Ecomax ELG02 User manual

ALTON INDUSTRY LTD. GROUP

643 Innovation Drive West Chicago, IL 60185

info @ altonindustries.com

https://www.altonindustries.com

USER'S MANUAL ELECTRIC

CORDED TILLER

WARNING: Read carefully and understand all INSTRUCTIONS before operating. Failure to follow the safety

rules and other basic safety precautions may result in serious personal injury. Save this instructions in a safe

place and on hand so that they can be read when required.

Model:ELG02

MADE IN CHINA

BEFORE YOU START

Please read all instructions carefully.

Retain instructions for future reference.

Separate and count all parts and hardware.

Read through each step carefully and follow

the proper order.

We recommend that, where possible, all items

are assembled near to the area in which they

will be placed in use, to avoid moving the

product unnecessarily once assembled.

Always place the product on a flat, steady and

stable surface.

Keep all small parts and packaging materials for

this product away from babies and children as

they potentially pose a serious choking hazard.

CONTENTS

FEATURES 01

EXPLANATION OF THE SYMBOLS ON THE EQUIPMENT 07

INTRODUCTION 08

DEVICE DESCRIPTION 08

SCOPE OF DELIVERY 09

INTENDED USE 09

SAFETY INFORMATION 09

OPERATION 14

ELECTRICAL CONNECTION 14

TROUBLE SHOOTING GUIDE 17

CLEANING AND MAINTENANCE 15

TECHNICAL DATA 13

WARRANTY 18

01

https://www.altonindustries.com

02

info@altonindustries.com

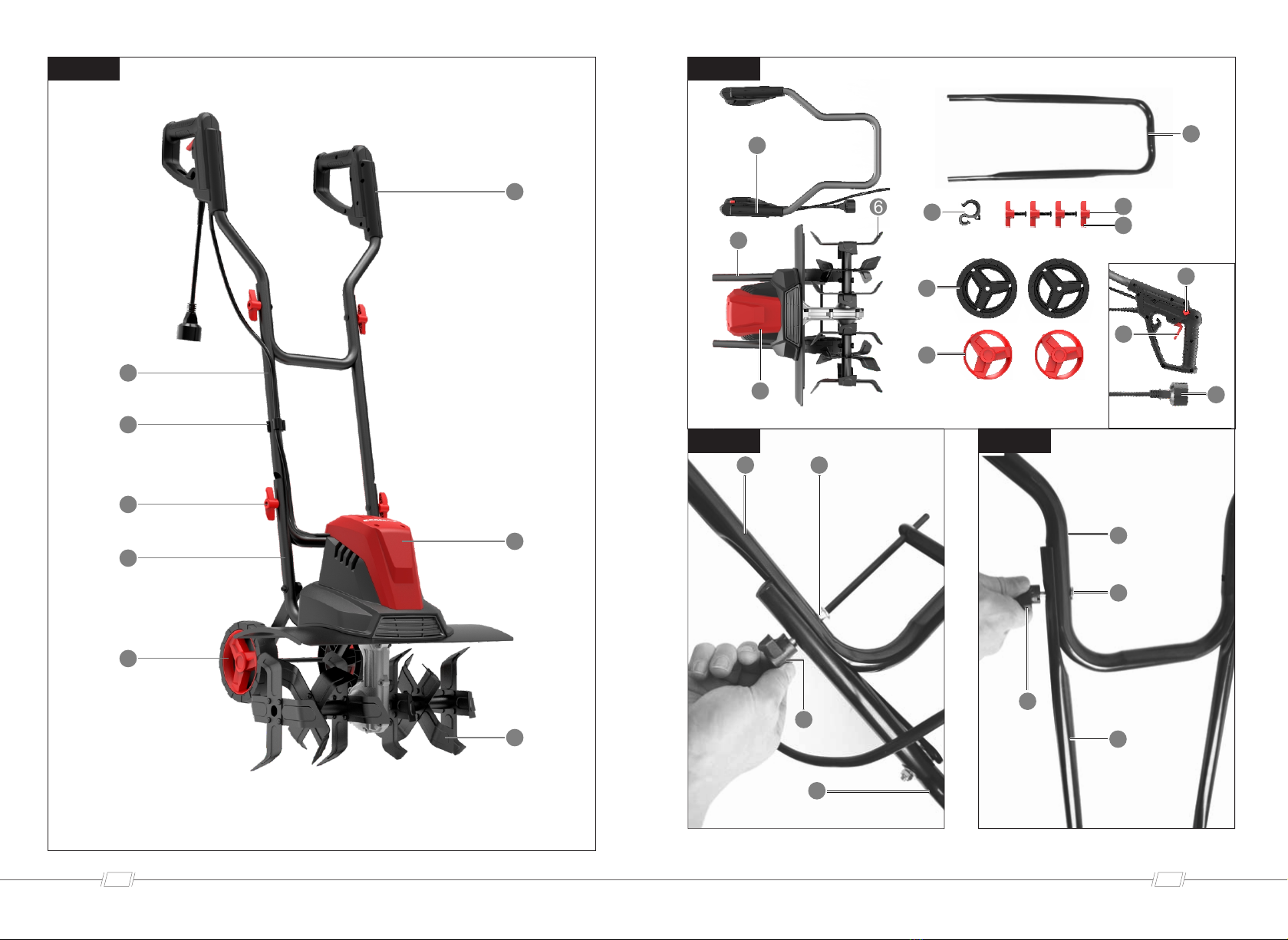

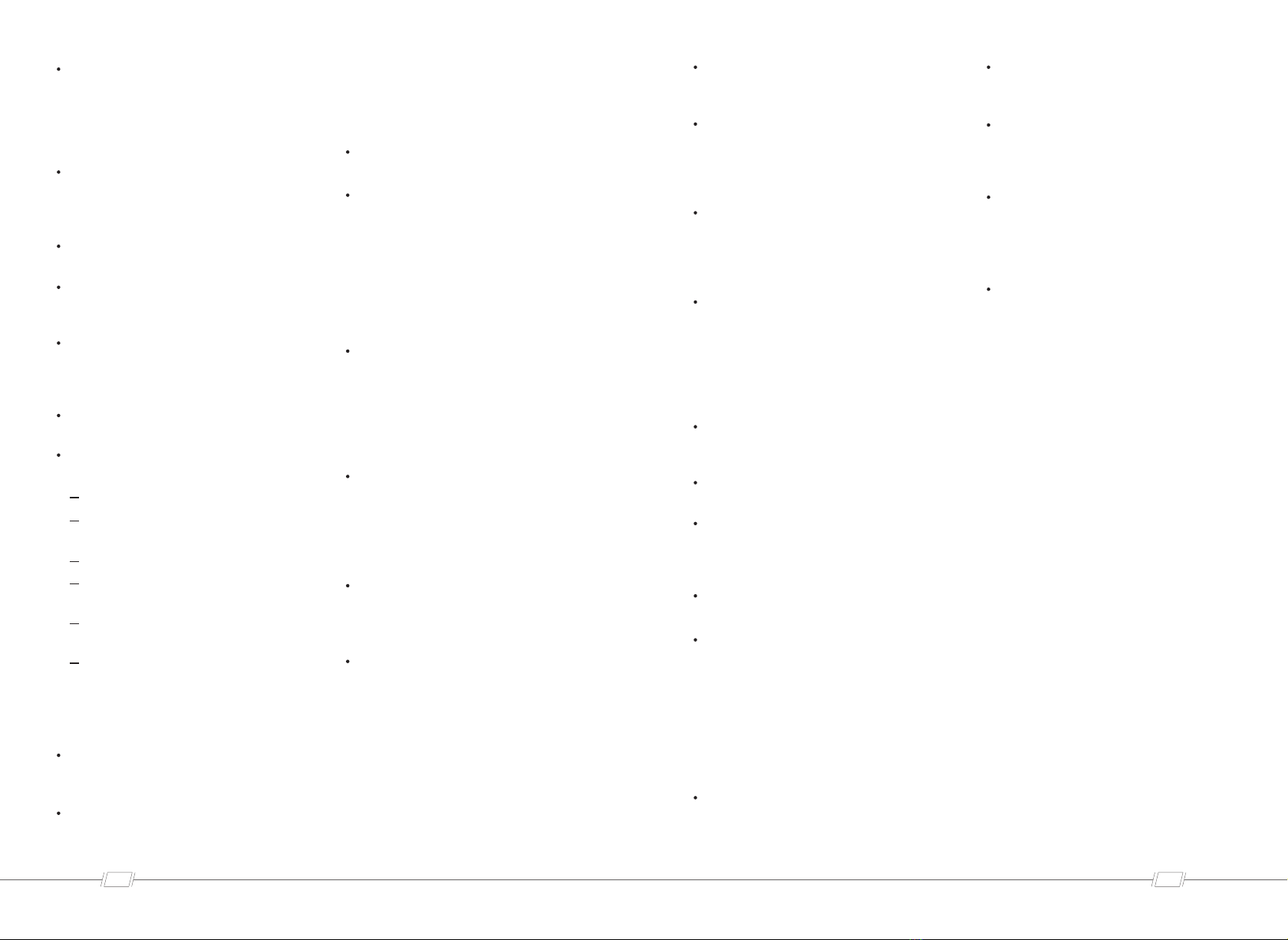

Fig.1

3

11

9

4

7

6

5

1

3

3 9

1

9

10

3

4

10

FEATURES

5

4

6

12

13

2

1

7

8

9

10

11

Fig.2

Fig.3 Fig.4

03

https://www.altonindustries.com

04

info@altonindustries.com

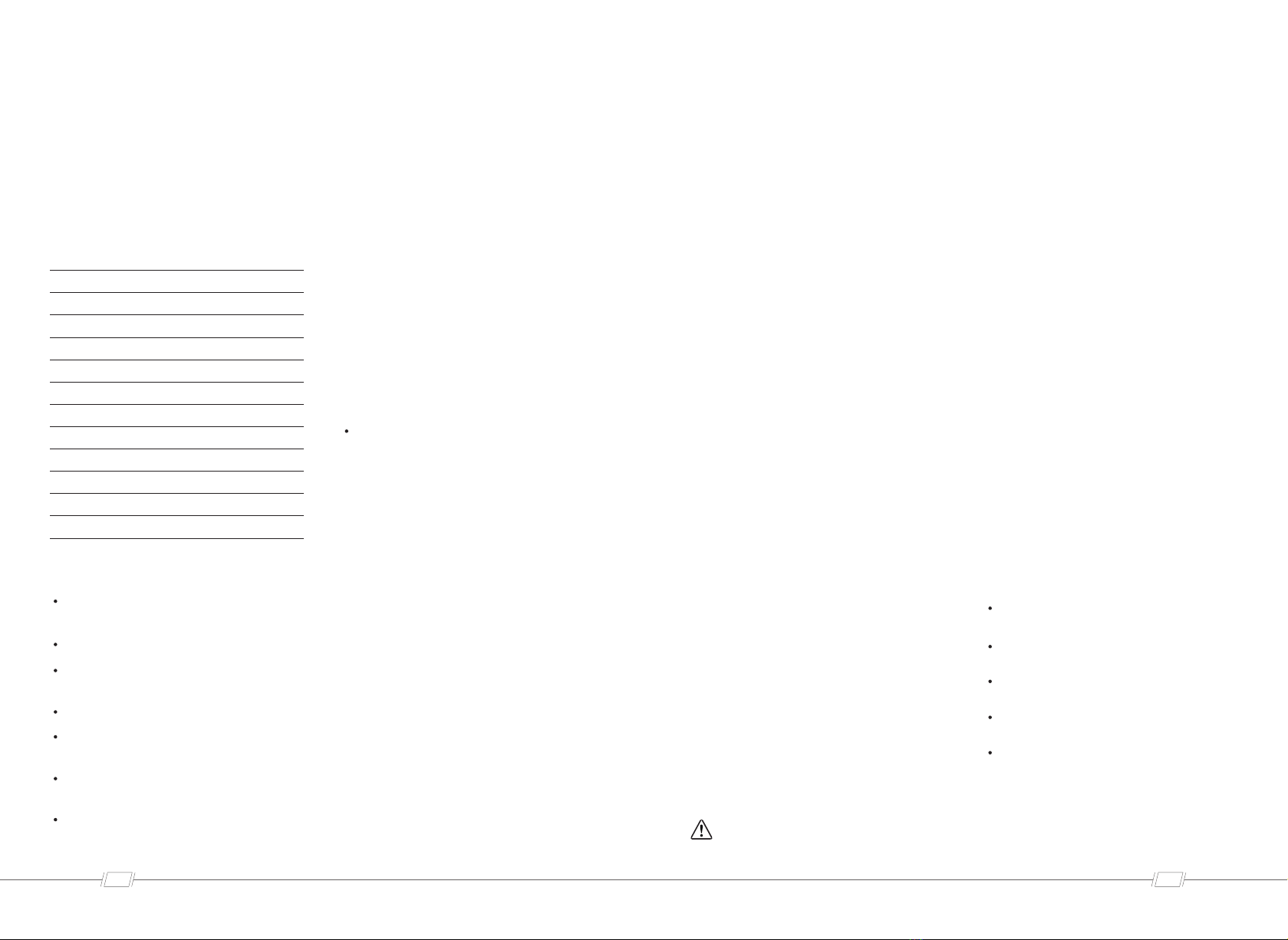

3

1

15

16

14

17

8

7

7

17

7

12

13

2

11

3

4

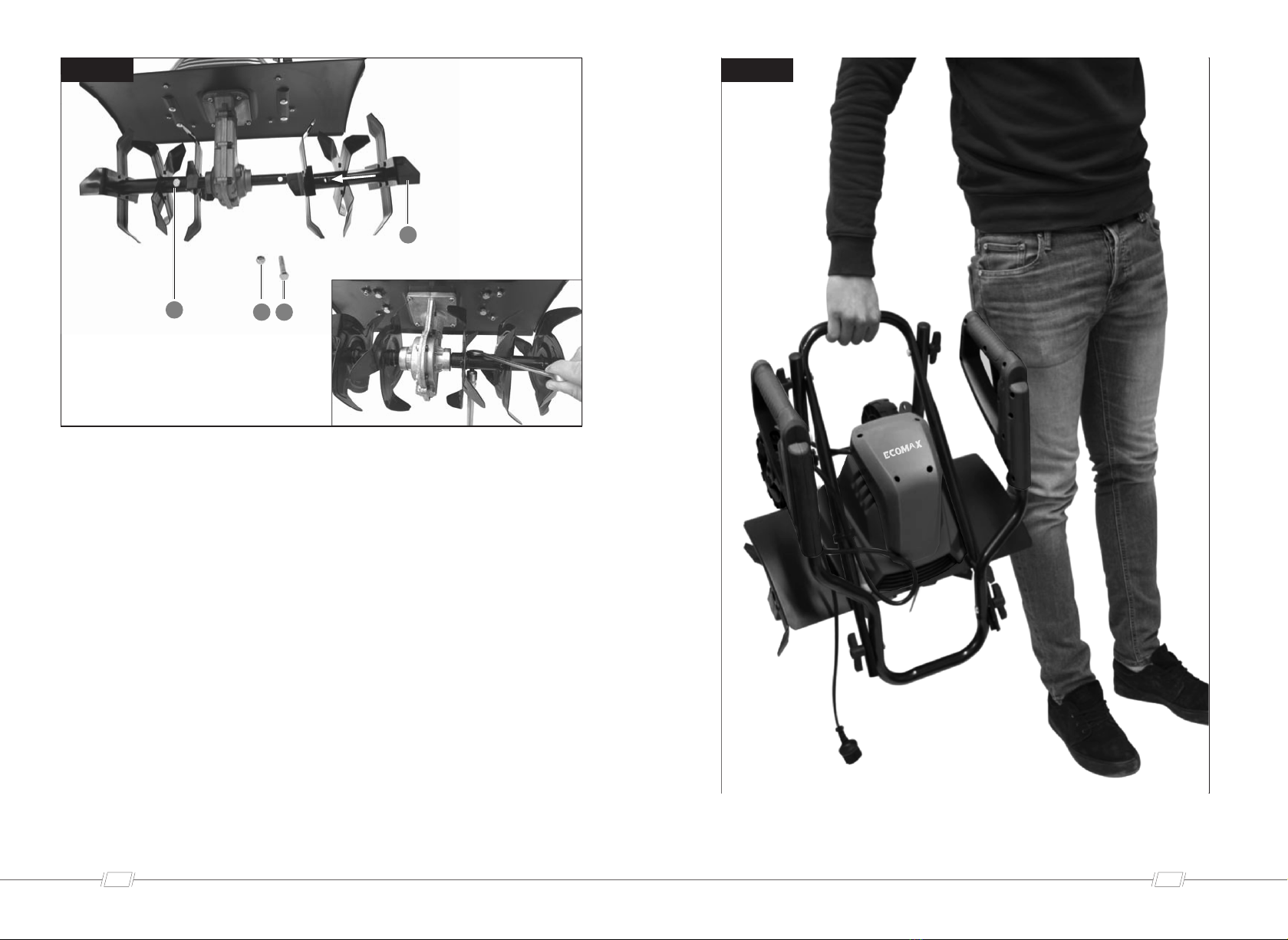

Fig.5 Fig.6

Fig.7 Fig.8

Fig.9

Fig.10

20 19 18

6

05

https://www.altonindustries.com

06

info@altonindustries.com

Fig.12Fig.11

07

https://www.altonindustries.com

08

