EDILGRAPPA PR16 Operation instructions

2

BENDING-STRAIGHTENING TOOL

PR16-32 WITH ADJUSTABLE HEAD

USE AND MAINTENANCE

INSTRUCTIONS

MANUAL

PR16-32

2

BENDING-STRAIGHTENING TOOL PR16-32

AVAILABLE IN THE FOLLOWING VERSIONS:

1. SINGLE-PHASE ELECTRIC MOTOR 230 V 50 Hz

NAME

P/N

BENDING-STRAIGHTENING TOOL PR16-32 WITH ADJUSTABLE HEAD

1.50.2631

PR16-32

3

CONTENTS

0 DESCRIPTION OF THE MACHINE ...........................................................5

0.01 MACHINE COMPONENTS......................................................................................................5

0.02 SAFETY AND DANGER STICKERS -CE PLATE ...................................................................6

0.03 LIST OF ACCESSORIES INCLUDED INTHE SUPPLY...........................................................7

1 TECHNICAL FEATURES .............................................................................7

1.01 HYDRAULIC, MECHANICAL AND ELECTRICAL SPECIFICATIONS....................................7

2 DELIVERY, COMMISSIONING AND SET-UP.........................................9

2.01 DELIVERY...............................................................................................................................9

2.02 ELECTRIC MOTOR...............................................................................................................10

2.02.01 ELECTRICAL CONNECTIONS....................................................................................10

2.02.02 COMMISSIONING .......................................................................................................10

2.03 DOUBLE-ACTING LEVER....................................................................................................10

2.04 EQUIPMENT OPERATION....................................................................................................11

2.04.01 HEAD IN STANDARD CONFIGURATION....................................................................11

2.04.02 ACCESSORIES AVAILABLE ON REQUEST...............................................................12

2.04.03 STARTING...................................................................................................................13

2.05 FORESEEN USE AND RESIDUAL RISKS............................................................................17

3 ROUTINE MAINTENANCE .......................................................................18

3.01 CHANGING AND TOPPING UP THE OIL..............................................................................18

3.02 CHECKING SCREWS...........................................................................................................20

3.03 HYDRAULIC COMPONENTS................................................................................................20

3.03.01 UNSUCCESSFUL OUTWARD STROKE .....................................................................20

3.03.02 MAX. PRESSURE VALVE INCORRECTLY ADJUSTED..............................................20

3.03.03 MAIN CHECKS ON THE MOTOR................................................................................20

3.04 CHECKING TOOLS...............................................................................................................21

4 POTENTIAL PROBLEMS AND MEASURES TO BE ADOPTED

...................23

4.01 GENERAL.............................................................................................................................23

4.02 TROUBLESHOOTING THE MOTOR.....................................................................................23

4.03 TROUBLESHOOTING THE HYDRAULIC COMPONENTS ...................................................24

5 STORAGE AND RESTARTING ................................................................25

5.01 STORAGE.............................................................................................................................25

5.01.01 ELECTRIC MOTOR.....................................................................................................25

5.01.02 CYLINDER AND HYDRAULIC COMPONENTS...........................................................25

5.02 RESTARTING .......................................................................................................................25

6 MACHINE DISPOSAL.................................................................................26

PR16-32

4

A brief legend indicating the most important symbols used in this manual is shown below.

THIS SYMBOL WARNS USERS TO PAY SPECIAL ATTENTION WHEN FOLLOWING

THE RELATIVE INSTRUCTIONS.

FAILURE TO OBSERVE THESE INSTRUCTIONS CAN CAUSE THE MACHINE TO

OPERATE INCORRECTLY.

THIS SYMBOL INDICATES POSSIBLE HAZARDS, TAKE ALL PRECAUTIONS TO

PREVENT THESE SITUATIONS FROM OCCURRING.

BEFORE WORKING ON THE MACHINE, CAREFULLY READ ALL THE

INSTRUCTIONS, ESPECIALLY THOSE CONTAINED IN BOXES.

“OPERATOR”: A person suitably trained and authorised to operate,

adjust, clean and transport the machine.

“MAINTENANCE

PERSON”: A person trained and authorised to perform routine

maintenance on the machine and replace certain

components.

“MACHINE”: The equipment described in this manual.

“ELECTRIC TOOL”: Used in the safety precautions, it is a more general

definition of the machine in question as it refers to

mains-powered electric tools (with cable) or battery-

powered electric tools (cordless).

PR16-32

5

0 DESCRIPTION OF THE MACHINE

CAUTION!! FIRST READ THE MANUAL REGARDING THE GENERAL AND SAFETY

REGULATIONS!

