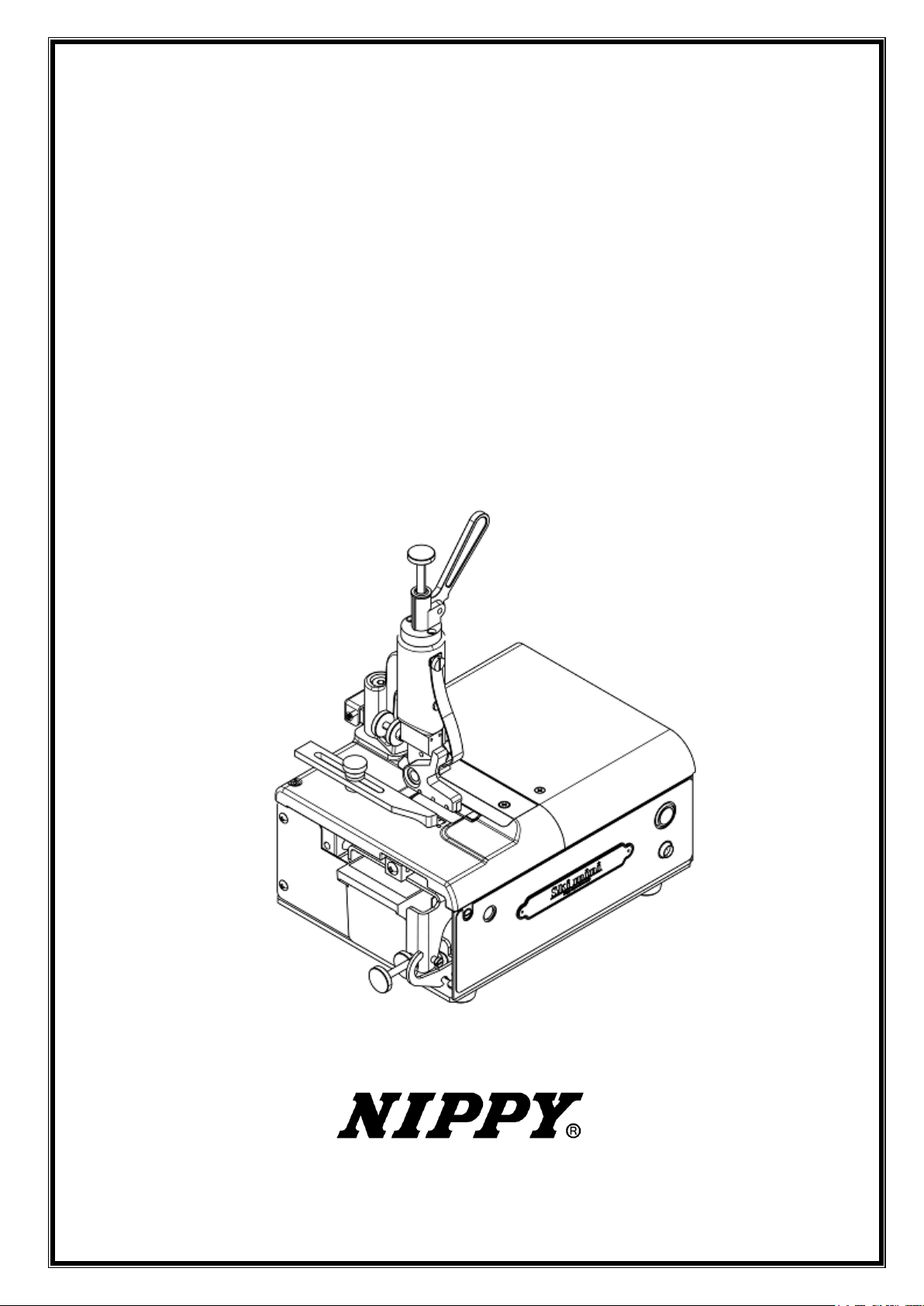

NIPPY NP-S7B Ski-mini User manual

NP-S7B Ski-mini

INSTRUCTION MANUAL

(AC100V-240V)

◆◆◆ table of contents ◆◆◆

1.Before using ・・・1

2.Name of parts ・・・3

3.Operating Instruction(How to adjust each part)

