ECOFER Fairland INVERX VERTICAL Instruction Manual

CONTENTS

1. General information: ................................................................................................................................ - 3 -

1.1. Contents:................................................................................................................................................ - 3 -

1.2. Operating conditions and range:........................................................................................................... - 3 -

1.3. Advantages of different modes:............................................................................................................ - 3 -

2. Operations................................................................................................................................................. - 6 -

2.1. Notice before using................................................................................................................................ - 6 -

2.2. Operation instructions........................................................................................................................... - 6 -

2.3. Daily maintenance and winterizing....................................................................................................... - 9 -

3. Technical specification............................................................................................................................ - 10 -

4. Transportation......................................................................................................................................... - 11 -

5. Installation and maintenance................................................................................................................. - 11 -

5.1. Notice before installation:................................................................................................................ - 11 -

5.2. Installation instruction......................................................................................................................... - 12 -

5.3. Trial after installation ....................................................................................................................... - 15 -

5.4. Maintenance and winterizing........................................................................................................... - 15 -

6 . Trouble shooting for common faults..................................................................................................... - 16 -

7. Failure code............................................................................................................................................. - 17 -

APPENDIX 1: HEATING PRIORITY WIRING DIAGRAM (OPTIONAL)............................................................ - 18 -

APPENDIX 2: HEATING PRIORITY WIRING DIAGRAM (OPTIONAL)............................................................ - 19 -

APPENDIX 3: HEATING PRIORITY WIRING DIAGRAM (OPTIONAL)............................................................ - 20 -

8. Wifi setting.............................................................................................................................................. - 22 -

Installation and user manual

- 1 -

Warning:

a. Please read the following tips before installation, use and maintenance.

b. Installation, removal and maintenance must be carried out by Professional personional in

accordance with the instructions.

c. Gas leakage test must be done before and after installation.

1. Use

a. It must be installed or removed by professionals, and it is forbidden to dismantle and refit

without permission.

b. Don’t put obstacles before the air inlet and outlet of the heat pump.

2. Installation

a. This product must be kept away from any source of fire.

b. The installation can’t be in a closed environment or indoors, and must be kept well ventilated.

c. Vacuum completely before welding, field welding is not allowed, welding can only be

performed by professional personnel in professional maintenance center.

Installation and user manual

- 2 -

d. Installation must be stopped if any gas leakage, and the unit must be returned to

professional maintenance center.

3. Transportation & Storage

a. Sealing is not allowed during transportation

b. Transporting goods at a constant speed is needed to avoid sudden acceleration or sudden

braking, so as to reduce the collision of goods.

c. The unit must be far away from any source of fire.

d. Storage place must be bright, wide, open and good ventilation, ventilation equipment is

required.

4. Maintenance Notice

a. If maintenance or scrap is required, contact an authorized service center nearby

b. Qualification requirement

All operators who dispose gas must be qualified by valid certification which issued by

professional agency.

c. Please strictly comply with the requirement from manufacturer when maintenance or filling

gas. please refer to the technical service manual.

Installation and user manual

- 3 -

1. General information:

1.1. Contents:

After unpacking, please check if you have all the following components.

NOTICE: Please do not install wrong direction of the water union.