info@altonindustries.com

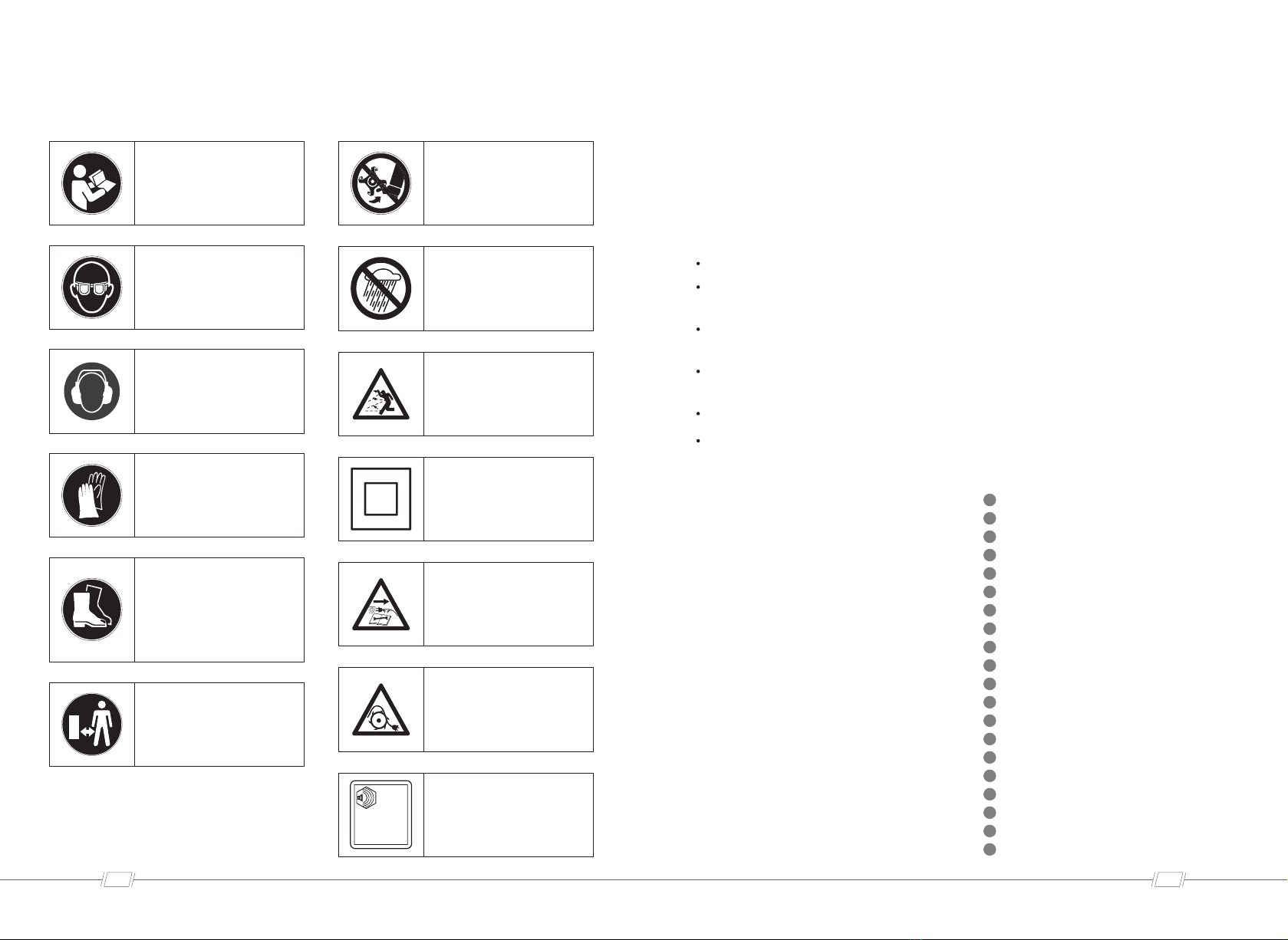

EXPLANATION OF THE SYMBOLS ON

THE EQUIPMENT

Read instruction manual

and safety instructions

before starting up and

pay attention!

Wear safety goggles!

Wear ear-muffs!

Wear work gloves!

Make sure that other

persons maintain a

sufficient safety distance.

Keep uninvolved persons

away from the device.

93dB

L WA

Attention! Do not touch

rotating parts.There is a

serious risk of injury!

Attention! Do not touch

rotating parts.There is a

serious risk of injury!

Don't use your device in

moisty weather.

Risk of catapulted parts

if the engine is running.

Be sure to keep a safe

distance.

Protection class ll

Switch off and unplug

the device before

cleaning or performing

maintenance on it.

Attention! Power cord

can be pulled in.Keep

the power cord away

from the cutting roll-ers.

Guaranteed sound

power level

1. INTRODUCTION

Dear Customer,

we hope your new tool brings you much

enjoymentand success.

Note:

According to the applicable product liability

laws, the manufacturer of the device does not

assume liability for damages to the product or

damages caused by the product that occurs

due to:

Improper handling,

Non-compliance of the operating

instructions,

Repairs by third parties, not by authorized

service technicians,

lnstallation and replacement of non-

original spare parts,

Application other than specified,

A breakdown of the electrical system that

occurs due to the non-compliance of the

electric regu-lations and VDE regulations

0100,DIN 57113 / VDE0113.

WE RECOMMEND:

Read through the complete text in the

operating in-structions before installing and

commissioning the device.

The operating instructions are intended to

help the user to become familiar with the

machine and take advantage of its application

possibilities in accord-ance with the

recommendations.

The operating instructions contain important

infor-mation on how to operate the machine

safely, pro-fessionally and economically, how

to avoid danger, costly repairs, reduce