(1)How to skive ・・・4

(2)Thickness adjustment・Presser foot handle set ・・・4

(3)Adjustment of presser foot angle(Diagonal skiving method)・・5

(4)How to replace presser foot ・・・5

(5)Blade replacement ・・・6

(6)Feed roll adjustment ・・・6

(7)Position adjustment of spring tension adjustment lever ・・・7

(8)Removing the feed holder frame ・・・7

(9)Fuse replacement ・・・8

(10)Switching between operation switch and foot pedal ・・・8

(11)How to operate the foot pedal ・・・9

4.Abnormality of machine and its cause and adjusting method

・・・10

5.Specifications ・・・12

6.PRODUCTWARRANTY ・・・12

1

1.Before using

■Safety Precautions■

◆Readthis"SafetyPrecautions"carefullybeforeuse.

◆Afterreading,keepwhereyoucanseeatany time.

WARNING

Riskofdeathorseriousinjuryform improperuse.

⚫UseonlyAC100V-240V.

⚫In thefollowingcases,turnoffthe powerswitch andunplug.

☑Whenleavingthemachine.

☑After usingthemachine.

☑Whena powerfailure occursduringuse.

☑Whenabnormality,afailureoccurs.

⚫Forthe preventionof electricshock,shortcircuit andfireaccident,do not applyexcessive

force to thecable duringuse.

⚫Fortheprevention ofelectricshock,shortcircuitandfireaccident, Donotconnect overloading

anelectrical circuit.

⚫Openingthecovermaycause anelectricshock, Donotopen the cover.

⚫Do notuseorkeepmachineout ofwater,extreme humidity(70%ormore)oroutdoors.

⚫Do notusenearvolatilecombustibles.

⚫When unplugging the powerplug,holdand unplug thepowerplug,notthecord.

⚫Do notblockthevent.Heatmaybuildupinsideandcausefire.

CAUTION

Riskofinjuryordamagetopropertyfrom improperuse.

⚫Usethe machine ona stable platformorafterinstalling ona table.

⚫Ensure enoughbrightness.

⚫Do notusein directsunlight

⚫Forthe preventionof personalinjury,donotputyourfingeronthecuttingedge.

⚫If takingthetrash,besuretoturnoffthe mainpowerbeforetaking it.

⚫Keepawaythismachine form children.

⚫Neverdoremodelingofthemachine,separating.

⚫Do not regrindthebroken bladeand useitagain.

⚫Forthe preventionof personalinjury,donotusetheLeatherskivingmachinefor anything

otherthanitsintendeduse.

⚫Whenreplacingblade,besuretoturn offthemain power.

⚫Useatroom temperatureof5 ℃to35 ℃.

⚫Storeat roomtemperatureof-10°C to 45° C.

2

■Handling Instructions■

⚫Do notburdenthemachine.(extremely thickorhard)

⚫Do notusewhereitgetswet.Avoid using wethands.

⚫Becarefulnotto touchthe cuttingedge whenreplacing blade.

⚫Keepyourfingers awayfrom the blade whileoperating.

⚫Notto giveexcessiveshocksuch asfalls.

⚫Do notoperate with the presserfootincontact withtherollerorcutter.

⚫Do not operate the roller in contact with the blade.(It may cause the blade to chip or the

sharpness todeterioratequickly.)

⚫Do not stop the processed product and keep moving the skiving Machine.(It will cause the

sharpness todeterioratequickly)

⚫Neverruncontinuously formore than15minutes.(interval45 minutes)

⚫Besure tokeep the cardboard boxesthatthemachine wasin.

➢(Itis usedwhenshipping toourcompanyif thereisaproblem.)

■Safety device■

⚫Spindlemotor・Feedmotor

✓There is a safety device that automatically shuts off the machine when a certain load is

applied.

✓Once the safety device has been activated, turn off the main power and remove the one

withtools that caused the overload.

✓Atthis time,becarefulnottotouchthebladewithyour hands.

✓If itcan beconfirmedthatithasbeenremoved,turnonthemainpoweragainandcheckthat

theindicatorlamp is lightingreenbefore restartingoperation.

⚫Maincircuit

✓If thecircuitisshorted,the fusebuiltintothe mainunit willblow.

