EDG Fv Plus Sinter User manual

Manual

CAPA

Manual 1

Date of manufacture

200

Serial Number

Vacuum Furnace

1Recepting

Theequipmentispackedseparatelyfromthevacuumpump,checkifyouhavetwo

boxes if you have acquired the furnace and the pump. Check the general

conditions of the package, if any damage is noticed contact the company

immediately which will provide guidance on how to proceed. We remind you that

the equipment is shipped at the purchaser's account and risk and it is insured by

theconveyor.

1.1The FV-PLUS package should include:

A)Afurnacesettledininjectedfoam.

B)Arigidmat-I–Pic-5-Item-(24).

C)Asoftmat.

D)Asetofisothermalpins.Pic-5-item-(25).

E)Instructionmanual.

F)Warrantydeed.

Manual

2

1.1The FV-PLUS package should include:

A)Afurnacesettledininjectedfoam.

B)Arigidmat-I–Pic-5-Item-(24).

C)Asoftmat.

D)Asetofisothermalpins.Pic-5-item-(25).

E)Instructionmanual.

F)Warrantydeed.

NOTE: If you have acquired the furnace without the pump, please do not consider

thematerialmentionedonitem(1-2).

1.2The vacuum pump package should include:

G)Thevacuumpump

H)A1.5mN.P.T.hose

I)Metallicclamps.(2pieces).

J)Rubber,floorinsulatingcapsforfixation(4pieces).

K)Labelsforconnectionsidentification.

!Warning: The FV-Plus-Sinter furnace needs to have the vacuum

pumpalwaysconnectedtothefurnaceevenwhenthevacuumisnotusedfor

the burn, as it happens with the sintering/infiltration. For this procedure the

S.A.L.V® Sistema deAquecimento de Longa Vida (long life heating system) requires

thevacuumpumptohelpwiththeaircirculationinsidethemuffle,therefore having its

heatingelementdurabilityincreased(resistance).

!Note: Not checking the procedures above will interfere on the

equipmentcorrect working and also guarantee will belost. Keep thepump

alwaysconnectedandinperfectworkingconditions.

2S.A.L.V. SYSTEM

Your Fv-Plus-Sinter has highly technological devices that allow it to perform 3

functions perfectly: traditional ceramic burn, sintering and infiltration of alumina-

glass composites. When sintering alumina, the lining used heated over 500º C

releasessub-productswhichareabsorbedbythemuffleundervacuumandcan

Manual

contaminate the ceramic, staining and fissuring it during the sintering process.

Long periods under high temperatures (1,180°C) in pressurized chambers

(vacuum muffles) can shorten the heating resistance useful life. The S.A.L.V.

systemwasspeciallydevelopedtoovercomesuchproblems

S.A.L.V.®Pat.Pending.

SistemadeAquecimentodeLongaVida(LongLifeHeatingSystem)

Twoyearsguaranteeathightemperatures

The metallic alloys used as heating resistance have chemical elements in its

composition that, when heated and in contact with air, create an oxide adherent

layerwhichprotectsthemfromoutwear.

In ceramic furnace muffles, the process for the oxide layer formation can be

impairedduetotheresistanceimprisonmentandtothevacuumoperation.

TheexclusiveS.A.L.V.system,developedandpatentedbyEDG,promotesairflow

inside the quartz pipe that supports the muffle resistance. This flow renews and

maintains the protective oxide layer, increasing the useful life of the resistance at

hightemperatures.

This exclusive technological advance allowed EDG to extend the guarantee to 2

yearsforthefurnacesequippedwiththissystem.

To endure the high temperatures involved in the processes, the sensor (termopar)

should be made of platinum which, on the other hand, is not adequate for low

temperatures and for the necessary speed for eliminating water during the

sinteringprocess.

Ahigh level software was developed to compensate theplatinum limitations in low

temperatures. Due to the characteristics of the sintering process, new thermal

insulating materials were used and an efficient ventilation system keeps the

componentstemperatureunderadequatevalues.

3Main characteristics

• Quartz muffle with thermal insulation ceramic mat molded through low thermal

massvacuum,whichinsuresperfecttemperaturehomogeneity.

•S.A.L.V®SistemadeAquecimentodeLongaVida(longlifeheatingsystem)

• Muffle forced ventilation for sintering/infiltration, which eliminates stains and

minimizesfissuring.

•50programs:39forceramicand10forsintering/infiltration.

•Exclusive4stagesmufflemovablesystemtofacilitatethepositioningofworks

3

Manual

doneontheburnplatform.

•Managementbymicroprocessing.

•Easyoperationandvisualizationoftheburnparameters.·

•Nonvolatilememorykeepsthelastprograminuse.

•Ambientworkingtemperatureat1,100°Cforceramicand1,180°C

forsintering/infiltration.

•Maximumtemperaturelimiterat1,200°C

•Linearheatingspeedfrom0.1to70.0°C/min.

•Thyristoredpowercontrol

•Burntimeforceramicfrom0to30minutes.

• Burn time for sintering/infiltration from 0 to 9 hours and 59 minutes.v Decreasing

timevisualization.

•Vacuumtimefrom0to30minuteswithdecreasingtimevisualization.

• Automatic or manual (which can be activated ant any stage of the process)

vacuumoperation

•Safetysystemsprotecttheequipmentfromoperationmistakesordefects.

•Flashingandbeepingsignsofallprocesssteps.

•Toavoidambienceheating andsaveenergy,analarm willsoundafter 10minutes

if the equipment is not being operated and a “Prot” message will also be displayed

warningthatthemuffleshouldbepartiallyandmanuallyclosed.

•Quickcooling.

•Operationtimetotalizer.

•Lowcostmufflereplacingsystem.

•Electronicsystemforcedventilationkeepsthecomponentssafe.

4Installing

Thenumbersinparenthesesrefertothepicturesthatfollow.

Your Fv-Plus-Sinter should be far from curtains and inflammable material. A

furnace is a heat generator which needs to be dissipated; otherwise its

components will be overheated. Therefore, place the equipment at a ventilated

area which allows free air circulation. It is advisable to leave a 15cm clearance

betweenthefurnaceandanythingthatcanimpairtheventilation.Placethefurnace

farfromtapsorbasinswhichcansprinklewaterovertheequipment.

4

Manual

2

1

3 4

5

Pic.1 Pic.2 7

6

01-Networkvoltageidentifier/powercable.

02-Fuseholder.

03-Serialcommunicationportforcheck-up(technicalassistance)

04-Vacuumhoseconnection.

05-Socketforpluggingthevacuumpump.

06-Muffleventilation.

07-Mainswitchon/off.

4-1)Networkvoltageidentifier/powercable.

4-1) Check if your network voltage is the same as the one shown on the furnace

labelPIC-1-Item(1).

4-2) Install the furnace into an exclusive electrical network using 6mm wiring to a

110voltsnetwork,or4mmwiringtoa220voltsnetwork.