downtimes and how to in-crease reliability

and service life of the machine.

In addition to the safety regulations in the

operating instructions, you have to meet the

applicable regula-tions that apply for the

operation of the machine in your country.

Keep the operating instructions package with

the machine at all times and store it in a

plastic cover to protect it from dirt and

moisture.

Read the instruction manual each time

before oper-ating the machine and carefully

follow its information. The machine can only

be operated by persons who were instructed

concerning the operation of the ma-chine

and who are informed about the associated

dangers. The minimum age requirement

must be complied with.

ln addition to the safety notices contained in

this operating manual and the particular

instructions for your country, the generally

recognised technical reg-ulations for the

operation of identical devices must be

complied with.

We cannot accept any liability for damage or

acci-dents which arise due to a failure to

follow these in-structions and the safety

instructions.

2. DEVICE DESCRIPTION

Handle

Power cord

Frame tubing

lower bar

Machine frame

Blade roller

Wheel

wheel cap

Carriage bolt

Wing nut (plactic)

Cable clip

Safety release catch

On / Off switch

Wheel suspension

washer (pre-assembled)

Split pin (pre-assembled)

Lock pin

Screw M8

Nut M8

Drive shaft

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

09

https://www.altonindustries.com

10

info@altonindustries.com

3. SCOPE OF DELIVERY

1x Handle

1x Machine frame

1x Frame tubing

4x Carriage bolt

4x Wing nut (plactic)

2x Cable clip

2x Wheel

2x Wheel cap

1x Manual

Open the packaging and remove the

device care-fully.

Remove the packaging material as well as

the packaging and transport bracing (if

available).

Check that the delivery is complete.

Check the device and accessory parts for

trans-port damage. lf there is any damage,

please contact customer service in time

and we will provide you with a satisfactory

solution.