1.2. Operating conditions and range:

ITEMS

RANGE

Operating range

Air temp

-15℃~43℃

Temp. setting

heating

18℃-40℃

The heat pump will have ideal performance in the operation range Air 15

℃~

25

℃

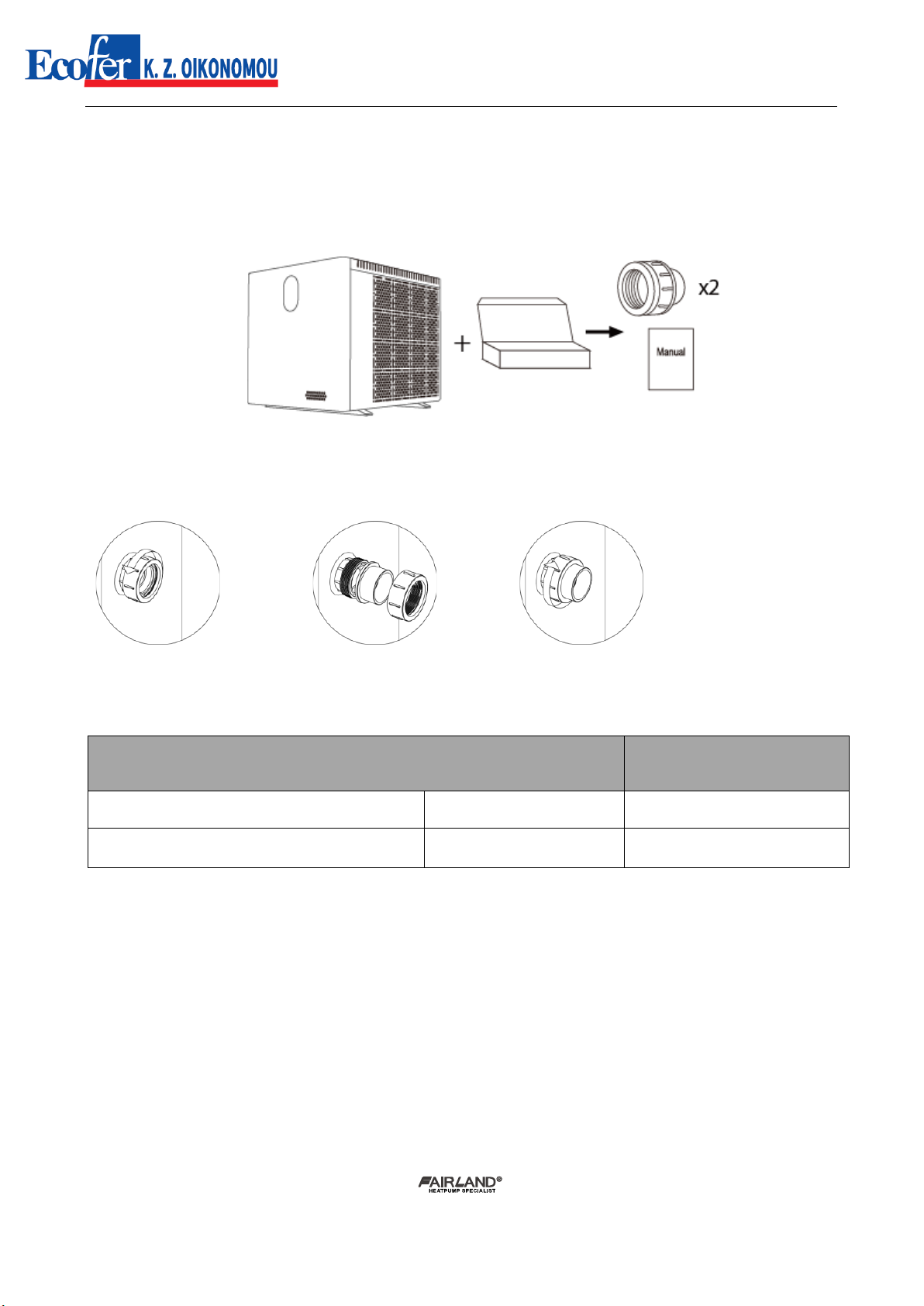

1.3. Advantages of different modes:

The heat pump has three modes: Turbo, Smart and Silence. They have different advantages under

different conditions.

Installation and user manual

- 4 -

Kind reminder:

This heat pump has Power-off memory function. When the power is recovered, the heat pump

will restart automatically.

1. The heat pump can only be used to heat the pool water. It can NEVER be used to heat other

flammable or turbid liquid.

2. Don’t lift the water union when moving the heat pump since the titanium heat exchanger inside

the heat pump will be damaged.

3. Don’t put obstacles before the air inlet and outlet of the heat pump.

4. Don’t put anything into inlet or outlet, or the efficiency of the heat pump will be reduced or

even stopped.

MODE

ADVANTAGES

Turbo mode

Heating capacity: 120%

Fast heating

Smart mode

Heating capacity:100%~20%

Intelligent optimization according to ambient temperature

and water temperature

Energy efficiently saving

Silence mode

Heating capacity: 60%~20%

Use at night

Installation and user manual

- 5 -

5. Don’t use or store combustible gas or liquid such as thinners, paint and fuel to avoid fire.

6. If any abnormal circumstances occurred, e.g.: abnormal noises, smells, smokes and leakage of

electricity, switch off the main power immediately and contact your local dealer. Don’t try

to repair the heat pump by yourselves.

7.. The main power switch should be out of the reach of Children.

8. Please cut off the power in the lightning storm weather.

Installation and user manual

- 6 -

9. Please note that following codes are not failure.

Codes

No water flow

Anti-Freezing Reminder

Out of the operating range

Insufficient water flow or pump

blocked

Power abnormal

2. Operations

2.1. Notice before using

①For longer service life, please ensure water pump is on before heat pump is on, and water

pump is off after heat pump is off.

②Ensure no water leakage on piping system, then unlock screen and power on the heat pump.

