LED1

LED2

LED3

LED4

TAB1

1

8

1

8

1

8

1

8

1

6

SW1

SW2

SW3

SW4

SW5

F1

IEC T10AL250V

F2

IEC T6.3AL250V

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

3

1

3

CNBHT

(BK)

CNIH

(OG)

CNV1

(WH)

CNP4

(RD)

CNP1

(WH)

TBO.1

TBO.2

TBO.3

TBO.4

1

2

3

4

5

6

7

8

TBO.5

1

3

5

1

3

CNP4

(RD)

F1

F2

CN01

(BK)

TBO.1 X1

X2

X3

X14

1

3

3

CNPWM

(WH)

CNP1

(WH)1

3

M

1~

2WV2b

MP3

MP4

1

2

3

4

5

6

TBO.2

1

3

5

CNV1

(WH)

3WV

1

2

3

4

5

6

7

8

TBO.3

X4

X10

X16

X11

X12

TBO.4

1

2

3

4

5

6

7

8

TBO.5

X15

X13

X9

X8

Signal output

(Boiler)

Signal output

(thermo on)

Signal output

(Error)

Signal output

(Defrost)

Signal output

(Comp. on)

CNIH

(OG) 2WV2a

1

3

X6

X7

N

(3)

L

(1)

42

BU

RD

315

A1

426

A2

IHT

IH

BA

BU

RD

1

3

2CNIH

(OG)

OG

OG

Power supply

to Immersion heater

(Except PAC-IF071B-E)

~/N 230V 50Hz

ECB2

IHC

1

5

3

1

5

3

1

3

1

3

FTC board

X5B

X5A

MXV

Close

N

Open

MP2

MP1

M

1~

M

1~

TBI.2 TBI.3 TBI.4 TBI.5 TBI.6

1234567812345678123456781234567812345678 12345678

1

2

3

4

5

6

1

4

t° t° t°

12345678

IN4IN3IN2IN1

12345678

IN10IN7IN6IN5

12345678

IN12IN9IN8 IN11

12345678

OUTA1

Flow

Sensor

12345678

t°

THW6 THW7 THW8 THW9

t° t°

12345678

THWB1 THW10

Main remote

controller

FTC

(Slave)

TBI.1 TBI.2 TBI.3 TBI.4 TBI.5 TBI.6

CN20

(RD)

t°

CN21

(YE)

13

12

CNW12

(RD)

14

CNW5

(BU)

t°

TAB1

THTH1TH2 *

THW5B *

-+ +-

V

-+-+

14

t° t°t°

THW2THW1

1

5

SW6

M

1~

M

1~

M

1~

M

1~

M

1~

NL

S3S2S1

NL

S3S2S1

To outdoor

unit

TB1

OG OG

YE

YE

GNYE

To outdoor

unit

Power supply

~/N 230V 50Hz

TB1

OG

BU

RD

BU

RD

YE

GNYE

1

3

1

3

OG

BN OG

BN

Indoor unit powered

by independent source

Indoor unit powered

via outdoor unit

CIRCUIT

BREAKER

1

3

5

CN3C

(BU)

CN3C

(BU)

CN01

(BK)

OG

YE

1

3

5

CN01

(BK)

2WV1

M

1~

4 5 6

TBO.2

1

2

3

4

5

6

7

8

Signal output for booster

heater protection

Signal output

(booster heater 1)

Signal output

(booster heater 2)

CN1A

(WH)

14

<How to useTBO.1 to 5>

14

Pressre

Sensor *

CN401

(WH)

1

4

CN401

(WH)

t°

THW5A *

1

BHT

CNBHT

(BK)

3

Tool Tool

Conductor Conductor

Outline view Top view

Connect them using either way as shown below.

*1. External output (OUT11) will be available. For safety reasons, this function is not available for certain errors. (In that case, system operation must be stopped and only the

water circulation pump keeps running.)

*2. This switch functions only when the FTC unit is connected with a PUHZ-FRP outdoor unit. When another type of outdoor unit is connected, the heating mode function is

active regardless of the fact that this switch is ON or OFF.

*3. Space heating and DHW can be operated only in indoor unit, like an electric heater.

*4. If emergency mode is no longer required, return the switch to OFF position.

*5. Active only when SW3-6 is set to OFF.

*6. Active only when SW4-1 is set to ON.

Table 3 DIP switch functions

DIP switch Function OFF ON Default settings:

Indoor unit model

SW1

SW1-1

Boiler WITHOUT

Boiler WITH Boiler OFF

SW1-2

Heat pump maxi-

mum outlet water

temperature 55ºC 60ºC ON

SW1-3

DHW tank WITHOUT

DHW tank WITH DHW

tank

OFF : PAC-IF071B-E

ON : Except

: PAC-IF071B-E

SW1-4

Immersion heater WITHOUT Im-

mersion heater WITH Immer-

sion heater

OFF : PAC-IF071B-E

ON : Except

: PAC-IF071B-E

SW1-5

Booster heater WITHOUT

Booster heater WITH Booster

heater

OFF

SW1-6

Booster heater

function For heating

only For heating

and DHW

OFF

SW1-7

Outdoor unit type Split type Packaged type

OFF : PAC-IF071B-E

ON : Except

: PAC-IF071B-E

SW1-8

Wireless remote

controller WITHOUT

Wireless re-

mote controller

WITH Wireless

remote control-

ler OFF

SW2

SW2-1

Room thermostat 1

input (IN1) logic

change

Zone1 opera-

tion stop at ther-

mostat short

Zone1 opera-

tion stop at ther-

mostat open

OFF

SW2-2

Flow switch 1 input

(IN2) logic change Failure detec-

tion at short Failure detec-

tion at open OFF

SW2-3

Booster heater

capacity restriction Inactive Active OFF

SW2-4

Cooling mode func-

tion Inactive Active OFF

SW2-5

Automatic switch to

backup heat source

operation (When

outdoor unit stops

by error)