0.01 MACHINE COMPONENTS

This machine is fitted with a single-phase alternating current motor.

The equipment comprises:

- a motor,

- a hydraulic pump driven by the motor,

- a rod actuator (piston) driven by the oil pressured by the pump,

- a fixed head with tool.

Figure 1 shows the main parts of the equipment, in particular:

1. cylinder with hydraulic components

2. tool-adjustable head

3. double-acting lever

4. grip with start button

5. electrical connecting cable complete with plug

6. electric motor

7. handle

8. oil cap

Fig. 1

PR16-32

6

0.02 SAFETY AND DANGER STICKERS - CE PLATE

Position of plate and safety and danger stickers on the machine:

PR16-32

7

Observe the warnings on the plates and stickers. Failure to do so could lead to

injury or death. Make sure the plates and stickers are attached and legible. If not,

apply them or request the maker for replacements.

0.03 LIST OF ACCESSORIES INCLUDED IN THE SUPPLY

•Case

•General safety rules, Use and maintenance instructions

•Declaration of conformity

•Warranty certificate

•Simple repair key, if appropriate

1 TECHNICAL FEATURES

1.01 HYDRAULIC, MECHANICAL AND ELECTRICAL SPECIFICATIONS

Maximum bending size and characteristics of material [ mm and

daN/mm² ]

Ø 32 mm / R = 75 daN/mm²

Maximum output force from rod [ t ]

21.1

Maximum operating pressure [ bar ]

550

Dimensions: Length X Width X Height [ mm ]

601 x 300 x 229

Bending angle

180° to 80° (depending on the

diameter and hardness of the

material)

Weight [ kg ]

24.4

Guaranteed no-load LwA sound level (CEI EN 60745-1 and CEI

EN 60745-2-8) [ dB ]

98

No-load operator Lpa (CEI EN 60745-1 and CEI EN 60745-2-8)

[ dB ]

87

Vibrations when bending Ø 32 mm rod (CEI EN 60745-1 and EN

ISO 5349)

4.01 m/s²

Input voltage [ V ]

230

Frequency [ Hz ]

50

Electrical power [ W ]

1100

Input current [A]

5.3

Insulation class

II

RPM

10000

PR16-32

8

PR16-32

9

2 DELIVERY, COMMISSIONING AND SET-UP

2.01 DELIVERY

The machine is normally shipped and delivered inside

a special hard case, well secured and in a stable

position (see adjacent figure). All materials shipped

are checked prior to delivery.

Upon receipt, check the machine for any damage (breakages or major denting)

caused during transport. If so, it is necessary to immediately inform the shipping

company and to write on the Delivery note the “Accepted subject to checking"

clause.

In the event of damage, send a written complaint to the forwarder within 8 days of

receipt.

Promptly inform Edilgrappa s.r.l. if major damage, caused during transport, is

found upon receipt, or if any parts are missing.

It is also necessary to check the delivered materials against the detailed shipping

list.

The machine can be moved easily both when it is inside its special rigid case, using the

upper handle, and by gripping its upper or lower handle.

Loads must be moved in compliance with current occupational safety regulations.

After use, put the machine back into its case or place it on a stable surface, making sure

this can withstand its weight.

PR16-32

10

2.02 ELECTRIC MOTOR

2.02.01 ELECTRICAL CONNECTIONS

THE USER SYSTEM AND THE RESPECTIVE CONNECTIONS MUST BE MADE IN

STRICT OBSERVANCE OF THE REGULATIONS IN FORCE, BY COMPETENT

PERSONNEL QUALIFIED TO DO THE JOB.

BEFORE CONNECTING THE APPLIANCE BY MEANS OF THE PLUG SOCKETS,

TURN THE MAIN SWITCH TO OPEN POSITION "O".

2.02.02 COMMISSIONING

These machines do not need any adjustment or particular precautions before

commissioning.

The only controls to perform concern:

- Machine integrity:

make sure that nothing happened during transport that could damage the insulation or

mechanical parts.

- Completeness of supply:

check that all the supplied accessories are fitted.

- Oil level:

check the oil level and top up if necessary as per the instructions in Para 3.01.

IMPORTANT: Before loosening the oil cap carefully read the instructions in Para

3.01.

2.03 DOUBLE-ACTING LEVER

The double-acting lever has two positions (see fig. 2)

-Position 1 ( open ): The piston returns to its original position.

-Position 2 ( close ): The piston performs its outward stroke (bending-straightening

phase).

