Metal-Fach SE Operator's manual

Technical and operational documentation

SE

Original instructions, issue 08/2021

English

1

INTRODUCTION

Dear customer, thank you for purchasing METAL-FACH heating boiler. We hope that the operation of the device will meet your expectations and provide much satisfaction. The heating

boiler has been designed and manufactured in accordance with applicable norms and standards, which guarantee safe and reliable operation. Operation with strict observance of the recommendations

included in the manual attached to the device will ensure optimal and reliable operation of the central heating boiler for many years.

The product is not intended for use by persons with reduced physical / mental capabilities or lack of experience and knowledge, if these persons are supervised or instructed by a person responsible for

their safety. Operation by children is prohibited.

2

Table of Contents:

1. Introductory acts................................................................................................................3

2. Informative pictograms .....................................................................................................3

3. Symbols used in the manual.............................................................................................3

4. Definition of terms used in this manual ..........................................................................3

5. General information ..........................................................................................................4

6. Boiler equipment ...............................................................................................................4

7. Application ..........................................................................................................................4

8. Basic elements of boiler construction..............................................................................4

9. Basic dimensions of SE boilers .........................................................................................7

10. Technical data of SE boilers ..............................................................................................9

11. Fuel ....................................................................................................................................10

12. Requirements for the boiler house and boiler installation..........................................10

13. Boiler installation .............................................................................................................11

14. Boiler connection to the heating system.......................................................................12

15. Requirements for the expansion vessel ........................................................................14

16. Boiler connection to the electrical installation..............................................................14

17. Connection of boiler to chimney ....................................................................................14

18. Commissioning the boiler ...............................................................................................15

19. When using the boiler, remember .................................................................................15

20. Cleaning and maintenance of the boiler .......................................................................16

21. Instructions for disposal of the boiler at the end of its service life.............................16

22. Examples of equipment failure ......................................................................................16

Warranty conditions 19

Confirmation of inspection, warranty repair, service: 21

EC/EU Declaration of Conformity 23

Warranty card for steel boilers, central heating water boilers 25

Boiler complaint notification 27

Report on the first start-up of the boiler 29

Report on the first start-up of the boiler 31

Table of Tables:

Table 2.1 Pictograms 3

Table 6.1 Boiler accessories 4

Table 9.1 Boiler dimensions (mm) SE 60 - 350 8

Table 10.1 Technical data for boiler SE 60-350 9

Table 13.1 Flammability of building masses and materials 11

Table 14.1 Designations used in the diagrams 12

Table 14.2 Designations used in the diagrams 12

Table 14.3 Designations used in the diagrams 13

List of Figures:

Figure 1.1 Nameplate 3

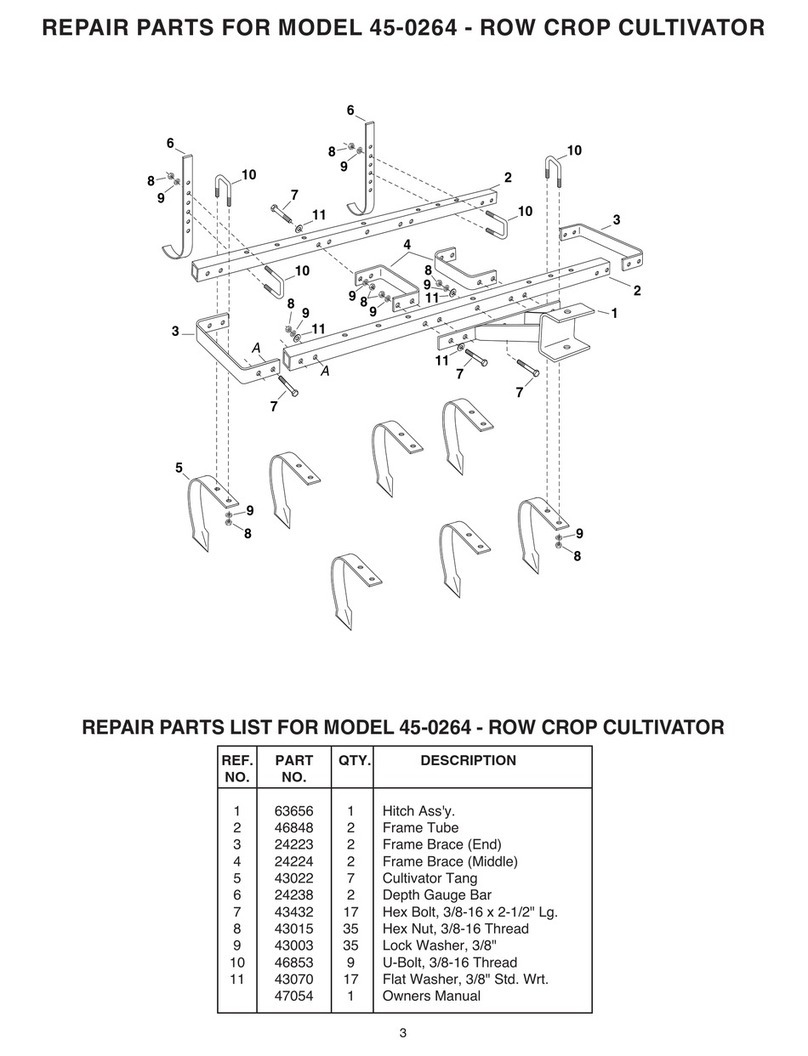

Figure 8.1 Basic components of the SE 60 boilers 5

Figure 8.2 Basic components of the SE 75 boilers 5

Figure 8.3 Basic components of the SE 120 - 250 boilers 6

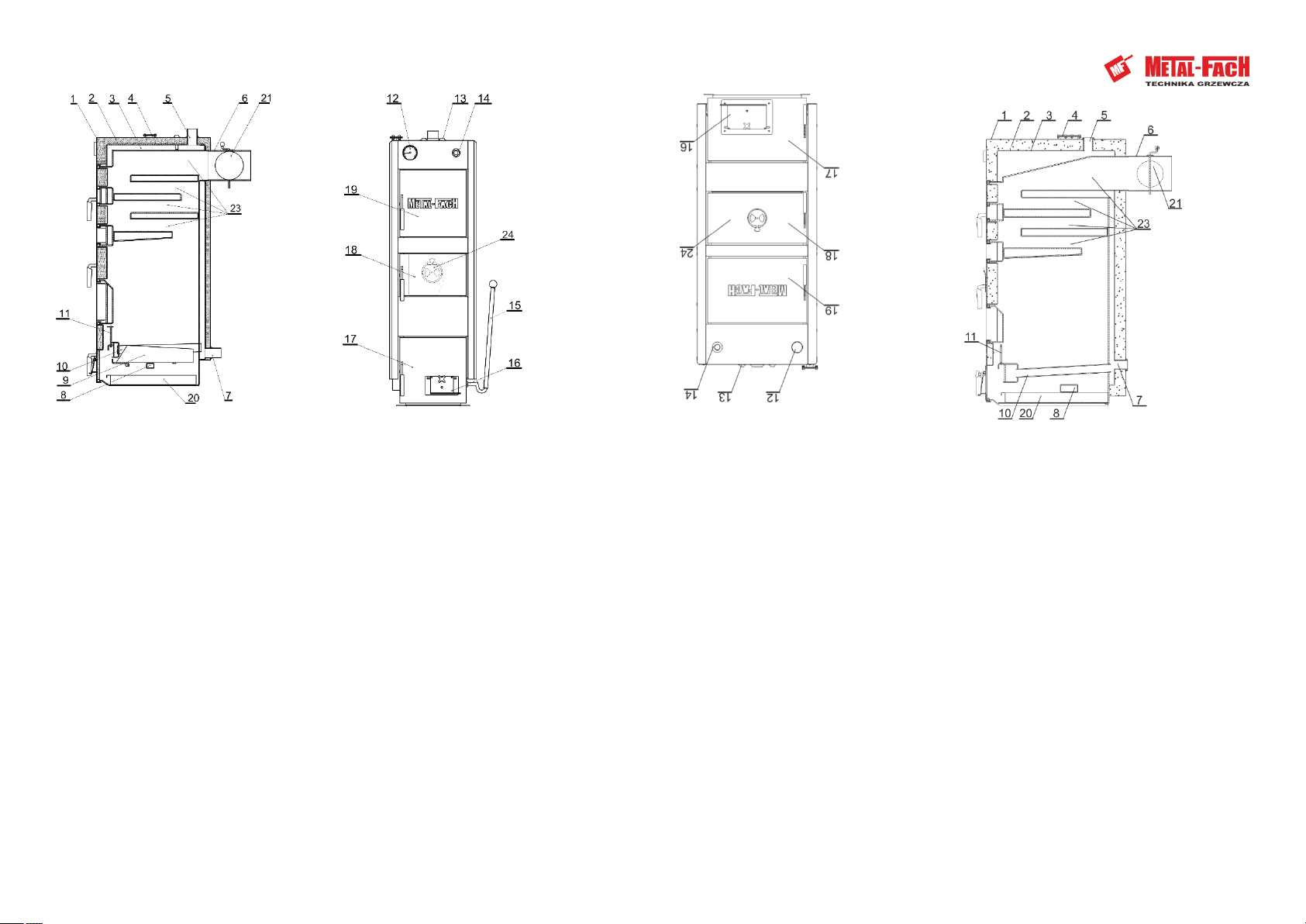

Figure 9.1 Dimensions of boiler SE 60-350 7

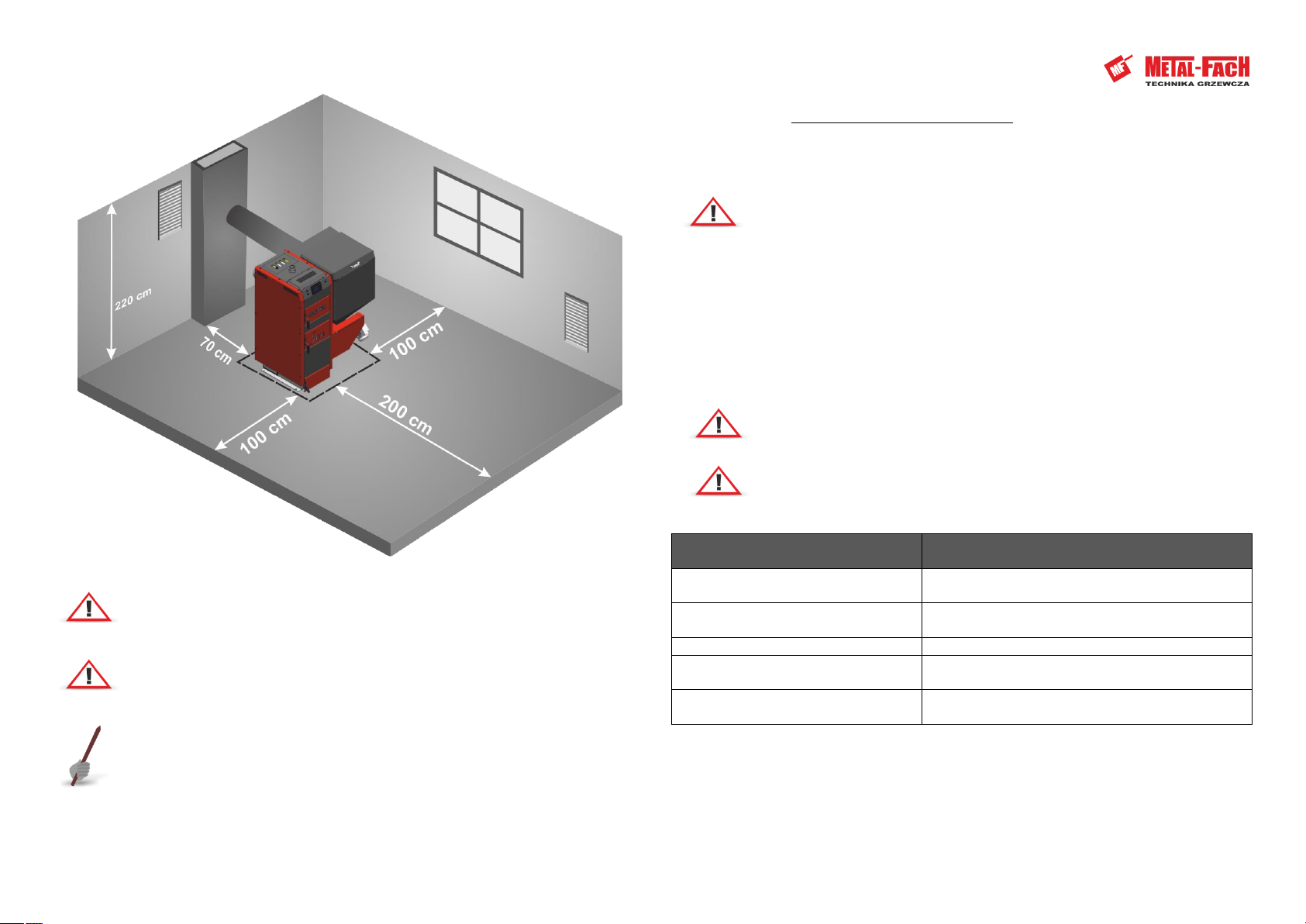

Figure 12.1 Minimum distances for positioning the boiler in the boiler room 11

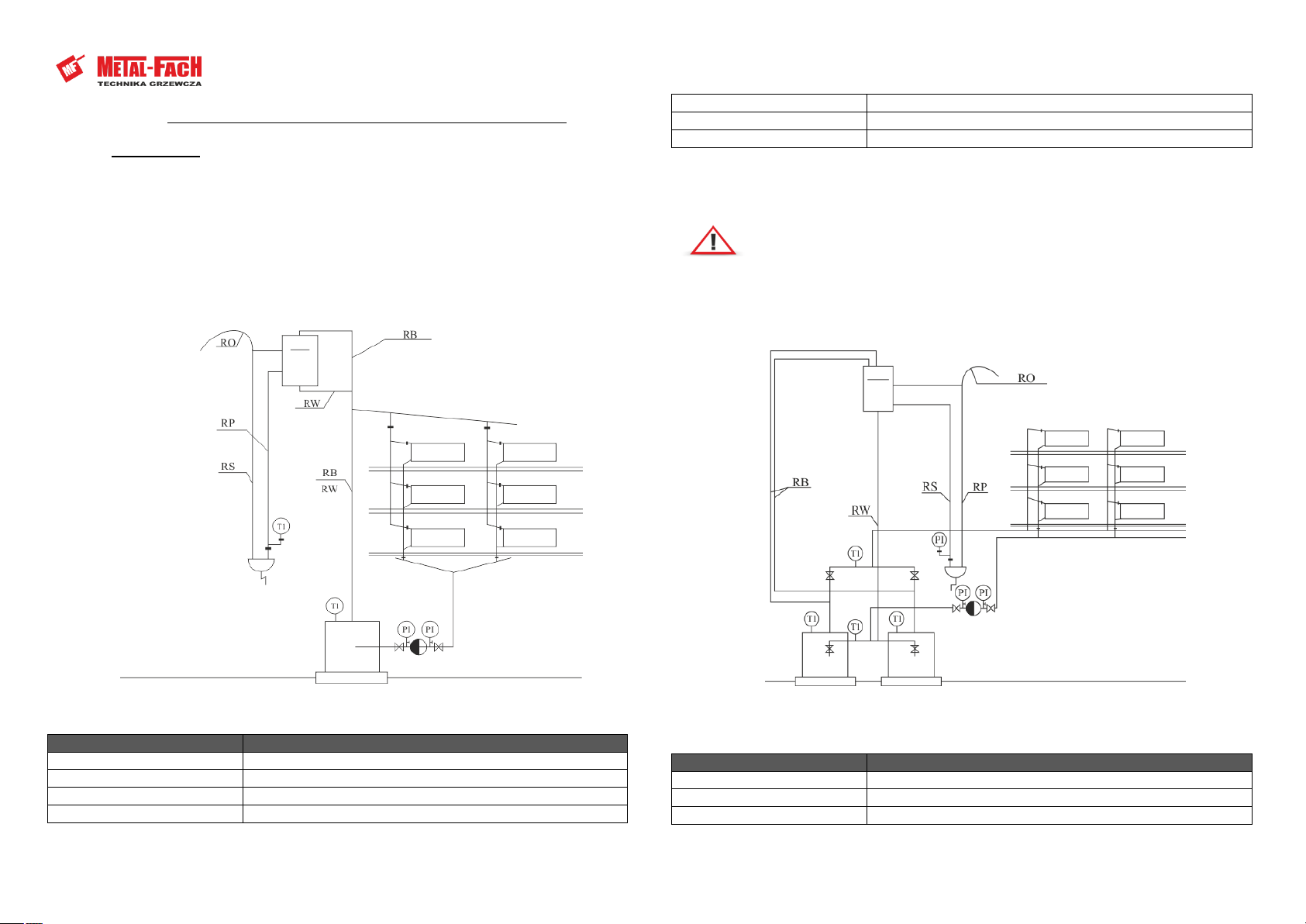

Figure 14.1 Scheme of connection of the boiler to the heating system 12

Figure 14.2 Scheme of connection of the boiler to the heating system 12

Figure 14.3 Connecting the boiler to the heating system 13

Figure 14.4 Connecting the boiler to a heating system with laddomat and buffer. 13

3

1. Introductory acts

(USER)

Activities to be performed during the METAL-FACH boiler acceptance:

●Check carefully that the boiler has been delivered complete (Table6.1) and that it has not

been damaged in transit;

●Compare the rating plate mounted on the boiler casing on the left or right side with your

order (Figure1.1);

●carefully read this manual - it contains information necessary for correct boiler operation.

In the event of problems encountered, please contact the service department or METAL-FACH

authorized service center. These persons have appropriate training and access to original parts to

correctly perform the service and installation of METAL-FACH boilers, confirmed by a certificate

issued in the company's headquarters.

Figure 1.1 Nameplate

2. Informative pictograms

(USER)

Table 2.1 Pictograms

Symbol

Description

Symbol

Description

Years of warranty (exchanger)

Controller

Approved boiler steel

Fan

Water grate

Thrust limiter

Adjustment of the chimney

draught

Large loading chamber

3. Symbols used in the manual

(USER/INSTALLER)

NOTE!

Very important information, always read it if it is present.

TIP!

It is worth reading this information, it makes it easier to use.

4. Definition of terms used in this manual

(USER/INSTALLER)

Central heating boiler - a device for burning various types of solid fuels to heat the heat

carrier (usually water) circulating in the central heating cycle.

Draft limiter - a device whose task is to regulate temperature in solid fuel boilers. As the

temperature rises, the airflow to the furnace is limited, which slows down the burning of fuel. As

the temperature decreases, the air inflow increases, which makes it possible to ignite the fuel

again.

Chimney draught regulator - is used to stabilize and reduce excessive negative pressure in

chimney ducts.

4

5. General information

(USER)

The Operation and Technical Manual is one of the product parts, delivered together with the

purchased central heating boiler. The Operation and Maintenance Manual includes data

concerning the construction, assembly and method of operation of the SE 45-200 series boilers.

Careful reading of the Operation and Maintenance Manual ensures proper and safe operation of

our boiler.

NOTE!

The user is advised to observe all instructions regarding the device contained in this

Operation and Maintenance Manual, in the Warranty Terms and Conditions and in

generally applicable legal regulations.

The boilers are delivered assembled. They are set up and fixed to a pallet permanently.

Additional protection in the form of foil packaging is used.

When transporting the boiler, it should be secured against shifting or rotation on the truck's

loading bed with the use of protective equipment, e.g. belts. The transport of boilers should be

done in accordance with the rules concerning the transport of materials. Loading and unloading