4-3) Never connect the furnace to the same network in which other furnaces,

compressors, electrical taps or any other high electricity consumption devices are

alreadyconnected.

4-4)Checkifthe outletinwhichthefurnacewillbepluggedinis inperfectcondition

andofgoodqualitytobearatleast20amperes.

4-5) Connect the grounding end (round pin) to a grounding rod and never to the

electricalnetworkneutral.

NOTE: Not checking the procedures above will interfere on the equipment

correctworking,onitsguaranteeandalsoontheoperatorsafety.

4-6)Ifyourelectricalnetworkisveryinstable(thelightsflashalot),itisadvisableto

use a voltage regulator such as a saturated autotransformer with at least 2kw

capacity.Neveruse,byanymeans,regulatorsusedincomputers.

5

Manual

apropriadosparaestaaplicação.

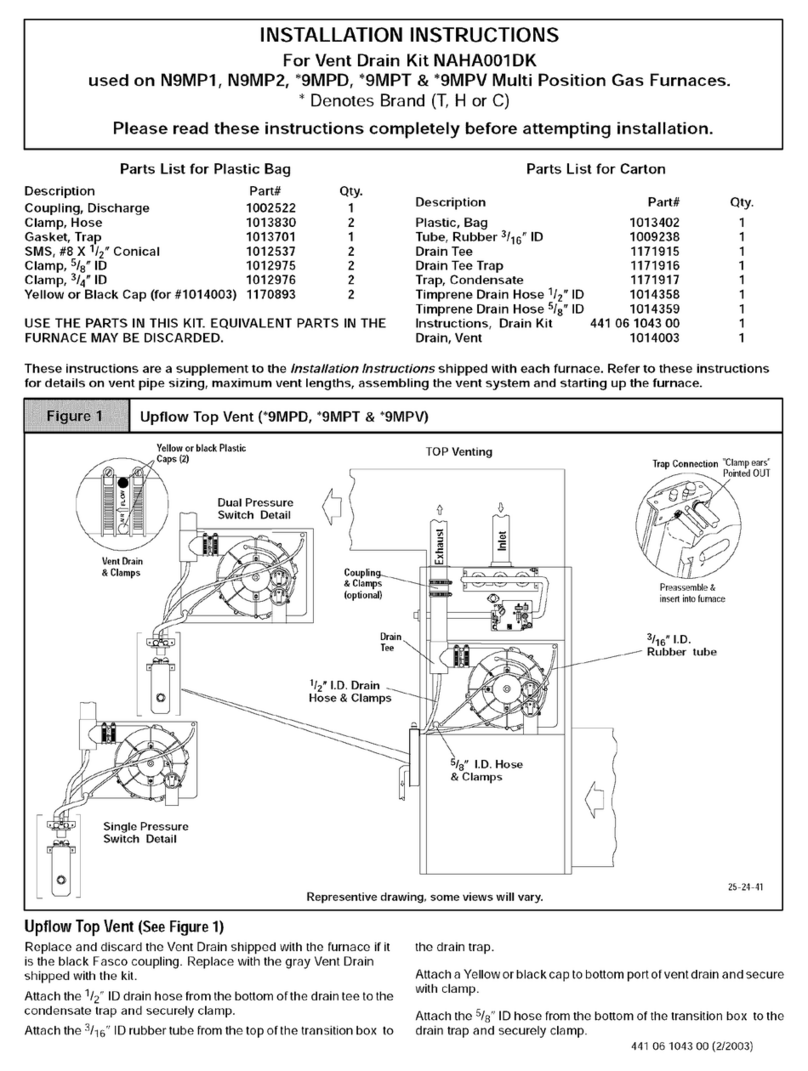

4-7) Connect the vacuum hose to the furnace PIC-1 item (4). Plug the vacuum

pump power cable to the outlet which is at the backside of the furnace PIC-1 Item

(05).

5Control panel

5-1) The control panel has a digital display with four red numeral digits which

provideseasyidentificationoftheprogrammingfunctionsandrecordmonitoring.It

indicatessomemessagesofthesafetyprocesssuchassystemflawandoperation

mistakes.

5-2) It has a touch sensitive thin layer which makes the activation of its keys and

functionseasier.

5.3Identifying the keys and its functions

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

(08)4digitsdisplay.

(09)Parametersprogrammingadjustmentkeys

(10)TemperaturekeyT2,finalburn.

(11)TemperaturekeyT1,pieceentry.

(12)Heatingspeedkey(veloc.2).A2.

(13)Burntimekey(baseline).Pat-2.

(14)VacuumtimekeyVac-2.

(15)Databaserecipeskey.

(16) Muffle opening and closing mode key (0 to 9

min).

(17)Databaserecipesavingkey.

(18) Start / stop, key to begin and finish the burn

process.

(19)Manualvacuumsystemkey.

(20) Database recipes access key, unlocks the

“saveandread”(salvareler)functions.

(21)Equipmentmainswitch.

(22)Analogvacuumindication.

6

Manual

6System start-up

6-1) Plug the furnace into an exclusive and of good quality socket which should be

correctly grounded to a copper rod and never to the electrical network neutral.

Check if the network voltage is the same as the one in the equipment, which is

shownonthepowercablelabelorprintedatthefurnacebackside. Pic-1item(01).

6-2)Turnthe main switch on Pic-3 item (21) and waitfortheequipment to start-up.