lf possible, store the packaging until the

warranty period has expired.

ATTENTION!

The device and packaging materials are not

toys! Children must not be allowed to play

with plastic bags, film and small parts!

There is a risk of swal-lowing and

suffocation!

4. INTENDED USE

lf possible, store the packaging until the

warranty period has expired.

The equipment is allowed to be used only for

its pre-scribed purpose. Any other use is

deemed to be a case of misuse. The

user/operator and not the man-ufacturer will

be liable for any damage or injuries of any

kind resulting from such misuse.

Please note that our equipment has not been

de-signed for use in commercial, trade or

industrial ap-plications.

Our warranty will be voided if the equipment

is used in commercial, trade or industrial

businesses or for equivalent purposes.

5.SAFETY INFORMATION

General safety instructions

This implement can cause serious injuries if it

is not properly used. Please read these

Operating Instruc-tions carefully and

familiarize yourself with all the control

elements before operating this implement.

Keep these Operating Instructions in a readily

ac-cessible place so that this information is

always at your disposal.

Operating the implement:

WARNING! The implement can cause

serious inju-ries. How to a avoid accidents

and injuries:

Preparations:

Never allow children and people who are

not fa-miliar with these Operating

Instructions to use the i mplement. Local

regulations may stipulate a mini-mum age

for operators.

This appliance is not intended for use by

persons(including children) with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge, unless

they have been given supervi-sion or

instruction concerning use of the appliance

by a person responsible for their safety.

Never start up the implement while other

people, but especially children and

domestic pets, are in the vicinity.

Check the area on which the implement is

to be used. Remove all stones, sticks, wire

and other for-eign bodies that could be

caught up and flung out.