should be done with the use of lifting devices (forklift) with a lifting capacity greater than 1000 kg.

6. Boiler equipment

(USER)

The scope of delivery includes both basic and additional elements, depending on the order.

During the acceptance of the product it is necessary to inspect it carefully to check if it was not

damaged during transport and check the completeness of the equipment. The elements included

in the basic and additional equipment are described below (Table6.1).

Table 6.1 Boiler equipment

Basic equipment:

Unit of

measuremen

t

Quantity

Central heating boiler

piece

1

Ash drawer

piece

1

Boiler cleaning tools:

●poker

●brush

piece

1

Thermometer

piece

1

Additional equipment:

Unit of

measuremen

t

Quantity

Thrust limiter

piece

1

Documentation:

Unit of

Quantity

measuremen

t

Technical and propulsory documentation of the boiler

piece

1

NOTE!

METAL-FACH company reserves the right to introduce without prior notice changes

in technical parameters, equipment and specifications of the offered goods.

7. Application

(USER/INSTALLER)

Steel water boilers are designed for heating usable water in central heating systems. They are

designed for heating residential buildings such as: single-family and multi-family houses, utility

buildings, public utility facilities. Thanks to the application of modern constructional solutions the SE 45-

200 boiler reaches efficiency of ≤81%. Correct operation and achieving the full capacity of the boiler

depend on the quality of the executed installation, appropriate chimney draught, correct operation and

maintenance of the boiler.

NOTE!

The boilers are designed to work in open and closed water systems with

gravitational or forced circulation, with safety devices in accordance with the

requirements of the current standard PN-B-02413 Heating and Heat Engineering

and a closed system in accordance with PN-EN 12828 Heating Installations in

Buildings. Design.

8. Basic elements of boiler construction

(USER/INSTALLER)

The water body is made as a welded structure from approved steel sheets 6 mm thick P265GH

(for elements in contact with exhaust gases) and 4 mm (for other elements) S235JR+N.

5

Figure 8.1 Basic components of the SE 60 boilers

Figure Description:

1. Boiler casing

2. Thermal insulation

3. Boiler body

4. Fan fixing

5. Supply spigot

6. Flue

7. Return spigot

8. Blow-up window

9. Movable grate

10. Water grate

11. Slatted doors

12. Thermometer

13. Temperature sensor sockets

14. Air distribution valve stub

15. Lever for the redrawing

16. Air dispenser

17. grate and ash door

18. Charging door

19. Clearance doors

20. Ash drawer

21. Exhaust gas throttle

22. -

23. Convection channels

24. Secondary air damper

Figure 8.2 Basic components of the SE 75 boilers

Figure Description:

1. Boiler casing

2. Thermal insulation

3. Boiler body

4. Fan fixing

5. Supply spigot

6. Flue

7. Return spigot

8. Blow-up window

9. -

10. Water grate

11. Slatted doors

12. Thermometer

13. Temperature sensor sockets

14. Flue converter stub

15. - –

16. Air dispenser

17. grate and ash door

18. Charging door

19. Clearance doors

20. Ash drawer

21. Exhaust gas throttle

22. - –

23. Convection channels

6

Figure 8.3 Basic components of the SE 120 - 250 boilers

Figure Description:

1. Boiler casing

2. Thermal insulation

3. Boiler body

4. Fan fixing

5. Supply spigot

6. Flue

7. Return spigot

8. -

9. -

10. Water grate

11. Slatted doors

12. Thermometer

13. Temperature sensor sockets

14. Flue converter stub

15. - –

16. Air dispenser

17. grate and ash door

18. Charging door

19. Clearance doors

20. -

21. Exhaust gas throttle

22. - –

23. Convection channels

7

9. Basic dimensions of SE boilers

(USER/INSTALLER)