Four screens will be visualized in a sequence showing the complete equipment

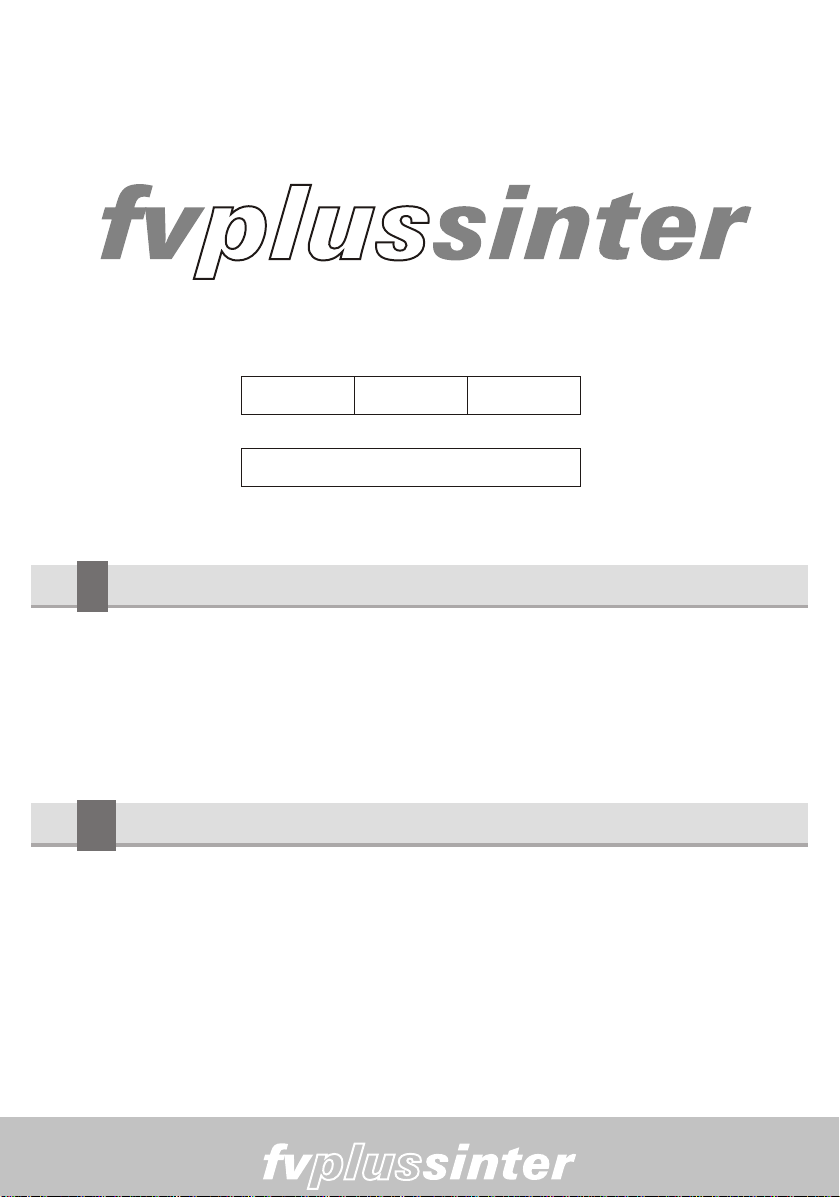

6-3) SCREEN-1 -> The message (EDG) can be visualize

don the first screen as the system checks its functions and

performsthefirstconfigurations.

INICIALIZAÇÕES

LIBERA VÁCUO

TEMP-AMBIENTE

VERSÃO-PROGRAMA

6-4) SCREEN-2 -> On the second screen, the current

program version can be seen for product manufacturing

6-5) SCREEN-3 -> The message (Ar) can be seen on the

third screen and the program waits for 30 seconds for the

airtoreturntothemuffle.

6-6) SCREEN-4 -> On the fourth screen, after the

checking-up is done, the system loads the sintering

standard no. 40 recipe (padrão de sinterização n. 40) and

willkeepwaitingforthenextinstructionbytheoperator.We

remind you that for sintering, the furnace will only heat up

after the (start) command is activated by the operator, therefore the temperature

shownonthedisplaywillbeclosetotheambiencetemperature.

6-7) The furnace must not start the heating process without the burn platform

moldedinceramicfiberputonthebase,PIC-4item(23)otherwisethesealringand

the base will be seriously damaged. Use adequate accessories according to the

wantedproceduresPIC-5.

7

Manual

6-8)PIC-4–AccessoriesforSINTERINGandINFILTRATIONburn.

A)Usetherigidmat-I,item(24)ontheplatform,item(23)

6-9)PIC-5–AccessoriesforconventionalCERAMICburn.

B)Usetherigidmat-I,item(24)ontheplatform,item(23).

C)Useisothermalpinstosupportthepiece,Item(25).

20 24 25

7Programming ceramic recipes

7-1) For better explanation, we will follow practical examples for conventional

ceramic,sinteringandinfiltrationrecipes.

Starting from the ambient temperature, raise it to T1 = 620°C that is the furnace

entrytemperature.

-Keepthistemperatureuntiltheoperator'scommandtostarttheburn.

-Themuffleclosingprocess(preheating/drying)shouldtakeabout5minutes.

-Theburntemperatureis900°C.(T2).

Note: Place the piece on the isothermal pins ends in a way that it can be heated

from all angles; this procedure improves the burn uniformity. Keep the piece on the

thermalcenter.

8

Manual

ABRE FECHA

620 60 ABRE 900 55 01:00 00:30 1 5

EX-1 RECIPE MODEL – CONVENTIONAL CERAMIC

SECAGEM MANUALTEMP-1

ºC VEL-1

Fixo PAT-1

Mufla TEMP-2

ºC VEL-2

Fixo PAT-2

Mufla VAC-2

min

EX - 1 MODELO DE RECEITA - CERÂMICA CONVENCIONAL

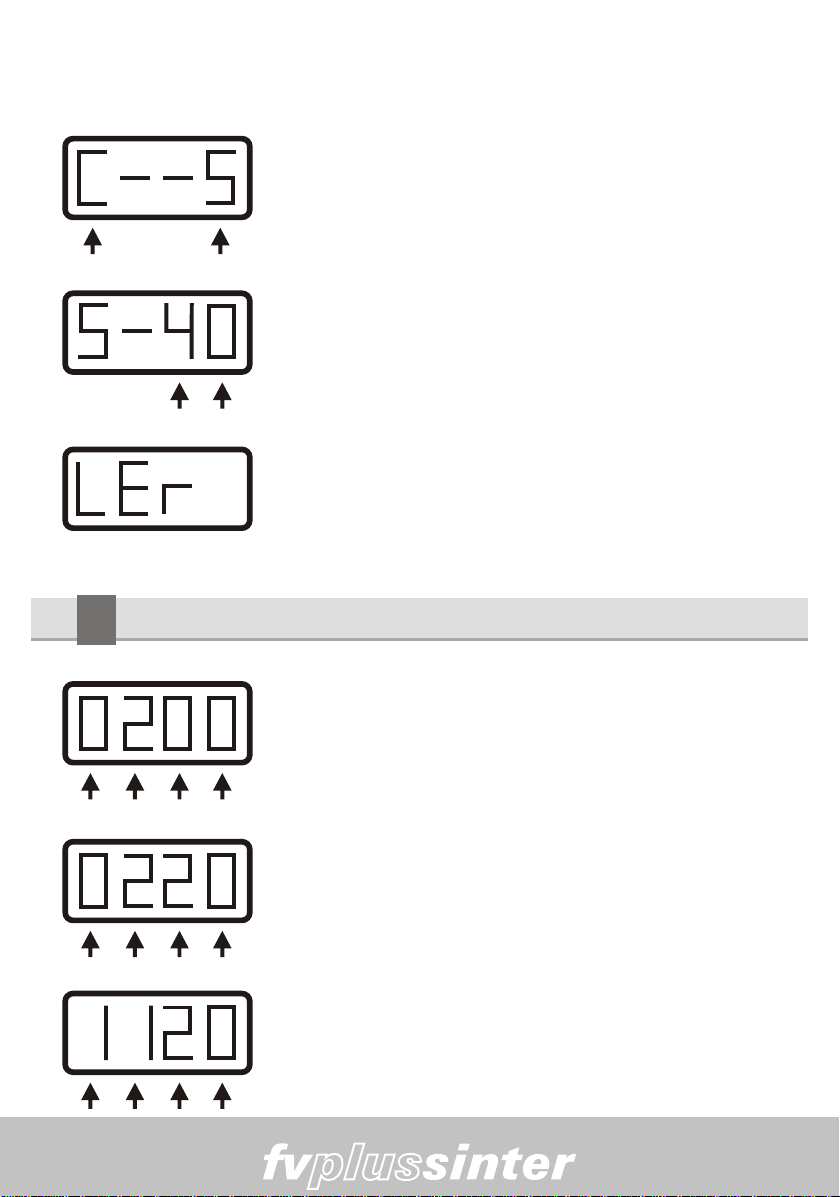

7-2) When activating the PROG. (20) key, the message “C--S” (“C” stands for

Ceramic while “S” stands for sintering/infiltration) will be shown on the display

askingyoutochoosebetweenceramicorsintering/infiltrationprocess.