✓If thefuse isbroken, replaceitwithanewone. Referto8page“ Fuse Replacement”.

■Makesure tocheckthe followingitemsbeforework■

⚫Checkifeach part hasnoloosescrews.

⚫Checkthat thebladeandpresserfootare firmlyfixed.

⚫Check if the presser foot is not in contact with the bladeor roller and the roller is not in contact

with the blade.

⚫Adjustmentthethicknessintrialandthenworkonit.

3

2.Name of parts

power jack

fuse holder

foot pedal

lock

Green light : Operationcondition

Lamp display

status

foot clamp screw

main power

dust box

flat spring

angle adjustment screw

guide

Presser foot

power switch

table

guard

spring tension adjustment lever

feed roller

blade

thickness adjustment screw

arm

presser handle

feeding holder frame

adjustment screw

indicator lamp

4

3.Operating Instruction(How to adjust each part)

(1)How to skive

①Turnonthe mainpoweronthe backofthemachine.(Whenthe powerison,theindicatorlamp

lightsupingreen.)

②Adjust the guide tothedesiredwidth.

③Adjustthepresserfoottothedesiredthickness(Refertothe followingfortheoperationmethod)

④Turnonthepowerswitch.

⑤Feedthematerial between thefeed rollerandthepresserfootwhile keepingitalong the guide.

(2 )Thickness adjustment・Presser foot handle set

Turnthethicknessadjustmentscrewtotheright,thepresserfootapproachestheblade.

Turn to the left, wider distance from the blade. (The presser foot moves up and down by 1

mminonerotation.)

By raising and lowering the presser handle, it is possible to raise and lower the presser foot

with one touchwithoutchangingthethicknessadjustment.

When skiving from the middle of workpiece or workpiece gets between feed roller and the

blade,itisusefulfor removalwork.

①Whenskivingthinly

Thethicknessadjustingscrew isturned ontherightdirection.

②Whenskivingthickly

Thestepsof①aboveshouldbe performed inreverse order(left direction).

Thin

Thick

the thickness adjusting screw

feedingdirection

presser foot

material

feed roller

table

skiving debris

finished material

blade

guide

feedingdirection

material

5

( 3 )Adjustment of presser foot angle(Diagonal skiving method)

①Replacewith the 20mmwidth plasticpresser footincluded intheaccessories.

※The20mmwide presserfootisalready 15° angled comparedtothe40mmone.

②Whenturningtheangleadjustmentscrewleft orright,changesthedistancebetween the

presserfootandthe bladeandadjusttoanyangle, fix firmlywith lock nut.

(WhenTurned totheleftwith anangle.When turnedtothe right,itapproachesparallel.)

③Afterchangingtoanyangle,adjustthepresserfootupanddownwiththe thicknessadjustment

screw.

Atthis time,the presserfootisloweredtoomuch,becarefulnottotouchthe feed roller.

④If theangleandupperandlowerposition isdecided,passthroughthematerialasusual.

(Precaution)

Too muchangle,note thatthe feedforceofthe materialwillbeweak.

( 4 ) Howto replace presser foot

①Raise thethicknessadjustingscrew upward, remove the presserfoot fromtheblade,shiftthe

flatspring.

②Loosen theknurled screw ofthepresser foot andremovethe lockand removedtogetherwith

thepinfor presser foot.

③Remove thetwo setscrewsontherightside ofthepresserfoot, replacetipattachment.

④Attach thereplacementpresserfootbya reverseprocess.

(Precaution)

Thereplacedpresserfootmust besecurelyfixed.Thethicknessadjustingscrewis fastenedtoo

tightlyandit mayimpairthefeedrolland the presser foot.

The thickness adjusting screw must be loosened in advance and replace. Then tighten the

thickness adjustingscrewandadjustthe presserfootheight.

loosen

angled

lock nut

angle adjustment screw

presser pin

flat spring

shifttothe side

remove

lock

Plastic presser foot

(base material)

Presser foot accessory parts

6

( 5 ) Blade replacement

①Turnoffthemainpower.

②Loosen thescrewoftheguardwith the accessorydriver, remove the guard.

③Loosenthebladefixingscrewwiththeaccessorydriver, remove thebladeholder.

④Replacethebladeandassembleinthereverseprocess.