Always wear appropriate protective work

clothes and firm shoes with nonslip soles,

strong long trou-sers, ear defenders and

goggles. Never operate the implement while

bare footed or when wearing open sandals.

Never operate the implement if it is damaged,

in-complete or has been modified without

the consent of the manufacturer. Never work

with damaged or missing protective devices

(e.g. starting lever, un-locking knob, impact

protector).

Never disengage protective devices (e.g. by

tying the starting lever).

Children must be supervised in order to

ensure that they do not play with the

equipment.

Before starting the equipment, ensure that no

ob-jects or branches are pushed into the

blade open-ing, that the equipment is

standing stably and that the workspace is tidy

and not blocked. Check the condition of your

extension cable and the connect-ing cable of

your equipment. Use the necessary protective

equipment.

lf your equipment vibrates or emits unusual

noises w hen switched on, disconnect the

plug from the socket and check the cutting

cylinder. Ensure that no remains of chopped

matter are blocking the c utting cylinder or

jammed between the blades. lf you still didn't

find the problem after checking these, return

the equipment to a customer service centre.

lf the blades no longer dig correctly or if the

motor is overloaded, check all the parts of

your equipment and replace the worn parts. lf

a more extensive re-pair is required, contact a

customer service centre.

Use:

CAUTION - A very sharp tool. Avoid

cutting your fi ngers or toes. While working

always keep your feet and fingers well

away from the cutting cylinder a n d t h e

ejector opening. There is the danger of

serious injury!

Do not operate the implement while it is

raining, in p oor weather conditions and

when the surround-ing area and lawn are

wet. Operate the implement o nly during

daylight hours or with bright lighting.

Do not operate the implement if you are

tired or are lacking in concentration and

after having d runk alcohol or taken

medicine. Always take a work break in due

time. Approach the work with common

sense.

Familiarize yourself with the terrain and

remain focused on the potential hazards

that you could miss on account of the

motor noise.

Always maintain a secure footing while

working, especially on a slope, never up

and down! Be particularly careful when

changing the travelling direction. Do not

work on very steep slopes.

Always guide the implement at a walking

pace with both hands on the handle. Be

especially careful when you turn the

implement around or draw it towards you.

Danger of stumbling!

Start or actuate the starting lever with care

and in conformity with the directions in

these lnstructions.

Do not tilt the implement when starting,

other than it has to be lifted. In this case tilt

the implement only to the extent that is

absolutely necessary and always lift the

implement on the side that is oppo-site to

the operator.

1

5

3

9

10

11

7

8

11

https://www.altonindustries.com

12

info@altonindustries.com

Do not operate the implement in the

vicinity of in-flammable liquids or gases

as this could give rise to the danger of a

fire or explosion.

Work intervals:

After the implement has been turned off,

the cutting cylinder will continue to rotate

for a few seconds. Keep hands and feet

well away.

Only shift working depth when the

implement is completely still standing.

Only remove plant parts and soil when

the imple-ment is standing completely

still.

Switch off the power when the

implement is to be transported, lifted or

tilted and when traversing other surfaces

than soil.

Never leave the implement unattended

at the place of work.

Always switch off the implement and

disconnect the power plug:

Whenever you leave the implement

Before you clean the ejector opening

or unblock or unclog the implement

When the implement is not being used

During all maintenance and cleaning

work

When the power cable is damaged or

has become tangled

When the implement hits an

obstruction during work or when

unusual vibrations arise. Establish the

cause and see if the implement has

been damaged.

Do not repair it yourself! Have the

implement re-paired by an authorised

workshop!

Store the implement in a dry place well

out of reach of children.

CAUTION! The following states how to avoid

damage to the implement and any resulting

harm to people:

Take care of your implement

Switch off the power when the implement

is to be carried across steps.

lnspect the implement each time before it

is to be used. Never operate the

implement if safety de-vices (e.g. impact

protector, parts of the cutting facility or

bolts are missing, worn out or damaged.

Check especially the power cable and

starting lever for damage. To avoid

imbalance, all tools and bolts must be

exchanged as complete sets.

Only use spare parts and accessories that

have been supplied or recommended by

the manufactur-er. The use of alien parts

results in the immediate loss of all

guarantee claims. Ensure that all nuts, bolts

and screws are firmly tightened and that

the implement is in a safe working state.

Never try to repair the implement yourself,

other than you have been trained

accordingly. All work that has not been

listed in these Instructions must only be

carried out by authorised servicing agen-

cies.

Treat the implement with the greatest care.

Always keep the tool clean for better and

safer work. Follow the maintenance

instructions.

Never overload the implement. Always

work within the specified capacity range.

Do not use low-power machines for

heavy-duty work. Do not operate the

implement for purposes for which it is not

intended.

Electrical safety:

CAUTION! The following states how to

avoid acci-dents and injuries due to electric

shock:

Before each use, carry out a visual

inspection of the power and extension

cables for signs of dam-age or ageing.

lf the power cable for this equipment is

damaged, it must be replaced by the

manufacturer, a customer service agent of

the same or a similarly qualified person in

order to prevent hazards.

Keep the power cable well away from the

cutting tools. Should the power cable

become damaged during work, then

instantly disconnect the power cable from

the mains.

Keep the power cable well away from the

cutting tools. Should the power cable

become damaged during work, then

instantly disconnect the power cable from

the mains.

DO NOT touch the power cable before it

has been disconnected from the mains.

Keep the extension cables away from the

teeth. The teeth may damage the cables

and result in contact with live parts.

Check that the mains voltage is the same

as indi-cated on the rating plate.

Wherever possible connect the implement

to a power socket with a residual- current

circuit break-er that has a rated current of

not more than 30 mA.

Avoid body contact with earthed parts (e.g.

metal fences, metal posts).

Only use approved extension cables of the

type HO5VV-F or H05RN-F with a

maximum length of 75 m and which have

been approved for open-airuse.The

stranded cord diameter of the extension

cable must be at least 2.5 mm2. Always

unreel a cable drum to its full length so that

the entire cable can be checked for

damage.

Use the envisaged cable suspension when

attach-ing an extension cable.

Never pull the cable to disconnect the

plug from the socket. Protect the cable

from heat, oil and sharp edges.

lf the connecting cable is damaged, first

disconnect the extension cable from the

socket. You can then disconnect the

connecting cable of the equipment.

lf the power cable for this equipment is

damaged, it must be replaced by the

manufacturer, a customer service agent of

the same or a similarly qualified person in

order to prevent hazards.

lf the power cable for this equipment is

damaged, it must be replaced by the

manufacturer, a customer service agent of

the same or a similarly qualified person in

order to prevent hazards.

Residual risks

Even if you use this electric power tool in

ac-cordance with instructions, certain

residual risks cannot be ruled out. The

following hazards may arise in connection

with the equipment's con-struction and

layout:

1.Damage to hearing if no suitable ear

protection is used.