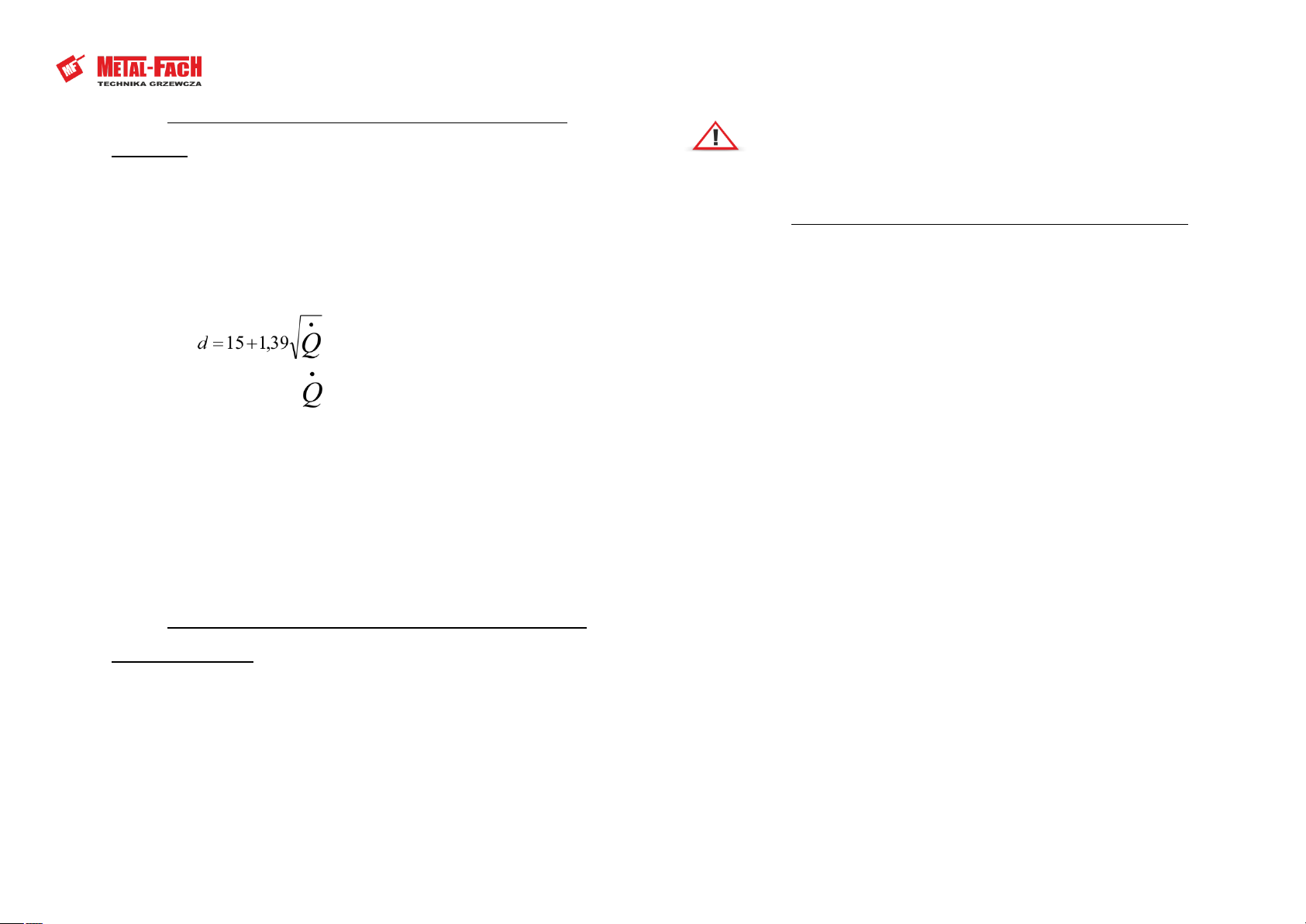

Figure 9.1 Dimensions of boiler SE 60-350

8

Table 9.1 Boiler dimensions (mm) SE 60 - 350

TYPE

SE 60

SE - 75

SE - 95

SE - 120

SE - 150

SE - 200

SE - 250

SE- 350

A

-

-

-

-

-

-

-

-

B

530

580

680

770

860

860

860

1202

C

1530

1530

1530

1830

1910

2110

2110

2030

D

800

800

800

1120

1170

1170

1270

1726

E

1330

1330

1330

1690

1780

1980

1980

1553

F

584

584

584

480

660

655

655

711

G

3/4"

3/4"

3/4"

3/4"

3/4"

3/4"

3/4"

1 ¼”

H

1,5"

1,5"

1,5''

2''

2''

2''

2''

101,6

I

200

200

200

250

250

250

250

350

J

1,5"

1,5"

1.5''

2''

2''

2''

2''

101,6

K

225

225

225

195

180

180

180

382

L

175

175

185

100

155

155

155

344

M

-

-

-

-

-

-

-

-

N

-

-

-

-

-

-

-

-

O

130

160

210

185

234

234

234

356

P

960

960

960

1550

1580

1580

1580

2230

R

550

550

550

650

700

900

900

1045

S

600

600

600

900

950

950

1050

990

T

340

390

490

540

640

640

640

984

U

340x200

390x200

490x250

540x300

640x300

640x300

640x300

624x468

9

10. Technical data of SE boilers

(USER/INSTALLER)

Table 10.1 Technical data for boiler SE 60-350

PARAMETERS

UNIT S.I.

BOILER MODEL

SE 60

SE - 75

SE - 95

SE - 120

SE - 150

SE - 200

SE - 250

SE- 350

Nominal heat output when burning hard coal

[kW].

60

75

95

120

150

200

250

350

Heating surface

[m2]

3,4

3,8

4,5

6,9

8,0

9,2

10

18,32

Area that can be heated

[m2]

600

600-750

750-950

950-1200

1200-1500

1500-2000

2000-2500

2500-3500

Water capacity

[L]

90

105

115

260

290

316

330

713

Maximum operating pressure

[bar].

1,5

1,5

1,5

1,5

1,5

1,5

1,5

1,5

Maximum operating temperature

[°C]

95

95

95

95

95

95

95

95

Test pressure

[bar].

4

4

4

4

4

4

4

4

Boiler class

[bar].

3

3

3

3

3

3

3

3

Boiler efficiency

[%]

≤81

≤81

≤81

≤81

≤81

≤81

≤81

≤81

Fuel

[-]

hard coal, wood

Design flow resistance ΔT

[10K]

2,36

3,14

4,20

7,45

11,65

16,76

26,20

-

Design flow resistance ΔT

[20K]

1,18

1,57

2,10

3,73

5,825

8,38

13,10

-

Boiler weight

[kg].

438

480

521

850

1015

1090

1160

2050

10

11. Fuel

(USER)

The fuel for SE series boilers is deciduous firewood with humidity not exceeding 20%, hard

coal of OI range.

It is recommended to use deciduous wood such as: beech, hornbeam, oak, birch, alder, ash.

The use of coniferous wood is not recommended, as it causes the boilers to smoke and requires

more frequent cleaning.

NOTE!

When using wood with moisture content of more than 20%, it is advisable to use

an acid resistant steel insert in the flue pipe.

