Edlund Company 350 User manual

Please read thoroughly before operation and keep for future reference

1

M092 REV. C

PRODUCT MANUAL- M092

MODEL 350 & 350XL PRODUCE

SLICER

Please read thoroughly before operation and keep for future reference

2

M092 REV. C

SAFETY

WARNING: THE BLADES ARE VERY SHARP! BE SURE NOT TO TOUCH THE

CUTTING EDGE OF THE BLADES.

Grounding/Earthing Instructions

Slicer MUST be grounded. Grounding reduces risk of electric shock by providing an

escape wire for the electric current, if a electrical short occurs. This slicer is equipped

with a cord having a grounding wire with a grounding plug. The plug must be plugged

into an outlet that is properly installed and grounded.

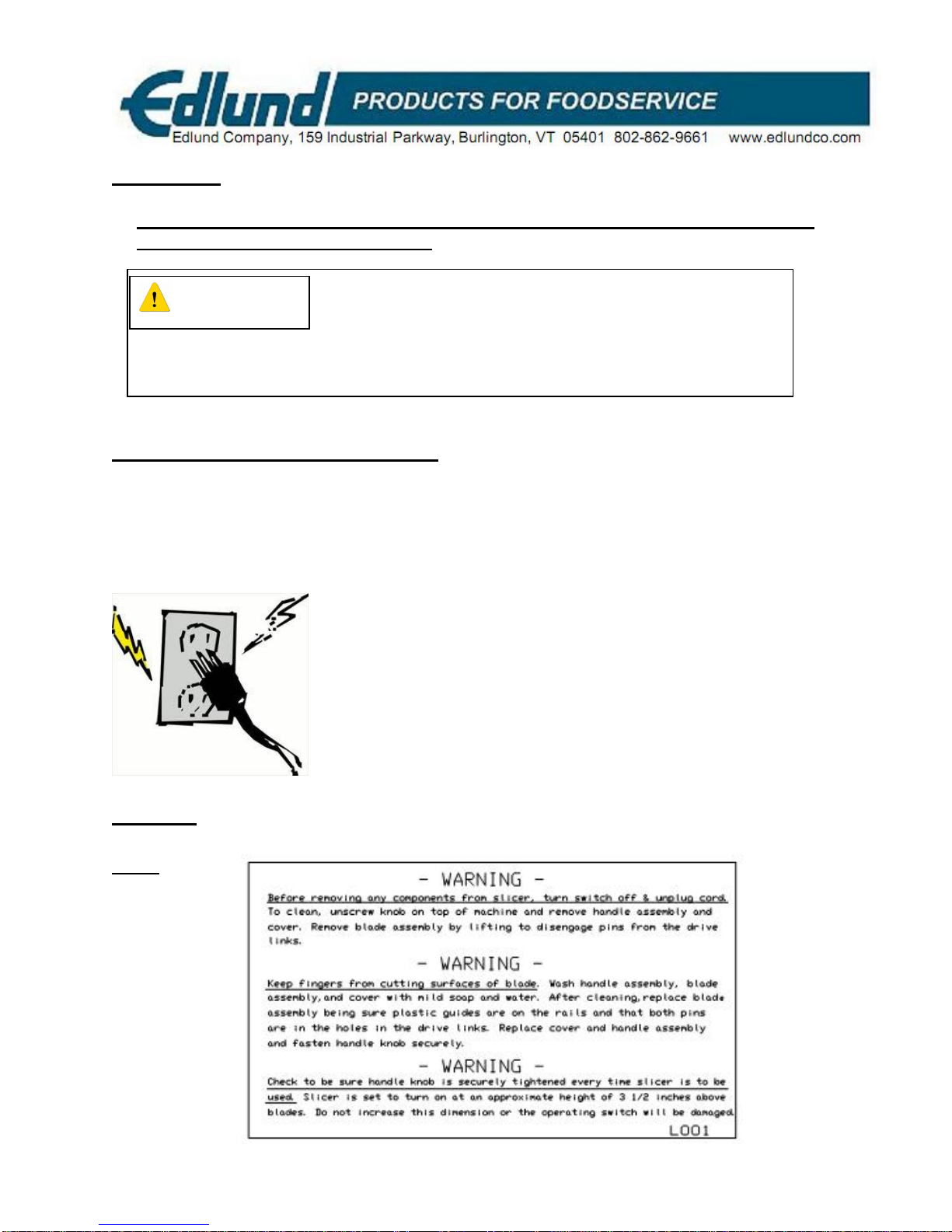

LABELS

L001

To avoid risk of electrical shock, this slicer must be

grounded and plug must not be altered.