(Precaution)

・Workcarefullynot totouch the cutting edge.

※Ifyoutouchedge ofblade,pleasewear protective glovesetc.

・Workcarefullynottodropthe removedscrewinside themachine.

・Tighten the blade fixing screw little by little alternately to the left and right, tighten firmly at the

end.

(6 )Feed roll adjustment

Thefeedrollandblade’s spaceis properlyadjusteddependon

thethickness ofaworkpiece.

Turningtheadjustment screw to the rightincreases thedistancebetween the rollerand theblade,

turntotheleft tonarrow.

Oncetheposition isdetermined,turnthe lock nutand fixtheadjustmentscrew.

(Precaution)

Notto contact between the roller and the blade,the stop position atthe stopper is the upper limit

position.

go down

guard

push forward and pull

up

guard

blade holder

blade

blade fixing screw

stopper

blade holder

lock in

lock nut

adjustment screw

roller

blade

go down

presser foot

7

(7 )Position adjustment of spring tension adjustment lever

①Whenahard workpieceisskived

Pull the spring tension adjustment lever forward and hang in the back groove, strengthen the

force of the spring.

②Whenasoft workpieceisskived

Hanginthefrontgrooveofthespringtensionadjustmentlever,weakentheforceofthe spring.

( 8 ) Removing the feed holder frame

①Pulloutthedust box.

②Hookthespringtensionadjustmentleveronthesideofthe stopper.

③Loosen thescrews ofinnercover withtheaccessorydriverandremovethe cover.

④Loosen the center set screw with the accessory hex wrench and pull the center pin

sideways while supporting the feed support frame with your hand, the feed support frame

willberemoved.

⑤After pulling out the feed support frame, disconnect the feed motor harness from the

connector.

⑥Assembleinthereverseprocess.

strength

weak

spring strength by groove position

stopper

dust

box

center pin

inner cover

spring tension adjustment

lever

center set screw

feed support frame

connector

pullout

8

( 9 ) Fuse replacement

①Turnoffthemainpowerandunplugthepowercord.

②Pulloutthefuseholderofthepowerjack.

③Replacea newfuse,assemble in thereverse process.

Useacommercially available 5A, 250Vminiatureglasstubefuse.(φ5.2×20mm)

➢Thefuseholderisattached ina spare fuse.

(10 )Operation switching between run switch and foot pedal

There isoperation switchingbetweenrunswitch andfoot pedalonthebackofthe main unit.

Theupperside isthe foot pedal,and thelowerside istherun switch.

(Precaution)

Note that when switching to the foot pedal, if you hold down the pedal, it will start moving

immediately.

Note that if the power switch is operation mode, it will start moving immediately when you

switched it.

【Stop the back switch ⇒Operation】

power jack

fuse holder

fuse

main power

fuse holder

9

Switchingoperation

Operation

Behavior

Set the backswitchtothe

runswitch

Presstherunswitch

Startoperation

Pressthefootpedal

No reaction

Set the backswitchtothe

footpedalside

Presstherunswitch

No reaction

Pressthefootpedal

Startoperation

(11 )How to operate the foot pedal

Takeoutthefootpedalfromtherightsideand installthepedal inanypositiontouseit.

Avoidtheplace wheresteppingerrorsare likelytooccurorplacesthatare pronetocollapse.

Makesure thebackoperateswitching isonthe footpedalside.

It onlymoveswhile with themain poweronandpressingthefoot pedal.

Byturningthe footpedalon/off,youcan controlthefeedspeed.It isuseful when youwantto

workonacurveorslowly.

(Precaution)

Do notbendthecableforcibly.

Theplugisn’t removable.