12. Requirements for the boiler house

and boiler installation

(USER/INSTALLER)

In Poland, boiler houses built for solid fuel should meet the requirements of the following

standard

PN-87/B-02411 "Boiler houses built for solid fuel" and

Dz. U. 2015.0.1422 They are divided into two types:

1) For small boiler plants up to 25 kW capacity, the following requirements should be met:

●The boiler should be placed as centrally as possible in relation to the heated rooms and in

a separate room;

●The material of which the boiler room floor is made should be non-flammable, in case of

flammable material, the floor should be covered with 0,7 mm thick steel sheet at a

distance of at least 50 cm from the edge of the boiler; the boiler should be placed on a

foundation made of non-flammable materials, protruding 0,5 cm above the floor level and

edged with steel angles;

●there should be artificial lighting in the room, natural lighting is also advisable;

●the distance from the back of the boiler to the wall should not be less than 70 cm, from the

side of the boiler to the wall not less than 100 cm and from the front of the boiler to the

opposite wall not less than 200 cm;

●the height in new buildings should be at least 220 cm, in case of existing buildings the

boiler room height is at least 190 cm, with ensured proper ventilation (supply and

exhaust);

●Supply ventilation shall be by means of an unsealed opening having a minimum cross-

section of 200 cm2 and placed up to a maximum of 100 cm above floor level;

●exhaust ventilation should be carried out with an exhaust duct made of non-flammable

material, minimum cross-section 14 x 14 cm, with an inlet opening under the boiler room

ceiling; the exhaust duct should be led above the roof and located near a chimney; no

devices allowing to close it can be located on the exhaust duct

●the chimney section should not be smaller than 20 x 20 cm;

●there should be a floor drain in the floor of the boiler room;

●The optimal place for fuel storage is a separate room located near the boiler room;

●ash and slag must be collected in suitable containers for daily emptying.

2) Boiler houses with a heat output of 25 kW and over shall additionally meet the

following requirements:

●The distance between the boiler and the chimney furthest away from the chimney, for

gravity draught, must not exceed 50 cm of chimney height;

●Fuel storage and slag storage should be located next to the boiler hall at a storage height

of up to 220 cm with a minimum of 50 cm free space above the fuel;

●facilities and equipment shall be provided to enable the vertical and horizontal transport

of fuel and slag;

●fuel storage rooms shall be naturally unforced ventilated to permit one complete change

of air per hour in the fuel storage room and three complete changes of air in the slag

storage room;

●boiler house entrance door should be non-flammable (class 0,5 of fire resistance),

minimum width 80 cm, opening to the outside; it should have a handleless locking system

enabling opening to the outside under pressure, to the inside using the handle;

●requirements concerning ventilation are the same as for boiler houses of smaller capacity;

additionally, in boiler houses whose capacity exceeds 400 kW, in addition to supply and

exhaust ventilation, there should be mechanical ventilation, periodically activated when

pouring fuel and slagging the boilers, ensuring a minimum of 10 full air changes per hour;

●natural light should be provided in the boiler room, illuminating the boiler from its front,

and the window area should be minimum 1/15 of the boiler room floor area; half of the

installed

●shall be capable of being opened; electric lighting and an electrical socket, having a voltage

not exceeding 24 volts, shall also be provided in the room;

●there should be a drainage well in the floor to allow water cooling, and its capacity should

be equal to the water capacity of the largest boiler, but not more than 2 m3;

●in the boiler room, thermal conduits should be insulated;

●The boiler location with the minimum required distances is shown in the boiler room

diagram (Figure12.1).

NOTE!

Mechanical exhaust ventilation should not be used in the boiler room.

NOTE!

Ensuring a sufficient supply of fresh air into the boiler room will enable efficient

combustion of the fuel.

11

Figure 12.1 Minimum distances for placing the boiler in the boiler room

NOTE!

Excessive carbon dioxide in the room should be prevented.

NOTE!

More detailed information on the requirements for the construction of a boiler

house can be found in the Regulation of the Minister of Infrastructure

dated March 12, 2009.

TIP!

The aforementioned provisions are guidelines that should be reviewed as the

regulation is subject to revision.

13. Boiler installation

(USER/INSTALLER)

An important part of the installation is a correct positioning and leveling of the SE type boiler,

these boilers do not require special foundations. The boiler must stand vertically.

NOTE!

An improperly leveled boiler can be damaged.

The boiler must be placed on a heat-insulating, non-flammable pad that is 2 cm larger on each

side than the base of the boiler. If the boiler is located in a basement, it is recommended that it be

placed on a foundation of at least 5 cm. The strength of the foundation as well as the fire

protection conditions are key guidelines when placing the boiler in the right location, these

include:

●20 cm safety distance from flammable materials;

●40 cm for flammable materials of flammability grade C3;

●40 cm if flammability is not known.

NOTE!

The return water temperature from the system to the central heating boiler should

not be lower than 45ºC.

NOTE!

It is required to connect the boiler to the heating system using a four-way valve.

Table 13.1 Flammability of building masses and materials

Flammability of building masses and

products

Building materials and products

A - Non-flammable

Sandstone, concrete, bricks, fire plaster, mortar,

ceramic tiles, granite

B - Hard to burn

Wood and cement boards, fibreglass, mineral

insulation

C1 - Hard to burn

Beech wood, oak wood, plywood

C2 - Medium flame

Pine, larch and spruce cork, sawn timber planks,

rubber floor coverings

C3 - Readily combustible

Asphalt plywood, celluloid, polyurethane, polystyrene,

polyethylene, plastic, PVC

12

14. Boiler connection to the heating

system

(INSTALLER)

Boiler connection to the central heating system should be performed by a firm authorized by

the manufacturer, and the fact of proper connection should be confirmed on a warranty card

attached to this manual. Boiler should be connected according to producer recommendations, in

accordance with this manual.

Boiler connection diagrams to the heating system in accordance with the PN - 91/B - 02420

standard.