WARNING

Please read thoroughly before operation and keep for future reference

3

M092 REV. C

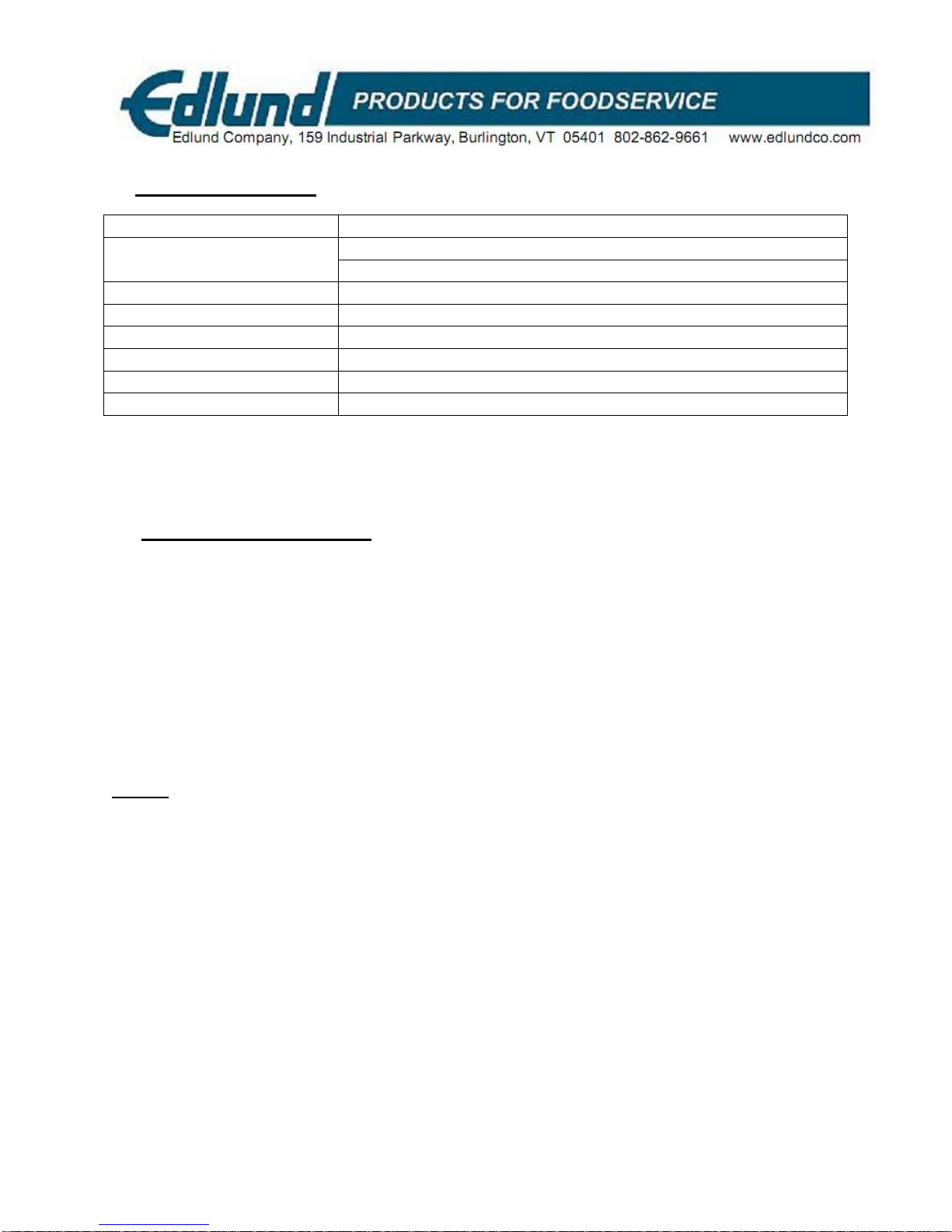

I. SPECIFICATIONS

MODEL NO. 350, 350XL

Power Requirement 115 volt, 1.5 Amp, 50-60 HZ

230 volt, 0.8 Amp, 50-60 HZ

Speed 600 – 750 RPM for drive cam assembly

Slice Thickness 3/16 inch, 1/4 inch, 3/8 inch standard slice thickness*

Size 350 12” W x 14-1/2” H x 18.5” D (305mm x 368mm x 470mm)

Size 350 XL 12” W x 14-1/2” H x 20” D (305mm x 368mm x 508mm)

Weight 350 19.1 lb. (8.7 kg)

Weight 350 XL 20.5 lb. (9.3 kg)

*Measured from center of blade to center of blade. There are other

sizes available upon request. Call factory or your dealer.

II. SLICER DESCRIPTION

The Model 350, 350XL electric produce slicer is designed to slice tomatoes,

oranges, peppers and other soft products into multiple slices with a single stroke. It

will slice produce up to 3-1/2 inches in diameter. The 350 slicer throat length is 4.25”,

while the 350 XL is 5.75”. The slicing of any hard, dense produce such as onions or

potatoes will void the warranty and will severely damage the blades and the pusher

fingers. The slicer is approved by the appropriate certifying organizations.

The slicer is manufactured of stainless steel and aluminum and it can be easily

disassembled for cleaning and/or maintenance.

NOTE: All slicers manufactured starting 2009 have the style pusher assembly

A1500 and use either the PI368 3/16”-3/8” Pusher Insert or PI014 1/4” Pusher

Insert. The insert is a plastic resin (lexan) design.

Please read thoroughly before operation and keep for future reference

4

M092 REV. C

III. Operating Instructions

CAUTION: WITH POWER SWITCH OFF, CHECK TO BE SURE THAT PUSHER

SECURING KNOB IS TIGHT AND PUSHER FINGERS ARE CENTERED

BETWEEN THE BLADES THE FIRST TIME SLICER IS USED AND AFTER

CLEANING OR MAINTENANCE. FOR PUSHER ASSEMBLY ALIGNMENT AND

ADJUSTING PROCEDURE, SEE PAGE 9.

To operate the slicer, plug the power cord into a grounded outlet with the same

voltage as listed on the legend plate located on the side of the motor cover. Lift the

pusher assembly so that it rotates about its hinge point and raise it until the pusher

arms are vertical. Turn the on and off switch, located on the side of the motor cover,

to the on position. The slicer motor should not start. Place a tomato or any other

soft product that is to be sliced in the center of the bank of blades of the blade carrier

assembly, with the product to be sliced orientated in the desired direction.

WARNING: THE BLADES ARE VERY SHARP! BE SURE NOT TO TOUCH THE

CUTTING EDGE OF THE BLADES.

