Ecotech Italia DCS-BT Series User guide

ViaCopernico,85–47122Forlì(FC)ITALY

Tel.+39(0)543774314‐Fax+39(0)543778658

web:http://www.ecotechitalia.com

RevisionDateDescription

101/10/2014REVISION

025/05/2010ISSUE

USEANDMAINTENANCEINSTRUCTIONMANUAL

LAWNMOWERBRUSHCUTTER/LAWNMOWERFOREDGES

Series:DCS‐BT

Models:60‐60Traction/60SwingTop

OriginalInstructions

Translationoftheoriginalinstructions(forotherlanguages)

BT60DCS60 DCS60Traction DCS60SwingTop

TABLEOFCONTENTS

1PREMISE....................................................................................................................................................................................................................................3

1.1GeneralInformation......................................................................................................................................................................................................3

1.2IntendedUsers...............................................................................................................................................................................................................3

1.2.1UserQualifications...................................................................................................................................................................................................3

1.2.2Symbols....................................................................................................................................................................................................................3

2GENERALINFORMATION..........................................................................................................................................................................................................5

2.1ManufacturerIdentificationInformation.......................................................................................................................................................................5

2.2Machineidentificationratingplatesanddata:..............................................................................................................................................................5

2.3Declarations...................................................................................................................................................................................................................

5

2.3.1DeclarationofConformity........................................................................................................................................................................................5

2.4SafetyRegulations.........................................................................................................................................................................................................6

2.5Guarantee......................................................................................................................................................................................................................6

2.6Attheexpenseoftheclient...........................................................................................................................................................................................6

3DESCRIPTIONOFTHEMACHINE...............................................................................................................................................................................................6

3.1OperationalPrinciple.....................................................................................................................................................................................................8

3.1.1IntendedUse............................................................................................................................................................................................................8

3.2Dimensions....................................................................................................................................................................................................................8

3.3EnvironmentalConditions..............................................................................................................................................................................................8

3.4Lighting..........................................................................................................................................................................................................................8

3.5Vibrations.......................................................................................................................................................................................................................9

3.6Noiseemissions.............................................................................................................................................................................................................9

3.7TechnicalSpecifications.................................................................................................................................................................................................9

4INSTALLATION...........................................................................................................................................................................................................................9

4.1TransportandHandling.................................................................................................................................................................................................9

4.1.1Packaging:.................................................................................................................................................................................................................9

4.2Storage.........................................................................................................................................................................................................................10

4.3Preliminarychecks.......................................................................................................................................................................................................10

4.4Scrapping.....................................................................................................................................................................................................................11

5SAFETY....................................................................................................................................................................................................................................11

5.1GeneralWarnings........................................................................................................................................................................................................11

5.2UseRestrictions...........................................................................................................................................................................................................11

5.3DANGERousZones.......................................................................................................................................................................................................11

5.4Safetydevices..............................................................................................................................................................................................................11

5.5Signs.............................................................................................................................................................................................................................12

5.6ResidualRisks...............................................................................................................................................................................................................12

6MACHINEUSE.........................................................................................................................................................................................................................12

6.1Adjustments.................................................................................................................................................................................................................12

6.2OperationalModes......................................................................................................................................................................................................13

6.2.1WORKINGONLEVELGROUND...............................................................................................................................................................................13

6.2.2WORKINGONASLOPE(onlyontheSwingversion)...............................................................................................................................................13

6.3Normalstop.................................................................................................................................................................................................................14

6.4Emergencystop...........................................................................................................................................................................................................14

7MAINTENANCE.......................................................................................................................................................................................................................14

7.1MaintenanceStatus.....................................................................................................................................................................................................14

7.2Cleaning.......................................................................................................................................................................................................................

14

7.3Lubrication...................................................................................................................................................................................................................14

7.4OrdinaryMaintenance.................................................................................................................................................................................................14

7.5ExtraordinaryMaintenance.........................................................................................................................................................................................15

7.6Diagnosticsandtroubleshooting.................................................................................................................................................................................15

8SPARESANDACCESSORIES.....................................................................................................................................................................................................16

8.1Service.........................................................................................................................................................................................................................16

8.2Spareparts...................................................................................................................................................................................................................16

9PURPOSEOFTHEINSTRUCTIONMANUAL..............................................................................................................................................................................16

9.1Conservationoftheinstructionmanual.......................................................................................................................................................................17

9.2InstructionManualupdatingmethods........................................................................................................................................................................17

9.3GLOSSARY....................................................................................................................................................................................................................17

9.3.1Glossary(AnnexIp.1.1.1Dir.2006/42/CE)............................................................................................................................................................17

9.3.2Otherdefinitions....................................................................................................................................................................................................17

Table1‐1:Symbolsconcerninginformationand/orprocedures..........................................................................................................................................................4

Table1‐2:Symbolsconcerningoperatorqualifications.......................................................................................................................................................................4

Table1‐3:Symbolsconcerningsafety..................................................................................................................................................................................................4

Table2‐1:ExtractoftheDeclarationofConformity............................................................................................................................................................................5

Table2‐2:SafetyRegulations..............................................................................................................................................................................................................6

Table3‐1:Dimensions.........................................................................................................................................................................................................................8

Table3‐2:TechnicalSpecifications......................................................................................................................................................................................................9

Table6‐1:Adjustments......................................................................................................................................................................................................................13

Table6‐2:Workingonaslope...........................................................................................................................................................................................................13

Table7‐1:ExtraordinaryMaintenance..............................................................................................................................................................................................15

1PREMISE

IMPORTANT!

ThismachinehasbeenmanufacturedincompliancewiththeMachineDirective2006/42/ECandiscertifiedwiththemark.

BEFOREPERFORMINGANYOPERATIONSONTHEMACHINE,THEASSIGNEDOPERATORSANDTECHNICIANSMUSTCAREFULLY

READTHEINSTRUCTIONSCONTAINEDINTHISPUBLICATION(ANDINTHOSEATTACHED)ANDFOLLOWTHEMDURINGTHE

EXECUTIONOFTHEPROCEDURES.

INCASEOFDOUBTSONTHEPROPERINTERPRETATIONOFTHEINSTRUCTIONS,CONTACTTHECLOSESTSUPPORTCENTRE.

1.1 GENERALINFORMATION

ThisManualhasbeendividedintoindependentchapters,eachofwhichisaimedataspecificoperatorrole(OPERATOR/USER,

MAINTENANCEMECHANIC),forwhichthecompetenciesnecessarytooperatethemachinesafelyhavebeendefined.

Thechaptersequencecorrespondstothetemporallogicoftheservicelifeofthemachine.

Tofacilitaterapidcomprehensionofthetext,certaintermsandabbreviationsareused,themeaningsofwhichareindicatedin

thetablesfollowingParagraph1.2.2SymbolsandParagraph9.3GLOSSARY.

Below,themeaningsofthesymbolsaredescribedfor:

Thedifferentlevelsofdangerinthe“UseandMaintenance”operationsonthemachine;

Theoperatorqualifications;

Safety,asapplieddirectlytothemachine.

Theuseofthesesymbolsenablestheinformationnecessaryfortheproperandsafeuseofthemachinetobeprovidedquickly

andunambiguously.

1.2 INTENDEDUSERS

Themanualinquestionisdirectedtoward:

theOperator/User,QualifiedPersonnelcertifiedforthemaintenanceofthemachineandanyandallpersonnelthatmaywork

onorinterfacewiththemachineatanylevel.

1.2.1 UserQualifications

Themachineisintendedforusebyqualifiedpersons,inparticularthosewho:

Areoflegalage;

Arephysicallyandpsychicallysuitabletoperformworkofacertainleveloftechnicaldifficulty;

Havebeensuitablytrainedontheuseandmaintenanceofthemachine;

Arecapableofunderstandingandinterpretingtheoperatormanualandthesafetyrequirements;

Knowemergencyproceduresandtheirimplementation;

Possesstheabilitytorunthisspecifictypeofequipment;

Arefamiliarwiththespecificstandardsinvolved;

Haveunderstoodtheoperationalproceduresdefinedbythemachinemanufacturer.

1.2.2 Symbols

Thedescriptionsprecededbyasymbolcontain:

Veryimportantinformation/requirements,particularlywithregardforsafety;

Non‐compliancemaybringabout:

Dangerforthesafetyoftheoperators;

Lossofthecontractualwarranty;

Disclaimerofthemanufacturer'sliability.

1.2.2.1 Symbolsconcerninginformationand/orprocedures

SymbolDescription

DANGER!!

Informationorprocedurethat,ifnotexecutedcarefully,couldbringaboutdeathorseriouspersonalinjuries.