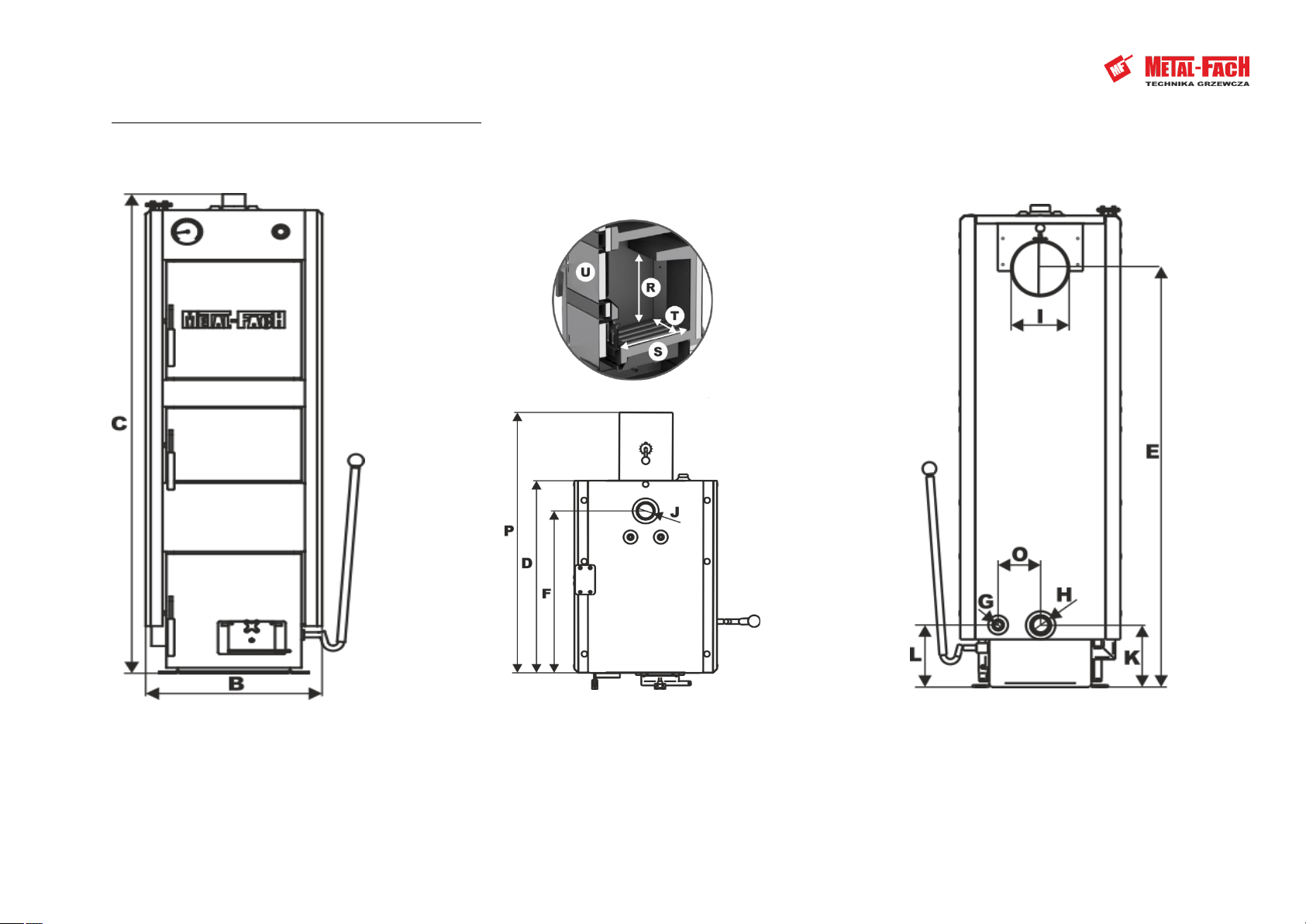

Figure 14.1 Scheme of connection of the boiler to the heating system

Table 14.1 Designations used in the diagrams

Designation

Description

RO

Vent pipe

RW

Collector pipe

RS

Signal tube

RP

Overflow pipe

RB

Safety pipe

T1

Temperature

P1

Pressure

NOTE!

It is recommended to perform the first start-up of the boiler in accordance with

the guidelines included in the Operation and Technical Documentation, by a person

holding a valid license (information about persons authorised to start up the boiler

is available from the Producer - phone: +48 85 711 94 56).

Figure 14.2 Scheme of connection of the boiler to the heating system

Table 14.2 Designations used in the diagrams

Designation

Description

T

Temperature sensor

Tk

Boiler temperature sensor

Tz

Outdoor temperature sensor

13

Tcw

Domestic hot water temperature sensor

Tco

Central heating temperature sensor

Tpw

Boiler return temperature sensor

Tpod

Feeder temperature sensor

Figure 14.3 Connecting the boiler to the heating system

Table 14.3 Designations used in the diagrams

Designation

Description

T

Temperature sensor

Tk

Boiler temperature sensor

Tz

Outdoor temperature sensor

Tcw

Domestic hot water temperature sensor

Tco

Central heating temperature sensor

Tpw

Boiler return temperature sensor

Tpod

Feeder temperature sensor

Figure 14.4 Connecting the boiler to a heating system with laddomat and buffer.

Figure Description:

1. Outside the building

2. Expansion vessel

3. Room controller

4. Mixer

5. Heater

6. Heating circuit

7. Central heating pump

8. Central heating water (DHW) pump

9. Buffer

10. Laddomat

14

15. Requirements for the expansion

vessel

(INSTALLER)

Every open heating system should be equipped with a collecting vessel whose task is to absorb

the increase in the volume of water filling the system and to vent it. The vessel should be installed

in the highest point of the system, if possible in a vertical line above the boiler(s).

The volume of the collection vessel can be estimated by taking the unit volume in relation to

one kW of thermal capacity is 1-2 dm3.

The vessel is equipped with a ferrule for the connection of a tolerable safety pipe, a

precipitation safety pipe and an overflow pipe with associated vent.

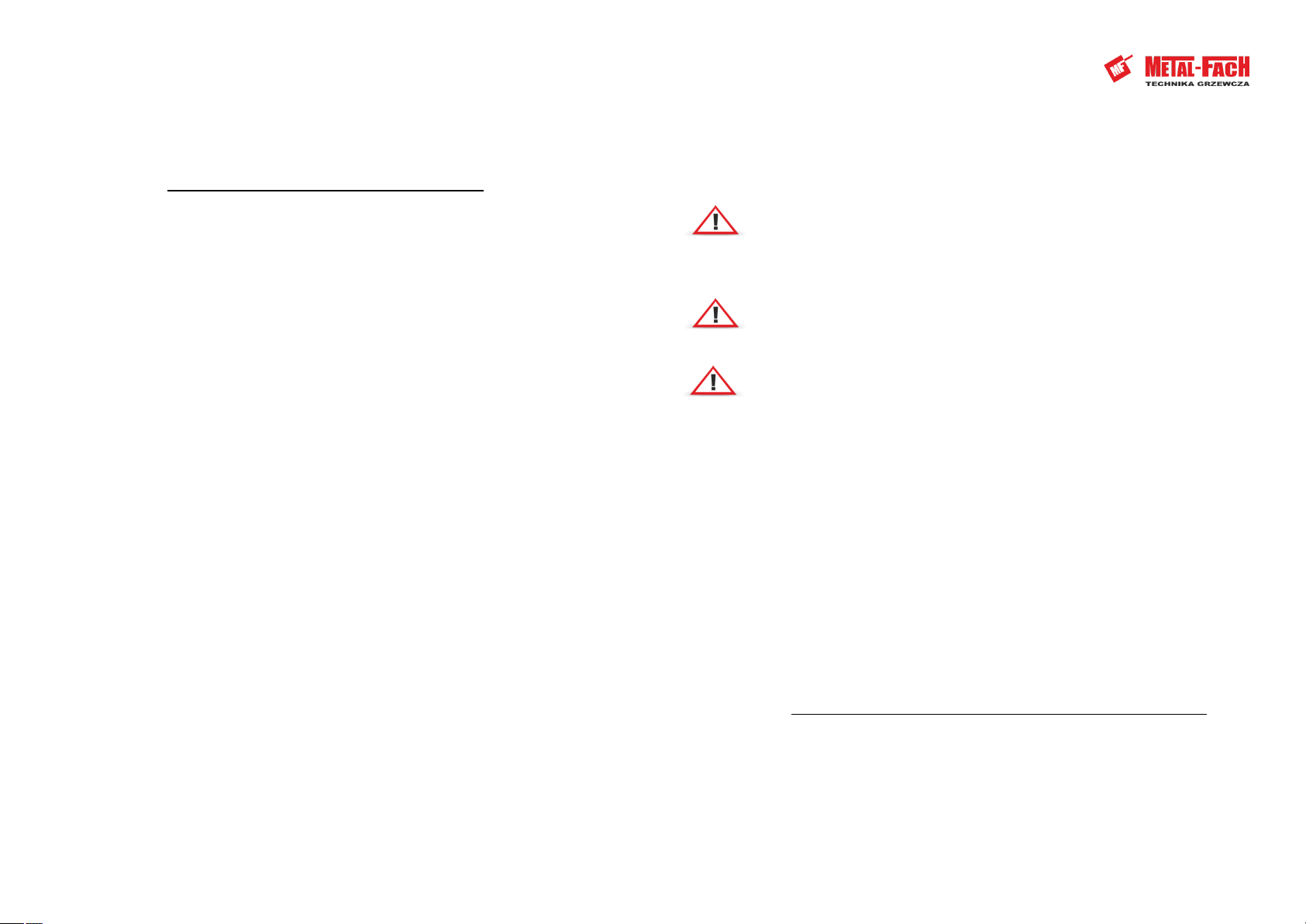

The diameter of the vent pipe and the overflow pipe shall be at least:

[MM]

- boiler output [kW].

The most important requirements for safety devices are as follows:

●the vessel should have a volume of approximately 3.5% of the volume of water contained

in the heating system including the boiler;

●Every boiler should absolutely have a safety pipe and an overflow pipe;

●The system should be equipped with a signalling and collecting pipe and a venting stub for

the collecting vessel.

If several boilers are set up, each of them should be equipped with a safety pipe according to

the given rules in PN-91/B02413 - protection of open-system water heating installations. No shut-

off valves can be installed on safety and overflow pipes, and the pipes and vessel should be

protected against freezing.