2.2. Operation instructions

Installation and user manual

- 7 -

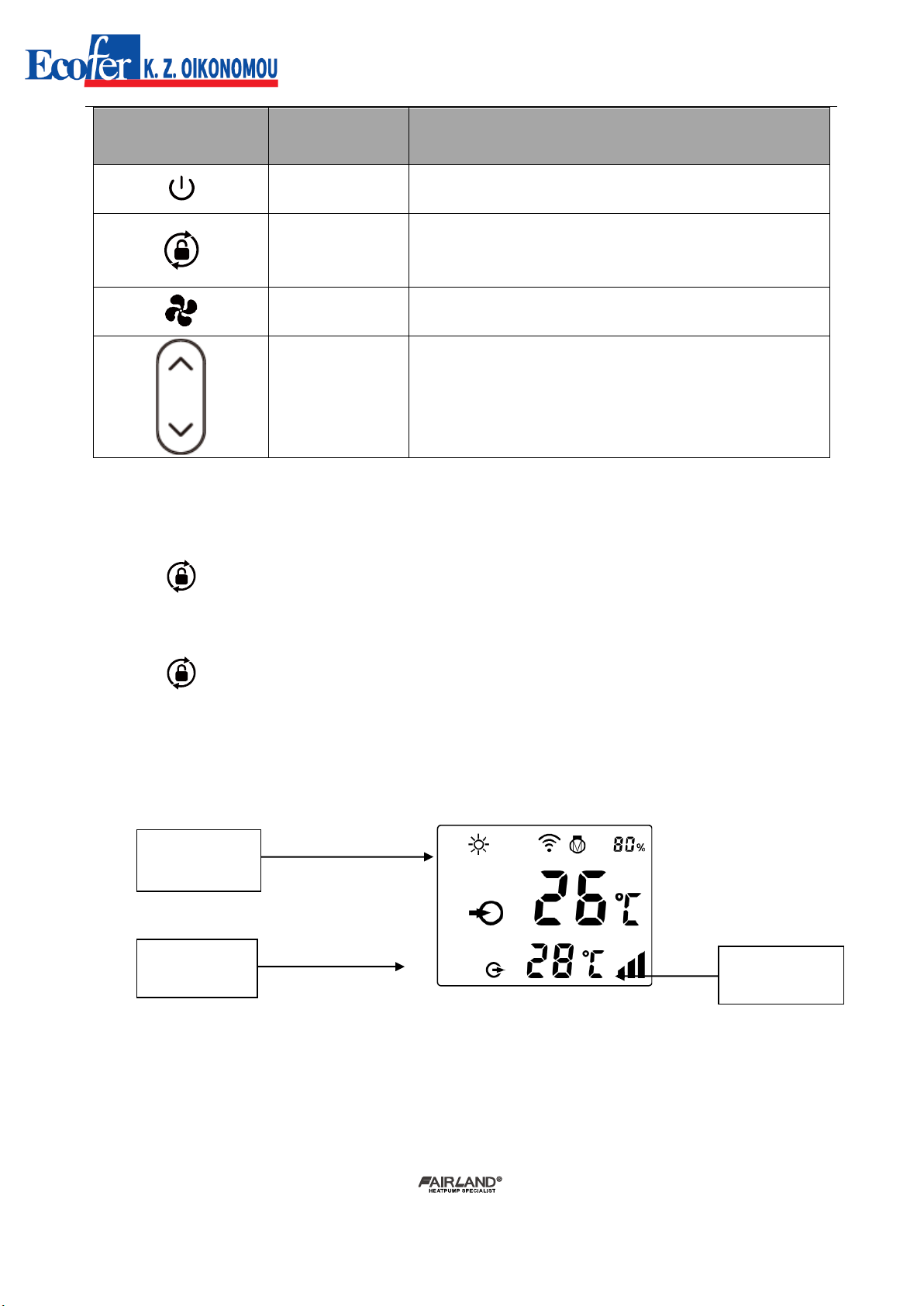

SYMBOL

DESIGNATION

FUNCTION

ON/OFF

1. Power On/Off

2. Wifi setting

Lock/Unlock

Mode Selection

1. Press it for 3 seconds to unlock/lock screen

2. After screen is unlocked, press it to select mode.

Auto (12~40℃) Heating (18~40℃) Cooling (12~30℃)

Speed

Select Turbo/Smart/Silence mode

Up / Down

Adjust set temperature

Note:

①Screen lock:

a. If no operation in 30 seconds, screen will be locked.

b. When HP is off, screen will be dark and “0%” will be displayed.

c. Press for 3 seconds to lock screen and it will be dark

②Screen unlock:

a. Press for 3 seconds to unlock screen and it will be lit up.

b. Only after screen is unlocked, any other buttons can be functioned.

Water inlet

temperature

Water outlet

temperature

Turbo/Smart/

Silence mode

Installation and user manual

- 8 -

Heating

Heating capacity percentage

Wifi connection

Water inlet

Water outlet

1.Power On: Press for 3 seconds to light up screen, then press to power on heat

pump.

2.Adjust Set Temperature: When screen is unlocked, press or to display or adjust the set

temperature.

3. Mode Selection: Press to select mode.

Heating : adjustable temperature range 18~40℃

4. Turbo/Smart/Silence mode selection:

① Smart mode as default will be activated when heat pump is on, and screen shows .

② Press to enter Turbo mode, and screen shows , then press to enter Silence

mode, the screen shows . Press again, the screen shows and return to Smart

mode.

Attention:

a.

When use the Turbo mode, you should select it every time, the machine will not automatically

enter the Turbo mode.

b.

During the Turbo mode, when the machine reaches the set temperature, it will automatically

return to the smart mode.

5. Defrosting

a. Auto Defrosting: When heat pump is defrosting, will be flashing. After defrosting,

will stop flashing.

Installation and user manual

- 9 -

b. Compulsory Defrosting: When heat pump is heating, press and together for 5

seconds to start compulsory defrosting, and will be flashing. After defrosting, will stop

flashing.

(Note: Compulsory defrosting intervals should be more than 30 minutes and the compressor

should run for more than 10 minutes.)

6.Temperature display conversion between ℃and ℉:

Press " " and " " together for 5 seconds to switch between ℃and ℉.

7. Wifi setting

Please kindly check the last page.

2.3. Daily maintenance and winterizing

2.3.1. Daily Maintenance

Please don’t forget to cut off power supply of the heat pump

➢Please clean the evaporator with household detergents or clean water, NEVER use gasoline,

thinners or any similar fuel.

➢Check bolts, cables and connections regularly.

2.3.2. Winterizing

In winter season when you don’t swim, please cut off power supply and drain water out of

the heat pump. When using the heat pump under 2℃, make sure there is always water flow.

