EcoFast D600 User manual

Ecofast Environmental UK Ltd

1

Product Manual

D600 – Food Waste Dehydra

Mini Dewaterer

Version

V1.

2

Ecofast Environmental UK Ltd

2

Model Number

Serial Number

Table of contents

PRODUCT DIMENSIONS 3

IMPORTANT NOTICE 3

HEALTH & SAFETY 4

INSTALLATION INSTRUCTIONS 5

WATER & WASTE CONNECTIONS 5

ELECTRICAL INSTALLATION 6

OPERATOR INSTRUCTIONS 8

WARRANTY DETAILS ERROR! BOOKMARK NOT DEFINED.

TROUBLE SHOOTING & FAULT FINDING 13-14

ERROR FAULT CODES ERROR! BOOKMARK NOT DEFINED.

SPARES PARTS & EXPLODED DIAGRAMS 14

CE CERTIFICATE OF CONFORMANCE 18

TESTING & APPROVALS 19

WHERE TO FIND FURTHER HELP / CONTACT DETAILS 26

DISPOSAL OF MACHINE / END OF LIFE ACTIONS 27

D600

E

xample

60

-

05

-

22

-

001

Ecofast Environmental UK Ltd

3

Heavy Duty castors

for ease of

installation, cleaning

& servicing

Recovered

Wastewater

Macerated

food waste

inlet (from

macerator)

Product Dimensions

Operator Control Panel

Food waste receptacle /

collection bin (20l)

Hot water supply

Ecofast Environmental UK Ltd

4

Important Notice

This manual constitutes an integral part of the product and must always be readily available. The

manufacturer reserves the right to update the manual with modifications or upgrades without notice.

All tasks detailed in this product manual must be undertaken by qualified personnel.

The machine should not be operated without having read and understood the user manual beforehand,

misuse of the machine can result in damage to the machine and the warranty being void.

Health & Safety

These signs are actively used in this Product manual and on the product itself.

Attention Live parts

Isolate the power and unplug the machine

Wear gloves

Wear foot protection

Technical Details

D600R Mini Dewaterer Mark III (DxWxH)

D1000 Dewaterer Dimensions (mm)

EXCLUDING THE CONTROL PANEL

DIMENSIONS

719x600x715

Water connections –

1 x Cold Water

1 x Hot water for cleaning system only

15mm with ¾ standard hose connections

Water Consumption (flow rate) Cold Water 8-10 litres per minute

Water Consumption (flow rate) Hot Water 3 litres per cleaning cycle

Discharge height (mm) 207

Discharge size (mm & inches) 50 / 2”

Capacity (Food Waste) per minute / hour (kg) 13 / 800

Air-break Supplied as standard

Weight (kg) 128

Decibels (dB) 63-70

Electrical Phase 3

Motor voltage (v) 380-415

Motor frequency (Hz) 50

Motor kilowatt (kW) – Macerator / Disposer BY OTHERS

Motor kilowatt (kW) – Pump 0.75

Motor kilowatt (kW) – Dewaterer 1.1

Total kilowatt (kW) 1.85

Amps 16

Electrical Connection (see installation guide) Flying leads to be hard wired to site connection

Cutlery Saver Supplied as standard

Ecofast Environmental UK Ltd

5

Installation Instructions

After Unpacking and locating the machine to it’s operation area;

Water & Waste Connections (local regulations apply).

Both the cold water and hot water connections are colour coded and come with colour coded water

hoses. These have standard European washing machine fittings (3/4” threaded connections) and must

have a 3 bar pressure (±0.5 bar) water supply. High water pressure & temperature could prevent the unit

working.

Water connections should be located within 1 meter of the installation location prior to final positioning

of the machine. Hot water suppliers need to be supplied via a braked tank and supplied at a

temperature between 30-50°C. Cold water supply dependant on model purchased.

The waste connection is a standard 2” or ∅63mm pipe fitting. We suggest using a rubber straight

connector between the WasteStation and the site plumbing fittings. This will avoid any issues between

types of fittings used.

The size of the product outlet must not be reduced, the drainpipe should run into 54mm outside

diameter pipe work as far as its junction with the main pipe or outside manhole connection. The length

of run between the machine and the main junction must be kept to a minimum and the pipe run must

have a fall of at least 1° fall.