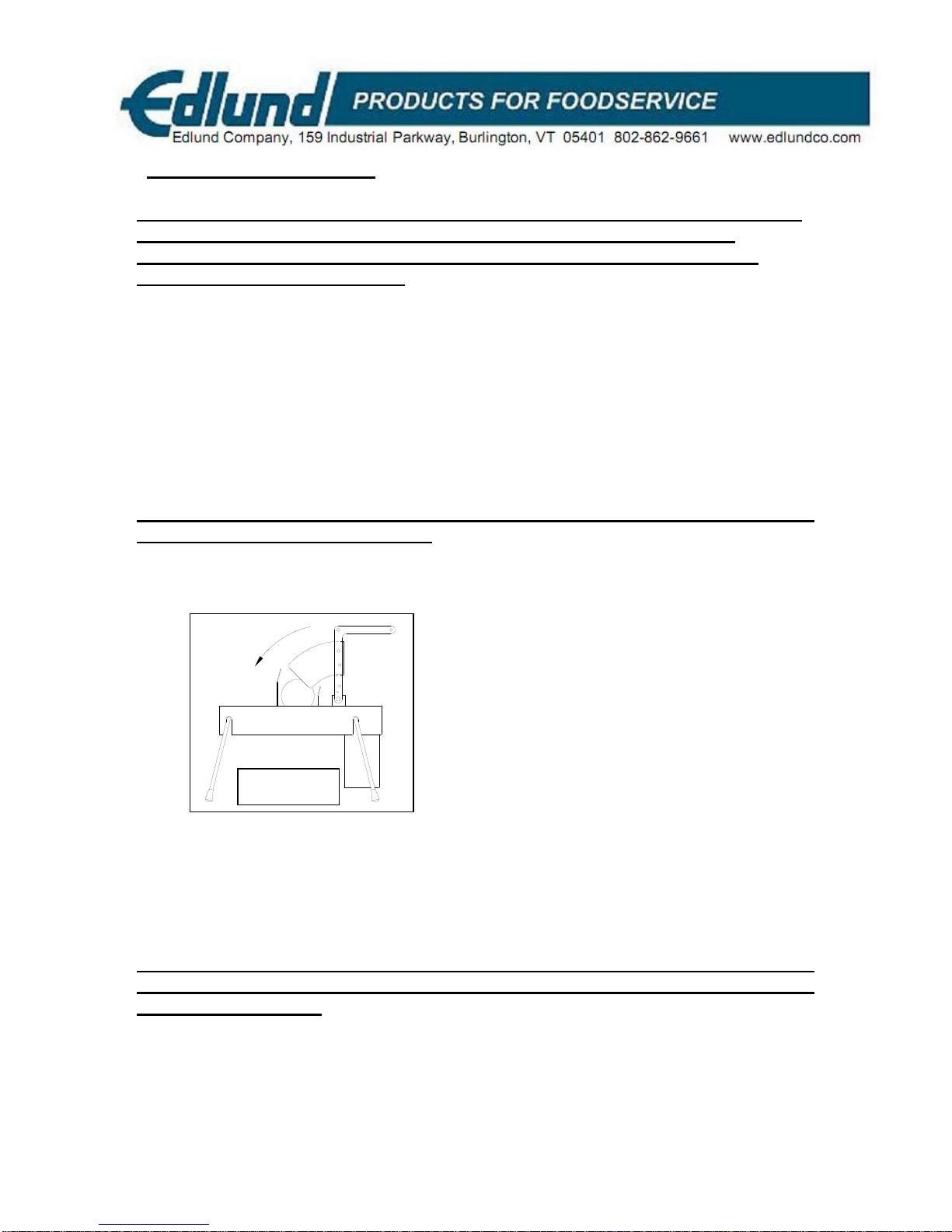

1. Lower the pusher assembly toward the blades. The slicer motor will start

when the pusher reaches a pre-set distance

from the blades. Keep lowering the pusher

assembly until the pusher fingers contact the

product to be sliced and continue the

downward motion using a very light downward

force until the product is completely sliced.

(See Figure 1).

Lift the pusher assembly to its original

position. The slicer motor will stop and

another product can be placed on the blades

and the slicing process can be repeated.

The pre-set activation distance can be adjusted by loosening the thumb screw,

on the side of the pusher head, and rotating the metal cam. Retighten thumb

screw once desired activation height is achieved.

WARNING: NEVER FORCE PUSHER ASSEMBLY DOWN. USE A LIGHT

DOWNWARD PRESSURE ONLY OR BLADES AND PUSHER FINGERS WILL

BECOME DAMAGED.

Figure 1

Please read thoroughly before operation and keep for future reference

5

M092 REV. C

IV. Cleaning and Maintenance Instructions

WARNING: NEVER CLEAN OR MAINTAIN THE ELECTRIC SLICER WITHOUT

TURNING THE ON AND OFF SWITCH TO THE OFF POSITION AND

UNPLUGGING POWER CORD FROM POWER SOURCE.