foot pedal

cable

plug

10

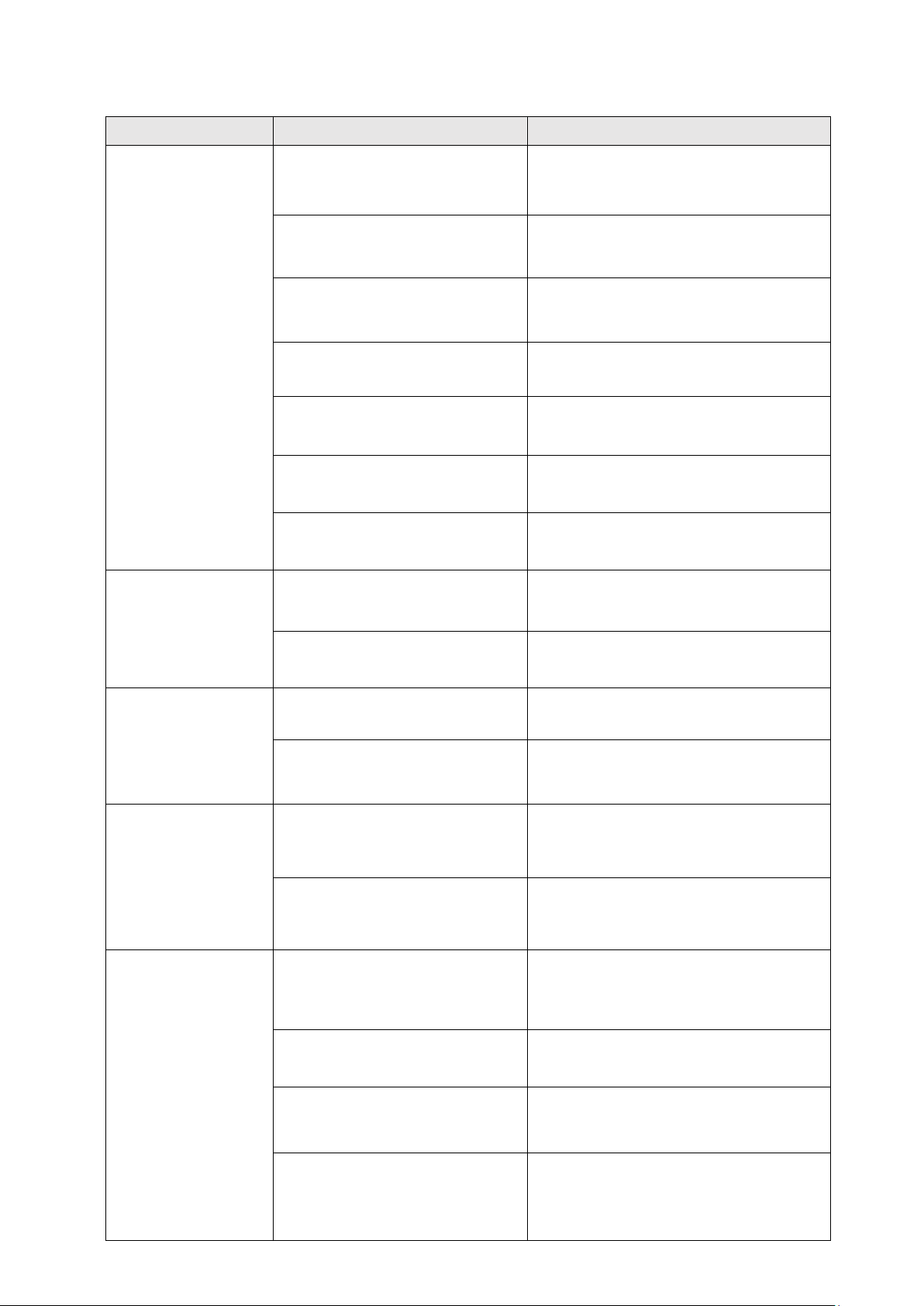

4.Abnormality of machine and its cause and adjusting method

Abnormality

Cause

Adjusting method

Work piece does not enter

themachine smoothly

The up and down space between presser

footandthebladeiswide

Thintheskiving thickness,because it istoothick

The space between the feed roll and the

blade iswide

Bring the feed roller as close to the blade as

possible

The space between the feed roll and the

blade isnarrow

When a work piece is thick, lower the feed roll little

bylittle

Thebladedoesn’t cut well

Replacewithanewone

Spring tension adjustmentlevertoo strong

Weaken spring tension adjustment lever as much

aspossible

Thesurfaceofthepresserfootiswornout

Replacewitha newone

Slippageof presserfootis bad

ApplyTeflontapetothepresser footslidingsurface

Leather does not enter

between presser foot and

flatblade

The up and down space between the

presserfootandthebladeis narrow

Increasethespace betweenpresserfootandblade

The space between the feed roll and the

blade isnarrow

Increasethespace betweenfeedroll andblade

Leather isn’t skiving

(orcleanly)