2.Health damage caused by hand-arm

vibrations if the equipment is used over a

prolonged period or is not properly guided

and maintained.

3.Even when all safety measures are taken,

some remaining hazards which are not yet

evident may still be present.

4.Remaining hazards can be minimized by

follow-ing the instructions in Safety

Precautions, Proper Use and in the entire

operating manual.

5.lnjuries caused by the rotating blade.

6.Health risks caused by electricity. When

incor-rect or damaged mains cables are

used. Follows instructions in the manual

Electrical Connections.

13

https://www.altonindustries.com

14

info@altonindustries.com

Warning! This electric tool generates an

electro-magnetic field during operation. This

field can impair active or passive medical

implants under certain conditions. In order to

prevent the risk of serious or deadly injuries,

we recommend that persons with medical

implants consult with their physician and the

manufacturer of the medical implant prior to

operating the electric tool.

6. TECHNICAL DATA

Main Voltage

Power Input

Working width

Working depth

L sound pressure

PA

L level, uncertainty

PA

L sound power level

PA

K uncertainty

PA

Vibration left hand

Vibration right hand

K uncertainty

Protection class

Protection type

120V/ 60Hz

13.5A

450mm(17.7")

max.220mm(8.7")

80,4 dB(A)

3 dB(A)

91,57 dB(A)

1,28 dB(A)

2

0,968 m/s

2

0,947 m/s

2

1,5 m/s

ll

lPX4

Keep the noise emissions and vibrations to

a minimum.

Only use appliances which are in perfect

work-ing order.

Service and clean the appliance regularly.

Adapt your working style to suit the

appliance.

Do not overload the appliance.

Have the appliance serviced whenever

necessary.

Switch the appliance off when it is not in

use.

Wear protective gloves.

7. BEFORE STARTING THE

EQUIPMENT

Before you connect the equipment to the

mains sup-ply make sure that the data on the

rating plate are identical to the mains data.

Warning!

Always pull the power plug before making

ad-justments to the equipment.

The Electric Tiller is delivered unassembled.

The handles and the driving device must be

assembled and mounted before using the

Electric Tiller. Follow the operating instructions

step-by-step and use the pictures provided as

a visual guide to easily assemble the machine.

Montage (fig.3-9)

lmportant !

You must fully assemble the appliance

before using it for the first time!

Connect the bar (3) and the handle (1) to

the lower bars (4) using the wing nut (10)

and lock screw (9).(fig.3,4)

Laying the power cord (fig. 5,6)

Mount the cable and the cable guide (11) on

the low-er right bar (4) and (in the working

direction) bar (3)by pushing them on.

Install the transport aid (fig. 8,9)

Remove the pre-assembled split pin (16) and

the washer (15).Place the wheel (7) on the

wheel holder (14).Secure it with the washer

(15) and the split pin(16). Then mount the

wheel cap (8).(Assembly is identical on both

sides)

Blade roller installing / uninstalling (fig. 11)

Push the blade roller (6) on the drive shaft (20)

of the machine. The blade roller (6) can be

mounted left or right side. Be sure that the

holes of the blade roller (6) and the drive

shaft(20) are aligned.

Now the M8 screw (18) is pushed through

and se-cured with the M8 locking nut (19).

Tighten the lock nut (19) hand-tight using a

fork wrench or ratchet with socket (the tools

are not in-cluded).

For uninstall: Proceed in reverse order.

8. OPERATION

Start and stop the implement (fig.7)

To prevent an accidental start-up of the

implement, the throttle handle (1) is equipped

with a safety re-lease switch (12) which must

be pressed before the On/Off switch (13) can

be pressed. lf the On/Off switch (13) is

released, the equipment switches off. Repeat

this process several times so that you are sure

that the machine functions properly. Before

you perform any repair or maintenance work

on the ma-chine, ensure that the cutting unit

is not rotating and that the power supply is

disconnected. Always ensure that a safe

distance (provided by the long handles) is

maintained between the user and the

housing.

The safety distance between housing and

user given by the handle (1) must always be

observed. Be espe-cially careful when digging

and changing direction on slopes and inclines.

Maintain a solid footing and wear sturdy, non-

slip footwear and long trousers. Always dig

along the in-cline (not up and down). For

safety reasons, the Elec-tric Tiller may not be

used to dig up inclines whose gradient

exceeds 15 degrees. Use special caution when

backing up and pulling the implement

(tripping hazard)!

Tips for proper working

Always guide the machine slowly and wisely

forward. Dig up the area in straight lines. Let

the tracks overlap slightly to not miss any

stripes to dig. Only use the machine to dig up

already loosened soil.