Fig. 2

PR16-32

11

2.04 EQUIPMENT OPERATION

2.04.01 HEAD IN STANDARD CONFIGURATION

In its standard configuration, the tool head is supplied as shown in fig. 2A.

In particular, the following can be seen:

1. Cam support;

2. Cam, applicable for both push bending and pull bending;

3. Bending rollers (standard version: for bending - straightening from Ø28mm to Ø32mm).

Fig. 2A

PR16-32

12

2.04.02 ACCESSORIES AVAILABLE ON REQUEST

The following accessories are available on request ( see fig.2B ):

- Bending rollers for bending - straightening from Ø16mm to Ø20mm ( see ref.1 in fig. 2B );

- Bending rollers for bending - straightening from Ø22mm to Ø26mm ( see ref.2 in fig. 2B )

Fig. 2B

PR16-32

13

2.04.03 STARTING

Insert the plug in a suitable power socket and follow the instructions below, depending on

the kind of machine involved.

Make sure the characteristics of the work piece are compatible with the contents

of the technical specifications table.

IMPORTANT: When processing hard and fragile materials ( not included among

the functions of this tool ) metal elements (steel splinters and the like) may be

projected from the work piece and accelerate to considerable speeds.

This situation has been described in the machine instructions manual in order to

allow the operator to take the precautions required to avoid this potentially

hazardous situation, by wearing a helmet, goggles and suitable protective

clothing.

Make sure the workpiece lies at right angles with respect to the axis of the

equipment (fig. 3A).

IMPORTANT: If the machine is moved towards the workpiece, hold it still with

both hands and maintain a fixed position.

If the machine lies on a surface, keep one hand on the grip and hold the

workpiece with the other (fig. 5 by way of example )

PR16-32

14

2.04.04 BENDING OR STRAIGHTENING

This type of machine can bend-straighten in both directions of travel ( refs. A and B in fig.

3A ). The hook die ( ref. 2 in fig. 3A ) can work when both pushed and pulled.

More force is generated when pushing the tool ( ref. A in fig. 3A ) than when pulling it.

•Position the rod that it lies firmly on the base of the head and on the rollers ( ref. 1

in fig. 3A ) and perpendicular to the longitudinal axis of the machine (fig. 3A).

•After correctly positioned the work piece as indicated in fig. 3A, move the double-

acting lever to “ open “ or “ close “ as required;

•press the start button and hold it down until the bending or straightening operation

has been completed;

•Once bending or straightening have been completed, move the piston slightly in

the opposite direction from that required ( always with the help of the double-

acting lever and the start button ) in order to release the material and remove it

from the head.

The following picture (fig. 3A) is only an example

Fig. 3A

The following simplified diagram shows how bending and straightening operations must be

performed.

See Fig. 2C and Fig. 2D.

PR16-32

15

PUSH AND PULL BENDING WITH THE CAM ASSEMBLED:

Assemble the cam as described in fig. 2C (see also para 3.04), according to the bending

method to be performed (see Ref. A in fig.2C).

1. Pull bending

2. Push bending

Fig. 2C

PUSH AND PULL STRAIGHTENING WITHOUT CAM:

See fig. 2D

1. Push straightening

2. Pull straightening

Fig. 2D

PR16-32

16

2.04.05 ADJUSTING THE HEAD

The head of this machine can be freely adjusted ( rotated by 180° ) to help the operator

during positioning and subsequent processing.

To adjust the head, simply turn the handle ( ref. 1 in fig. 2E ), as indicated by the arrows.

Fig. 2E

PR16-32

17

Adjusting the head with the tool disconnected and not working. Hold the grip ( ref.

1 in fig. 2E ) and handle ( ref. 4 in fig. 1 ) firmly, without touching the on/off button,

and move the head to the required position.

2.05 FORESEEN USE AND RESIDUAL RISKS

The machine may only be used for bending or straightening. The maximum diameter of

the material is 32 mm and its unit tensile strength must not be greater than 750 N/mm².

Do not use the machine for bending other elements that are not specified above.

The machine may only be used if powered by an electrical system compliant with

legislation and current law (suitably connected to an earth system and protected from

current surges and short circuits).

Any use other than that expressly indicated shall be considered as improper and

therefore not permitted.

Edilgrappa S.r.l. declines all liability for any improper use of the machine and for any

modification or change made to it.

Operators must observe the instructions in this manual in order to minimise the risk of

accidents. In particular, they must pay attention when working in conditions that could

cause:

- Possible burns from overheated metal parts;

- Injury due to incorrect positioning or inadequate lifting or moving;

- Injury caused by splinters discharged from the work piece.