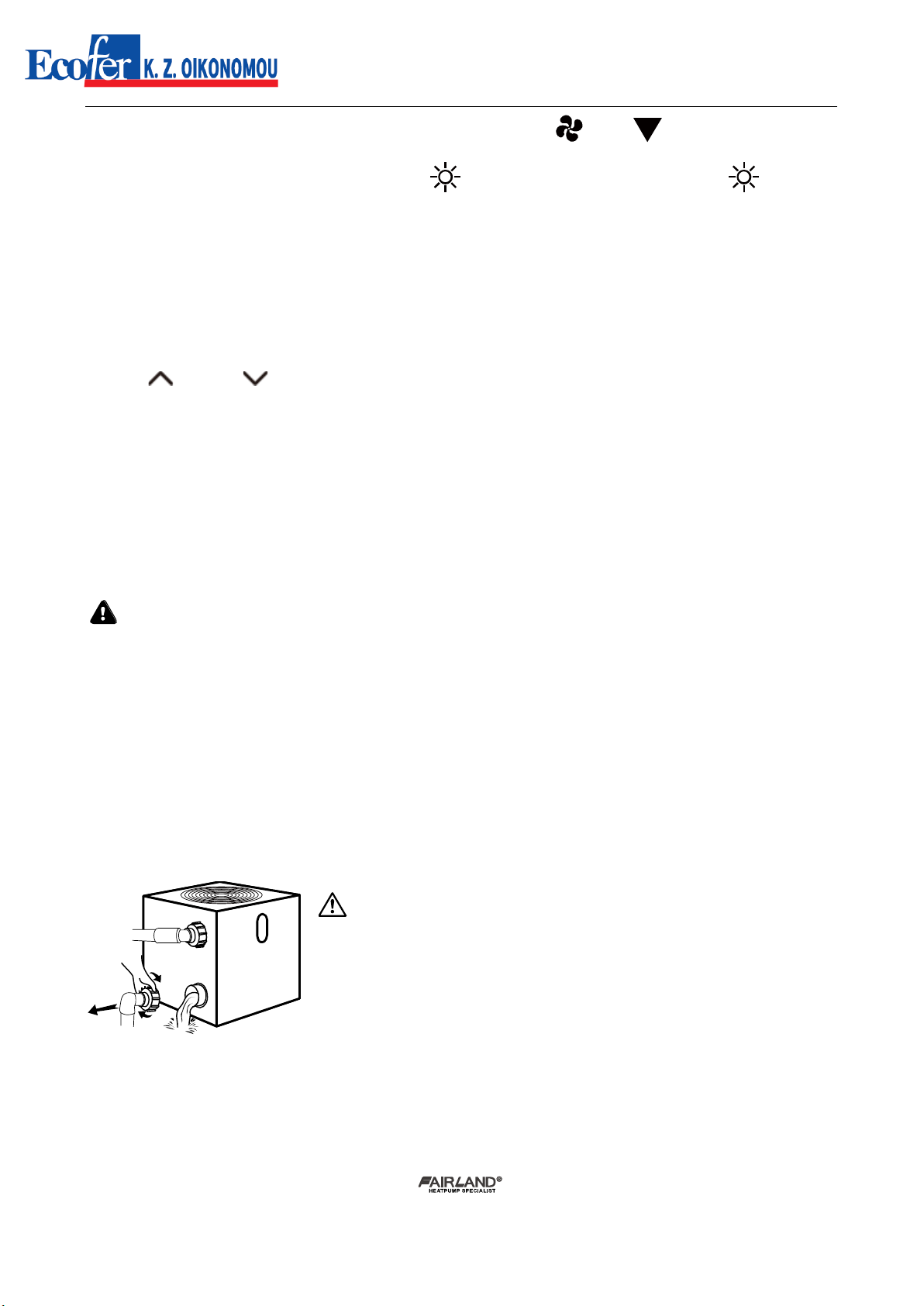

Important:

Unscrew the water union of inlet pipe

to let the water flow out.

When the water in machine freezes in

winter season, the titanium heat

exchanger may be damaged.

Installation and user manual

- 10 -

3. Technical specification

Model

IXCR26V

IXCR36V

IXCR46V

IXCR56V

IXCR66V

IXCR80V

IXCR80VT

IXCR110VT

Advised pool volume (m3)

20~40

25~50

30~60

40~75

50~100

65~120

65~120

90~160

Working air temp (℃)

-15οC ~ +43οC

Performance Condition: Air 28°C, Water 26°C, Humidity 80%

Heating capacity (kW) in SMART

mode

9,3

12,0

15,4

19,0

24,3

29,0

29,0

37,0

Heating capacity (kW) in TURBO mode

11,0

14,3

18,5

22,8

28,5

34,0

34,0

42,0

C.O.P in SMART mode

8,3

8,3

8,5

8,1

8,5

8,0

8,0

7,9

C.O.P

16.3~7.5

16.5~7.4

17.0~7.1

16.9~6.9

16.2~7.5

17.2~6.9

17.2~6.9

16.9~7.0

C.O.P at 50% capacity

12,2

12,5

12,8

12,7

12,3

12,2

12,2

12,1

Performance Condition: Air 15°C, Water 26°C, Humidity 70%

Heating capacity (kW) in SMART

mode

6,3

7,5

10,0

12,0

15,0

18,5

18,5

24,5

Heating capacity (kW) in TURBO mode

7,5

9,0

12,0

14,5

18,0

22,0

22,0

28,5

C.O.P in SMART mode

5,1

5,1

5,0

5,0

5,1

5,5

5,5

5,3

C.O.P

7.2~4.5

7.5~4.6

8.0~4.6

7.6~4.5

7.5~4.9

8.0~5.0

8.0~5.0

7.9~4.8

C.O.P at 50% capacity

6,6

6,7

6,9

7,0

6,5

7,0

7,0

6,9

Performance Condition: Air 32°C, Water 28°C, Humidity 80%

Cooling capacity (kW)

4,95

6,4

7,8

9,0

13,2

15,4

15,4

18

Rated input power(kW) at air 15°C

0.17~1.66

0.21~1.95

0.26~2.51

0.33~3.08

0.42~3.67

0.46~4.4

0.46~4.4

0.60~5.94

Rated input current(A) at air 15°C

0.74~7.21

0.91~8.48

1.14~10.9

1.43~13.4

1.82~15.9

2.01~19.1

0.66~6.35

0.87~8.57

Τροφοδοσία / Power supply

230V/1 Ph/50Hz

400V/3 Ph/50Hz

Advised water flux (m³/h)