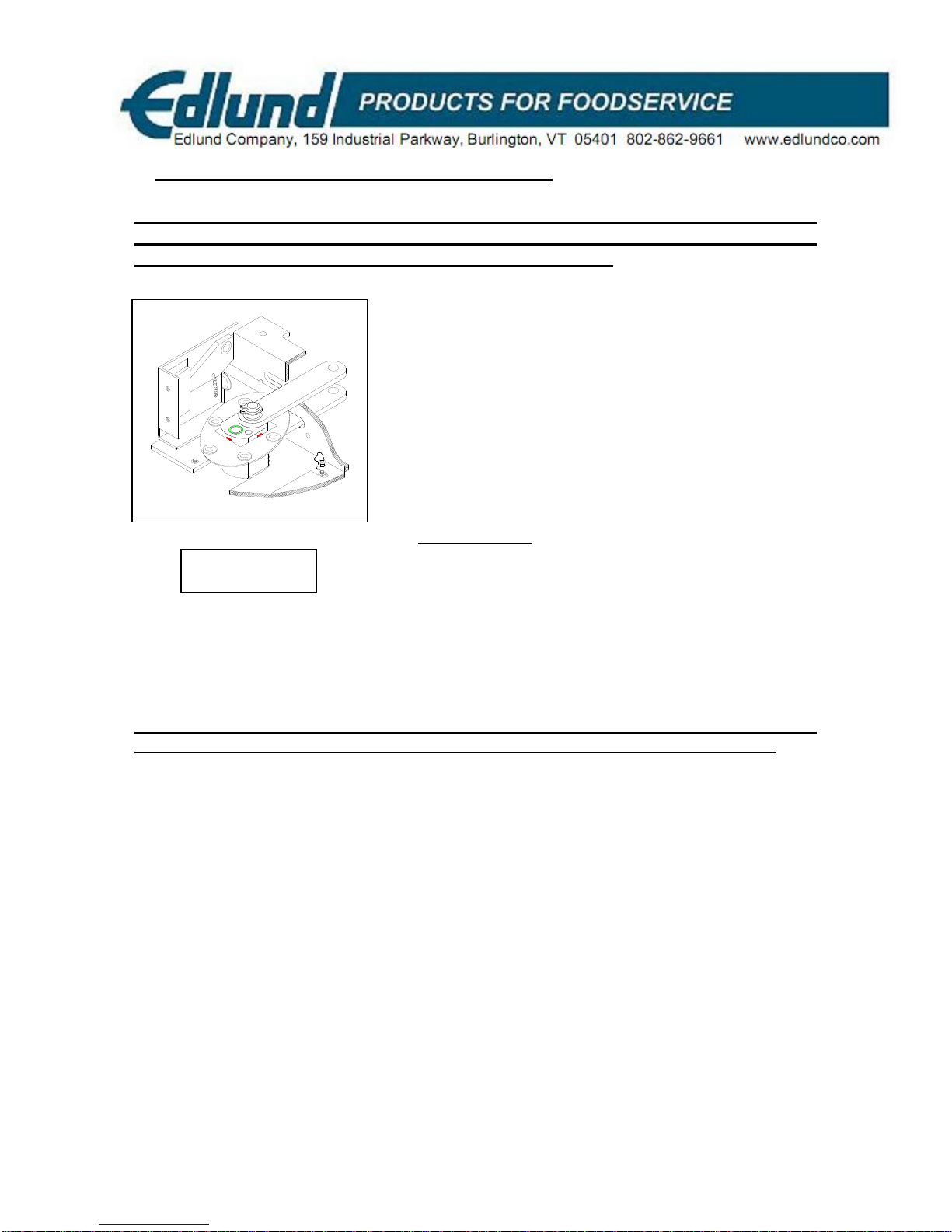

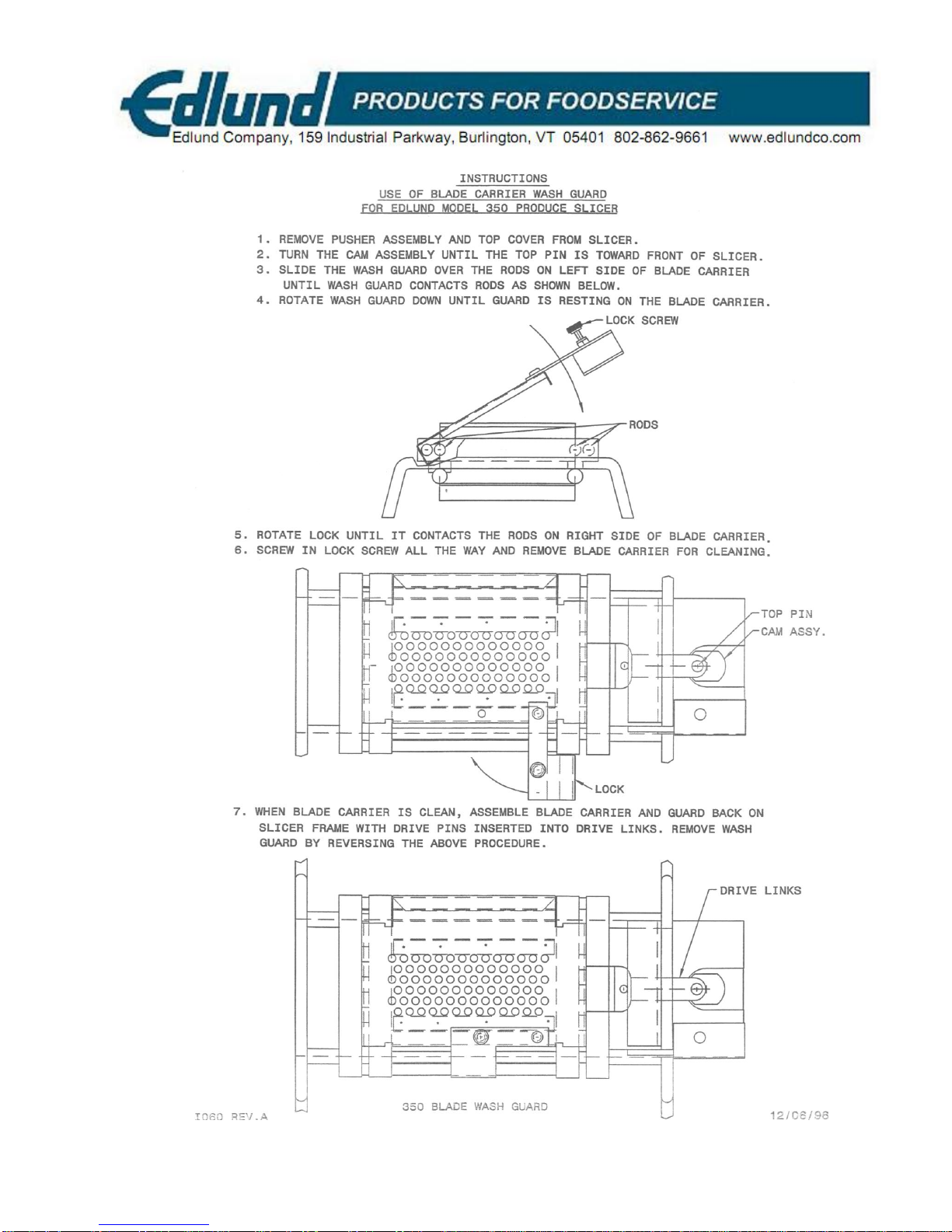

1. The pusher assembly, cover and blade carrier

assembly is easily removed for cleaning. In order to

remove these items, loosen the pusher assembly

retaining screw and lift the pusher assembly off the

unit. Remove the cover and remove the blade

carrier assembly by first turning the cam assembly

until the top pin is towards the front of the slicer.