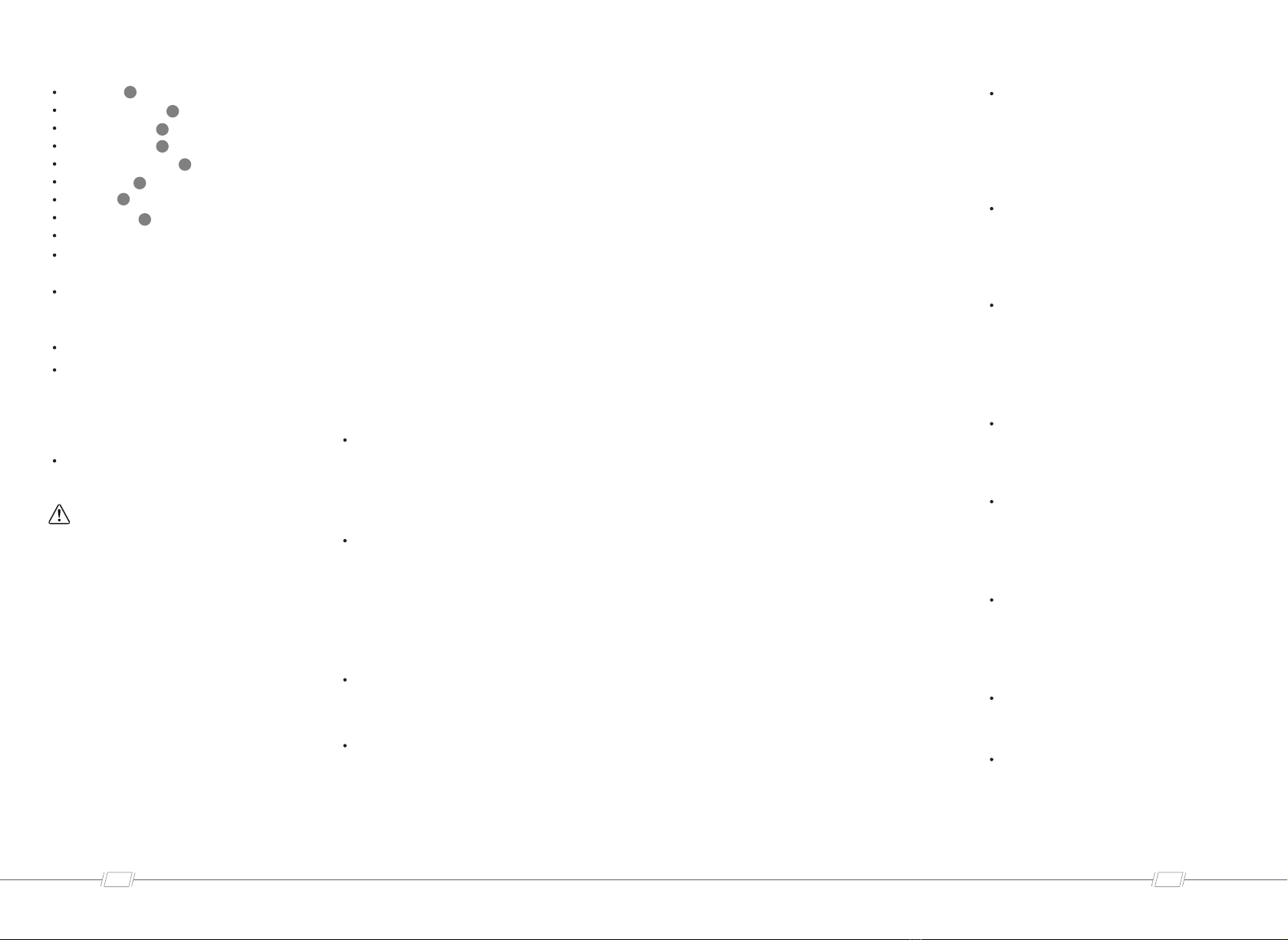

Transport and storage (fig. 10,12)

Always pull out the power cord before

transporting! Pull the lock pin (17). You can

now move the wheels(7) to the lower

position. Make sure that the lock pin(17 )

engages again in the lower position. (fig.10)

ATTENTION! The wheels must be fixed

in the upper position during operation!

For storage or transport in a limited space,

proceed as follows:

Open the wing nuts (10) until you can fold

the handles forward. Attention! Danger of

crushing your fingers. Now you can

transport your machine with the trans-port

handle (3).

So you can storage the machine too.

For storage or transport in a limited space,

proceed as follows:

Open the wing nuts (10) until you can fold

the handles forward. Attention! Danger of

crushing your fingers. Now you can

transport your machine with the trans-port

handle (3).

So you can storage the machine too.

9. ELECTRICAL CONNECTION

The electrical motor installed is connected

and ready for operation. The connection

complies with the applicable VDE and DIN

provisions. The customer's mains

connection as well as the extension cable

used must also comply with these

regulations.

Damaged electrical connection cable

The insulation on electrical connection cables

is of-ten damaged.

This may have the following causes:

Passage points, where connection cables

are passed through windows or doors.

Kinks where the connection cable has

been im-properly fastened or routed.

Places where the connection cables have

been cut due to being driven over.

Insulation damage due to being ripped

out of the wall outlet.

Cracks due to the insulation ageing.

Such damaged electrical connection cables

must not be used and are life-threatening

due to the insula-tion damage.

15

https://www.altonindustries.com

Check the electrical connection cables for

damage regularly. Make sure that the

connection cable does not hang on the

power network during the inspection.

Electrical connection cables must comply with

the applicable VDE and DIN provisions. Only

use con-nection cables with the marking

“H05VV-F”.

The printing of the type designation on the

connec-tion cable is mandatory.

AC motor

The mains voltage must be 120V/60Hz

Extension cables up to 25 m in length

must have a cross section of at least 1,5

2 2

mm , above 25 m at least 2,5 mm

The mains connection is protected with a

16 A slow-blow fuse.

Connections and repairs of electrical

equipment may only be carried out by an

electrician.

Please provide the following information in

the event of any enquiries:

Type of current for the motor.

Machine data - type plate.

Motor data - type plate

10.CLEANING AND

MAINTENANCE

Danger!

Always pull out the mains power plug before

starting any cleaning work.

Keep all safety devices, air vents and the

motor housing free of dirt and dust as far

as possible. Wipe the equipment with a

clean cloth or blow it with compressed air

at low pressure.

We recommend that you clean the device

immediately each time you have finished

using it.

Cleaning

Clean the equipment regularly with a

moist cloth and some soft soap. Do not

use cleaning agents or solvents; these

could attack the plastic parts of the

equipment. Ensure that no water can seep

into the device. The ingress of water into

an electric tool increases the risk of an

electric shock.

ln case of excessive sparking, have the

carbon brushes checked only by a qualified

electrician.

Carbon brushes

Danger! The carbon brushes should not be

replaced by anyone but a qualified

electrician.

Maintenance

A worn out or damaged cutting unit

should be re-placed by an authorised

expert.

Take care that all fastening elements

(screws, nuts, etc. ) are firmly tightened, so

that you can work safely with the Electric

Tiller.

Store the Electric Tiller in a dry place.

For longer life, all screw-fastened parts,

such as wheels and axles should be

cleaned and subse-quently oiled.

Regular servicing of the implement not

only se-cures longer endurance and

performance, it also contributes to an

accurate and simple dig up of your bed.

At the end of the season, carry out a

general check of the Electric Tiller, and

remove all residue col-lected. Before the

start of every season, it is ab-solutely

necessary to check the state of the ma-

chine.Contact our Customer Service if

repair work is necessary.

11.STORAGE

Store the device and its accessories in a dark,

dry and frost-proof place that is inaccessible

to children. The optimum storage

temperature is between 5 and 30℃.

16

info@altonindustries.com

Store the electrical tool in its original

packaging.

Cover the electrical tool in order to protect it

from dust and moisture. Store the operating

manual with the electrical tool.

12.DISPOSAL AND RECYCLING

The equipment is supplied in packaging to

prevent it from being damaged in transit. The

raw materials in this packaging can be reused

or recycled. The equip-ment and its

accessories are made of various types of

material, such as metal and plastic. Defective

components must be disposed of as special

waste. Ask your dealer or your local council.

Old devices must not be disposed of with

house-hold waste!

This symbol indicates that this product

must not be disposed of together with

domestic waste in compliance with the

Directive(2012/19/EU) pertaining to waste

electrical and electronic equipment (WEEE).

This product must be disposed of at a

designated collection point. This can occur, for

example, by handing it in at an author-ised

collecting point for the recycling of waste

elec-trical and electronic equipment. Improper

handling of waste equipment may have

negative consequences for the environment

and human health due to po-tentially

hazardous substances that are often con-

tained in electrical and electronic equipment.