-TheheatingspeedbetweenT1andT2shouldbe55°C/minute.

-Theburntimewillbe1minute.

-Thevacuumshouldturnthemuffleclosingonandturnitoff30

secondsaftertheburntimehasstarted.

-Aftertheprocessisfinished,thepieceshouldberemovedin1minute.

7-3) Using the Parameters programming adjustment

keys (9) activate the arrow below the letter “C” informing

thatwearegoingtoworkwithceramic.

SEL- PROGRAMA

T2 = 900ºC PAT-2 = 1:00

VAC-2 = 0:30

VEL-2 = 55ºC

T1 = 620ºC

RESFRIAMENTO

NATURAL

MUFLAABERTA

SECAGEM NO ESTÁGIO (4)

CURVA DE AQUECIMENTO

CURVA DO VÁCUO

LEGENDA

9

Manual

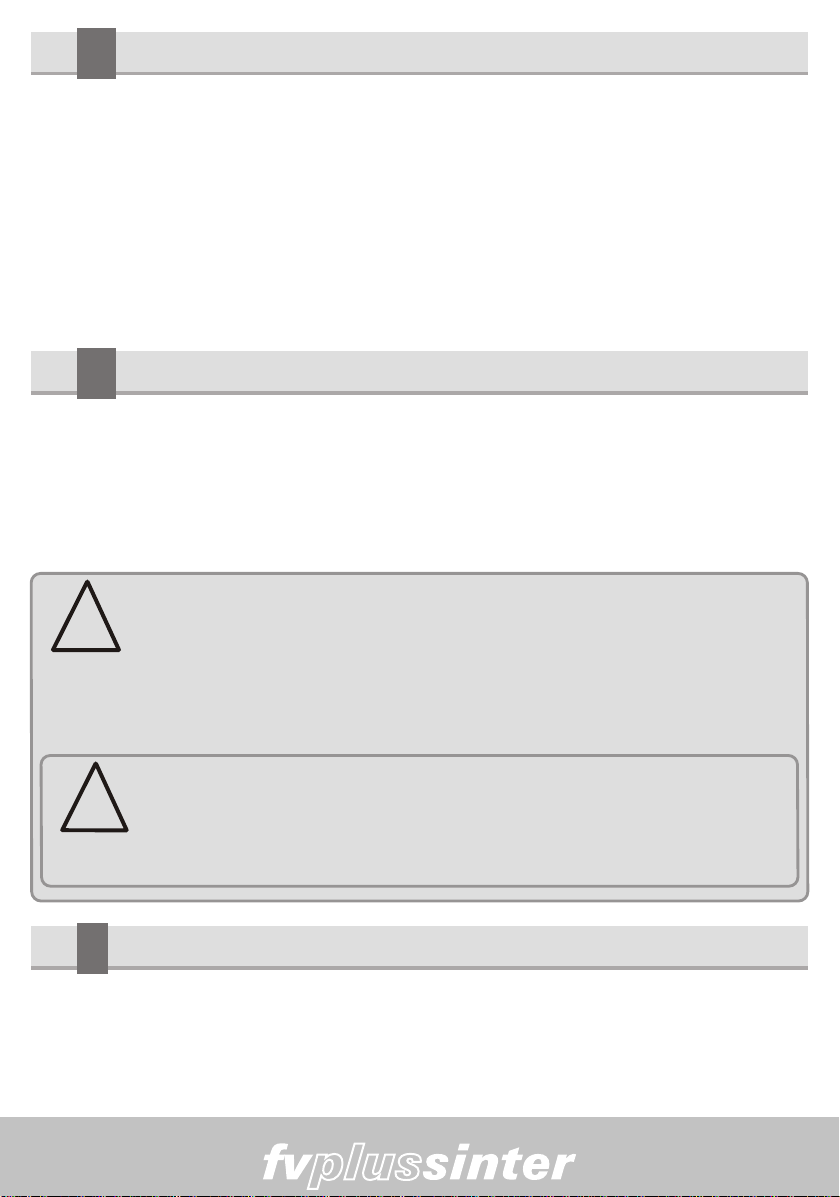

CERÂMICA 7-4) Next the display will show “C-01”, which is the

number of the ceramic standard recipe that serves as a

base for programming the next recipes. The arrows (09)

below the number will be used to select the desired

recipe,inthiscase(01).

LER RECEITAS 7-5) Confirm the reading operation activating the “Ler”

(“read”) key (15) this message will be kept on the display

whiletherecipeisbeingloaded.

7-6) Start the programming for a new recipe taking as base the ceramic standard

recipethathasbeenloadedinthememory.