ATTENTION!!

Informationorprocedurethat,ifnotexecutedcarefully,couldbringaboutdeathorseriouspersonalinjuries.

CAUTION!!

Informationorprocedurethat,ifnotexecutedcarefully,couldbringaboutsignificantpersonalinjuriesordamagetothe

machine.

WARNING

Informationorprocedurethatsuggestthebestmannerofusingthemachinetotheoperatorinordertoprolongitsservicelife,

avoiddamagingitandoptimiseoperationsincompliancewithstandards.

NOTE

Importantinformationorprocedure.

Table1‐1:Symbolsconcerninginformationand/orprocedures

1.2.2.2 Symbolsconcerningoperatorqualifications

Table1‐2:Symbolsconcerningoperatorqualifications

1.2.2.3 Symbolsconcerningsafety

Symbolssurroundedbyatriangleindicatedanger

SymbolName:

Itwouldbebesttoreadthismanualthoroughlybeforestartingupthemachineandoperatingit.

Nevertouchthebeltsorthepulleyswheninmovementasthesemaycauseseriousinjuriestotheoperator.Forno

reasonshouldanymaintenanceproceduresbecarriedoutwiththemotorrunning.Openthemachinemotor

housingonlywiththemotorturnedoff.

Themotorfuelishighlyinflammable,therefore,handleitwithgreatcareandattention.Never,underany

circumstancesorforanyreason,refuelwiththemotorrunning,whilesmokingorinthepresenceofopenflamesor

sparks.

Theexhaustgasesareextremelyharmfulandmaycauseseriousillnessordeath.Neverstartthemachineinsideof

anenclosedareainabsenceofasuitableexhaustaspirationconduitcapableofexpellingtheexhaustgasesfromthe

motoroutdoors.Itisbestpractice,inanycase,tostartthemotorofthemachineinoutdoorandifpossiblewell

ventilatedenvironments.

Duringoperation,themachinemayprojectstones,piecesofplantmatterorotherobjects.

Itisbestiftheoperator,inordertonotcausedamagetothirdparties,beforeusingthemachine,makessurethat

therearenopersonswithin15metresoftheoperationalarea.

Neverplacethehandsorfeetnearthebladesinrotation,norundertheprotectivehousings:shearingdangerofthe

extremitiespossible.

Genericdanger

Table1‐3:Symbolsconcerningsafety

TheunitsofmeasureonthemachinearethoseprovidedforintheInternationalSystemofUnits(SI).

Symbol Description

A) Genericworker:operatorwithnospecificskills,capableofcarryingoutsimpletaskswheninstructedtodosobyqualified

technicians.

B) Hoistandhandlingequipmentoperator:operatorqualifiedfortheuseofequipmentorvehiclesforhoistingandhandling

materialsandmachines(carefullyfollowingtheinstructionsofthemanufacturer,incompliancewiththelawsinforcein

thecountrywherethemachineisbeingused.

C) MaintenanceMechanic:qualifiedtechniciancapableofoperatingthemachineundernormalconditions,ofoperatingit

usingthesustained‐actioncontrols(JOG)withtheprotectivedevicesdeactivatedandofinterveninguponthemechanical

componentsforadjustmentoperations,maintenanceprocedures,aswellasforanynecessaryrepairs.Usually,this

technicianisnotqualifiedtoperformproceduresonliveelectricalsystems.

D) MaintenanceElectrician:qualifiedtechniciancapableofoperatingthemachineundernormalconditions,ofoperatingit

usingthesustained‐actioncontrols(JOG)withtheprotectivedevicesdeactivatedandisassignedtoallproceduresinvolving

theelectricalsystem,includingadjustment,maintenanceandrepair.Thistechnicianisqualifiedtoperformprocedureson

liveelectricalsystemsinsideofthecabinetsandjunctionboxes.

E) ManufacturerTechnician:Thisqualifiedtechnicianismadeavailablebythemanufacturertoperformcomplexoperations

inparticularsituations,or,inanycasewhenagreedtowiththeenduser.Thistechnician'sexpertise,dependingonthe

case,maybemechanicaland/orelectricaland/orelectronicand/orsoftware.

2GENERALINFORMATION

2.1 MANUFACTURERIDENTIFICATIONINFORMATION

ECOTECHITALIAs.r.l.ViaCopernico85–47122Forlì(FC)‐Italy

Tel.0039(0)543774314Fax.0039(0)543778658E‐mail.[email protected]

AFTERSALESSERVICE/SPARES:

foundatResellersorAuthorisedServiceCentres:seethelistonwww.ecotechitalia.com.

2.2 MACHINEIDENTIFICATIONRATINGPLATESANDDATA:

EachmachineisidentifiedbyaCEplateonwhichinformationconcerningthemachinehasbeenprintedindelibly.

Foranycommunicationwiththemanufacturerortheservicecentresalwayscitethefollowingreferences:

Figure2‐1CEplates

Thelocationoftheplatemayvaryfrommachinetomachine.

2.3 DECLARATIONS

ThemachinehasbeenmanufacturedinconformitywiththeEuropeanCommunityDirectivespertinentandapplicableatthe

momentofitsreleaseonthemarket.

2.3.1 DeclarationofConformity

DECLARATIONOFCONFORMITY

(AnnexII‐ADir.2006/42/CE)

THEMANUFACTURER

ECOTECHITALIAs.r.l.viaCopernico,8547100ForlìFC‐ITALY,declares,underitsexclusiveresponsibility,thattheproduct:

Lawnmowerbrush‐cutter/Lawnmowerforedges–SeriesDCS/BT–Model:60‐60Traction/60SwingTop

Type:SeriesDCS/BT YearofManufacture: 2011

ConformstothefollowingEUregulations

MachineDirective(Directive2006/42/EC)andtoallnationalprovisionsforimplementation;

EuropeanDirective2000/14/ECandlateramendments,concerningenvironmentalnoiseemissionsofmachinesandequipmentintendedfor

useoutdoors.

Harmonisedstandardsapplied:

UNIENISO3744:2009;UNIENISO20643:2008;UNIENISO12100‐1:2009;UNIENISO12100‐2:2009;UNIENISO14121‐1:2007

ThepersonauthorizedtocompiletheTechnicalManufacturingFileisMr.RobertoRomboliatECOTECHITALIAviaCopernico,8547100ForlìFC–ITALY.

TheTechnicalManufacturingFilerequiredbytheMachineDirective2006/42/ECiskeptonfileatthecompanyoffices.

Alloftheinstructionsonusefoundinthemanualsuppliedwiththemachinemustbecompliedwithaswellasallofthesafetyandaccidentprevention

standardsinforceinthecountryofoperation.TheproductbearstheCEMark.

Date:

Jan.03,2011Signature:

Table2‐1:ExtractoftheDeclarationofConformity

2.4 SAFETYREGULATIONS

Themachinehasbeenmanufacturedtakingintoaccounttheprovisionsfoundinthetechnicalsafetystandardslistedbelow:

UNIENISO12100‐1.SafetyOfMachinery‐BasicConcepts,GeneralPrinciplesForDesign‐ (Part1BasicTerminology,Methodology)

UNIENISO12100‐2.SafetyOfMachinery‐BasicConcepts, GeneralPrinciplesForDesign‐ (Part2Technicalprinciples)

UNIENISO14121‐1.MachineSafety

–

Riskassessmentprinciples

UNIENISO13857MachineSafety‐SafetyDistancestokeepupperandlowerextremitiesawayfromreachingdangerousareas.

UNIEN349MachineSafety‐MinimumSafetyDistancestoavoidcrushingpartsofthebody

UNIENISO3744Acoustics

–

Determinationofthesoundlevelsfromsourcesofnoisebywayofthemeasurementofsoundpressure

UNIENISO20643MechanicalVibration‐PortableMachinesandthosemanuallyoperated‐ Principlesfortheassessmentoftheemissionsof

vibrations.

Table2‐2:SafetyRegulations

2.5 GUARANTEE

Themachinesarecoveredbywarrantyasprovidedforinthegeneralsalesconditions.Ifduringthewarrantyperiod

malfunctionsordefectsweretooccurinpartsofthemachine,whichfallwithinthecasesindicatedbytheguarantee,the

Manufacturer,aftersuitablechecks,willseetotherepairorreplacementofthedefectiveparts.

Theseparts,inanycasemustbedeliveredtothemanufacturerattheexpenseofthepurchaser.Expensesfordisassemblyof

thepartstoberepairedorreplacedaretobepaidbythepurchaser.ThesepartsaresuppliedExWorksattheManufactureror

Resellerfacility.