2~4

3~4

4~6

6.5~8.5

8~10

10~12

10~12

12~18

Sound pressure 1m dB(A)

38.8~46.5

38.8~47.9

42.2~48.6

43.1~52.1

41.0~52.9

43.6~53.8

43.6~53.8

42.8~54.0

Sound pressure of 50% capacity at 1m

dB(A)

39,0

41,9

44,3

45,2

45,3

46,7

46,7

46,9

Sound pressure 10m dB(A)

18.8~26.5

18.8~27.9

22.2~28.6

23.1~32.1

21.0~32.9

23.6~33.8

23.6~33.8

22.8~34.0

Exchanger

Spiral titanium tube in PVC

Casing

Aluminum

Water pipe in-out Spec (mm)

50

Net Dimension LxWxH (mm)

710x753x

693

710x753x

693

710x775x

693

710x775x

693

710x775x

743

729x955x

943

729x955x

943

845x955x

943

Net Weight (kg)

61

66

71

77

95

108

117

141

Refrigerant R32 (gr)

550

700

1000

1200

2000

2300

2300

3200

CO2 equivalent (tonnes)

0,371

0,473

0,675

0,810

1,350

1,553

1,553

2,160

GWP

675

1. The values indicated are valid under ideal conditions: Pool covered with an isothermal cover, filtration system running at least 15 hours a day.

2. Related parameters are subject to adjustment periodically for technical improvement without further notice. For details please refer to

nameplate.