7.7T1 And T2 Temperature adjustment

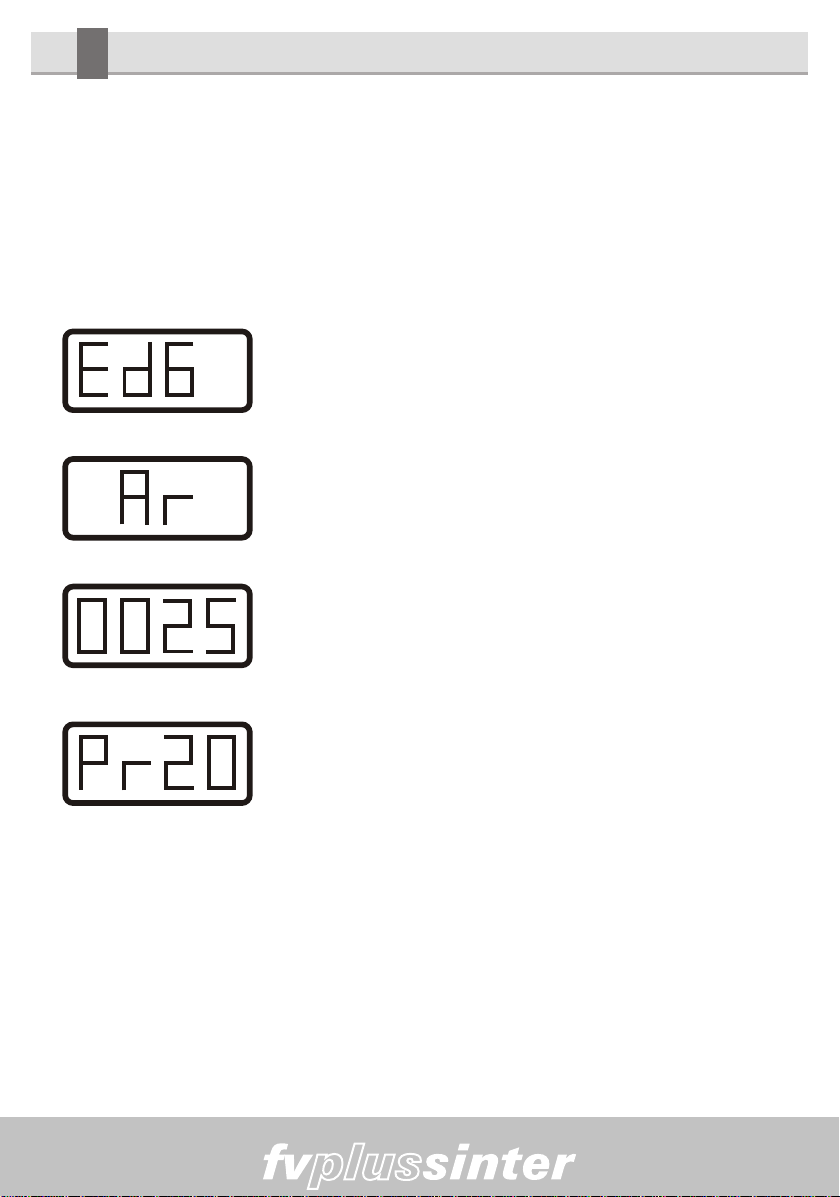

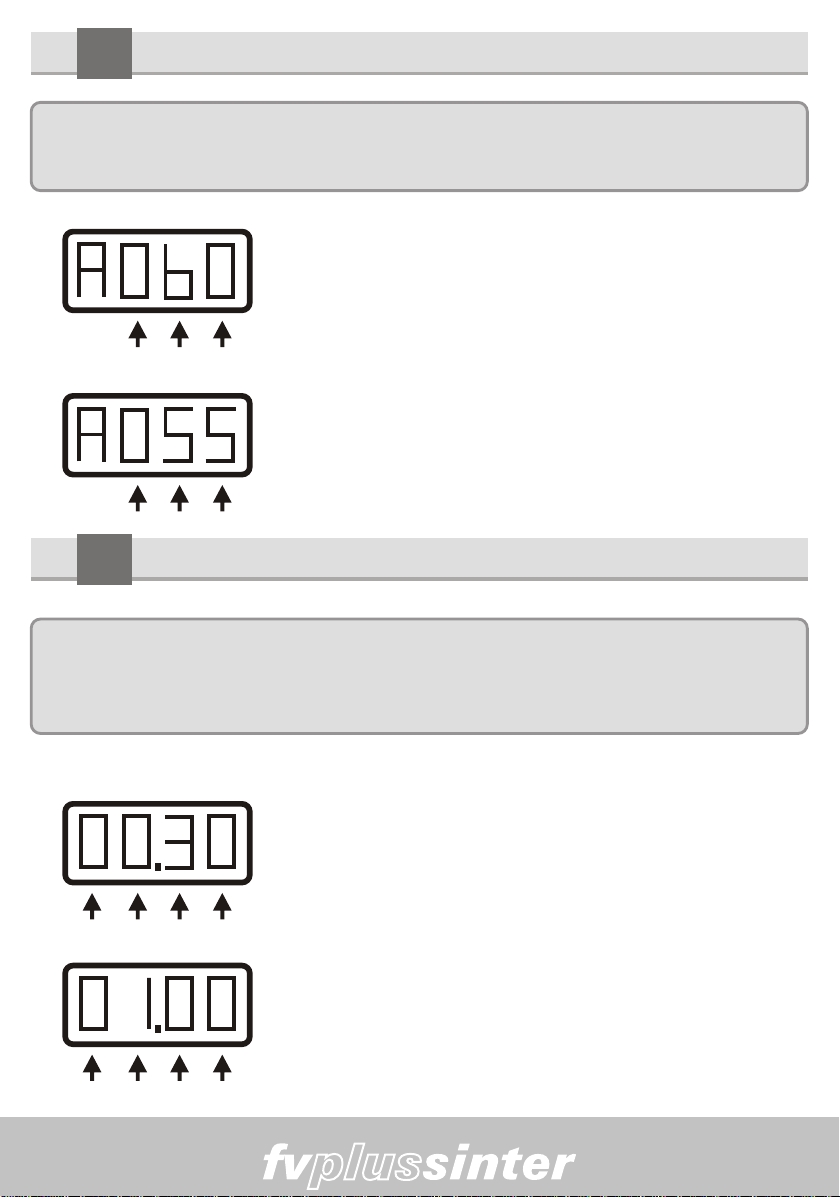

7-8)Temperatureadjustment-T1

Activate the T1 (11), key and the display will show the

programmed temperature of the standard recipe that

comesfromthefactory“0600”.

PROG - TEMP - T1

7-9) Next, activate the parameters adjustment keys (09),

one for each digit showing on the display the desired

value for T1 of 0620°C. The furnace will heat until this

temperature.

TEMPERATURA - T1

7-10)Temperatureadjustment–T2

Activate the T2 (10) key, and the display will show the

programmed temperature of the standard recipe that

comesfromthefactory“0960”.

PROG - TEMP - T2

TEMPERATURA = T2

7-11)Next,activatetheparametersadjustmentkeys(09),

one for each digit showing on the display the desired

valueforT2of0900°C.

10

Manual

7.12 Heating speed adjustment VELOC-2

Note: We remind you that for ceramic recipes at ambient speed theT1 is fixed at

60ºC/minute.

7-13) Activate the Veloc. (12) key and the display will

show “A060” degrees/minute, which is the standard

recipeheatingspeedthatcomesformthefactory.

PROG - VELOC - 2

VELOCIDADE 2 7-14) Next, activate the parameters adjustment keys

(09), one for each digit showing on the display the

desiredvalueof“A055”degrees/minute.

7.15 Burn time adjustment – T2 - BASELINE

Note:Theburntimeoftheceramicprocessesareshowninminutesandseconds.

Forexample:00.30correspondstothirtyseconds;05.35correspondsto5minutesand

thirty-fiveseconds.