Thebladedoesn’t cut well

Replacewitha newone

The up and down space between the

presserfootandthebladeis wide

Thintheskiving thickness,because itis toothick

Wavy stripes are present

ontheskivedsurface

The edge of the blade is partly broken or

thebladedoesn’t cut well

Replacewitha newone

Thebladeisnotcompletelyfixed

Tightenthe bladeholderscrew

Anskivedportions

areleft

Thepresserfootisnotcompletelyfixed

Thesetting screw forthepresserfootis loose,fix the

presserfootnottomove

Thepresserfootcontactswiththefeedroll

Loosen the thickness adjusting screw, and raise the

presserfoot

Uneven portions existon the feedroll

Thefeedrollisdefective,replace theroll

Not pushing the center pin of the feed

supportframecompletely

Push the center pin completely and tighten center

setscrew

11

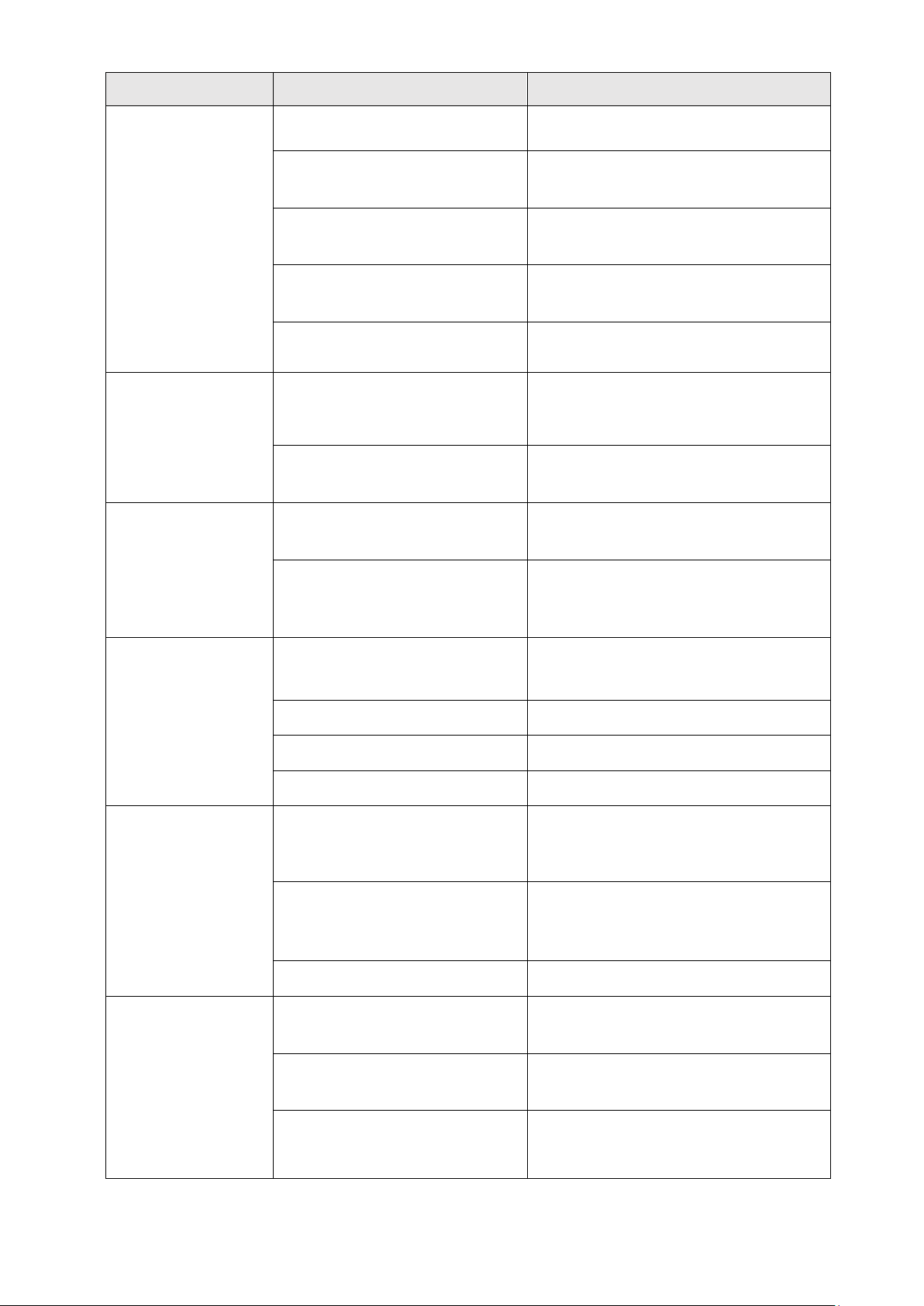

Abnormality

Cause

Adjusting method

Work piece goes under the

blade

The space between presser foot and the

blade isnarrow

Thicktheskivingthickness,becauseitistoothin

Thepresserfootisbelowthe bladeedge

Raisethepresserfoot

The space between the feed roll and the

blade istoowide

Bringthefeed rollclosertotheblade

Thesharpness ofthe bladeisbad

Replacewithanewone

The spring tension adjuster is too device is

tooweak

Strongthe springtension adjuster

The skived scrap is rolled

upward

Thedustis fullofdustbox

Throwaway thedust

There are irregularities on the surface of

thefeedroll

Replacewithanewone

Thesharpness of the blade

gets worsesoon

stopping and running the processed

skivingpiece inthemiddleof work

Finish theprocessedproducttotheend

Skiving for something thick, hard or hard to

cut

When skiving something that is likely to damagethe

blade,replace withanewonefrequently

Bladedoesn’t move

Foreign matter is caught at both ends of

theblade

Because the safety device is working, Eliminate the

causeof overload(suchasthedust)

Mainpowerorpowerswitchisoff

Turnon main powerorpowerswitch