(See Figure 2.)

2.Lift the blade carrier off the unit.

3. IMPORTANT: To avoid injury, blade carrier

should be stored and washed sharp side down in

provided wash/storage guide. If you do not have

this guide one should be ordered as Edlund part

#A350 (A350L for XL version).

4. For the Pusher Assembly, follow the disassembly procedure below for cleaning

parts, replacing a damaged pusher insert or changing slice size.

CAUTION: ALWAYS MATCH BLADE SIZE TO PUSHER INSERT SIZE. DAMAGE TO

BLADES, AND OR PUSHER FINGERS CAN OCCUR IF INCORRECTLY MATCHED.

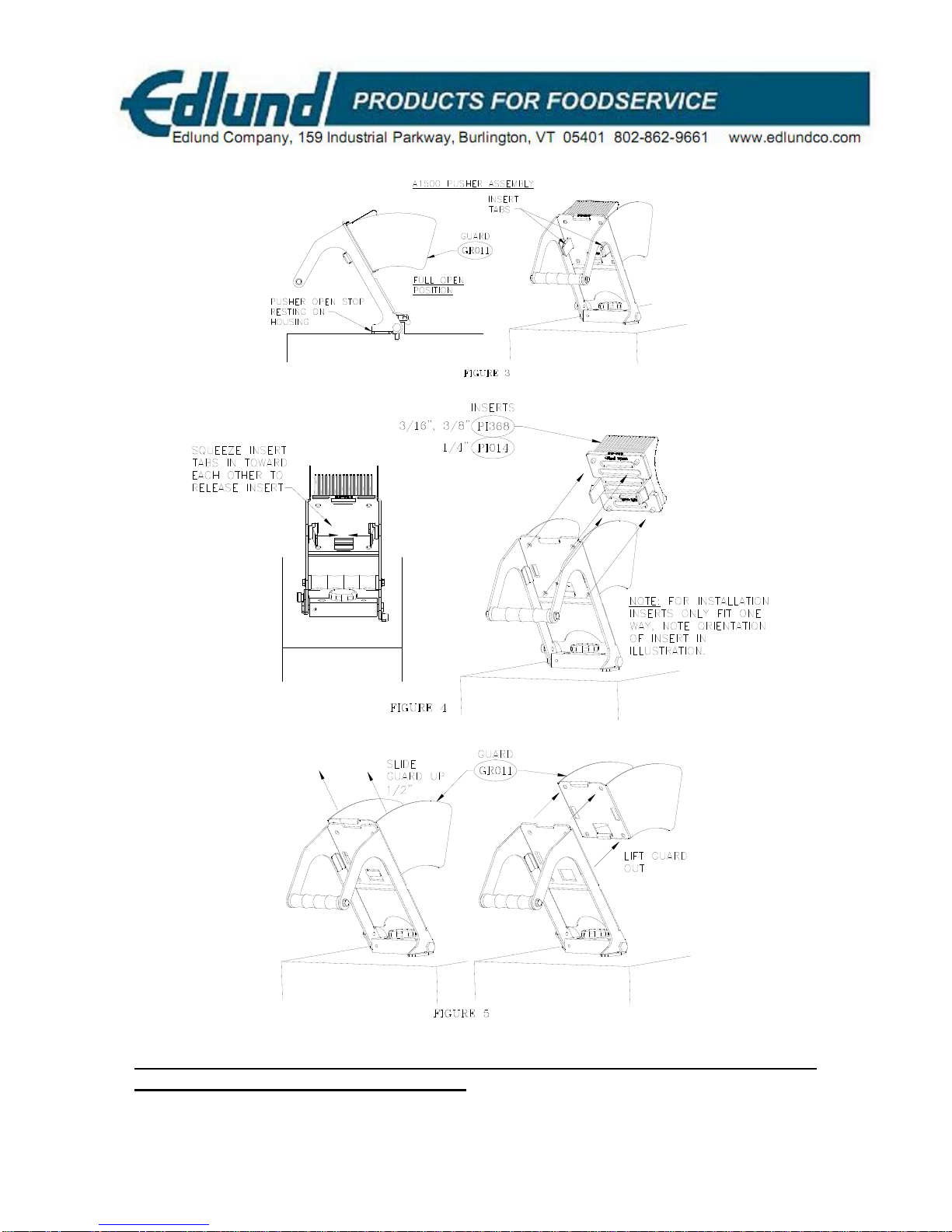

A) Open Pusher Assembly to full open position using handle. The Pusher Open

Stop should be resting on cover as seen in figure 3 below.

B) Squeeze Insert Tabs in toward each other to release Insert. Pull Insert

straight out away from Pusher. See figure 4.

C) Slide Guard GR011 up approx. ½” then lift Guard straight out away from

Pusher Frame. See figure 5.

FIGURE #2

Please read thoroughly before operation and keep for future reference

6

M092 REV. C

WARNING: THE BLADES ARE VERY SHARP! BE SURE NOT TO TOUCH THE

CUTTING SURFACE OF THE BLADES.