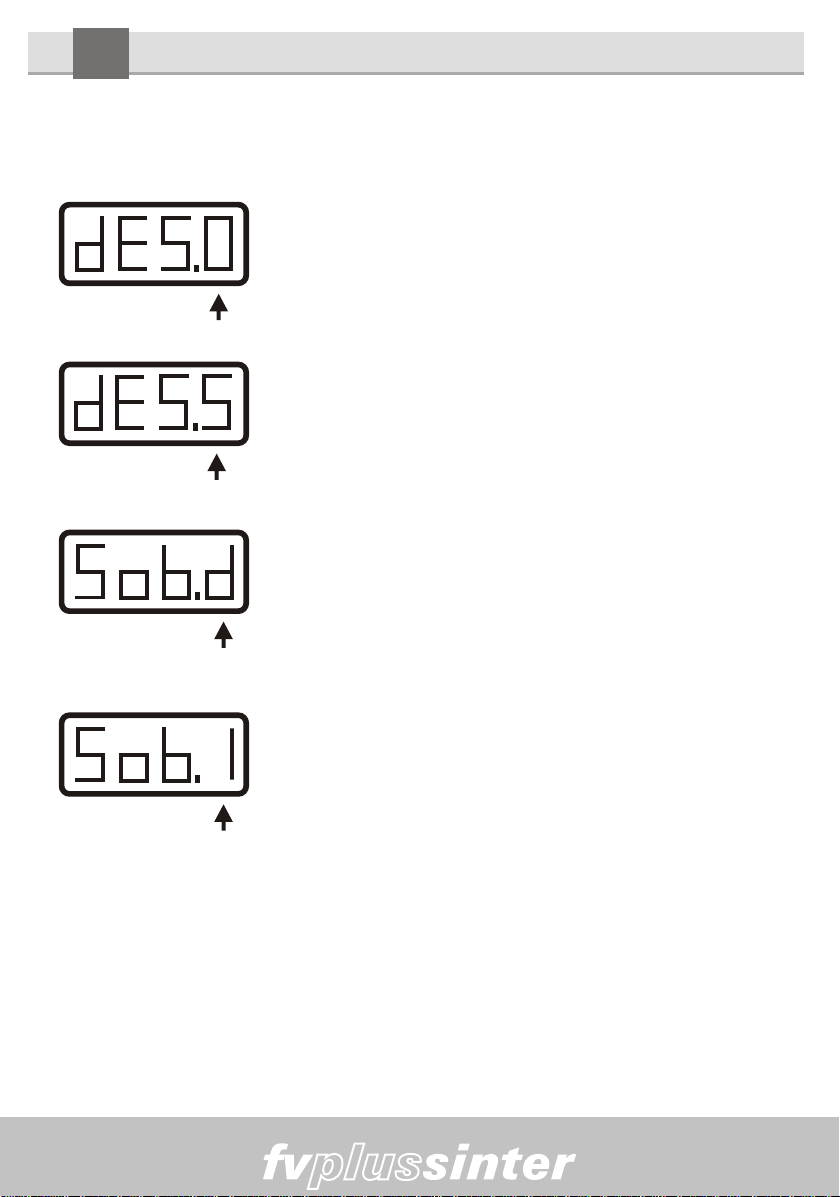

PROG - VÁCUO - T2 7-16) Activate the burn time (13) key and the display will

show “00.30” seconds which is the standard recipe burn

timethatcomesfromthefactory.

PROG - PATAMAR -2 7-17) Next, activate the parameters adjustment keys

(09),oneforeachdigitshowingonthedisplaythedesired

valueof “01.00”minute.

11

Manual

7.18 Vacuum time adjustment – VAC-2

7-19) Activate the vacuum time (14) key, and the display

will show “00.00” minutes which is the standard recipe

vacuumtimethatcomesfromthefactory.

TEMPO - VÁCUO - T2

7-20) Next, activate parameters adjustment keys (09),

one for each digit showing on the display the desired

valueof“00.30”seconds.

PATAMAR - T2

NOTES ABOUT THE VACUUM

A)Thevacuumtimecanneverbehigherthantheburntime,ifthevaluefor thevacuum

timeishigherthanthevaluefortheburntime,thefurnacewilldetermineforthevacuum

timethesamevalueastheburntime.

B) Vacuum time the same as “00.01” (1-segundo) indicates that the vacuum will be

performed on the heating ramp between T1 and T2. When the T2 temperature is

reachedthevacuumwillbeturnedoff.

C) ) Vacuum time the same as “00.00” (zero) indicates that the vacuum will not be

performedatanytimeduringtheburnprocess.

D) Vacuum time higher than (1-second) Ex: ”00.30” indicates that the vacuum will be

performedontheheatingrampusingthebaseline.

7.21 Manual vacuum adjustment sim/não (yes/no)

This key is used when one wants to change the vacuum time

duringtheburn.

Activate the manual vacuum key (19) when you want to start or

interrupt the vacuum at any stage of the process, the pump will

perform the desired function over any previous programming.

When the LED above the key is on it means that the pump is activated. When the

LEDisoffitmeansthatthepumpisdeactivated.

VÁCUO

MANUAL

12

Manual

7.22 Programming the drying – entry/exit

The muffle closing and opening can be programmed independently Ex: (Sob.1) e

(dES.d).

FECHA / DESCE 7-23) Activating the key (16) once and the display will

showthemessage“dES.0”.

Activating the parameters adjustment key (09) below “0”

wechoosethedesiredpositionforthemuffleclosing.

FECHA / DESCE

7-24) In this case, on the position “5” the piece entry will

take about 5 minutes to complete the course through the

4stagestoclosethemuffle.

ABRE / SOBE 7-25) Activating the Open/Close (Abre/Fecha) key (16)

twice, the display will show the message “Sob.d”.

Activating the parameters adjustment key (09) below “d”

we choose the desired position according to the table

below.

7-26) In this case, on the position “1” the piece entry will

takeabout 1 minute to complete the course through the 4

stagestoopenthemuffle.

ABRE / SOBE

7-27)Onthepositionzero“0”therewillnotbecountingtimeforclosing.

On the following positions the course times through the 4 stages are approximate:

EX: “1” = 1 minute, 2, 3, 4, 5, 6, 7, 8, 9 minutes, according to the table beside. For

each stage an alarm will sound warning the operator that to move the muffle

articulated to the next position until the whole opening or closing course is

completed.

13

Manual

S 0 . D 0

S 1 . D 1 1 Minuto

S 2 . D 2 2 Minutos

S 3 . D 3 3 Minutos

S 4 . D 4 4 Minutos

S 5 . D 5 5 Minutos

S 6 . D 6 6 Minutos

S 7 . D 7 7 Minutos

S 8 . D 8 8 Minutos

S 9 . D 9 9 Minutos

TABLE FOR ASCENT AND DESCENT -

DRYING

ABRE / FECHA

SOBE / DESCE

MUFFLE MANUAL COURSE, BY OPERATOR

Zero não conta tempo

Entrada e saída da peça

TEMPO APROXIMADO

7.28 Muffle course examples in the 4 closing stages

4º - Entry or exit stage

04

Pic.10

3º - Entry or exit stage

03

Pic.09

1º - Entry or exit stage

01

Pic.07

2º - Entry or exit stage

02

Pic.08

14

Manual

Burn position

Pic.06

7-29)PIC-06indicatesthatthemuffleis

on the correct position to begin with the

burn process. The vacuum pump will

be activated and the operator will keep

pressing down the muffle puller for

someseconds topromotethe chamber

sealing and then start with the vacuum

action.