By properly disposing of this product, you are

also con-tributing to the effective use of

natural resources. You can obtain information

on collection points for waste equipment

from your municipal administration, public

waste disposal authority, an authorised body

for the disposal of waste electrical and

electronic equipment or your waste disposal

company.

13.SPARE-PART ORDERING

Please quote the following in your order for

spare parts:

Type of device

Article No. of deviceldent. No. of device

Spare Part No. of the required spare part

Service information

Please note that the following parts of this

product are subject to normal or natural

wear and that the fol-lowing parts are

therefore also required for use as

consumables.

wear parts*: Brush Assemblies, Blade Roller

*Not necessarily included in the scope of

delivery!

17

https://www.altonindustries.com

14.TROUBLE SHOOTING GUIDE

Possible causes Fault Rectification

Motor does not start No electricity in plug

Cable defective

Switch, switch/plug block

defective

Connections to motor or

capacitor disconnected

Blade roller blocked

Check line and fuse

Have machine checked by a

customer service center

Have machine checked by a

customer service center

Have machine checked by a

customer service center

lf necessary adjust working depth.

Clean housing so that the roller can

run freely

Engine performance

drops

Gearing defective By customer service workshop

Soil is too firm

Carbonbrushes worn out

Roller badly worn

Change working depth

Check by a customer service center

Replace roller

roller worn

Wrong working depth

Replace roller

Correct working depth

The Electric Tiller is

difficult to check.

Motor is running,

roller is not rotating

WARRANTY

ALTON INDUSTRY LTD. GROUP

2 YEAR LIMITED WARRANTY

This warranty covers any defects in materials or workmanship of the enclosed

product. Alton Industry Ltd. Group will repair or replace any defective

materials due to craftsmanship of the product. This warranty does not cover

any problem caused by misuse, abuse, accidents or acts of God, such as

floods or hurricanes. Consequential and incidental damages are not covered

under this warranty. Coverage terminates if you sell or otherwise transfer the

ownership. If you feel you have a defective product, please submit a copy of

your receipt to the address below and call 1-888-899-0146 for instructions

prior returning this item to the store or sending back to:

Alton Industry Ltd. Group

643 Innovation Drive

West Chicago, IL 60185

We will inspect the product and contact you within 72 hours to give you the

results of our inspection. We reserve the right to repair or replace the product

at our discretion. However, we may replace the product with one of similar

but not exact features. Parts and Service Information available call Alton

Industry at 1-888-899-0146. This warranty gives you specific legal rights. You

may have other rights which vary from state to state.

18

info@altonindustries.com

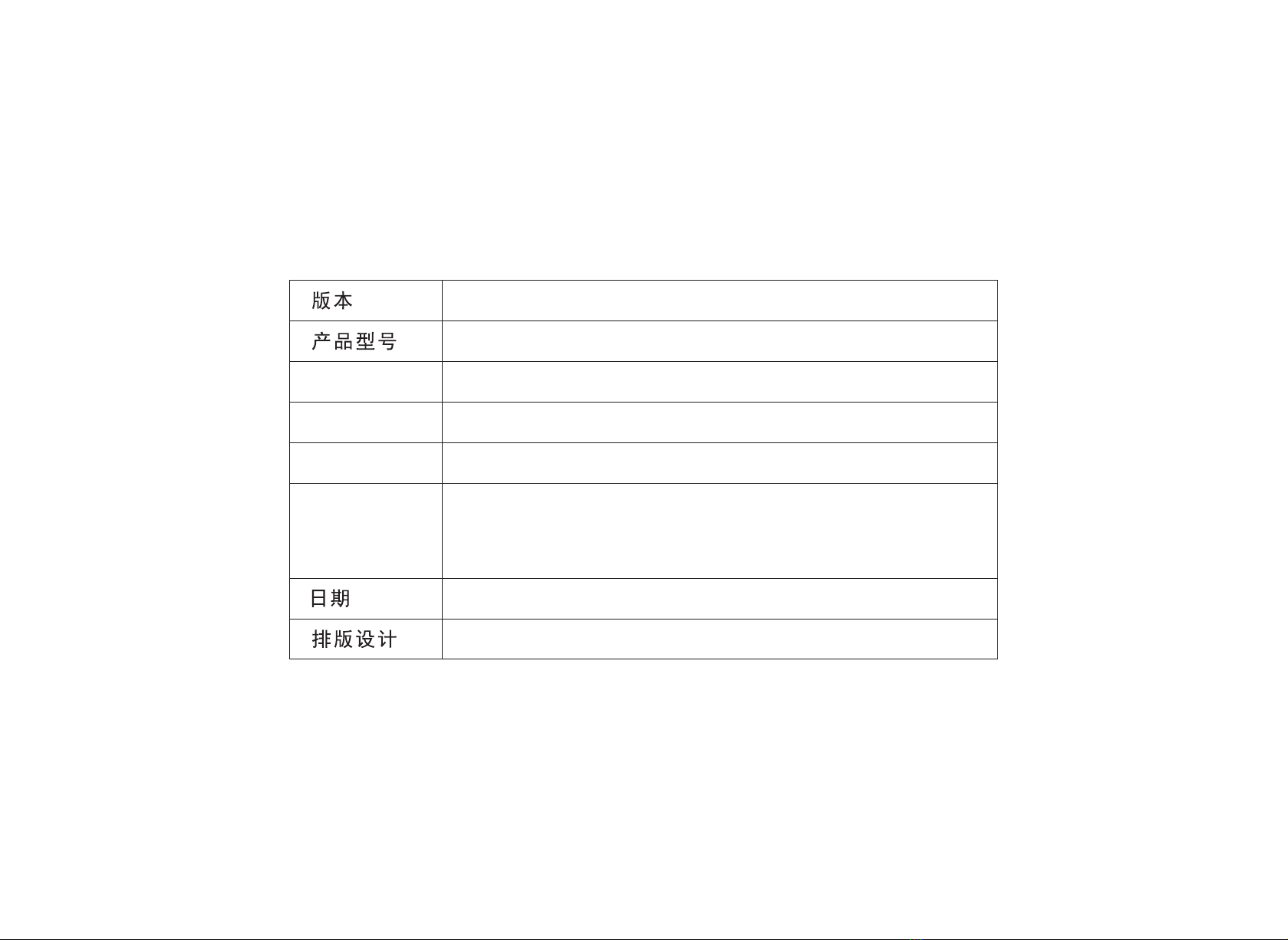

印刷要求

使用说明书-1.0

ELG02

ECOMAX

2022-02-23

Allen

157铜版纸

145X210(h)mm尺寸

材质

品牌

单黑双面印刷

骑马装订

Table of contents