Installation and user manual

- 11 -

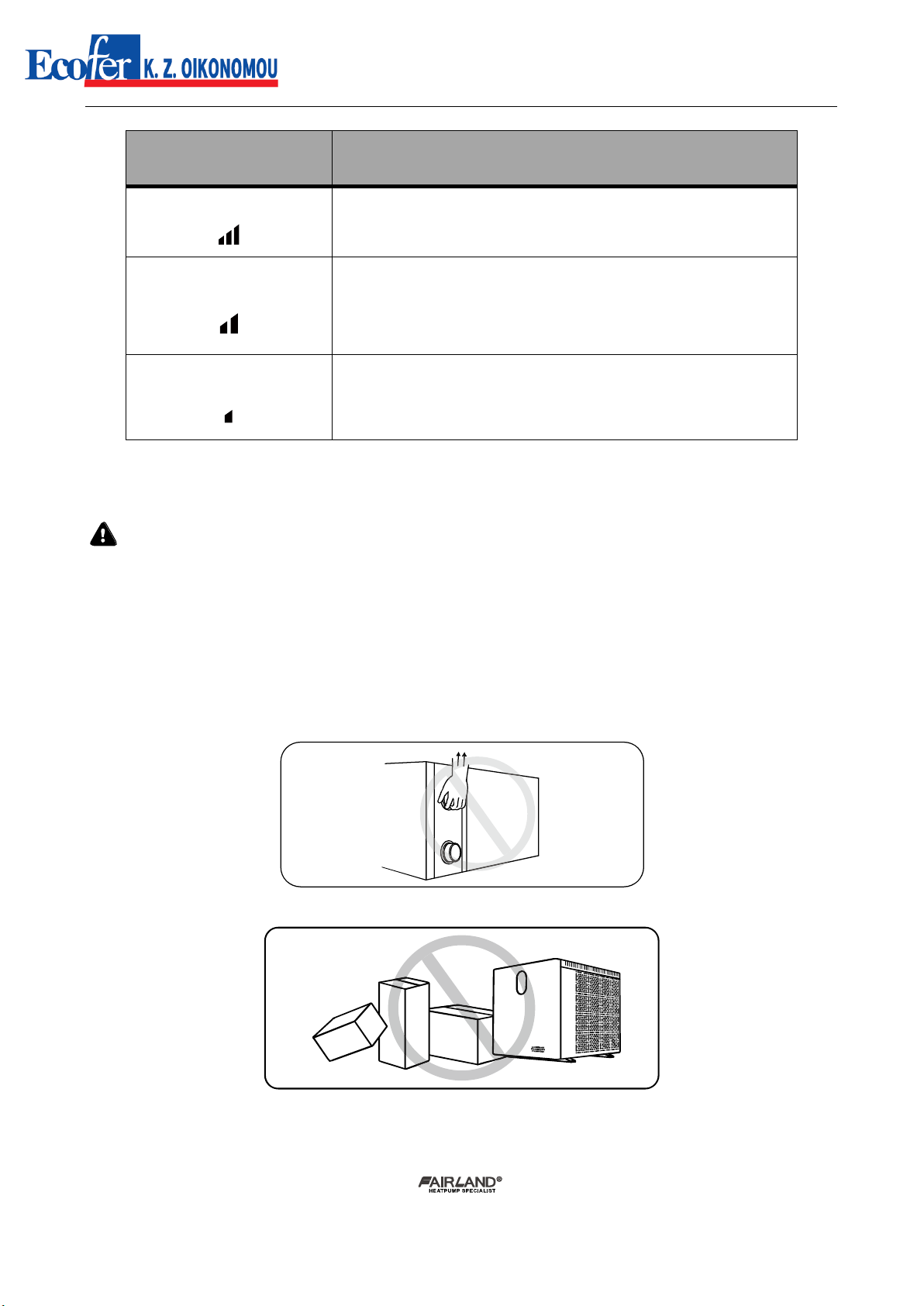

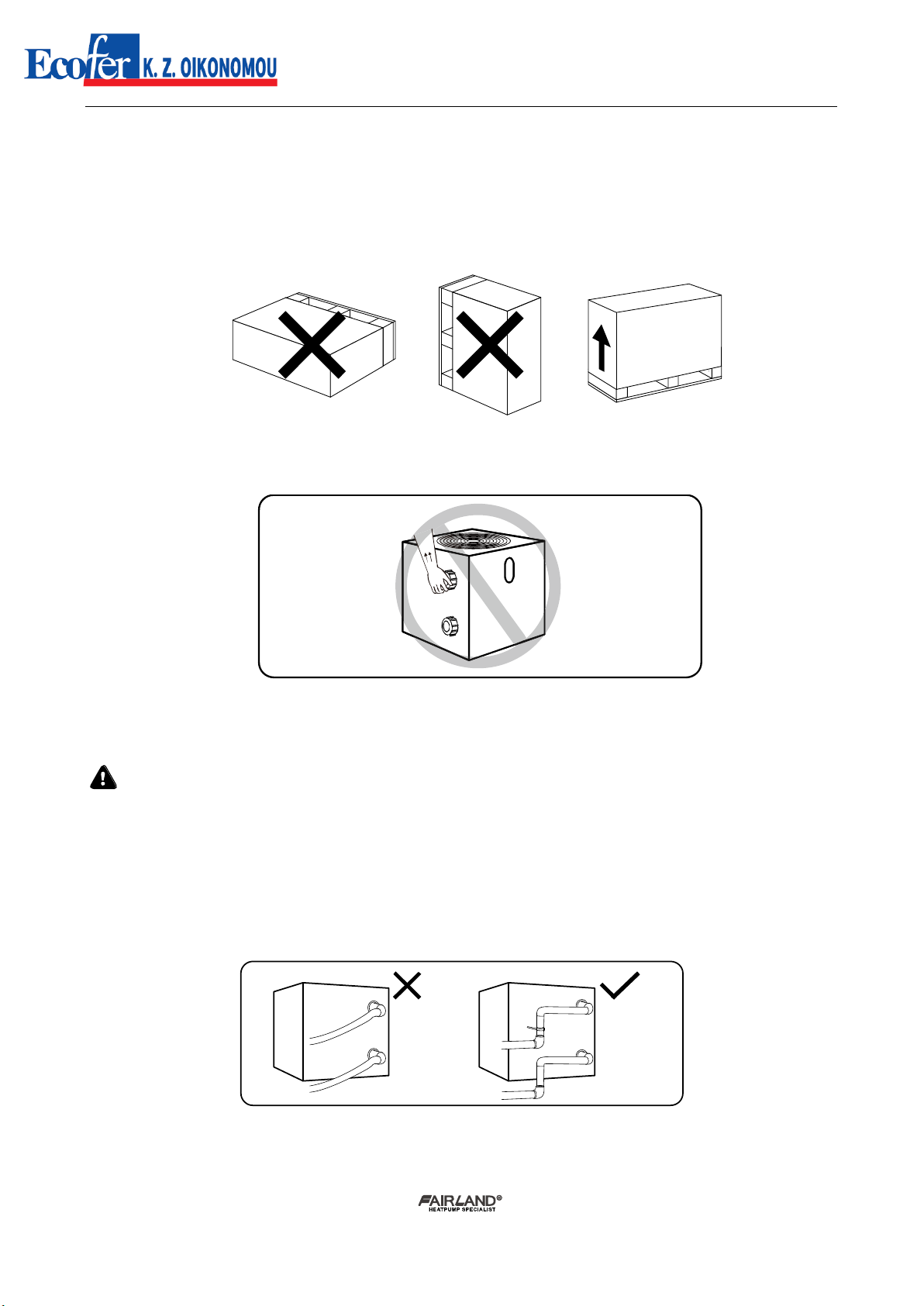

4. Transportation

4.1. When storing or moving the heat pump, the heat pump should be at the upright

position.

4.2. When moving the heat pump, do not lift the water union since the titanium heat exchanger

inside the heat pump will be damaged.

5. Installation and maintenance

The heat pump must be installed by a professional team. The users are not qualified to install

by themselves, otherwise the heat pump might be damaged and risky for users’ safety.

5.1. Notice before installation:

5.1.1. The inlet and outlet water unions can’t bear the weight of soft pipes. The heat pump must

be connected with hard pipes!

5.1.2.In order to guarantee the heating efficiency, the water pipe length should be ≤10m

between the pool and the heat pump.