A running trap should be fitted, although “P” or “S” type traps

should not be used . Do not use bottle traps. Changes of direction

should be made by swept bends not elbows and cleaning eyes

should be fitted where possible, in accordance with standard

plumbing practice.

Copper pipe and compression fittings should be used, but plastic tubing is acceptable to most drainage

authorities.

The WasteStations must have an independent waste pipe, which does not also serve sinks,

dishwashers and similar equipment.

Ensure the foot mechanism is

lowered into the correct position

ensuring the WasteStation wheels

are not in contact with the floor and

the unit cannot move.

Ecofast Environmental UK Ltd

6

The drainpipe to be installed must slope downwards by 1% and fitted without a trap. It is not suggested

these machines can be fitted with Grease Recovery Units (GRU’s) but should be installed upstream of

the sites grease trap.

Water flow sensors: these sensors prevent the machine from operating without water. If there is no

water to either of the sensors a message will be displayed on the display screen.

Electrical Installation

IMPORTANT: All electrical installations must be performed by a qualified electrician in accordance with

IEE Codes of Practice.

For safety reasons these instructions must be followed. Any deviation from these instructions will result

in a breach of conditions of sale and voiding the warranty contract.

Examine the rating plate located as shown below to ensure that the characteristics shown are correct

for the supply available.

Wastewater outlet

Example of a 2”/50mm rubber straight

connector

Hot

water

connectio

n for the cycling

cycle

Macerated waste

inlet

Location & example of the serial rating plate

Ecofast Environmental UK Ltd

7

The supply cable fitted is the minimum required for connection to the mains supply. Site conditions may

vary with additional length of cable run, encapsulation in trunking, bunched with other cables etc.

Should this apply, the electrician must alter the cable accordingly. The system should be connected to

a suitable 3-phase fused isolator providing at least 3mm separation in all poles.

The system should be connected to a 30A fused isolator providing at least 3mm separation in all poles.

The below illustrates typical fuse ratings for an ambient temperature of 25 to 35°C. Should the

environment temperature be greater than this, adjust accordingly.

Voltage Full Input kW Fuse Rating per Phase

400 –3– 50 1.85 16 Amps

The supply to the machine must also be protected by a 30mA RCD.

WARNING: This machine must be earthed.

If the supply cord becomes damaged it must be replaced by qualified electrician in order to avoid a

hazard.

Phase Sensor: the machine has a phase sensor to prevent the incorrect operation of the machine. In the

event of the phases being in the incorrect orientation the machine will not operate and a “incorrect

phase” message is displayed on the display screen.

Operator Control Panel. This panel comes prewired and needs to be mounted approximately, within 1

meter of where the operator will be working. The control panel needs to be set back from the operating

area to prevent damage to the buttons or screen.

DO NOT USE SHARP ITEMS TO OPERATE THE BUTTONS OR SCREEN.

Connecting the macerator.

The macerator motor must be a 3 phase machine to enable it to operate with the Ecofast Mini

Dewaterer. Before connecting a NON Ecofast macerator, please discuss with Ecofast.

1. The motor cable is identified as cable M1 from the dewaterer.

2. The Lid Safety interlock (FC1) needs to be wired into the main enclosure control panel

as detailed in the wiring diagram (EC060048A). This safety interlock should needs to

switch at 24voltsDC.

3. The solenoid valve (YV3) is 24vDC and the cable is prewired to the control panel and

the push terminals need to be connected to the solenoid spade terminals.

4. The Flow valve (SP2) is 24vDC and the cable is prewired to the control panel and the

push terminals need to be connected to the solenoid spade terminals.

TESTING

Check finally that all supply connections are correctly made and soundly fixed, that nothing has been

left in the grinding chamber, that the rotor is free to rotate and that the baffle interlock is in the correct

position.

The machine is now ready to operate!

Ecofast Environmental UK Ltd

8

WARNING – DO NOT

Tamper with the machine in any way

Insert anything but food waste into the hopper

Wash the machine by pressure jet

Use the machine in area with open flames

Operate the emergency button except in case of danger

Remove the identification label

Pour any kind of soap, detergent or Fats Oils & Grease (FOG) into the hopper

Wash the lid in the washing machine

Use the machine wearing loose fitting clothing such as with large sleeves, scarves,

ties, bracelets, necklaces

Sit on the machine or lay heavy objects on it

Leave anything in the hopper after use

Removing the baffle

–

ECOFAST

SYSTEM ONLY

Operator Instructions

Operating the Machine

Make sure the display shows “ready”

1. Press and hold the green button: the automatic cycle starts and display shows

“WORKING”

2. Introduce the food waste into the hopper at a steady pace. The machine can cope with

The cycle automatically stops in a default time or by pressing the red button. When the

display shows “stopping” don’t introduce any food into the hopper and wait for the

cycle to stop. Immediately after the machine has stopped it will undertake a quick

automatic cleaning cycle before fully stopping.