Thewarrantyexpiresifthemalfunctionsreportedhaveoriginatedfromimproperconductandoperationsnotincompliance

withtheindicationscontainedinthismanual,causedbythepurchaser,hisemployees,thirdpartiesorbyimproperuseofthe

machinery.

Itshouldberecalledthatanychangestodevicesorsafetysystemsandanyproceduredifferentfromordinaryandextraordinary

maintenance,performedonthemachinewithoutexplicitwrittenauthorisationfromthemanufacturer,arecausefor

cancellationofthewarrantyandrelievethemanufacturerofallliabilityfordamagescausedbyadefectiveproduct.

Theverificationoftheproperoperationofthemachinepursuanttothemachineryspecificationsistheresponsibilityofthe

purchaser.

ForallofthesereasonswesuggestthatourclientsalwayscontactourServiceCentres.

ForallcomponentsnotmanufacturedbytheSelleronlytheguaranteeconditionsoftheindividualmanufacturersarevalid.

Withtherepairorreplacementofanydefectivepartstheseller’sobligationsaretobeconsideredfulfilled,

thereforeremainingcompletelyexoneratedfromanydamageclaimrequest.

2.6 ATTHEEXPENSEOFTHECLIENT

Formachinesonwhichmorethanonecuttingplateisanticipated,installationofthesameistobeperformedbytheuser,

carefullyfollowingtheinstructionsannexedtothisaccessory.

3DESCRIPTIONOFTHEMACHINE

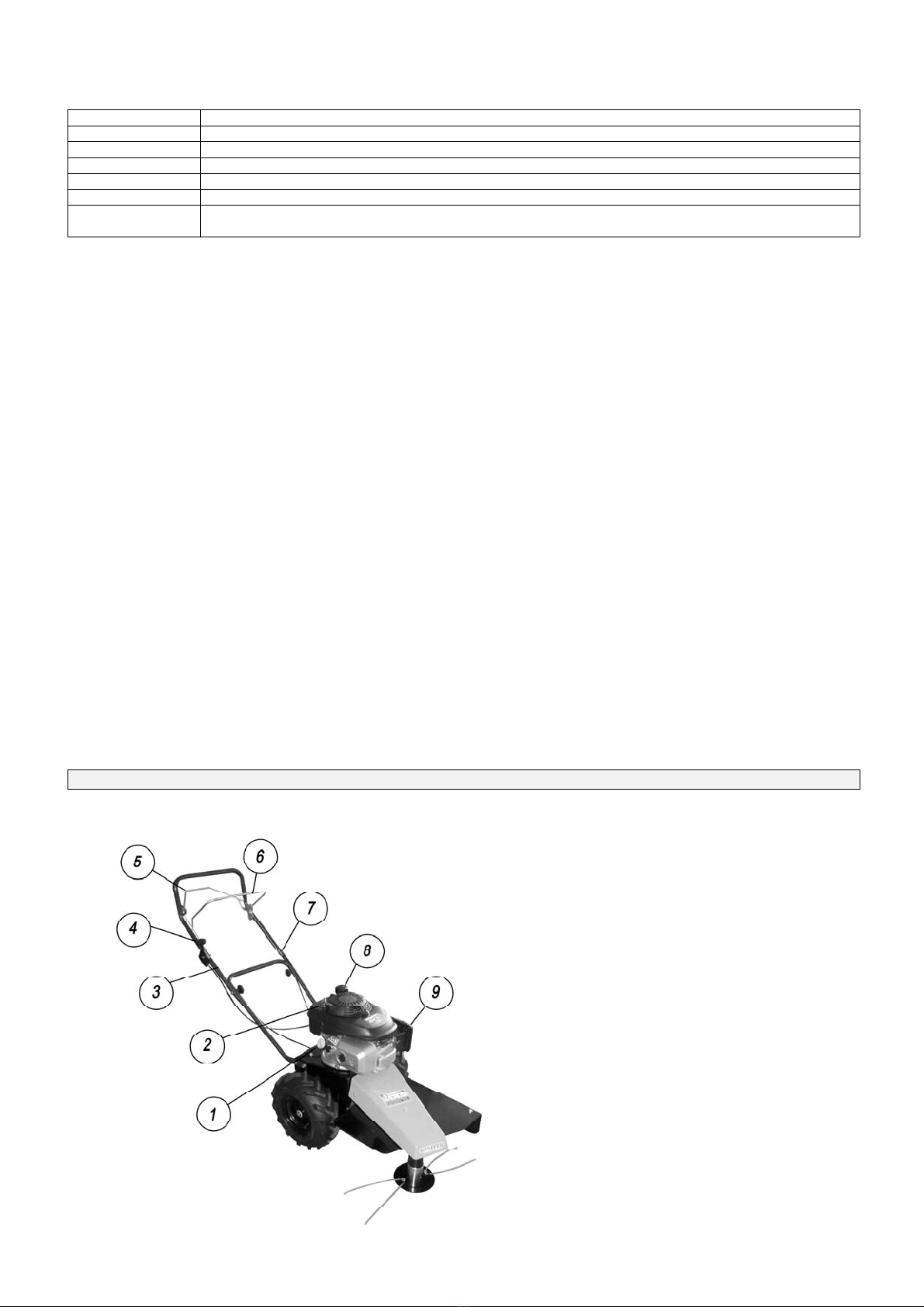

BT60

1OILFILLERCAP

2STARTERLEVER

3FORWARDMOVEMENTADJUSTMENT

4THROTTLELEVER

5FORWARDMOVEMENTENGAGEMENT

LEVER

6CUTTERENGAGEMENTLEVER

7CUTTINGADJUSTMENT

8FUELTANKCAP

9AIRFILTER

Figure3‐1:DetailsBT6

0

DCS60‐ Traction‐ SwingTop

Figure 3‐2:DetailsDCS6

0

1STARTER

2AIRFILTER

3FUELTANKCAP

4STARTERLEVER

5THROTTLELEVER

6CUTTERENGAGEMENTLEVER

7CUTTINGADJUSTMENT

8OILFILLERCAP

9ANGLECONTROLSWITCH

1STARTER

2AIRFILTER

3FUELTANKCAP

4STARTERLEVER

5FORWARDMOVEMENTADJUSTMENT

6THROTTLELEVER

7CUTTERENGAGEMENTLEVER

8FORWARDMOVEMENTENGAGEMENTLEVER

9CUTTINGADJUSTMENT

10OILFILLERCAP

Figure3‐3:DetailsDCS60Traction

3.1 OPERATIONALPRINCIPLE

3.1.1 IntendedUse

Thelawnmowerbrushcutteryouhavepurchasedwasdesignedandmanufacturedforcuttinggrass/brambles/brushon

uncultivatedgroundandunderbrush,particularlysuitableforfinishingandcuttinginlandwiththepresenceofdebris.

The60versionsweredesignedandmanufacturedtooperateonlevelgroundwithamaximumslopeof15°,whilstthe60Swing

Topversionsweredesignedtoworkonaslopeofupto45°,alwaysmaintainingthemotoralignedalongthehorizontal(0°).

Thetechnicalperformanceindicatedinthismanualrefersexclusivelytonewproductsorthosemaintainedefficient,following

theuse,inspectionandmaintenanceinstructions.

Asforanymechanicalequipment,propermaintenanceanditsbeingkeptcleanarerequired.Lubricatethemachineas

indicated.Followthesafetymeasuresandindicationsdescribedinthismanualandillustratedontheadhesivesafetylabelsand

signsonthemachine.

3.2 DIMENSIONS

Dimensions

ModelLength(mm)Length(mm) Length(mm)

BT601600580 970

DCS601600630 970

DCS60Traction1600580 970

DCS60SwingTop1700540 970

Table3‐1:Dimensions

3.3 ENVIRONMENTALCONDITIONS

Theequipmentdoesnotrequireanyparticularenvironmentalconditions.Themachinemayoperateondrygrass,butalsoon

wetgrass.

3.4 LIGHTING

Themachinewasdesignedandmanufacturedtoworkoutdoorswithnaturallight.Incaseofnighttimeoperationmakesure

thatsufficientartificiallightingissuppliedwithasourceofatleast150lux(UNIEN12646‐2:2008).

1STARTER

2AIRFILTER

3FUELTANKCAP

4STARTERLEVER

5FORWARDMOVEMENTADJUSTMENT

6THROTTLELEVER

7CUTTERENGAGEMENTLEVER

8FORWARDMOVEMENTENGAGEMENTLEVER

9CUTTINGADJUSTMENT

10OILFILLERCAP

11PARKINGBRAKE

12SLOPEADJUSTMENTLEVER

13SPEEDCHANGERCONTROLLEVER

Figure3‐4:DetailsDCS60SwingTop

3.5 VIBRATIONS

OperationalConditions:

MotorRPMduringtests3000rpm.