Installation and user manual

- 12 -

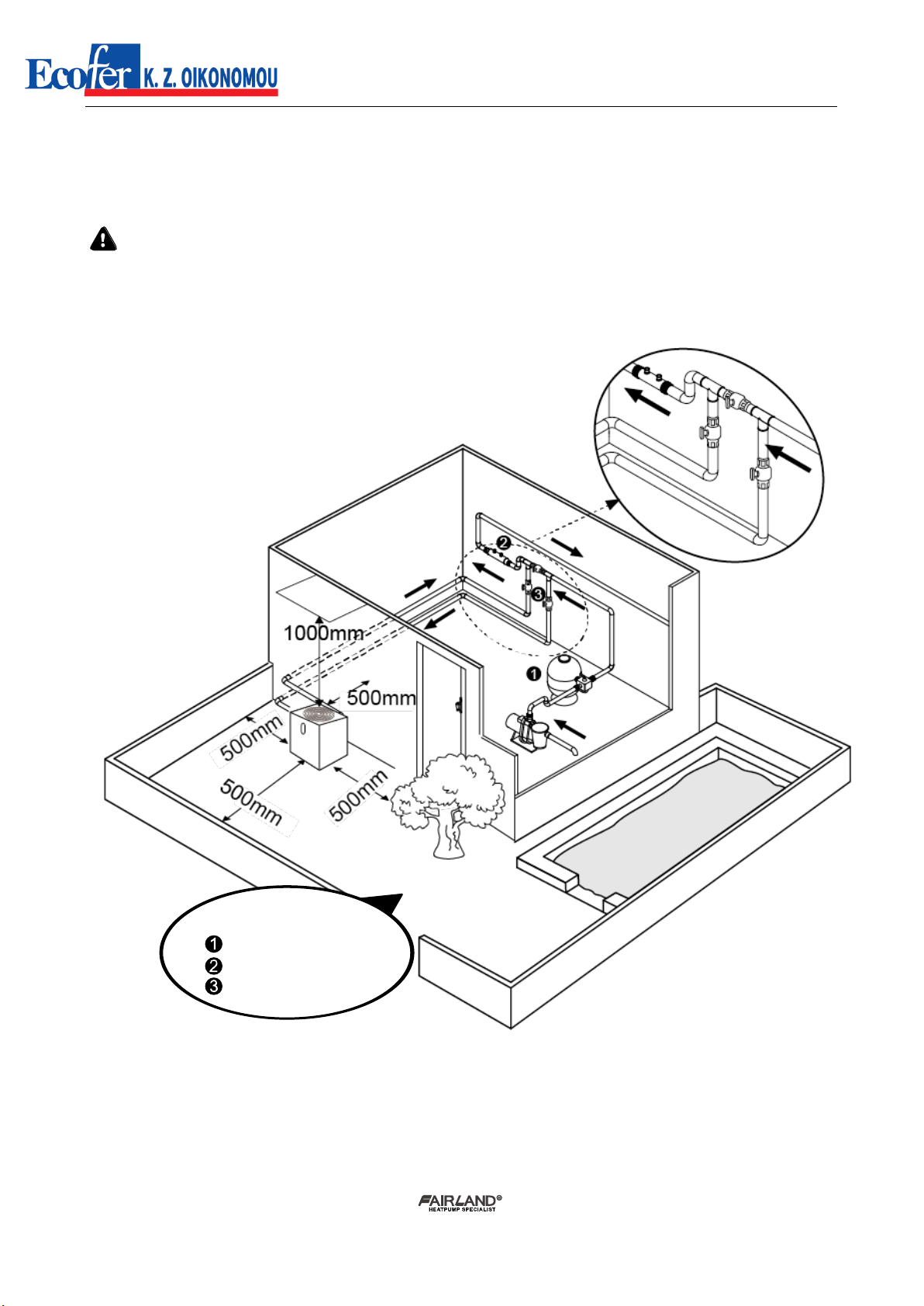

5.2. Installation instruction

5.2.1. Location and size

To avoid air recirculation, the heat pump should be installed in a place with good ventilation

or should reserve sufficient space for installation and maintenance. Please refer to the schema

below:

* MINIMUM DISTANCE

Filter

Water processor

Water switch

Installation and user manual

- 13 -

※

Above data is subject to modification without notice.

5.2.2. Heat pump installation.

➢The frame must be fixed by bolts (M10) to concrete foundation or brackets. The concrete

foundation must be solid; the bracket must be strong enough and anti-rust treated;

➢The heat pump needs a water pump (Supplied by the user). The recommended pump

specification-flux: refer to Technical Parameter, Max. lift ≥10m

➢When the heat pump is running, there will be condensation water discharged from the bottom,

please pay attention to it. Please insert the drainage tube(accessory) into the hole and clip it

well, then connect a pipe to drain off the condensation water.

5.2.3. Wiring & protecting devices and cable specification

➢Connect to appropriate power supply, the voltage should comply with the rated voltage of the

products.

➢Well earth the heat pump.

UNIT=MM

A

B

C

D

E

F

G

H

MODEL

IXR26V

685

441

753

710

688

300

75.5

693

IXR36V

685

441

753

710

688

280

75.5

693

IXR46V

685

463

775

710

688

350

75.5

693

IXR56V

685

463

775

710

688

390

75.5

693

IXR66V

685

463

775

710

688

460

75.5

743

IXR80V

703

555

955

729

707

640

75.5

943

IXR80VT

703

555

955

729

707

640

75.5

943

IXR110VT

819

555

955

845

823

650

75.5

943

Installation and user manual

- 14 -

➢Wiring must be connected by a professional technician according to the circuit diagram.

➢Set breaker or fuse according to the local code (leakage operating current ≤ 30mA).

➢The layout of power cable and signal cable should be orderly and not affecting each other.

1. Wiring diagram

NOTE:

Must be hard wired, no plug allowed

For your safe use in winter, it’s strongly recommended to equip heating priority function.

For the detailed wiring diagram, please refer to Appendix 1.

2.Options for protecting devices and cable specification

MODEL

IXR26

IXR36

IXR46

IXR56

IXR66

IXR80

IXR80T

IXR110T

Breaker

Rated Current A

12.0

15.0

19.0

22.5

24.5

28.5

11.3

15.0

Rated Residual Action Current mA

30

30

30

30

30

30

30

30

Fuse A

12.0

15.0

19.0

22.5

24.5

28.5

11.3

15.0

Power Cord(mm2)

3×2.5

3×2.5

3×4

3×4

3×6

3×6

5×2.5

5×2.5

Signal cable(mm2)

3×0.5

3×0.5

3×0.5

3×0.5

3×0.5

3×0.5

3×0.5

3×0.5

A. For power supply: 230V 50Hz

Distribution Box(Customer prepare)

Power Cord

Swimming Pool Heat Pump Wiring Board

Power Supply

400V 50Hz

Breaker

Distribution Box(Customer prepare)

Power Cord

Swimming Pool Heat Pump Wiring Board

Power Supply

230V 50Hz

Breaker

B. For power supply: 400V 50Hz

Earthing

Earthing

Fuse

Fuse

Installation and user manual

- 15 -

NOTE: The above data is adapted to power cord ≤ 10m .If power cord is

>

10m, wire diameter must be

increased. The signal cable can be extended to 50m at most.