People remaining in the vicinities of the machine while it is working are subject to the

following risks:

- flying debris (dangerous objects, etc…);

Hand/arm vibration. Standard applied: EN ISO 5349

The mechanical vibrations transmitted to the hands and arms generate a risk to the

health and safety of workers, especially as concerns vascular, osteoarticular, neurological

and muscular ailments.

The Employer is responsible for assessing the risk generated by mechanical vibrations,

pursuant to Directive 2002/44/EC.

Operating temperature

-40° ÷ +50° C

Bending Ø and max. unit tensile stress

Ø 16 ÷Ø 32 mm

STEEL R=750 N/mm²

•It is strictly forbidden to use the machine for purposes other than those

indicated in this installation and maintenance manual.

•It is forbidden to use the machine in areas subject to the risk of explosion.

PR16-32

18

3 ROUTINE MAINTENANCE

1.All maintenance, inspection and cleaning operations must be performed

with the power supply disconnected and the machine cool (see the person

responsible in the maintenance schedule);

2. Maintenance operations must be performed in a suitable place according to

current safety regulations;

3. Before any maintenance intervention, thoroughly clean the machine (see

Paragraph 5.01);

4. Wear suitable personal protective equipment while performing maintenance

work.

AFTER MAINTENANCE WORK, MAKE SURE THE GUARDS ARE PUT BACK INTO

THEIR CORRECT PLACE.

Periodic maintenance schedule

Frequency

Operation

Method

Person in

charge

EVERY 8 HOURS

•CHECKING THE INTEGRITY OF THE

MACHINE

Visual

Operator

EVERY 1600

HOURS

•CHANGE THE OIL

Para 3.01

Maintenance

person

EVERY 8 HOURS

•CHECK THE TIGHTNESS OF NUTS AND

BOLTS

Para 3.02

Operator

In case of doubts during the maintenance interventions, to order spare parts or for

complex maintenance work, contact your authorised retailer.

3.01 CHANGING AND TOPPING UP THE OIL

The oil change or top up must be performed so as to prevent impurities from

contaminating the oil or entering the tank. Impurities in the oil can irreversibly damage the

hydraulic parts.

ALWAYS MAKE SURE THE OIL CONTAINS NO IMPURITIES

DO NOT USE DIRTY TOOLS

DO NOT WORK IN DUSTY AREAS

CHANGING THE OIL:

USING A SUITABLE DISPENSER, PREPARE THE CORRECT QUANTITY OF OIL (0.6

l) TO POUR INTO THE TANK.

LEAKING OIL CAN CAUSE SHORT CIRCUITS, FIRE AND EXPLOSIONS.

1. Place the machine horizontally in a stable position on a work surface with the magnetic

cap facing upwards. Place a basin under the machine to catch any oil leaks;

2. Unscrew the magnetic cap (see part. 8 para 0.01) and remove any residues with the

piston in its retracted position;

PR16-32

19

3. Totally drain the oil tank using a suitable extraction system (used oil extraction pump)

so that no oil can leak into the machine;

4. Slowly pour in the correct quantity of oil (0.6 l) using suitable equipment (e.g. a funnel

as shown in fig. 4). Only use new or clean recommended oil (as indicated on the next

page);

5. Fill up to the upper rim of the hole;

6. Put back the oil cap and tighten slightly;

7. Perform some piston strokes to vent the large air bubbles;

8. Move the piston to its maximum extension and rapidly start and stop the motor several

times (before the piston automatically retracts);

9. Complete filling;

10.Put the oil cap on and tighten.

TOPPING UP THE OIL:

Before unscrewing the magnetic cap to check the oil level, make sure the piston is

fully extended and, if necessary, pull it out. If this is not done the oil may leak, air

bubbles may form and/or the oil level may be incorrectly measured, thus causing

the machine to operate incorrectly.

Only after completing the above operations, proceed as shown below:

1. Place the machine horizontally in a stable position on a work surface with the filling

hole facing upwards. Place a basin under the machine to catch any oil leaks;

2.

Unscrew the magnetic cap (see part. 8 para 0.01) and remove any residues;

3. Check the amount of missing oil;

4. Slowly top up to the upper rim of the hole with recommended new and clean oil using

suitable equipment (e.g.: a funnel as indicated in fig. 4);

5. Put the oil cap on and tighten.

Maximum quantity: 0.6 l.

Type of hydraulic oil: ESSO NUTO H46 or

approved equivalents HLP46

according to DIN 51 524 MIL-H 17672 C

PR16-32

20

When demolishing the machine or parts of it (oil, plastic, etc.) observe the

regulations in force in the country in which this operation is performed.