DCSBT60Traction‐SwingTop

AEQ

X1.6m/s²

Y2.2m/s²

Z4.1m/s²

3.6 NOISEEMISSIONS

TheweightedequivalentcontinuoussoundpressurelevelAintheworkstationis:

DCSBT60Traction‐SwingTop

93dB(A)

Otherphonometricmeasurementsintheworkplacemustbeperformedpursuanttowhatisprovidedforinthestandardsin

forceinthecountryofuse.

3.7 TECHNICALSPECIFICATIONS

BT60DCS60 DCS60Traction DCS60SwingTop

MotorHondaGCV160 HondaGCV190

HondaGXV160

StartupRecoilpullstarter

TransmissionBeltandmechanical‐‐ Beltandmechanical Beltandmechanicalwith

variablespeedcontrol

Speed1,6Km/h‐‐ 1,6Km/h Da1a2,3Km/h

Cuttingwidth20cmoutofrightwheelMax600mm Max600mm Max600mm

Cuttingheight30‐45‐60mm

Track580mm600 mm 580 mm min.520

max780mm

Wheels13"pneumatic16” 13"pneumatic 13"steeltoothed

Dryweight:38Kg33Kg 38 Kg 42Kg

Noiselevels92 dB

Table3‐2:TechnicalSpecifications

4INSTALLATION

4.1 TRANSPORTANDHANDLING

Incaseofhoisting/loweringalwayssetthemachinedownprogressively.

Alwayslaythemachinedownbackwards(loweringthehandlebarstowardtheground)when

inspecting/maintaining/cleaningunderthecutterplate,toavoidfueloroilleaks.Thisoperationistoalwaysbe

performedwiththemotorandthemovingpartsstopped.

Whenloadingaboardavehicle,alwaysusesolidrampsandpayattentiontoperformingtheloadingoperationsatthe

lowestspeed,payingattentiontokeepingthewheelsofthemachinesinsideoftheguides.

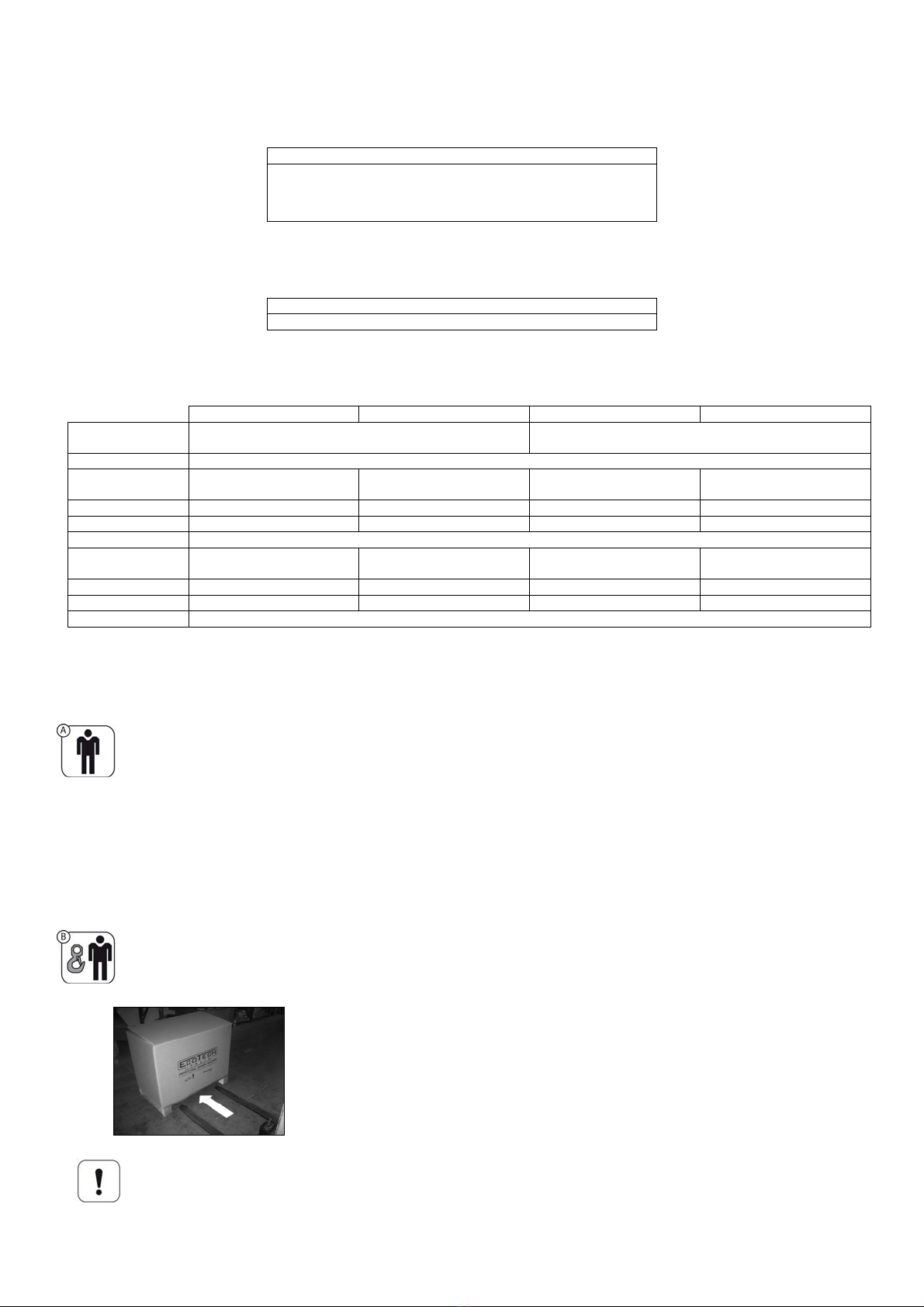

4.1.1 Packaging:

Themachinepackagingisasshowninthefollowingphoto:

Figure4‐1Packagingwiththearrow/directionforhoisting

ATTENTION!THELIFTINGPOINTFORTHEFORKLIFTFORKSISINDICATEDINTHEFIGURE!

4.2 STORAGE

Duringlongperiodsofstorageofthemachineitwouldbebestto:

Emptythefueltankoffuel;

Lubricatethecylinderwithasuitableproduct,availableatyourreseller;

Cleantheairfilter;

Emptyanyresidualgasolinefromthecarburettor;

Greaseanypartswiththepaintwornoffbywearorimpactofthemachineandanypartswherethetreatmenthas

wornofftoavoidpossiblerustformation.

4.3 PRELIMINARYCHECKS

Checkthatallofthesafetyinstructionadhesivelabelsareinorderandlegible.

Checkthatthemachineiscleanedofplantresidueanddebris.

Checkthatallofthesafetyguardsandgrillesareinorderandingoodcondition

Beforestartingthemotor

Visuallyinspectforanyleaksand/ordefective,missingorwornparts.Seetoanynecessaryrepairsbeforeusingthe

machineagain.

Checkthattheoillevelisnotbelowtheminimum:unscrewtheoilfillercaplocatedontherearofthemotor;usinga

cleanragcleanoffthedipstickandscrewthecapbackin.Unscrewthecapagainandmakesurethattheoillevelis

betweenthetwominimumandmaximummarks.Iftheoillevelisbelowtheminimum,topuptoasuitablelevel.

(requestthepropermotoroilfromyourreseller)

ATTENTION!!!ANEWMACHINEISSHIPPEDWITHOUTMOTOROIL

Makesurethatallofthescrewsareproperlytighteneddown.

