Take special care not to touch hot parts of the engine.

Prestate particolare attenzione a non entrare in contatto con parti surriscaldate del motore.

Veiller tout particulièrement à ne pas toucher des éléments surchauffés du moteur.

Achtung – keine heißen Motorteile berühren!

No tocar partes recalentadas del motor.

Tome muito cuidado para não entrar em contacto com as partes aquecidas do motor.

Engine exhaust fumes can cause sickness or death. If it is necessar to run an engine in an

enclosed area, use an exhaust pipe extension to remove the fumes. Alwa s tr to work in a well

ventilated area.

I gas di scarico possono causare malanni o morte. e è necessario mettere in moto un motore

in uno spazio chiuso, usare una prolunga tubo di scarico per far uscire il fumo. Lavorare in una

zona ben ventilata.

L’exhalation des gaz d’échappement peut être cause d’intoxication ou de mort. S’il est vraiment

nécessaire d’allumer le moteur à l’intérieur, appliquer au tu au d’échappement un autre tu au

extensible pour permettre la sortie des gaz. Il est toujours mieux de travailler en plein air.

Auspuffgase können Übelkeit oder Tod verursachen. Wenn es notwendig ist, einen Motor in

einem geschlossenen Raum laufen zu lassen, benützen ie eine Verlängerung, um das

Auspuffgas abzuleiten. Versuchen ie immer in einem gut belüfteten Raum zu arbeiten.

Los gases de escape pueden provocar enfermedades o muerte. De tener que poner en marcha

un motor en un espacio cerrado, usar una prolongación del tubo de escape para que salga el

humo. Trabajar en una zona bien ventilada.

Os gases de escape podem causar danos ou morte. Caso seja ncessário fazer com que o

motor funcione num espaço fechado, utilize uma extensão para o tubo de escape que os fumos

sejam expulso para o exterior. Trabalhe numa área bem ventilada.