Cleaning the Machine

At the end of the day, make sure the display shows “ready”

1. Open the baffle and ensure any left-over food waste is cleaned form the underside of

the baffle and inside the cutting chamber, rinse with warm water if needed.

2. Remove the bin with the dewatered food waste and replace with an empty bin. This will

ensure no water is introduced into the dewatered food waste.

3. Press and hold the blue cleaning button: the cleaning cycle will begin; the display will

register the “CLEANING” message.

4. Clean and dry the external surfaces of the machine with a cloth ready for the next

operation.

Ecofast Environmental UK Ltd

9

This

D

6

00

R

Mini Dewaterer

food waste management

system and all Ecofast’s products are designed to be

operated inside a commercial kitchen or utility

environment and MUST NOT be exposed to

environmental elements.

The machine should be operator in conditions

between 5°C to 35°C and between 20% to 80%

humidity.

Do not

sit or place heavy objects on

the machine.

Correct positioning of the operator

when using this machine.

Operation

of the Ecofast

products must

by

an competent operator who has

read this manual or

undertaken the online training (the link is available by emailing info@ecofastuk.com).

Stopping the Machine

Once the food waste has been disposed of and the machine needs to be stopped simply press the stop

button and the display will indicate the below message.

The machine will continue to run for a few seconds before

initiating its rinse cycle.

The rinse cycle is initiated automatically after each operation cycle to

prevent any obstructions being left in the macerating chamber, pump, dewaterer or the pipes.

Ecofast Environmental UK Ltd

10

The machine is intended to process food waste only.

Always process a mixture of materials and not just one type, especially if it is a dry material. Dry

material must be fed into the hopper slowly to avoid blockages.

The following are considered improper use of this machinery:

Inserting in the hopper material other than food waste

Washing the machine by pressure jet

Installing and use the machine in area with high dust concentration or oily substances

suspended in the air

Installing and use the machine in open air

Installing and use the machine in potentially explosive atmosphere or in area with open

flames

Tampering the machine in any way

Operating the emergency button in absence of a real danger

Removing the identification label

Pouring any kind of soap or detergent into the hopper

Washing the lid in the washing machine

Using the machine wearing dresses with large sleeves, scarves, ties, bracelets and

necklaces

Bin Full.

The system operates a sensor that monitors the level of the dewatered food waste to prevent over

filling.

If the bin full message is displayed on the operator display, the machine will stop working to

prevent over filling.

Replace the bin with an empty one and press the start button to reset and restart the machine.

Once the operation has finished and the rinse cycle is initiated, there is a very fine spray that

activates to clean the waste ejector. This will not alter the overall dewatered food waste is it is a

very fine spray – refer to Cleaning of the machine for end of day procedure.

Emergency Stop Button is only to be used in an emergency & not as a way to stop the machine

during normal operation. This isolates the machine and prevents any cleaning function taking place.

Operator Control Panel

Operator display indicating the system activity

Start button – press and hold to initiate

Stop button – press and hold to initiate

Cleaning button - to be used at the end of each day

Emergency Stop Button

Ecofast Environmental UK Ltd

11

Dos and Don’ts Poster

✔✔✔ YES ✗✗✗ NO

Plate scrapings

Fibrous fruit

& vegetables

(ie pineapple

crowns, corncobs &

artichokes)

Vegetable & fruit

peelings

Large bones

in large

quantities

Fish

Large

volumes of

cooked

starchy

products

Meat

Drink & Sauce

sachets

Vegetables

Paper/plastic

cups, stirrers

& packaging.

Fruit

Cutlery

Bread & Cakes

Rubber

Gloves

Egg Shells & Dairy

Products

Cloths and

towels

Note;

To assist the macerating process, during the

maceration of large quantities of stringy and fibrous

foods or large volumes of starchy foods, it is

recommended to mix it with other food waste whilst

adding to the hopper. This assists the flow of the

macerated waste through to the waste pipes

reducing the risk of potential blockages.