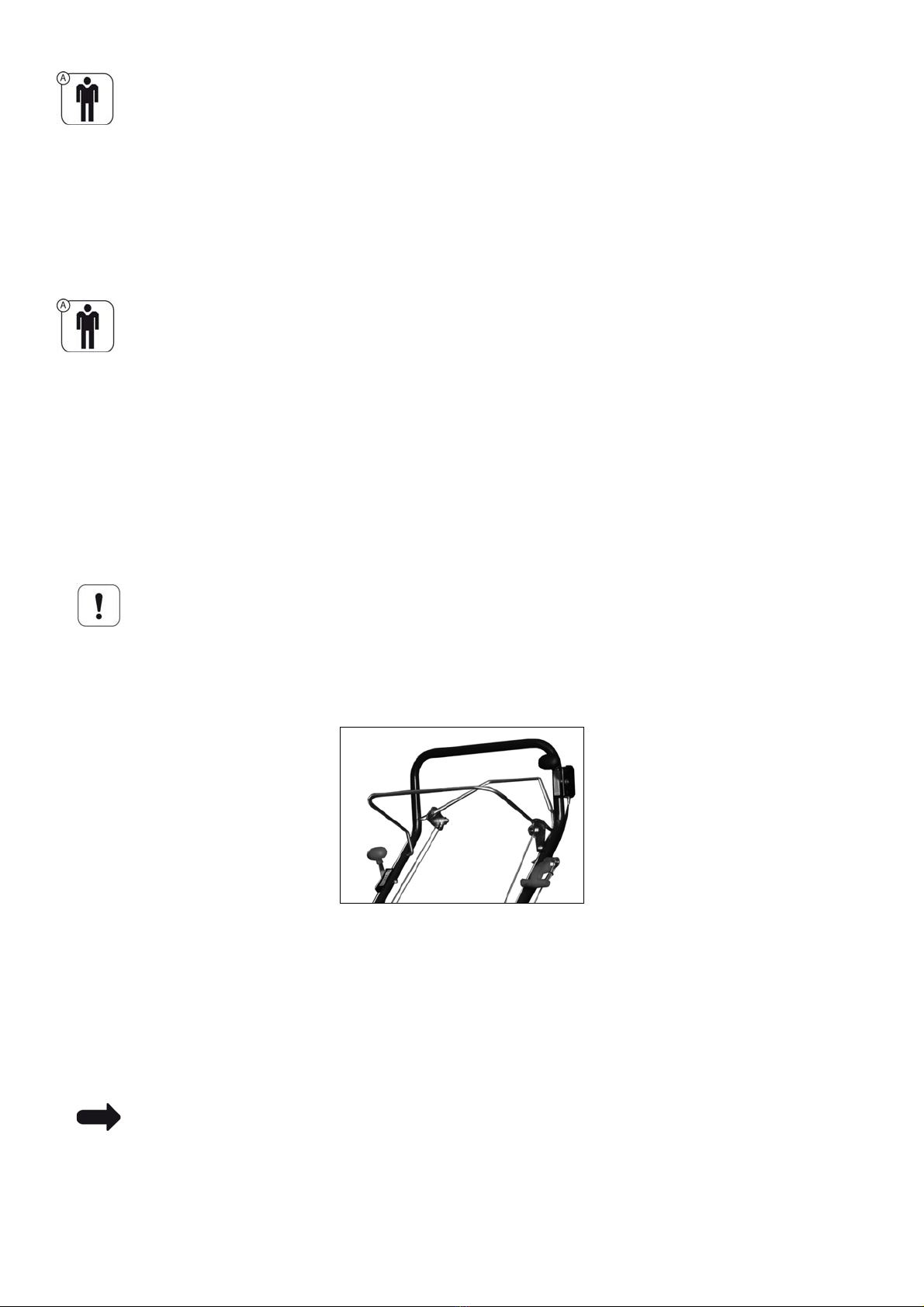

Makesurethatalloftheleversareintheirneutralposition.

Figure4‐2PositionofthelevelinNeutral

DCS/BT60‐Traction‐SwingTop

Cleantheairfilterwheneverthereisfouling.

Whenrefuellinguseafunnelwithafilterscreen,

Openthefuelcockand,ifthemotorisequippedwithastarterdeviceonthecarburettoractivateit.

Tostartthemotorcold,positionthegasleverintheSTARTpositionandwaitafewminutessothemotorreaches

operationaltemperaturebeforetakingittomaximumspeed.

Gripthepullstarterhandleandstartupthemotorwithastrongpull.

ITISRECOMMENDEDTHATYOUALSOFOLLOWTHEINSTRUCTIONSDESCRIBEDINTHEMOTORINSTRUCTION

BOOKLET.

Beforebeginningoperationsmakesurethatnopersonoranimalorthingiswithin30metresofthemachine;thenstartupthe

machinemotor.Oncethemotorhaswarmeduptakeittoitsmaximumrunningspeed.

4.4 SCRAPPING

Proceedwiththedisassemblyofthemachinedividingitspartsbasedonthematerialswithwhichtheyweremanufactured.

Followthewastemanagementanddisposalstandardsinforce.

5SAFETY

5.1 GENERALWARNINGS

Insideofthismanualandonthemachinethereareindicationsandprintedmessagestogetherwiththedangersymbolshown

belowthatindicatepotentialhazard.Itwouldbebest,thereforetopaycloseattentiontowhatisshownorwritteninorderto

ensuregreatersafetyfortheoperatorandanyoneelsewhomightbeintheoperationalrangeofthemachine.

Readthismanualbeforeusingthemachine.Onlytheinstructionsfoundinthismanualwillassistyouinusing

themachinesafelyandefficiently.

Safeusageisonlytheresultofproperoperationofthemachine,incompliancewiththestandardsand

limitationsdescribedinthismanual.Therefore,youmustknowandcomplywithallsafetywarningsinthis

manualandthoserelativetotheproperoperationofthemachine.

5.2 USERESTRICTIONS

Donotallowanyonetousethismachinewithouthavingfirstreadandunderstoodthismanual.

Keepawayfromchildren.

Donotwearbaggyclothing,whichmaybecomeentangledinthemachine'smovingparts.

Workonlyindaylightorwithsufficientartificiallighting.

Transportofpersons,animalsorloadsonthemachineduringitsoperationortransportisseverelyprohibited.

Reducetheforwardmovementspeedwhenworkingonaslopeandwhenturning,soastoavoidanypossibilityof

losingcontrolofthemachine.

Paycloseattentionwheninthevicinityofanytrench,hummockordip.

Turnoffthemotorbeforeundertakinganyprocedureonthemachine.

Neverworkunderneaththemachineorunderraisedpartsofthemachinethathavenotbeensafelysupportedinto

positionwithblocks,andalwayswiththemotorturnedoff.

Whenworkingonaslopealwaysworktransversally,neverdirectlyupwardsordownwards.

Keepasafedistancefromelectricalwiresandotherobstacles.Contactwithelectricalwiresorconductorscancause

electrocutionanddeath.

Itisobligatorythattheoperator,inordertoavoidbeingstruckbyobjectsprojectedfromthemachine,wear:

oFULLFACEPROTECTIONMASK

oCOVERALLS

oSAFETYBOOTS

oGLOVES

oHAT

5.3 DANGEROUSZONES

Cuttingcomponents;

Movementtransmissioncomponents;

Neverstandinfrontoftheoperatingmachine:thereisthedangeroftheprojectionofobjectsanddebris.

Alwayskeepatleast15metresdistancefromtheoperatingmachine:intheeventofsupervisionorobservationkeepto

thesideandatasafedistance.

5.4 SAFETYDEVICES

Relativetothedangerousareasidentifiedintheprecedingparagraph,protectivehousingshavebeeninstalledbothforthe

cuttingcomponentsandthetransmission.

1

–

Cuttingbladeshousing

2–Transmissionhousing

Figure5‐1Transmissionandcuttingbladeshousings

DONOTTAMPERWITHORREMOVETHESAFETYDEVICES.

5.5 SIGNS

SeeTable1‐3:Symbolsconcerningsafetyforthemeaningofthesymbols.

ONTOPOFTHEMACHINETHISFIGUREISFOUND:

Figure5‐2:Adhesivelabellocatedonthemachine

ATTENTION!!!Thismachineisequippedwithsharpcuttingcomponents;thereforekeephandsandfeeta

safedistanceawayfromthese.Neverperformanyproceduresonthemachinewhilstitisrunning.

Itisrecommendedtonotworkinareaswithgravel,rocksand/orforeignobjectsonthegroundthatmaybeprojectedbythe

cuttingbladesmakingitextremelydangerousforpersonsorthingsinthevicinityoftherunningmachine.Keepallpersonnelat

least15metresawayfromthemachine.Theoperatorshallalwayswearaprotectivefacemaskandasnecessaryrubberboots

aswell.

ATTENTION!!!Alwayskeepthehandsatasafedistancefromtheoscillatingmechanismonthemachineasit

caneasilycrushthefingers.

APPLICATIONOFTHESEREGULATIONSIS NOTAWASTEOFTIME!

THESEREGULATIONSCONTRIBUTETOKEEPINGPERSONSANDTHINGSFROMIRREPARABLEHARMAND

ENSUREOPERATORSAFETY.

5.6 RESIDUALRISKS

Noise:alwayswearearprotection.

Itisrecommendedthatonetakeregularbreaksduringworktime.Donotusethemachineformorethan8hoursinaday.