Please read thoroughly before operation and keep for future reference

7

M092 REV. C

Wash the pusher assembly, the cover and the blade carrier assembly in mild soap

and water or in a dishwasher. The rest of the slicer can be wiped off using a damp

cloth.

WARNING: NEVER SUBMERGE OR PLACE ENTIRE ELECTRIC SLICER OR

MOTOR HOUSING IN WATER.

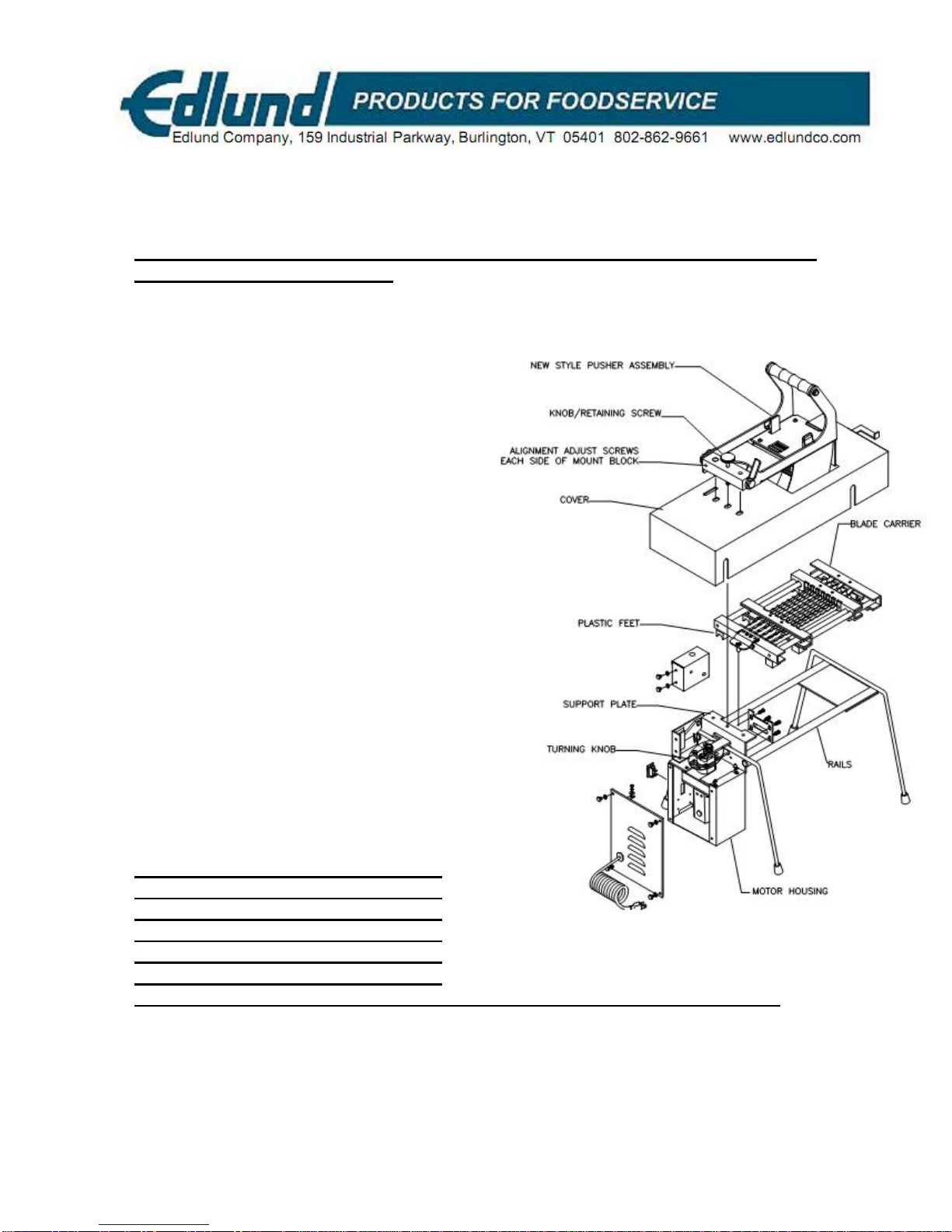

1. To assemble equipment after

cleaning, turn the cam assembly until

the top pin is toward the front of the

slicer and install the blade carrier in

place, making sure that plastic feet

are on the rails and that the drive

mount pins are engaged in the holes

of the drive links. Slide the cover in

place and line up the holes in the

cover with holes in the support plate.

Also make sure that the cover

interlock pin, located on the inside of

the cover, is aligned with the hole in

the interlock switch bracket. Install

the pusher assembly in place by

inserting the pins of the pusher mount

through the holes in the cover into the

holes in the support place. Start the

pusher retaining screw and leave the

screw loose. Lower the pusher

assembly until the pusher fingers

engage the space between the

blades, center the cover and tighten

the pusher retaining screw. (See

Figure 6)

WARNING: MAKE SURE THE

PUSHER FINGERS DO NOT

CONTACT THE BLADES. BLADES

AND PUSHER FINGERS WILL BE

DAMAGED IF SLICER MOTOR IS

STARTED WITH THE PUSHER

FINGERS IN CONTACT WITH THE BLADES OR USED WHEN MISALIGNED.

2. The set of blades can be replaced if the blades become dull. It is recommended

that all the blades be replaced at the same time because they may stretch during

use, and replacement of only a few blades may cause the old blades to be loose

when the blade-holders are tightened.

Figure 6

Please read thoroughly before operation and keep for future reference

8

M092 REV. C

3. The set of blades must be kept tight in order to function properly. Check the

blade tension of all the blades by turning the blade carrier assembly over with the

blade-cutting surface down. Run your fingers across the back of the set of

blades, one at a time, the blades should "ring" and have a similar sound. If any of

the blades appear to have a dull sound, contact your authorized service station.