16. Boiler connection to the electrical

installation

(INSTALLER)

The boiler is designed for connection to 230V/50Hz. Installation should be made by a qualified

person. The socket outlet 230V/10A with earthing should be easily accessible. Boiler power supply

and boiler room lighting should have a different circuit.

Completion of the installation and the heating test must be recorded in the Warranty Card. The

completed Warranty Card should be sent to the manufacturer's address by the user in order to

register the user in the company's system.

NOTE!

The first start-up of the boiler must be carried out only by a service technician

trained by the manufacturer, with a valid certificate of METAL-FACH Authorized

Service Provider, METAL-FACH Distributor or a person holding the SEP license up

to 1.5 kW.

17. Connection of boiler to chimney

(INSTALLER)

Smoke ducts

The purpose of flue pipes is to reliably carry exhaust fumes to the outside and to draw in air

for fuel combustion. The chimney draught required for this depends on:

●Temperature difference between hot exhaust gas and cold air;

●effective chimney height;

●chimney section not less than 20 x 20 cm;

●the execution of the chimney (as smooth internal surfaces as possible) and the tightness of

the joints;

The effective height of the chimney is the difference in height between the highest hearth and

the exit of the chimney. The effective height of individual chimneys must be at least 4 m and

common chimneys for solid and liquid fuels at least 5 m. The difference in height between two

fireplaces must not be greater than 6.5 m.

In the case of sloping roofs, chimneys should end at the ridge (the highest point of the roof), in

the area of free wind flow. This avoids draught disturbance. Always pay attention to the position of

the building in relation to other buildings.

Chimney selection

In most cases an approximate method or selection according to chimney manufacturer's

chimney diagrams is sufficient for selecting the chimney. in special cases (unfavourable pressure

and temperature relationships, large flue gas volume) chimneys are calculated according to PN-EN

13384-1+A2:2008 standard.

Chimneys for solid fuel boilers

Please note that solid fuel stoves with a nominal heat output >20 kW and without a fan need

their own chimney. For solid fuel stoves, single-layer brick chimneys can be used. Nowadays three-

layer chimneys with smooth surfaces and good thermal insulation are used.

Flue

The boiler is connected to the chimney by a flue pipe and a flue duct. Smoke ducts are pipes

and fittings that are laid indoors. Smoke ducts meet fire safety requirements concerning chimneys

and are often made of the same material as the main chimney. Smoke ducts should be made of

non-combustible products. Smoke ducts or casing should meet the requirements specified in the

Polish Standard concerning fire testing of small chimneys. A 12 cm thick solid brick housing, built

on cement-lime mortar with external plaster or pointing, is acceptable. Joints should be as short as

possible and laid with an elevation to the chimney to avoid heat loss and additional resistance.

They shall not be routed to other floors. Flue pipes should not be laid in rooms where fireplaces

cannot be fitted, nor should they be placed in walls or ceilings. In order to protect the chimney

15

against dampness and draught limitation, acid resistant or ceramic chimney liners should be used,

with condensate draining to the sewage grid. A distance of at least 6 m should be kept between

the chimney and the nearest edge of a tree crown.

18. Commissioning the boiler

(USER/INSTALLER)

Before you start a fire in the boiler, check if the central heating system has been properly

made and if it is properly filled with water - up to the overflow pipe from the vessel.

For filling the entire system or for making up for losses, softened/chemically treated water,

distilled water or rainwater would be most suitable.

In addition, check that the grate is cleaned of any unburnt fuel, ash and slag from the previous

firing and that the ash has been removed from the ash pan.

Recommended firing-up (correct firing from the top) - fill the prepared grate deck with fuel

(when burning wood - full load - to the bottom edge of the inlet, put logs across the boiler) Place a

kindling layer (paper, wood pieces) on the surface and set the fire. The boiler should be started up

with the primary air dosing flap in the lower door (grate and ash door) open, and with the

secondary air throttle in the charging door.

Boiler operation in the upper combustion system takes place in a system with cyclical fuel

filling, which means that after complete burning out of the fuel portion poured into the

combustion chamber and removing ash, the chamber is filled again and a new fuel portion is

ignited with the use of kindling fuel.

We do not recommend firing up the fuel "from below" in top-firing type boilers.

Before lighting the kindling layer, make sure that the chimney provides sufficient draught.

Insufficient draught is most often encountered when the boiler is started up for the first time or

after a longer break in operation, when the boiler and the chimney have cooled down.

To check the chimney draught, place a lit piece of wood close to the air inlet duct with the

damper open.

If you find that the flame is not being drawn intensively into the boiler, this indicates

insufficient chimney draught.

In this case, before setting the layer on fire, the chimney must be "warmed up" by proceeding

as follows:

●Put a few sticks of wood in the flue pipe and set it on fire;

●Keep the fire going until the chimney draught increases (the flame is drawn up the

chimney);

●After the wood has burnt out, scoop the unburnt residue and dispose of it in the ash pan.

When the boiler reaches the required water temperature, it is necessary to adjust the

combustion intensity. The combustion intensity is adjusted by a proper setting of the adjustment

screw of the primary air dosing flap and by a proper adjustment of the secondary air throttle.

During normal boiler operation it is necessary to periodically check and replenish the fuel as

specified above. In the case of hard coal, strike the hook to cause the fuel to fall down.

When opening the fuel door, be very careful, because if the door is opened abruptly, explosive

gases (degasification products) can be ignited. When opening the fuel door, stand at the side of

the boiler, slightly open the door, wait for a moment until the combustion gases are discharged

from the fuel tank into the chimney and then slowly open it. Do not stand in front of the door

opening. A similar procedure should be followed when opening the other doors during boiler

operation.

NOTE!

If for any reason there is a lack of water in the boiler - mains system, do not

top up with cold water. Cool the boiler down to the temperature of 30°C as soon

as possible and only after the boiler has cooled down, add water and start

burning again.

NOTE!

The flow of cold water on the boiler walls when the boiler is hot can cause

an explosion of the boiler and consequently damage the heating equipment. In

extreme cases, it can cause damage to buildings and injuries to people.

NOTE!

When opening the door do not stand in front of the boiler, it can cause burns.

When starting up the boiler cold or for the first time, a phenomenon of "sweating of the boiler"

can occur. This gives an impression of leakage. In this case, it is necessary to carry out an intensive

burning process (70-80ºC) to dry and warm up the boiler and the flue for even 2-3 days.

To increase the service life of the boiler it is recommended to keep the flue gas temperature

180ºC above the ambient temperature, and the boiler water temperature should not be lower

than 60ºC.

Maintaining a suitably low radiator temperature in this situation during autumn or spring can

be achieved by, among other things:

Correct boiler selection according to the size of heated rooms;

Use of three-way or four-way mixing valves between the water supply and return, manually or

automatically controlled.

Inadequate insulation of the expansion (overflow) vessel can also cause a boiler explosion with

all its negative consequences.

Frozen water in the expansion vessel breaks the connection between the central heating

system and the boiler and the atmosphere, and when the temperature of the boiler water rises,

the pressure in the system increases uncontrollably, which may result in a boiler explosion.

19. When using the boiler, remember

(USER)

●The boiler may only be operated by adults who have read the operating manual;

●It is forbidden for children to be near the boiler without the presence of adults;

●If flammable gases or vapours get into the boiler room or during the work, in which there

is an increased risk of fire or explosion (gluing, painting, etc.), the boiler must be switched

off before such work is started;

16

●When cleaning carbon in the retort, trough, the boiler should be turned off ("OFF"

position);

●When adding fuel to the tank, turn the boiler off ("OFF" position);

●Do not use flammable liquids for firing up the boiler, the boiler should ignite automatically

(by means of an igniter);

●When cleaning the boiler, turn the appliance off ("OFF" position);

●The boiler must not overheat in any way during operation;

●Do not place flammable objects on the boiler or in its close vicinity;

●When removing the ashes, flammable materials must not be located within 150 cm of the

boiler;

●The ashes should be put into heatproof dishes with a lid;

●When the boiler is operated at a temperature lower than 60°C, the steel exchanger may

dampen and cause corrosion due to low temperature, which shortens the exchanger's life;

therefore the temperature during boiler operation must be at least 60°C;

●After the end of the heating season the boiler and the flue pipe must be thoroughly

cleaned;

●The boiler room should be kept clean and dry.