6MACHINEUSE

Dearcustomer,wethankyouforthetrustyouhavegivenECOTECHITALIA.Weareconfidentthatuseofthisnewmachinewill

fullyfulfilyourrequirements.

Forthepurposeofobtainingoptimumapplicationandefficientmaintenanceofthemachineovertime,pleasereadallofthe

directionsandwarningsdescribedinthisbooklet,whichmustalwaysbekepttogetherwiththemachine.

BEFORESTARTINGUPTHEMACHINEREADTHEUSEINSTRUCTIONMANUALTHOROUGHLY!

6.1 ADJUSTMENTS

Model

AdjustmentBT60DCS60DCS60Traction DCS60SwingTop

Cutting

height

Withatubularsocketwrenchofsize13,loosen thescrew under

thecup(Figure6‐1),moveoneorbothoftheblocksfromthetop

platetothebottomofit(fig.6‐2),thenscrewthewholethingand

tightenthescrew.

Figure6‐1:cuttinghead

Figure6‐2:cuttingheights

SpeedSetspeed1.3Km/hN/ASetspeed1.3Km/h Setthespeedchangercontrol

leverontheleft(Figure3‐24n.

13)toincreaseorreducethe

speed

SteeringUsesufficientpressureonthehandgripstoturnrightorleft.

SlopeN/AN/AN/A Themachineenablesthree

inclinationanglestotheright

andthreetotheleft.Toadjust

theinclinationanglesusethe

redlefthandlever(Figure3‐2

no.4)thenadjustthe

correspondentpinsinoneof

thesevenangleadjustment

holes(no.15)

MotorRefertothemotorinstructionmanual.

Table6‐1:Adjustments

6.2 OPERATIONALMODES

6.2.1 WORKINGONLEVELGROUND

Afterhavingperformedthepreliminarychecksreferredtoinpoint4.3andafterstarting

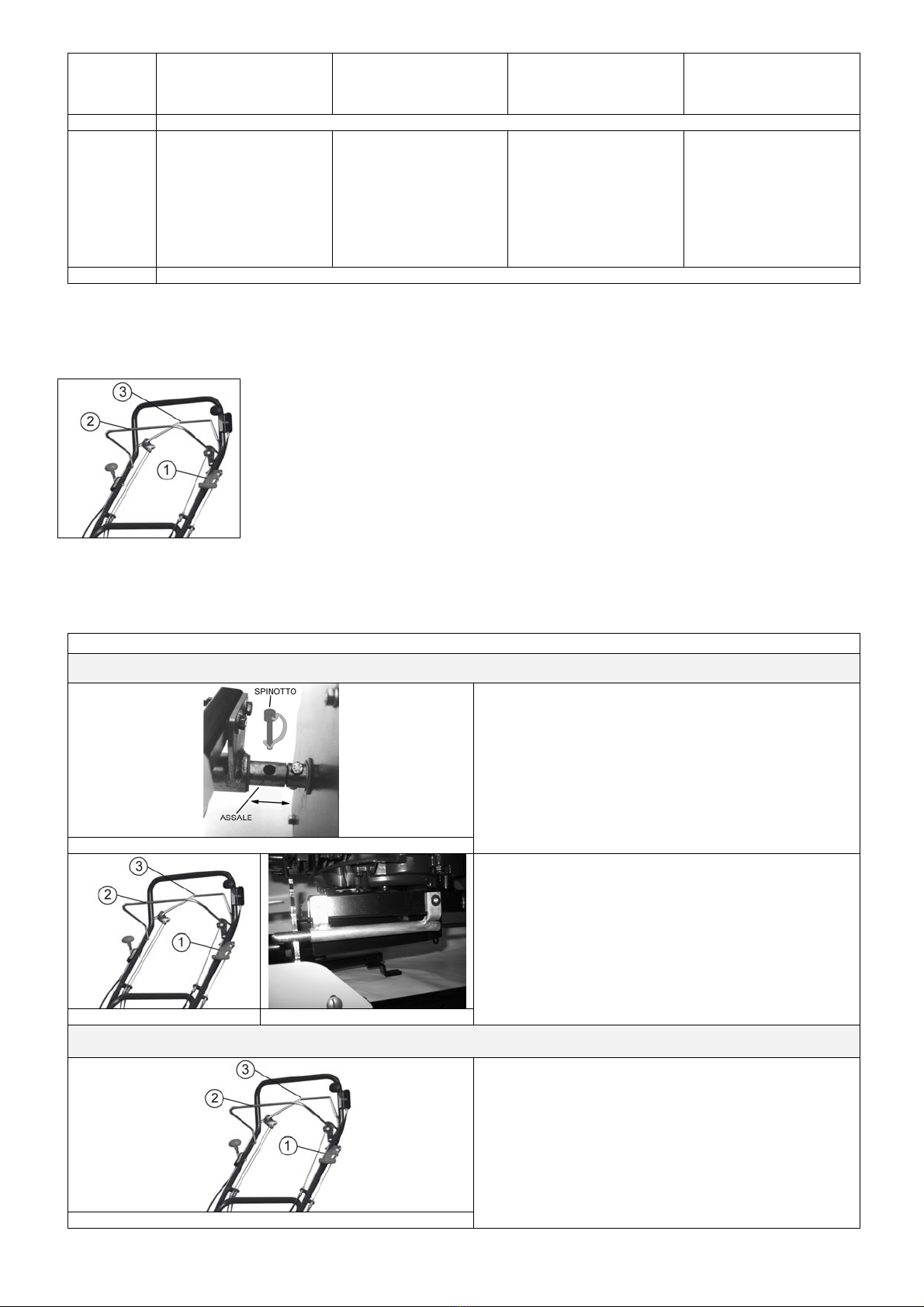

themotor,activatethebladecouplinglever(Figure6‐3–no.2),selectthegearinwhich

youwanttowork(dependingonthemodels),engagetheforwardmovementlever

(Figure6‐3–no.3)andbeginworkusingthegreatestcareatalltimes.

Figure6‐3:HandlebarsforModelDCS/BT60‐Traction‐SwingTop

6.2.2 WORKINGONASLOPE(onlyontheSwingversion)

DCS 60Swing Top

Whenworkingonslopingground,itisnecessarytowidenthetrackofthewheels.