NOTE: If for any reason the Model 350, 350XL Slicer does not function properly,

consult the trouble-shooting guide for assistance or call the factory or your local

service center.

WARRANTIES: The Edlund Company warrants these products to be free from

defects in material and workmanship for a period of one year from date of

purchase. The company's obligation under this warranty is limited to repairing

or replacing without charge any part or parts found to be defective under

normal use. It is the responsibility of the purchaser to return the entire unit to

the factory or a factory service branch, transportation charges prepaid. This

warranty does not cover parts that must be replaced under normal use,

including knives and drive gears on can openers. The company authorizes no

other warranty, written or verbal. Carrier is responsible for merchandise in

transit to you.

NEW BLADES SHOULD BE REPLACED BY EDLUND.

Please read thoroughly before operation and keep for future reference

9

M092 REV. C

Pusher Assembly Alignment Check and Procedure

1. With the unit unplugged and the ON/OFF switch in the OFF position and the

pusher assembly mounted to the unit check the alignment of the pusher

fingers to the blades. The pusher fingers should be centered in the spaces

between the blades. If they are not follow step 2 below.

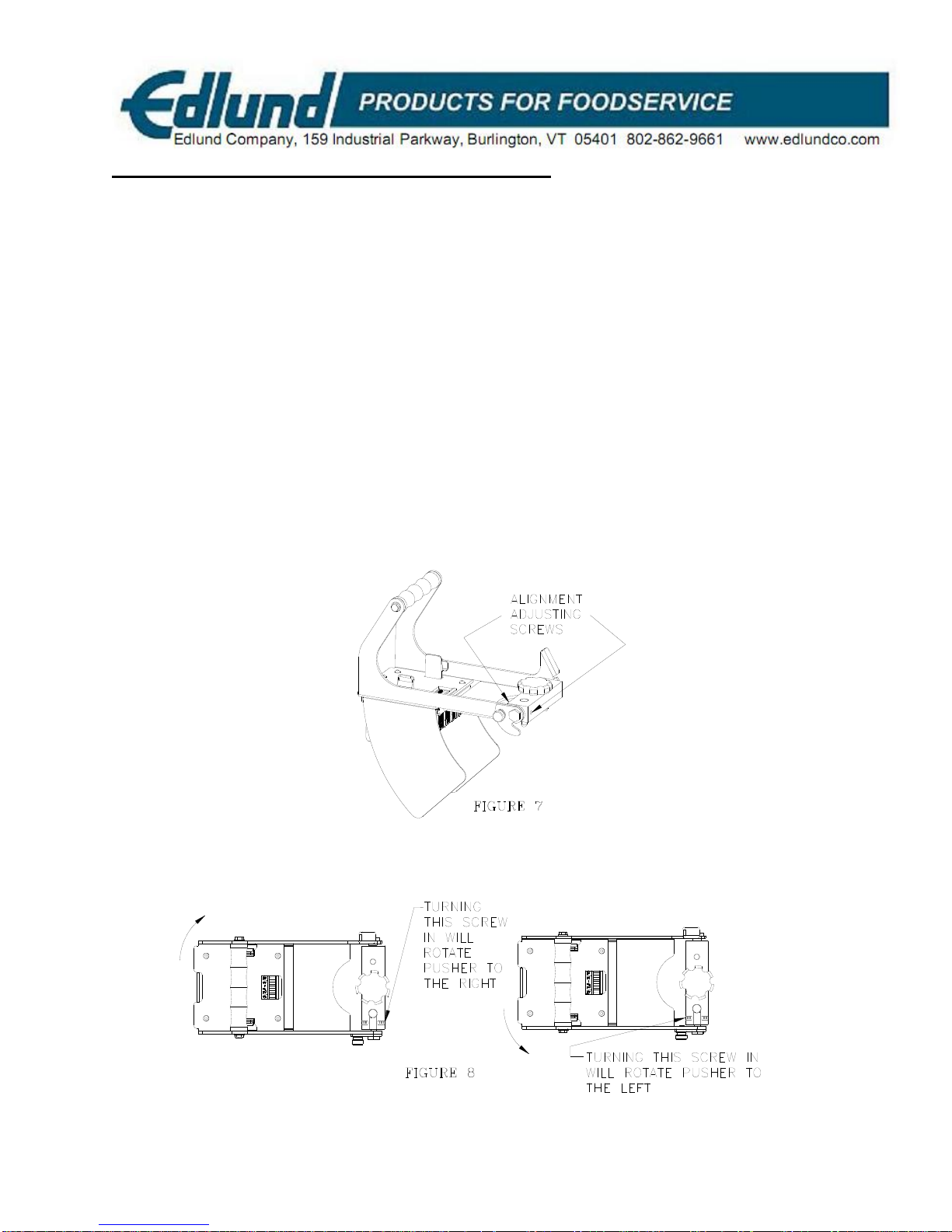

2. Locate the alignment adjusting screws shown in figure 7. Determine which

direction the pusher should rotate by observing where the pusher fingers align

in between the blades. Using a small standard screwdriver you can turn the

appropriate screw to rotate the pusher left or right. When adjusting a screw

inward the opposing screw must be turned outward or loosened first. Center

the pusher fingers and tighten the opposing screw. See figure 8 below. Check

alignment again after tightening and adjust again if needed.

NOTE: Proper alignment is critical to the functioning of the slicer and will help

ensure longevity of blades and pusher inserts. If blades or pusher assembly is

changed perform an alignment before use.