5.3. Trial after installation

Please check all the wirings carefully before turning on the heat pump.

5.3.1.Inspection before use

➢Check installation of the whole heat pump and the pipe connections according to the pipe

connecting drawing;

➢Check the electric wiring according to the electrical wiring diagram and earthing connection;

➢Make sure that the main power is well connected;

➢Check if there is any obstacle in front of the air inlet and outlet of the heat pump

5.3.2.Trial

➢The user is advised to start the water pump before the heat pump, and turn off the heat pump

before the water pump for long life circle.

➢The user should start the water pump, and check for any leakage of water; Power on and press

the ON/OFF button of the heat pump, and set desired temperature in the

thermostat.

➢In order to protect the heat pump, the heat pump is equipped with start delay

function. When starting the heat pump, the fan will start to run in 3 minutes, in another

30 seconds, the compressor will start to run.

➢After pool heat pump starts up, check for any abnormal noise from the heat pump.

➢Check the temperature setting

5.4. Maintenance and winterizing

5.4.1 Maintenance

The maintenance should be carried out once per year by qualified professional technician.

➢Cut off power supply of the

heat pump before cleaning,

examination and repairing .

Do not touch the electronic

components until the LED

indication lights on PCB turn off.

➢Please clean the evaporator with household

detergents or clean water, NEVER use gasoline, thinners or any similar fuel.

➢Check bolts, cables and connections regularly.

Installation and user manual

- 16 -

5.4.2 Winterizing

In winter season when you don’t swim, please cut off power supply and drain water out of the

heat pump. When using the heat pump under 2℃, make sure there is always water flow.

6 . Trouble shooting for common faults

FAILURE

REASON

SOLUTION

Heat pump doesn’t run

No power

Wait until the power recovers

Power switch is off

Switch on the power

Fuse burned

Check and change the fuse

The breaker is off

Check and turn on the breaker

Fan running but with

insufficient heating

evaporator blocked

Remove the obstacles

Air outlet blocked

Remove the obstacles

3 minutes start delay

Wait patiently

Display normal, but no

heating

Set temp. too low

Set proper heating temp.

3 minutes start delay

Wait patiently

If above solutions don’t work, please contact your installer with detailed information and your model number. Don’t

try to repair it yourself.

ATTENTION!Please don’t try to repair the heat pump by yourself to avoid any risk.

Important:

Unscrew the water union of inlet pipe to let the water

flow out.

When the water in machine freezes in winter season,

the titanium heat exchanger may be damaged.

Installation and user manual

- 17 -

7. Failure code

NO.

DISPLAY

NOT FAILURE DESCRIPTION

1

E3

No water protection

2

E5

Power supply excesses operation range

3

E6

Excessive temp difference between inlet and outlet water(Insufficient water flow protection)

4

Eb

Ambient temperature too high or too low protection

5

Ed

Anti-freezing reminder

NO.

DISPLAY

FAILURE DESCRIPTION

1

E1

High pressure protection

2

E2

Low pressure protection

3

E4

3 phase sequence protection (three phase only)

4

E7

Water outlet temp too high or too low protection

5

E8

High exhaust temp protection

6

EA

Evaporator overheat protection (only at cooling mode)

7

P0

Controller communication failure

8

P1

Water inlet temp sensor failure

9

P2

Water outlet temp sensor failure

10

P3

Gas exhaust temp sensor failure

11

P4

Evaporator coil pipe temp sensor failure

12

P5

Gas return temp sensor failure

13

P6

Cooling coil pipe temp sensor failure

14

P7

Ambient temp sensor failure

15

P8

Cooling plate sensor failure

16

P9

Current sensor failure

17

PA

Restart memory failure

18

F1

Compressor drive module failure

19

F2

PFC module failure

20

F3

Compressor start failure

21

F4

Compressor running failure

22

F5

Inverter board over current protection

23

F6

Inverter board overheat protection

24

F7

Current protection

25

F8

Cooling plate overheat protection

26

F9

Fan motor failure

27

Fb

Power filter plate No-power protection

28

FA

PFC module over current protection

Table of contents

Other ECOFER Heat Pump manuals

Popular Heat Pump manuals by other brands

Action Clima

Action Clima FCS Series Installation use and service manual

Nortek

Nortek RQ7RE installation instructions

ClimateMaster

ClimateMaster TMW Series Installation operation & maintenance

Daikin

Daikin RZQG71~140L7V1B Service manual

Trane

Trane Axiom VSHE024 Operating and maintenance

Nibe

Nibe F2050 user manual

Trane

Trane 4WCC4024E1000A Installation and operation manual

Dimplex

Dimplex LAS 10MT Installation and operating instructions

Zodiac

Zodiac Z900 TD20 Instructions for installation and use

CTC Union

CTC Union EcoPart 400 400V 3N Installation and maintenance manual

Heat Controller

Heat Controller AS-W303DPZ0 Service manual

Multistack

Multistack AirStack VersaTemp ARA 020X Product data