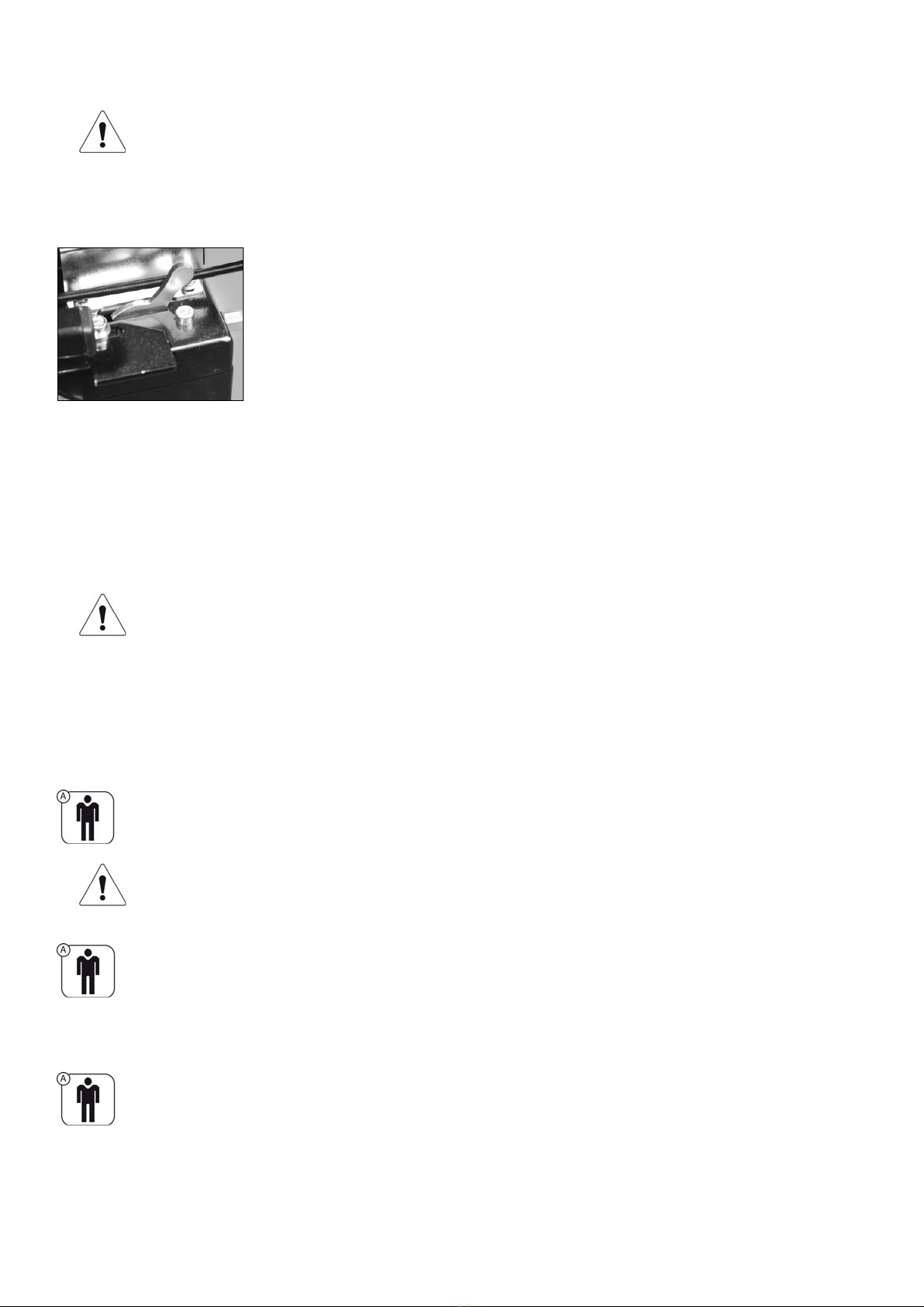

Tocarryoutthisoperation,raisethesafetyspringoffofthepinand

removethepin(seefigure).Slideoutthesemi‐axleandlocateitin

correspondencetothesecondhole,thenreplacethepinandtherelative

safetyspring.Engagetheparkingbrakelocatedontopofthe

transmissioncasing.

Figure6‐4:WheellockingpinDCS60

Atthispoint,unlockthemotor,movingtheleveronthehandlebar

backwards(Figure6‐5:Handlebarsno.1),settheinclinationangleofthe

machineaccordingtotheslopeonthegroundonwhichtheworkistobe

doneuntilthemotorisonthelevel,horizontally,thenlockthemotor

shiftingthesameleverforward.makesurethatthelockingpin(Figure

6‐6:LockingPin)ispositionedinoneofthethreeseatstotherightorto

theleft.

Figure

6

‐5:HandlebarsFigure

6

‐

6

:LockingPin

Nowthemachineisreadyforwork.

Toinverttheworkingdirectionontheslope,unlockthelever(Figure

6‐7:Handlebarsno.1),holditbalancedwiththehandlebars

rotatethemachine180turninguphill,setthemachineinclinationangle

ontheoppositeside,repositioningthemotoronthelevel,thenrelocking

themachinewiththesameleverandcontinuingtheworkinthe

oppositedirection.

Figure

6

‐7:Handlebars

Table6‐2:Workingonaslope

Alwaysstarttheworkatthebottomoftheslopeadvancingsidewaysandonparalleltracksupwardstoensurebetter

dischargeofthecutgrassdownwards.Itisrecommendedthatoneworkfirstonlevelgroundorwithaveryslightslope

soastofamiliariseone'sselfwiththemachine’soperation.Steepslopesshouldbeworkedononlybyveryexperienced

operators.

Themachinehasbeendesignedtoworkonslopestransversallyandnotinperpendicular.

THEMANUFACTURERWILLNOTBELIABLEFORANYDAMAGECAUSEDBYTHEMOTORSEIZINGDUETOINAPPROPRIATE

USEOFTHEMACHINE.

6.3 NORMALSTOP

Oncetheworkhasbeencompleted,tostopthemotor,putthegasleveronthe

(Figure3‐2no.6)STOPpositionand(orifthemotorisequippedusethestopswitch

alwaysafterhavingallowedthemotorRPMtodroptoidle),andthen,ifthereis

one,turnthefuelcocktooff.

OntheSwingversionengagetheparkingbrake(seefiguretotheside).

Figure6‐8:Parkingbrake

6.4 EMERGENCYSTOP

Incaseofanymalfunctionduringworkoperations,simplyreleasethehandlebars:themachinewillstopforwardmovementand

thecuttingbladeswillstop.

Tostopthemotor,refertothepreviouspoint.

7MAINTENANCE

7.1 MAINTENANCESTATUS

BEFOREperforminganymaintenanceoperationsonthemachine,turnoffthemotorandwaitfortheblades

tostopcompletely.

Ifthemaintenanceoperationsarenotperformed,theremaybedamagetothemachineorinjuriestotheoperatoror

bystanders.Thesedamagesandinjuriesarenotcoveredbythewarranty.

Dailymaintenanceistobeperformedbytheuser.

Maintenanceoperationsafterthefirst20,100and300hoursofoperationmustbeperformedatthereseller.

Asktheresellertocheckthemachine,ifproblemsarise.

7.2 CLEANING

ATTENTION!!!ABSOLUTELYDONOTUSEWATERJETCLEANINGSYSTEMS.

7.3 LUBRICATION

Regularlylubricate/greasethemechanicalcomponentsthatactuatethemovingpartsofthemachine:chains,gears,linkages,

etc.Forsuitablelubricants,contactyourreseller.

7.4 ORDINARYMAINTENANCE

Generallytheoillevelshouldbecheckedevery8hoursofrunningtime,whilsttheairfiltershouldbecleanedevery4hours,or

evenmoreoftenifworkinginaparticularlydustyenvironment.

Removeanycutgrassdepositsfromthemotorheadtoensurebetterairflow.

Forproperuseofthemachine,donoteverforcethemotor;ifwhitesmokebeginstocomeoutoftheexhaust,itisnecessaryto

slowdown.

7.5 EXTRAORDINARYMAINTENANCE

Asktheresellertoperformtheseoperationsthatrequirespecificcapabilitiesandequipment.

Componenttobe

checkedInspectionEvery10hoursEvery50hoursEvery100hours/

year

Cuttingheadbelt

Checkbelttension

Checkbeltwear

Replaceasnecessary.

Forwardmovement

engagementlever

Checkthatthemachinedoesnotmove

forwardwiththeleverinneutral

BrakeCheckefficiencyofthebrake

FrameCheckforrustand/orcracks

SafetywarningsCheckthattheyareintheirproperplace

andlegible

GuardsCheckthatthesearesecuredintheir

properplaceandingoodcondition.

Fueltankandlines

Checkthattherearenoleaksandthat

theyareingoodcondition.Replaceas

necessary.

AcceleratorcontrolCheckitsproperoperation

Wire

Checkthattheyaresecurelyfastenedin

placeandingoodcondition

Replaceasnecessary.

CutterengagementleverCheckthecorrectcabletension

MotorRefertothemotorinstructionmanual.

Table7‐1:ExtraordinaryMaintenance

7.6 DIAGNOSTICSANDTROUBLESHOOTING

A. Themotordoesnotstart:makesurethat:

Thereisfuelinthetank(no.10)

Thegascock,ifpresent,isnotclosed.

Withtheenginecold,thegaslevermustbeontheSTARTposition(no.9).

Withthemotorhot,thegaslevershouldnotbeontheSTARTposition(thiscouldfloodthemotor).

ThegasleverisnotintheSTOPposition.

Fuelreachesthecarburettor.

Theairfilterisnotfouled(no.13).

Theventholeontopofthefuelcapisnotcloggedwithdebris

(no.10).

Thesparkplugsparks.

Ifthesechecksarepositivebutthemotordoesnotstart,contactyour

localreseller.

Figure7‐1:MotorDetail

B. Theblades,whentheleverisengaged,donotrotate:

Checkthatthebeltisnotworn

Checkthatthebelthasnotcomeoutofthepulley

Makesurethattheleveriscapableofapplyingpowertothebelt

C. Theblades,whentheleverisdisengaged,continuetorotate:

CheckthatthebrakepulleyisengagedIfthisisnotthecaseloosenthecuttingadjustmentleveruntilthebrake

liningrestsagainsttheshoulderofthepulley.

Checkthatthebrakeliningisnotworn

Figure7‐2:Wirereplacement

D. Themachinedoesnotoperateproperly:check:

Thatthewireisnottoowornout.Ifitdidreplaceitasfollows:

oturnofftheengine,removetheoldwire,takeanew

oneandgivehimasimpleknotinthemiddle(Figure7‐

2),andfinallyfitsintoitshousing;

Thattheairfilter(no.13)isnottoofouledcausinganotableloss

inpowerofthemotor.Inthiscaseblowitoutwithcompressed

airorreplaceitwithanewone,whichmaybepurchasedatyour

reseller.