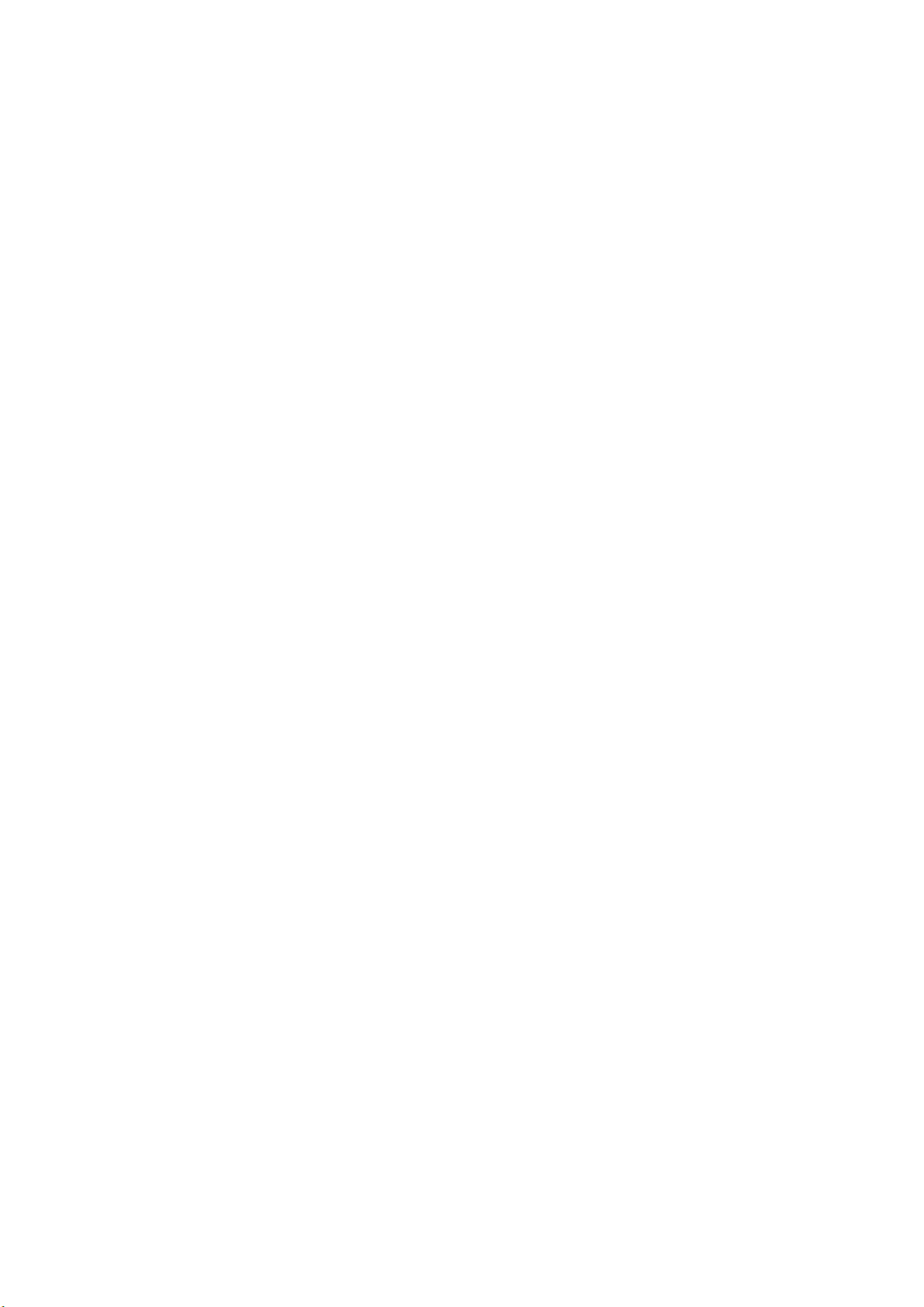

Caution! Never touch moving pulle s or belts. The can be ver dangerous. Never do

maintenance with engine running.

Attenzione! Non toccare mai pulegge o cinghie in movimento, creano gravi danni alla persona.

Non fare manutenzione col motore in moto.

Attention! Ne jamais toucher ni poulies ni courroies en mouvement, elles peuvent provoquer des

accidents aux personnes. Ne pas faire l’entretien quand le moteur est en marche.

Vorsicht! Nie laufende Riemenscheiben oder Treibriemen anfassen, da es gefährlich ist. Nie bei

laufendem Motor Instandhaltung machen.

¡Atención! No tocar jamás poleas o correas en movimiento, porque pueden crear graves daños

a la persona. No efectuar el mantenimiento con el motor en marcha.

Atenção! Nunca toque nas polias ou correias em movimento devido ao alto risco de ferimentos.

Nunca faça a manutenção da máquina com o motor ligado.

A burst which separates the t re from the rim parts can cause serious injur or death.

La separazione fra pneumatico e cerchione, causata dall’esplosione del pneumatico, può

provocare serie ferite o addirittura la morte.

La séparation entre le pneu et la jante, provoquée par l’explosion d’une roue peut causer des

dommages, blessures ou la mort.

Die Trennung der Räder von den Felgen durch Explosion kann schwere Verletzungen oder den

Tod verursachen.

La separación entre el neumático la llanta producida por la explosión del neumático puede

provocar graves herida e incluso la muerte.

A separação entre o pneumático e o aro, provocada pela explosão do pneumático, pode causar

graves ferimentos ou até mesmo a morte.

Prevent batter explosions: keep sparks, lighted matches and open flames awa from the top of

the batter . Batter gas can explode.

Per prevenire l’esplosione della batteria, tenete scintille, fiammiferi accesi e fiamme lontani dalla

stessa. Il gas della batteria può esplodere.

Prévenir l’explosion de la batterie: tenir les étincelles, les allumettes et le feu loin de la batterie.

Le gaz de la batterie peut exploser.

Vorbeugung der Batterie-Explosion. Entfernen ie Funken, Zündhölzer und Flammen von der

Batterie. Das Batteriegas kann explodieren.

Para prevenir la explosión de la batería, mantener chispas, cerillas encendidas llamas lejos de

la misma. El gas de la batería puede explotar.

Para prevenir explosão da bateria ter centelhas, fósforos acendido e chamas longe da mesma.

O gás da bateria poderia explodir.

Handle fuel with care, it is highl flammable: Do not refuel machine while smoking, when

machine is near an open flame or sparks, or when the engine is running. Stop the engine.

Maneggiare il carburante con cura, è altamente infiammabile; non fate rifornimento mentre

fumate, o vicino a fiamme o scintille, o quando il motore è acceso.

Manier avec soin le carburant car c’est très inflammable. Ne pas remplir le réservoir si vous êtes

en train de fumer ou pendant que la machine est près du feu ou d’étincelles ou encore pendant

que la machine travaille. Arrêter le moteur.

Treibstoff vorsichtig handhaben, da er sehr entzündbar ist: beim Tanken nicht rauchen. Nicht

tanken, wenn die Maschine in der Nähe von Flammen oder Funken ist oder wenn der Motor

läuft. Immer den Motor abschalten.

Manejar el combustible con cuidado porque es sumamente inflamable; no repostar mientras se

fuma o cerca de llamas o chispas, o cuando el motor está encendido.

Manuseie o carburante com cuidado, pois este è altamente inflamável; não fume durante o

abastecimento da máquina ou enquanto o motor estiver ligado, não o aproximado de chama ou

de faíscas.