Inactive Active *1 OFF

SW2-6

Mixing tank WITHOUT Mix-

ing tank WITH Mixing

tank OFF

SW2-7

2-zone temperature

control Inactive Active *5 OFF

SW2-8

Flow sensor WITHOUT

Flow sensor WITH Flow

sensor OFF

DIP switch Function OFF ON Default settings:

Indoor unit model

SW3

SW3-1

Room thermostat

2 input (IN6) logic

change

Zone2 opera-

tion stop at ther-

mostat short

Zone2 opera-

tion stop at ther-

mostat open

OFF

SW3-2

Flow switch 2 and 3

input logic change Failure detec-

tion at short Failure detec-

tion at open OFF

SW3-3

— — — OFF

SW3-4

Electric energy

meter WITHOUT

Electric energy

meter WITH Electric

energy meter OFF

SW3-5

Heating mode function *2

Inactive Active ON

SW3-6

2-zone valve ON/

OFF control Inactive Active OFF

SW3-7

Heat exchanger for DHW

Coil in tank

External plate HEX

OFF

SW3-8

Heat meter WITHOUT

Heat meter WITH Heat

meter OFF

SW4

SW4-1

Multiple outdoor control

Inactive Active OFF

SW4-2

Position of multiple

outdoor units

control *6 Slave Master OFF

SW4-3

— — — OFF

SW4-4

Indoor unit only

operation (during

installation work) *3 Inactive Active OFF

SW4-5

Emergency mode

(Heater only opera-

tion) Normal

Emergency mode

(Heater only

operation)

OFF *4

SW4-6

Emergency mode

(Boiler operation) Normal Emergency

mode

(Boiler operation)

OFF *4

SW5

SW5-1

— — — OFF

SW5-2

Advanced auto adaptation

Inactive Active ON

SW5-3

Capacity code

SW5-3 SW5-4 SW5-5 SW5-6 SW5-7

PAC-IF07*B-E OFF OFF OFF OFF OFF

SW5-4

SW5-5

SW5-6

SW5-7

SW5-8

— — — OFF

SW6

SW6-1

— ——

OFF : PAC-IF071/072B-E

ON : PAC-IF073B-E

SW6-3

Pressure sensor Inactive Active OFF

SW6-4

Analog output Inactive Active OFF

16

Electrical Work

regulations.

FTC (Master) powered by independent source

If FTC (Master) and outdoor units have separate power supplies, the following

requirements MUST be carried out:

• FTC (Master) unit electrical box connector connections changed.

• Outdoor unit DIP switch settings changed to SW8-3 ON.

• Turn on the outdoor unit before the FTC (Master).

• Power by independent source is not available for particular models of outdoor

unit model.

For more details refer to the connecting outdoor unit installation manual.

1. High voltage cables (OUTPUT)

2. High voltage cables (OUTPUT)

3. Low voltage cables (INPUT) and wireless receiver’s cable

4. Thermistor cables

5. Power cables

Wiring for PAC-IF07*B-E Notes:

1. Do not run the low voltage cables through a slot that the high voltage

cables go through.

2. Do not run other cables except low voltage cables through a slot that

the wireless receiver’s cable goes through.

3. Do not bundle power cables together with other cables.

4. Bundle cables as gure above by using clamps.

FTC (Master) power supply ~/N 230 V 50 Hz

FTC (Master) input capacity

Main switch (Breaker) *1 16 A

Wiring

Wiring No.

xsize (mm²)

FTC (Master) power supply 2 × Min. 1.5

FTC (Master) power supply earth 1 × Min. 1.5

FTC (Master) - Outdoor unit *2 2 × Min. 0.3

FTC (Master) - Outdoor unit earth —

Circuit

rating

FTC (Master) L - N *3 230V AC

FTC (Master) - Outdoor unit S1 - S2 *3 —

FTC (Master) - Outdoor unit S2 - S3 *3 24V DC

Electrical connections 1 phase/3 phase

*1. If the installed earth leakage circuit breaker does not have an over-current protection function,install a breaker

with that function along the same power line.

A breaker with at least 3.0 mm contact separation in each pole shall be provided. Use earth leakage breaker (NV).

The breaker shall be provided to ensure disconnection of all active phase conductors of the supply.

Note: In accordance with IEE regulations, the circuit breaker/isolating switch located on the outdoor unit should be installed with

lockable devices (health and safety).

*2. Max. 120m

*3. The values given in the table above are not always measured against the ground

value.

Notes: 1. Wiring size must comply with the applicable local and national codes.

2. FTC (Master) unit/outdoor unit connecting cords shall not be lighter

than polychloroprene sheather exible cord. (Design 60245 IEC57)

FTC (Master) unit power supply cords shall not be lighter than

polychloroprene sheathed exible cord. (Design 60227 IEC 53)

3. Install an earth longer than other cables.

4. Please keep enough output capacity of power supply for each

individual heater. Insucient power supply capacity might cause

chattering.

S1

S2

S3

L

N

L