8Programming sinterin / Infiltration recipe

Ex2: Infiltration/Sintering – Process description

8-1) The piece to be infiltrated/sintered is placed on the burn platform and should

dry for 1 minute. From ambience time, go up to T1 at 220°C at the speed of

10.5°c/min.Keepusingthistemperaturefor10minutes.

Next,raise thetemperaturetoT2 at 1,080°Catthe speedof35°C/min. Keep using

thistemperaturefor1hour.Thepieceexitshouldoccurin2minutesafterthat.

Note: Thesintering/infiltrationprocessesdonotusevacuum.

ABRE FECHA

220 10.5 00:10 1080 35.0 01:00 2 1

CONVENTIONAL CERAMIC RECIPE EXAMPLE

SECAGEM MANUALTEMP-1

ºC VEL-1

ºC / min PAT-1 H

/ min TEMP-2

ºC VEL-2

ºC / min PAT-2

H / min

CURVA DE AQUECIMENTO

LEGENDA

T1 = 220 ºC

PAT-1 = 00:10 min

25ºC

VEL-1 = 10.5ºC / min

VEL-2 = 35.0ºC / min

PAT-2 = 01:00 Hora

T2 = 1080 ºC

RESFRIAMENTO

NATURAL

EX-2 SINTERING/INFILTRATION RECIPE MODEL

15

Manual

8-2) When activating the PROG. (20) key, the message “C--S” (“C” stands for

Ceramic while “S” stands for sintering/infiltration) will be shown on the display

askingyoutochoosebetweenceramicorsintering/infiltrationprocess

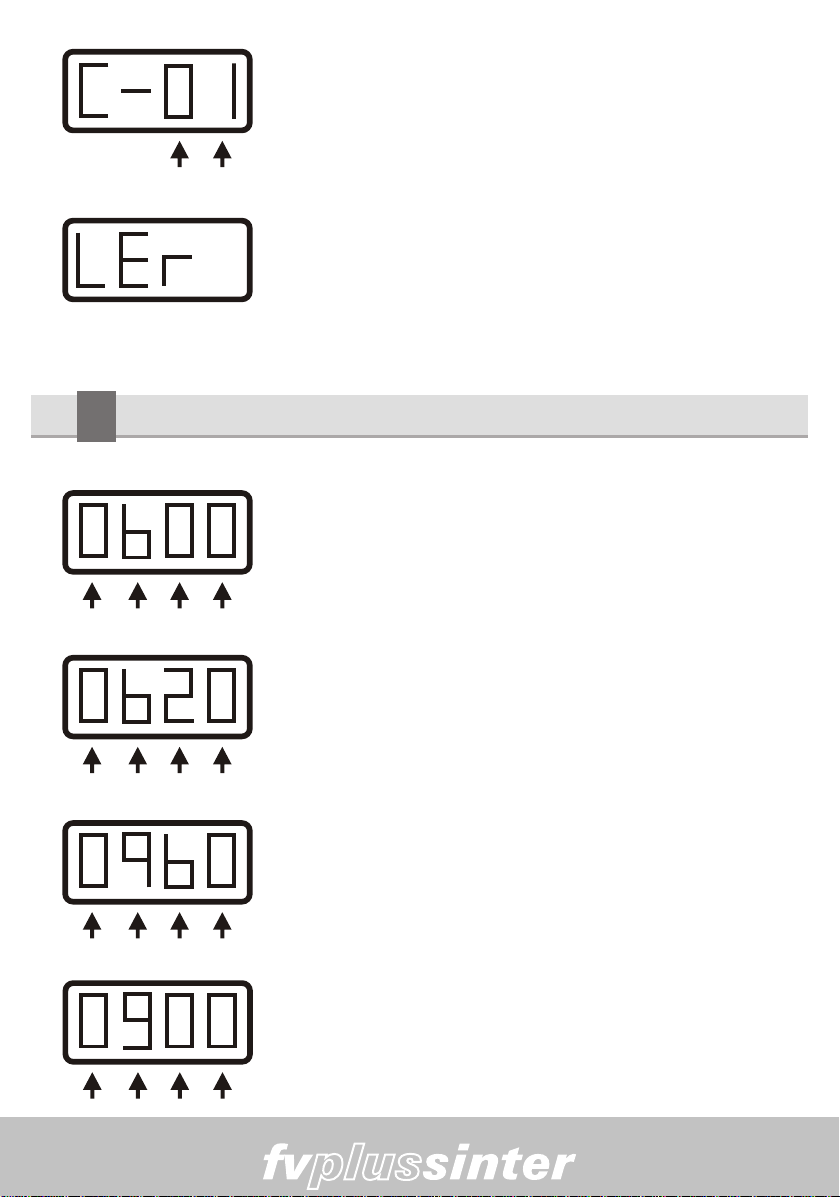

8-3) Using the Parameters programming adjustment

keys (09)activatethearrowbelowtheletter“S”informing

thatwearegoingtoworkwithsintering/infiltration.

SEL- PROGRAMA

8-4) Next the display will show “S-40”, which is the

number of the sintering/infiltration standard recipe that

comesfromthefactory.

SINTERIZAÇÃO

8-5) Confirm the reading operation activating the “Ler”

(“read”) key (15) this message will be kept on the display

whiletherecipeisbeingloaded.

LER RECEITAS

8-6)Starttheprogramming fora newrecipetaking asbase thesintering/infiltration

standardrecipethathasbeenloadedinthememory.