Spindlemotorfailure

Replacewitha newone

Power supplycircuitfailure

Requestrepair fromourcompany

The feed roll doesn’t move

Foreignmattersuchas shavingsiscaught

Because the safety device is working, Eliminate the

causeofoverload (suchasthedust)

Feedmotor failure

Replacewitha newone

Power supplycircuitfailure

Requestrepair fromourcompany

Cannotturnon

Powercordisnotstuck

Plugin thepowercode

Thefuseis blown

Replacefusewithanewone

Power supplycircuit failure

Requestrepair fromourcompany

12

MODEL

NP-S7B

Product

Number

Date of purchase

Warranty

period

1 Year

Customer

Address

Name

Tel

Store

5.Specifications

M O D E L

NP-S7B

Power source

AC100V –240V

R a t e d f r e q u e n c y

50/60Hz

P o w e r c o n s u m p t i o n

80W

Rate d t i m e

15min

U s e d f u s e

5A250Vminiatureglasstube fuse(φ5.2×20mm)

D i m e n s i o n s

H390×W330×D240mm

Standard skiving thickness

2.5mm(dependsonthetypeofleather)

W e i g h t

10.5kg

Ac ces so rie s

・Feedfootpedal

・Presserfoothandleset

・2kindsofPlasticpresserfoot(40mm、20mm)

・Powercode(Plug:AtypeorCtype)

・Blade5pcsset(forreplacement)

・Screwdriver, 2kindsof Hexwrench

・INSTRUCTIONMANUAL(thisdocument)

6.PRODUCT WARRANTY

●Spareparts(blade,feed roll,presserfoot)areoutofcompensation

●Malfunction occurred in wronguseorcarelessnesssuchasfalls

●Repair orremodelingexcepttheregularstore

●The damageby anatural disaster suchasfire,earthquake,storm,flood damage,thunderbolt and

abnormalvoltage

We will repair the product without charge for any failure that should occur in normal use for 1 year after

purchaseshowingthiswarranty.Inthe case of follows,itis chargedwhether they occur during the warranty

periodornot.

WARRANTY

MEMO

Aug. 2022

■MANUFACTURE AND SALES■

NIPPY KIKAI CO., LTD.

767-1 Shimomiyaki-cho, Kasai, Hyogo 675-2105 Japan

TEL: +81-790-49-1414 FAX: +81-790-49-2266

E-mail: info@nippy.jp URL: http://www.nippy.jp/

Table of contents