No Fats, Oils

or grease

Paper & cloth

napkins

Ecofast Environmental UK Ltd

12

The machine is intended to process food waste only.

Always process a mixture of materials and not just one type, especially if it is a dry material.

Dry material must be fed into the hopper slowly to avoid blockages.

The following are considered improper use of this machinery:

Inserting in the hopper material other than food waste

Washing the machine by pressure jet or hose

Installing and use the machine in area with high dust concentration or oily substances

suspended in the air.

Installing and use the machine in open air.

Installing and use the machine in potentially explosive atmosphere or in area with open

flames.

Tampering the machine in any way.

Operating the emergency button in absence of a real danger.

Removing the identification label.

Pouring any kind of soap or detergent into the hopper.

Washing the lid in the washing machine.

Using the machine wearing dresses with large sleeves, scarves, ties, bracelets and

necklaces

.

Bin Full.

The system operates a sensor that monitors the level of the dewatered food waste to prevent over

filling of the bin.

If the bin full message is displayed on the operator display, the machine will stop working to

prevent over filling.

Replace the bin with an empty one and press the start button to reset and restart the machine.

Once the operation has finished and the rinse cycle is initiated, there is a very fine spray that

activates to clean the waste ejector. This will not alter the overall dewatered food waste is it is a

very fine spray – refer to Cleaning of the machine for end of day procedure.

Emergency Stop Button is only to be used in an emergency & not as a way to stop the machine

during normal operation. This isolates the machine and prevents any cleaning function taking place.

Operator Control Panel

Operator display indicating the system activity

Cleaning button - to be used at the end of each day

Stop button – press and hold to initiate

Start button – press and hold to initiate

Emergency Stop Button

Ecofast Environmental UK Ltd

13

Warranty Details

This product comes with a 2-year parts and labour warranty in the UK and 2 years parts only in exported

regions. The warranty period is based on fair industry usage, regular service reviews in line with Ecofast

recommendations or a maximum run time of 2,200 hours over the warranty period.

The product’s onboard PLC (computer) will log running times which can be monitored remotely by

Ecofast UK as an optional extra to provide a surveillance, problems solving and preventative

maintenance service.

Spare Parts come with a limited 3-month parts only warranty from the point of purchase.

Trouble shooting & fault finding

Error fault codes – in the event of activation these error messages are display

on the operator display.

Error Message Corrective action

Motor overload Isolate power to the machine, check for & remove any blockage, turn

power back on. Wait for alarm to reset. Contact service dept if

message continues.

No Water Check water supply and restart – alarm will reset if water present

Phase error Contact electrician for corrective action

Bin is full Empty bin & restart machine

Emergency Check baffle and bin are correctly fitted

Should the above corrective actions not overcome the faults, try the additional actions; ISOLATE

MACHINE

Situation Action

Object jammed in the

macerator

Try unjamming the rotor by special tool EC000755. Remove the

macerator and disassemble it to remove the jammed object.

Replace the macerator

Bin is full but the machine

doesn’t stop;

or display shows BIN FULL

but the bin isn’t full

Stop the machine, remove I/O panel and manually test the level

sensor (page 10). Check whether led colour on sensor swaps

together with display message. Check sensor’s switch

distances by hand. Replace the sensor.

Machine works but drops

nothing into the bin

Press emergency button unplug power cord and remove

possible clogging along the material’s path. Run one or more

cleaning cycles. Remove and inspect the dewaterer. Replace

the dewaterer.

Macerator hopper is

flooding

Stop the machine normally. Remove I/O panel and check for the

pump to work. Check pump’s wiring. Remove pump’s cap and

let the material out. Unjam and replace pump’s impeller

Ecofast Environmental UK Ltd

14

Liquid leaks under the

machine

Check macerator emergency drainpipe. If the macerator’s

emergency drain (pag.11) is leaking, replace the macerator.

Water falls into the bin

during working cycle

Run one or several cleaning cycles. Unplug power cord and

remove possible clogging along the material’s path.