Thatthegashasnotnearlyrunout.

Thattheoillevelisnotlowerthantheminimumlevel(no.11)

Thatthebeltdoesnotslip:inthiscaseadjustthewire.

E. Withtheforwardmovementleverengaged,themachinedoesnotmove:

Checkthetensionontheengagementwireincaseitistooloose.

Checkthatthetransmissionbeltsarenottooworn.

8SPARESANDACCESSORIES

8.1 SERVICE

Allmaintenanceandrepairproceduresmustbecarriedoutbyqualifiedpersonnel:contactyournearestresellerorService

Centre.

Alistofauthorisedresellersmaybefoundonthewebsite:www.ecotechitalia.com.

8.2 SPAREPARTS

Alwaysuseonlyoriginalspareparts.Non‐originalsparepartscouldcauseinjuriestoyouandtobystanders,apartfromdamage

tothemachine.

Foranymachinereplacementpart,contactthenearestresellerorServiceCentre.

9PURPOSEOFTHEINSTRUCTIONMANUAL

ThisInstructionManualisanintegralpartofthemachineandhasthepurposeofprovidingalloftheinformationnecessaryfor:

Thepropersensitisationofoperatorsregardingsafety;

Safehandlingofthemachine,eitherpackagedorunwrapped;

Properinstallationofthemachine;

Detailedknowledgeofitsoperationanditslimitations;

Itsproperandsafeuse;

Performingmaintenanceproceduresproperlyandsafely;

Disassemblingthemachinesafelyandincompliancewiththeworkerhealthandsafetystandardsinforceaswellas

thosefortheenvironment.

Themanagersinthecorporatedepartmentswhopurchasethismachine,havetheobligation,pursuanttothestandardsin

force,toreadthecontentsofthisManualcarefullyandtohavetheassignedoperatorsandmaintenancepersonnelreaditas

regardsthepartsthatconcernthem.

Thetimeusedforthispurposewillbeforthemostpartcompensatedbytheproperoperationofthemachineandbyitssafe

use.

Thisdocumentassumesthatwhereverthemachineistobeputintooperation,thattheworkhealthandsafetystandardsin

forcewillbecompliedwith.

Theinstructions,drawingsanddocumentationcontainedinthisManualaretechnicalandconfidential,beingthepropertyof

ECOTECHITALIAandmaynotbereproducedinanymanner,eitherwhollyorinpart.

Thecustomer,inaddition,hastheresponsibilitytomakesurethat,intheeventthatthisdocumentweretobechangedbythe

manufacturer,onlyupdatedversionsofthemanualwillbeactuallyavailableintheplaceswherethemachineisbeingused.

TheECOTECHITALIA Companyisconsideredreleasedfromanyliabilityinthecasethatthemachineisusedimproperly,suchas

forexample:

Improperuseofthemachineoroperationbyuntrained/unqualifiedpersonnel;

Useincontrastwithspecificstandardsandlegislation;

Fuelsupplydefects;

Seriousdeficienciesinmaintenance;

Unauthorisedmodificationsorserviceprocedures;

Useofnonoriginalsparepartsoronesnotspecificallyforthemodelofthemachine

Totalorpartiallackofcompliancewiththeinstructions;

Extraordinaryevents.

9.1 CONSERVATIONOFTHEINSTRUCTIONMANUAL

Thisinstructionmanualistobeconservedcarefullyandshallaccompanythemachineineverychangeofhandsthatthe

machinemightundertakeduringitsservicelife.

Conservationofthemanualwillbefacilitatedbycarefulhandling,withcleanhandsandnotlayingitdownonsoiledsurfaces.Its

partsshouldnotbearbitrarilychanged,tornoutorremoved.

Themanualshouldbefiledinaplaceprotectedagainsthumidityandheatandinthevicinityofthemachinetowhichitrefers.If

themanualshouldbedamagedorrenderedunusableinanyway,theusermaycontactthemanufacturertorequestan

additionalcopyat:

ECOTECHITALIAs.r.l.ViaCopernico85–47122Forlì(FC)‐Italy

Tel.0039(0)543774314Fax.0039(0)543778658E‐mail.[email protected]

specifyingthetypeofmachineandtheserialorordernumberfoundonthemachineidentificationplate.

9.2 INSTRUCTIONMANUALUPDATINGMETHODS

ECOTECHITALIAreservestherighttochangethedesigninordertoimprovethemachinewithoutgivingnoticetocustomers,

andwithoutupdatingthemanualsalreadydeliveredtoendusers.

Therefore,incaseofchangestomachinesinstalledinthecustomer'spremises,asagreedtowiththemanufacturerandthat

bringaboutchangestooneormorechaptersoftheInstructionManual,itwillbethemanufacturer'sresponsibilitytosendthe

ownersoftheInstructionManualsinvolvedinthechanges,withanewrevisedversionofthesame.

Itistheenduser'sresponsibility,followingtheindicationsthataccompanytheupdateddocumentation,toreplaceinallofthe

copiesintheirpossessiontheoldchapterswiththenew,theintroductorypageandthetableofcontentswiththenewrevision.

ECOTECHITALIAisresponsibleforthedescriptionsgivenintheItalianlanguage;anytranslationscannotbefullyverified,

therefore,ifanincongruenceweretotakeplace,itisnecessarytorefertotheItalianlanguageversionandifnecessarycontact

oursalesoffices,whichwillprovideforanynecessarychanges.

9.3 GLOSSARY

Inthissectiontheuncommonterms,orthosewithameaningdifferentfromthenorm,willbelisted.

Belowtheabbreviationsusedareexplained.

9.3.1 Glossary(AnnexIp.1.1.1Dir.2006/42/CE)

DANGER:Apotentialsourceofinjuriesordamagetoone'shealthandsafety;

DANGEROUSZONE:Anyareainsideofand/ornearamachineinwhichthepresenceofanexposedpersonconstitutes

ariskforthehealthandsafetyofthatperson.

RISK:Acombinationoftheprobabilitiesandtheseriousnessofaninjuryorofdamagetothehealthandsafetythat

couldarisefromadangeroussituation;

HOUSING:Anelementofthemachineusedspecificallyforensuringprotectionbywayofasolidbarrier;

SAFETYDEVICE:Adevice(differentfromahousing)thatreducesriskwhetheraloneorincombinationwithahousing;

INTENDEDUSE:Useofthemachineincompliancewiththeinformationprovidedintheuseinstructions;

REASONABLYFORESEEABLEIMPROPERUSE:Useofthemachineinamannerdifferentfromthatindicatedintheuse

instructions,butthatcouldarisefromeasilypredictablehumanbehaviour.

9.3.2 Otherdefinitions

EXPOSEDPERSON:Anypersonwhoiscompletelyorpartiallywithinadangerzone.

OPERATOR:Thisistobeunderstoodasthepersonorpersonswhohavebeenassignedtoinstall,operate,adjust,clean,

repairandhandleamachineandcarryoutitsmaintenance;

QUALIFIEDPERSONNELorQUALIFIEDOPERATORThisistobeunderstoodasthepersonorpersonswhohave

undertakenaspecialisedcourseortraining,etc.,andwhopossessexperienceinregardtotheinstallation,

commissioningandmaintenance,therepairortransportofthemachine.

MAN‐MACHINEINTERACTION:Anysituationinwhichtheoperatorinteractswiththemachineduringanyoperational

phaseatanymomentintheservicelifeofthelatter;

OPERATORQUALIFICATION:Minimumcompetencelevelthattheoperatormustpossesstocarryouttheoperations

described;

NUMBEROFOPERATORS:Thenumberofoperatorsnecessaryforthepropercarryingoutoftheoperationsdescribed

andarisingfromacarefulanalysisundertakenbythemanufacturer,becauseofwhichanenduserusingadifferent

numberofpersonnelcouldinhibittheachievementoftheintendedresultorplacethepersonnelinvolvedinjeopardy.

MACHINESTATUS:Themachinestatusincludestheoperationalmode:forexample,automaticrunning,stop,etc.,the

safetyconditionsonthemachinesuchasguardsincluded,guardsexcluded,emergencystopbuttonpressed,typeof

insulationfromenergysources,etc.;

RESIDUALRISK:Risksthatremain,regardlessofthefactthatsafetymeasureshavebeenintegratedintothedesignof

themachineandofthecomplementarysafetymeasuresandguardsadopted;

SAFETYCOMPONENTS:Componentintendedfortheperformanceofasafetyfunctionthebreakageand/or

malfunctionofwhichcouldcreateadangerforthesafetyofpersonnel.

This manual suits for next models

4

Table of contents

Other Ecotech Italia Lawn Mower manuals