8.7T1 and T2 Temperature adjustment

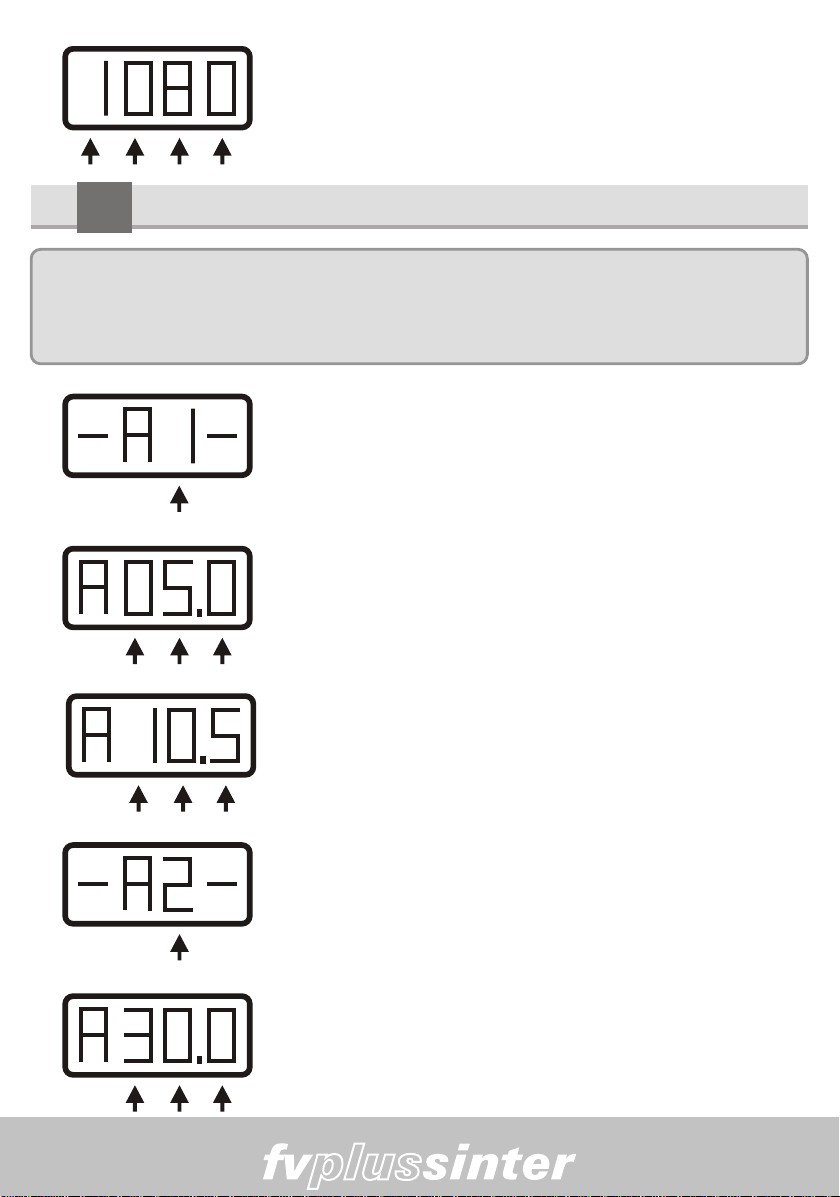

8-8)Temperatureadjustment-T1

Activate the T1 (11), key and the display will show the

programmed temperature of the standard recipe that

comesfromthefactory0200ºC.

RECEITA - FÁBRICA

PROGRAME - T1

8-9) Next, activate the parameters adjustment keys (09),

one for each digit showing on the display the desired

valueforT1of220°C.

RECEITA - FÁBRICA 8-10)Temperature Adjustment-T2

Activate the T2 (10) key, and the display will show the

programmed temperature of the standard recipe that

comesfromthefactory1120ºC.

16

Manual

RAMPA - VELOC - 1

8-11) Next, activate the parameters adjustment keys

(09),oneforeachdigitshowingonthedisplaythedesired

valueforT2of1080ºC.

8.12 Adjusting The Heating Velocities. V1 E V2

Note: The heating speed V1 can assume values: minimum of 0.1ºC/min and

maximum of 20ºC/min.And he heating speed V2 can assume the minimum speed of

1ºC/minandmaximumof 70°C/min.

8-13) PROGRAMMING - V1 - Activating the V1 (12) key

themessage“-A1-“willshowonthedisplayforspeed1.

PROGRAME - T2

RECEITA - PADRÃO 8-14) Activating the parameters adjustment keys (09),

under“1”onthedisplayitwillshowtheheatingspeedthat

comes from the factory: “A05.0” (five degrees per

minute).

PROGRAME - VEL - 1 8-15) Activating on the parameters adjustment keys (09)

the keys which are under the display we can adjust the

speedforthedesiredvalueof10.5°c/min.

RAMPA - VELOC - 2 8-16) PROGRAMMING - V2 - Activating the V1 (12) key

twice the message “-A2-“ will show on the display for

speed2.

RECEITA - PADRÃO 8-17) Activatingon the parametersadjustment keys (09),

under “2” the display it will show the heating speed that

comes from the factory: “A30.0” (thirty degrees per

minute).

17

Manual

PROGRAME - VEL - 2 8-18) Activating on the parameters adjustment keys (09)

the keys which are under the display we can adjust the

speedforthedesiredvalueof35.0°C/min

8.19 Adjusting burn time (BASELINES)

Note: The burn times Pat-1 and Pat-2 for the sintering/infiltration processes start

in Hours. Ex: H1.15 corresponds to one hour and fifteen minutes. We remind you that

theminimumtimeallowedforPat-1andPat-2canbezeroEx.H0.00andthemaximum

timecanbeninehoursandfifty-nineminutes.Ex.H9.59.

8-20) Programming baseline 1. Activating the burning

time key (13) once, the display will shoe the message

“Pat.1”.

SELECIONE - PAT- 2

PROGRAME - PAT - 1

RECEITA - PADRÃO 8-21) Activating the parameters adjustment keys (09),

under “1” on the display it will show the time that comes

fromthefactoryforthestandardrecipe:“H0.15”.

8-22)Activatingtheparametersadjustmentkeys(09),we

can adjust the burn time to the desired value, “H0.10”,

thatis10minutes.

SELECIONE - PAT- 2 8-23) Programming baseline 2. Activating the burning

time key (13) twice, the display will shoe the message

“Pat.2”.

18

Manual

RECEITA - PADRÃO 8-24) Activating the parameters adjustment keys (09),

under “2” on the display it will show the time that comes

fromthefactoryfor thestandard recipe:“H0.30” thatis 30

minutes.

PROGRAME - PAT - 2 8-25)Activatingtheparametersadjustmentkeys(09),we

canadjusttheburntimetothedesiredvalue“H1.00”,that

is1hour.

8.26 ) Programming the muffle opening and closing

Themuffleclosingandopeningprocessescanbeprogrammedindependently.

FECHA / DESCE 8-27) Programming the muffle closing.Activating the key

(16)oncethedisplaywillshowthemessage“dES.0”.

FECHA / DESCE 8-28) Activating the parameters adjustment key (09)

below“0”wechoosethedesiredpositionaccordingtothe

table below. In this case, on the position “2” the piece

entry will take about 2 minutes to complete the piece

entry.

ABRE / SOBE 8-29) Activating the Open/Close (Abre/Fecha) key (16)

twice,thedisplaywillshowthemessage“Sob.d”.

ELEVADOR - SOBE 8-30) Activating the parameters adjustment key (09)

below“d”wechoosethedesiredpositionaccordingtothe

table below. In this case, on the position “1” the piece

entrywilltakeabout1minutetocompletethepieceexit.

19

Table of contents

Other EDG Furnace manuals

Popular Furnace manuals by other brands

Haier

Haier GE NF97UM Service manual

International comfort products

International comfort products NAHB00101MH installation instructions

Lennox

Lennox EL195DF SERIES user manual

Vogelzang International

Vogelzang International 1500 owner's manual

Weld Rite

Weld Rite Shaver Pro 140 Installation and operating instructions

Maytag

Maytag Amana AMVC80 manual

Aspen

Aspen AAN Series installation guide

Lennox

Lennox EL196DFE Series User's information manual

Rinnai

Rinnai RHFE-201FA OWNER'S OPERATION AND INSTALLATION MANUAL

Goodman

Goodman GMV95 Series installation instructions

Bryant

Bryant 4-WAY MULTIPOISE TWO-STAGE CONDENSING GAS FURNACE... Product data

Nortek

Nortek TA Series installation instructions