NOTE!

The product is not intended for use by persons with reduced physical / mental

capabilities or lack of experience and knowledge, unless they are supervised or

instructed by a person responsible for their safety.

NOTE!

Any unauthorised interference with the electronics or the design of the boiler is

prohibited.

20. Cleaning and maintenance of the

boiler

(USER)

NOTE!

The boiler may only be cleaned when the appliance is switched off from the mains.

To save fuel it is necessary to keep clean the combustion chamber and convection ducts of the

boiler. It is necessary to clean walls and grates in the combustion chamber through the charging

and furnace doors. Boiler exchanger and ash collector must be also cleaned regularly.

The convection ducts (ducts) and the flue pipe must be cleaned through a cleanout on the

boiler flue and at the bottom on the side wall. Cleaning should be done with wire brushes on

extension tubes. The above actions must be performed during periodic boiler standstill, preferably

every 100 hours of boiler operation. Thorough cleaning of the boiler should be done once a

month.

In the case of combustion of poorer grades of fuel, these operations should be carried out

more frequently.

21. Instructions for disposal of the

boiler at the end of its service life

(USER)

Before scrapping the boiler, all electronic components must be disconnected from the boiler.

They must be disposed of in accordance with the European Directive 2002/96/EC on the disposal

of electronic and electrical equipment. For correct disposal, contact the manufacturer of the

electronic components according to the above mentioned European Directive.

Steel elements from which the boiler is made should be scrapped in designated places (scrap

metal purchase).

NOTE!

Do not dispose of the old boiler, intended for scrapping, or its components with

general waste.

22. Examples of equipment failure

(USER)

Before you call for service, read the frequently asked questions.

NOTE!

In case of an unjustified service call, the customer covers the costs of labour and

travel (price list is available at www.metalfachtg.com.pl).

You can report the problem online at our website: www.metalfachtg.com.pl/zglos-problem-

online.

HOTLINE: +48 85 711 94 54 ext.17

17

Question

Reply

Explanation

Smoke escapes from the

hopper or ash door

- no thrust;

- improper connection of the boiler to the chimney;

- fuel residue has got under the hinge or seal; second stove

fitted in the same flue pipe;

- too small chimney section.

- seal the entrance of the flue pipe to the flue pipe;

- check the patency of the chimney and its parameters;

- check the sealant sealing the door;

- seal the stove outlet to the flue pipe to prevent cold air being sucked in;

- enlarge the chimney opening.

During the first start-ups

water escapes from the boiler

(leakage).

- condensation (boiler sweating).

- We fire up the boiler to the temperature above 80OC and maintain it for at least 6 hours.

If necessary, repeat this operation.

Boiler temperature too low.

- improperly selected boiler power (size);

- calorific value of the fuel too low;

- incorrect boiler regulation.

- See the section on boiler operation and maintenance;

- improperly selected boiler power.

A sudden increase in

temperature and pressure in

the boiler.

- no seal of the ash chamber;

-too large a chimney section.

- ensure the tightness of the door and the cleanout openings, if any;

- reduce the chimney cross section, install a sunroof.

18

Water leakage from

convection channels.

- bad fuel;

- combustion temperature too low;

- no air supply through air dampers;

- exhaust damper closed.

- use fuel of appropriate calorific value and moisture content;

- open the air dampers;

- open the flue gas dampers.

19

Warranty conditions

(USER)

User Statement:

I hereby declare that the boiler (hereinafter also referred to as "appliance") was delivered to

me as ordered, new and complete. The Vendor has familiarised me with the operation of the

appliance and provided me with a set of documentation (in particular: Technical and Operating

Documentation including, but not limited to, instructions for installation and operation of the

device, warranty conditions). I acknowledge the manufacturer's recommendation to subject the

device to regular annual technical inspections, which should be confirmed in the warranty card.

…………………………………………………………….

Date and legible signature of the User

Warranty coverage:

1. Liability under the warranty covers only defects resulting from causes inherent in the

device at the time of its delivery to the user.

2. Warranty for the device is provided by the manufacturer (also referred to as the

"Guarantor"): Jacek Kucharewicz running the business activity under the name Metal Fach

Jacek Kucharewicz, 16-100 Sokółka, 66 Sikorskiego Street, Tax Identification Number (NIP):

545-100-10-62, Business Identification Number (REGON) 050073833, phone: +48 85 711

94 56).

3. Under the guarantee, the user shall be entitled to free-of-charge repair of the device, if

the defects of the device become apparent during the guarantee period. If the Guarantor

finds it impossible to repair the device or its part, the Guarantor reserves the right to

replace the device or its part with a new one.

Warranty Period:

For the device (boiler) - 2 years from the date of sale, but no longer than 36 months from the

date of manufacture, with the exception of:

a) exchanger - warranty is 5 years from the date of sale;

b) moving elements, cast iron, mechanical, worm - for which warranty is 1 year from the

date of sale;

c) operating elements (e.g. sealing cord, gaskets, verniculite, chamotte), electrical elements,

screw securing the screw coupling, pins - which are not subject to warranty.

Conditions for exercising the guarantee:

1. Installation of the appliance in accordance with the Technical and Operating

Documentation (in particular, connection of the boiler to a correctly installed system,

performing the first start-up in accordance with the guidelines of the appliance

manufacturer, use of devices protecting the boiler against cold water return (four-way

valve with a servo-motor, ice machine, etc.)

2. Sending to the Manufacturer's address a copy of a properly completed warranty card,

signed and stamped by the vendor within 30 days from the date of sale of the device

3. Presentation of properly filled warranty card (signed and stamped by the vendor) at the

time of claim and substantiation of the circumstances of purchase of the device (e.g.

receipt, invoice). In case of loss of the warranty card by the User, a duplicate will not be

issued.

4. User adherence to the recommendations contained in the Technical and Operating

Documentation of the device.

5. Perform the first start-up of the boiler, within 6 months from the date of installation of

the device by an installer, in accordance with the guidelines included in the technical and

operating documentation, by a person holding a valid license (information on persons

authorized to start up the boiler is available from the Guarantor - +48 85 711 94 56),

confirm this fact on the warranty card and send the start-up report to the Guarantor. The

first start-up of the boiler is a chargeable service and its cost is covered by the User.

6. Perform annual inspections of the device, in accordance with the guidelines contained in

the Technical and Operating Documentation, by specialist companies with appropriate

authorisations (a sample list of specialist companies is available from the Manufacturer -

under +48 85 711 94 56 and record their performance in the warranty card. Inspection of

the device is a chargeable service.

7. Servicing of the appliance (e.g. adjustment of the appliance, cleaning, measurements,

analyses of flue gases) should be performed by specialised companies with appropriate

authorisation (a sample list of specialised companies is available from the Manufacturer -

at +48 85 711 94 56), in accordance with the guidelines included in the Technical and

Operating Documentation, and the service should be recorded in the guarantee card. The

User may report the need for service interventions to the Manufacturer (infoline +48 85

711 94 56, www.metalfachtg.pl/zglos-problem-online). The service is chargeable.

8. Warranty repairs should be carried out only by specialised companies with appropriate

authorisation (a list of specialised companies is available from the Guarantor - phone +48

85 711 94 56) and recorded in the warranty card.

9. Use of spare parts and consumables that meet the parameters specified by the

manufacturer. It is recommended to use original parts.

10. The warranty covers the territory of the Republic of Poland.

Table of contents

Other Metal-Fach Tiller manuals