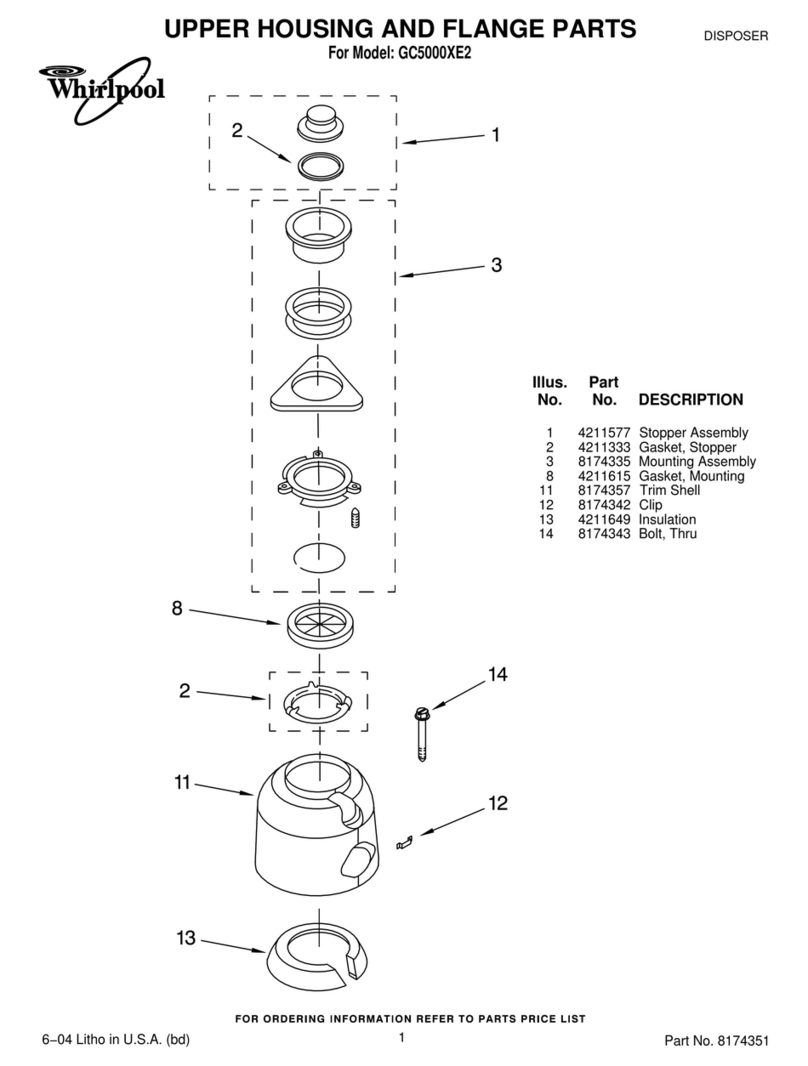

Spares Parts & Exploded Diagrams

EC090645 Splashguard

EC090633+EC020257

-

3 Scraping bar & cover

EC060069

–

Emergency Stop Button

EC060115

–

Operator Display

EC060085

–

Cleaning Button

EC060093

–

Stop Button

EC060075

–

Start Button

EP01326

–

Safety Baffle Assembly

Ecofast Environmental UK Ltd

15

Water Delivery Assembly – parts highlighted used on both cold & warm water assemblies. Cold water

assembly is for the macerator and the Hot water assembly is fitted within the D600 dewaterer.

Macerator / Disposer Exploded diagram & Spare parts

EC070038

–

Solenoid valve

EC070062

–

Flow sensor

EC070102

–

Y

-

type Filter

EC030056

–

Grinding Ring

EC090512

–

O

-

Ring

EC030037

–

Grinding Rotor

EC090295

-

Speedi Sleeve

EC090295

–

Double lip Seals

EC030042

–

Top casting

EC050027

–

Macerator Motor

2.2kW 400volts 3 phase 50Hz

Hot Water

Cold Water

Ecofast Environmental UK Ltd

16

Pump Exploded Diagram & Spare Parts

EC00297

–

Motor (0.75kW)

EC00999

–

Pump Assembly

EC00315

–

Motor Gearbox

EC050901

–

Pump Impellor

EC050903

–

O

-

Ring

EC050902

–

Impellor Seals

Ecofast Environmental UK Ltd

17

Dehydra (Dewaterer) & Spare Parts

EC090123 Upper Bearing

EP090116 Lip Seal 45x65x8

EC050001 Dehydra Motor 1.1kW 400

-

3

-

50Hz

EC090500 Drive Belt 776

-

8M-20

EP090117 Lip Seal 45x58x7

EP090116 Lip

Seal 45x65x8

EC090122 Lip Seal 50x68x8

EC090121 Lip Seal 50x65x8

EC090124 Bottom Bearing

Ecofast Environmental UK Ltd

18

UKCA CERTIFICATE OF CONFORMANCE

Declaration of conformity

According to Directive 2006/42/EC, annex II point 1.A

The Designer & Manufacturer

Ecofast Environmental UK Ltd

Maesbrook, Oswestry, SY10 8QN

Hereby declares that the following machine:

D600 Mini Dewaterer

complies with the following directives:

• 2006/42/EC – Machines Directive

• 2014/30/EU – EMC Directive

• 2011/65/EU – RoHS Directive

Name and address of the person authorized to manage the technical file:

Ecofast Environmental UK Ltd, Maesbrook, Oswestry, SY10 8QN

The main technical standards applied are

UNI EN ISO 12100:2010 Safety of machinery — General principles for design — Risk assessment and risk

reduction

UNI EN ISO 13857:2008 Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs

CEI EN 60204-1:2008 Safety of Machinery - Part 1 General Requirements CE Marking

UNI EN 14120:2015 - Safety of Machinery – Guards – General Requirements

ISO 12100:2010 - Safety of machinery — General principles for design — Risk assessment & risk reduction

EN 60204-1:2016 - Safety of machinery - Electrical equipment of machines - Part 1: General requirements

EN 1717:2000 - Protection against pollution of potable water in water installations and general requirements of

devices to prevent pollution by backflow - refer to The Water Supply (Water Fittings) Regulations 1999

EN IEC 61000-6-2 : 2019 - Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity

standard for industrial environments

Ecofast Environmental UK Ltd

19

CE CERTIFICATE OF CONFORMANCE

Declaration of conformity

According to Directive 2006/42/EC, annex II point 1.A

The Designer & Manufacturer:

Ecofast Italia S.r.l. Tecnologie Ambientali

Piazza Franco Martelli, 5 - 20162 Milano

Hereby declares that the following machine:

D1000 WasteStation (SC1B)

complies with the following directives:

• 2006/42/EC – Machines Directive

• 2014/30/EU – EMC Directive

• 2011/65/EU – RoHS Directive

Name and address of the person authorized to manage the technical file:

Ecofast Italia S.r.l. - Piazza Franco Martelli, 5 - 20162 Milano

Main technical standards applied:

• UNI EN ISO 12100:2010

• UNI EN ISO 13857:2008

• CEI EN 60204-1:2006

• UNI EN 953:2009

Milano,

The main technical standards applied are

EN ISO 12100:2010

EN 60204-1:2016

EN 1717:2000

EN 953:2009

EN 61000-6-2:2005

EN 61000-6-4:2007

Ecofast Environmental UK Ltd

20

MAINTENANCE MENU - RESTRICTED AREA – LOGIN

The display features a maintenance restricted area. Restricted area features orange background screens and

a key on the left. To enter proceed as follows:

1

Touch the orange lock

2

Select SERVICE user and touch

password

3

Type the password received from

the manufacturer and press enter

4

Touch OK button. Below the

password, a message displays

password accuracy. Touch the

arrow on the right

5

Touch the orange lock again,

access is complete

Your machine may not have a password protection unless it was requested. If this is the case follow the

instructions 1, click on the orange padlock and this will take you directly to routine maintenance page as

shown on the next page.

It is advised that only service / maintenance staff access these pages.

2

1

3

4

Table of contents

Other EcoFast Garbage Disposal manuals

Popular Garbage Disposal manuals by other brands

American Standard

American Standard 1397464 instruction manual

InSinkErator

InSinkErator Model SS-150 Specifications

Humboldt

Humboldt h-4169 product manual

Altrad

Altrad BELLE SF460 Operator's manual

InSinkErator

InSinkErator Badger 100 installation instructions

Weber mt

Weber mt 0116636 Operating and maintenance manual

MULTIQUIP

MULTIQUIP Mikasa Series Operation and parts manual

Westinghouse

Westinghouse QKG06 owner's manual

MQ Multiquip

MQ Multiquip MVC82VH Operation and parts manual

Caple

Caple WDU050 instruction manual

Delitek AS

Delitek AS DT-200i User & service manual

KitchenAid

KitchenAid Superba KCDS100T installation instructions