3.02 CHECKING SCREWS

Periodically, or every day in the event of frequent or prolonged work, make sure that all

the screws are perfectly tight.

FAILURE TO TIGHTEN LOCKING SCREWS CAN CAUSE SERIOUS DAMAGE.

3.03 HYDRAULIC COMPONENTS

3.03.01 UNSUCCESSFUL OUTWARD STROKE

If it is not possible to perform another outward stroke, make sure the double-acting lever

is correctly positioned ( see para 2.03 ).

3.03.02 MAX. PRESSURE VALVE INCORRECTLY ADJUSTED

In case of a pressure drop for a reason that cannot be directly identified, have a

maintenance person or the maker check the maximum pressure valve is clean and

calibrated.

3.03.03 MAIN CHECKS ON THE MOTOR

- Keep the motor surfaces clean, especially the fins on the head

- Keep the motor cooling slits clean and unobstructed

- Check the brushes for wear: replace them with authentic spare parts when their length is

less than 5mm.

This manual suits for next models

1

Table of contents

Popular Tools manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED KH 3017 HYDRAULIC CAR JACK Operation and safety notes

Matco Tools

Matco Tools BELT MASTER MESBT17 manual

9circle

9circle 9CL-40930 instruction manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN AKM1020P manual

Faithfull

Faithfull Fold Away Step Up User instructions

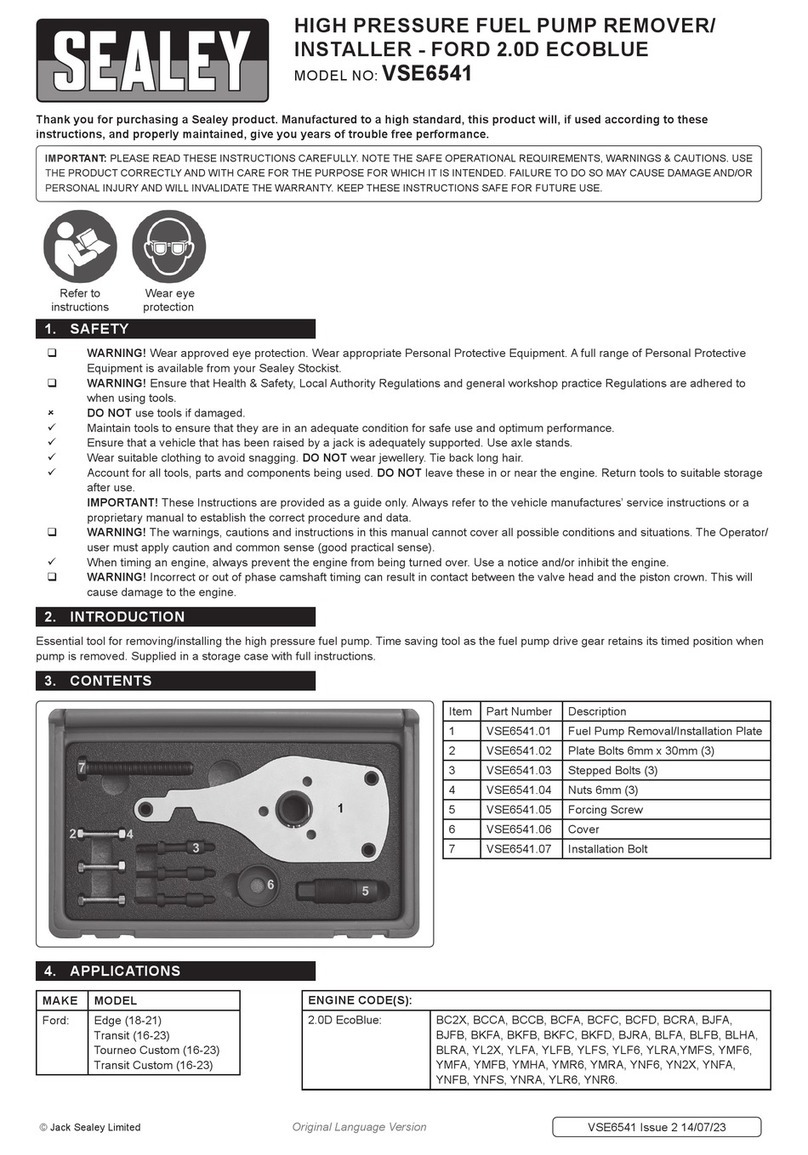

Sealey

Sealey VSE6541 manual