Please read thoroughly before operation and keep for future reference

10

M092 REV. C

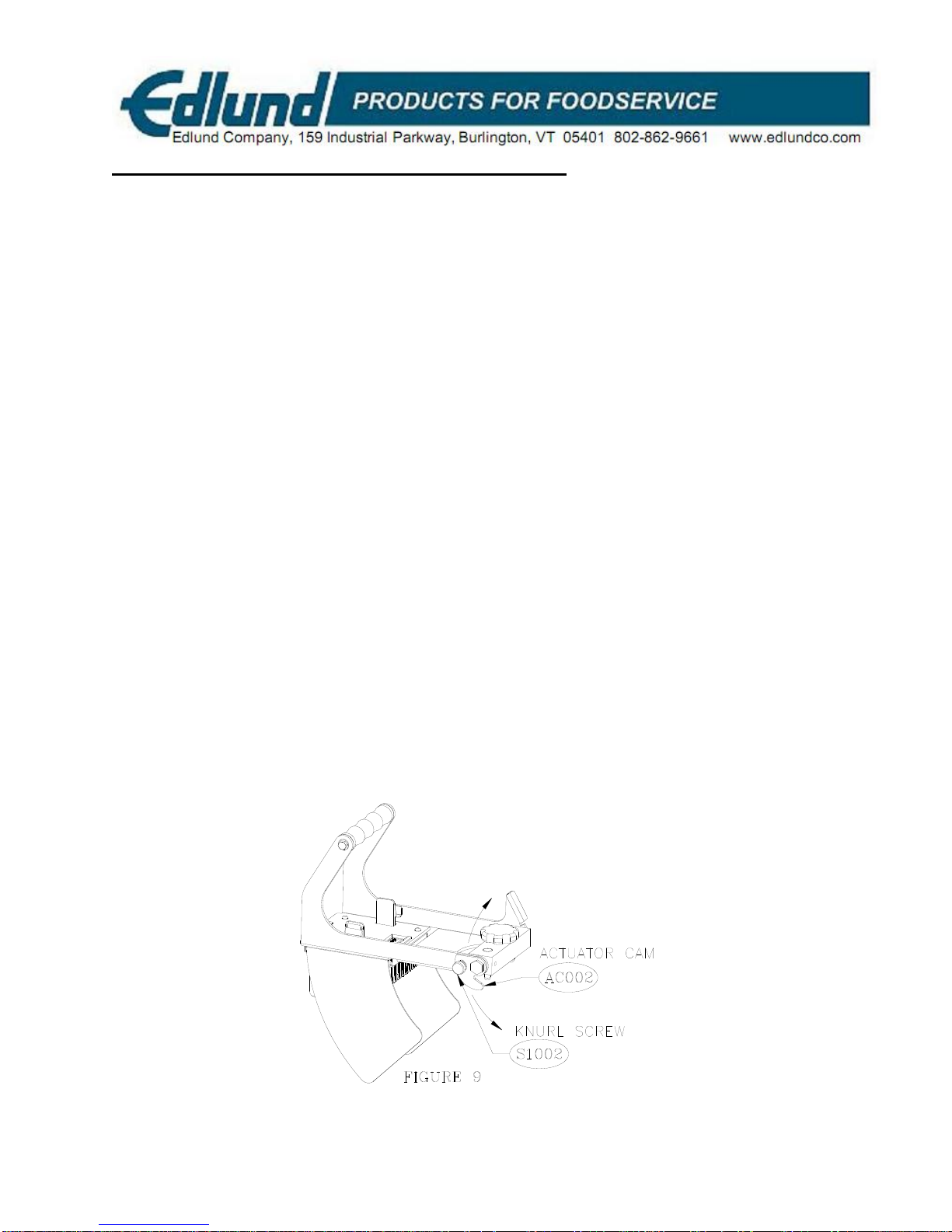

Pusher Assembly Actuator Cam AC002 Adjustment

The Pusher Assembly includes an easy adjustment for the triggering of the slicer blades

to start operating. This can be adjusted for a particular size of food product you are

slicing by having the slicing blades start operating earlier or later as the pusher is

lowered down to slice food product. Adjustment does not require the use of any tools. A

knurl screw has been provided for this and can be loosened and tightened by hand. The

knurl screw is also captivated on the pusher assembly to avoid accidental loss. To

adjust the actuator cam follow the procedure below. Proper adjustment of the actuator

cam helps ensure that the pusher fingers are in contact with the food product before the

blades start operating. When adjusted properly the food product will be held firmly while

being sliced providing the best slice possible. Follow procedure below and see Figure 9.

1. With the unit unplugged and the ON/OFF switch in the OFF position and the

pusher assembly mounted to the unit you can begin to make the actuator cam

adjustment. To adjust for slicing larger food product loosen the knurl screw by

hand and rotate the actuator cam AC002 down as needed. This will cause the

slicing blades to start operating sooner as the pusher is lowered onto the food

product. This also captures the larger food product properly between the pusher

insert fingers and blades. You can hear the actuator switch engage by listening

for the “click” sound as the pusher is lowered.

2. To adjust for slicing smaller food product loosen the knurl screw by hand and

rotate the actuator cam AC002 up as needed. This will cause the slicing blades

to start operating later as the pusher is lowered onto the food product. This also

captures the smaller food product properly between the pusher insert fingers and

blades. You can hear the actuator switch engage by listening for the “click” sound

as the pusher is lowered.

Please read thoroughly before operation and keep for future reference

11

M092 REV. C

Please read thoroughly before operation and keep for future reference

12

M092 REV. C

Trouble Shooting Guide

Problem Cause Correction

1. Not plugged into outlet. 1. Plug cord set into grounded outlet with the

same voltage as listed on the rating plate

located on the side of the motor housing.

2. Cover actuating switch

inoperative. 2. Replace leaf switch (S627) or contact dealer

/service center.

3. Switch actuator cam not

contacting roller switch bracket. 3. Adjust pusher head cam assembly (AC002).

See page “Pusher Assembly cam adjustment”

for procedure. If unit fails to energize, replace

roller switch (S626) or contact dealer /service

center.

4. On-off switch not turned on or

inoperative. 4. Contact dealer or service center.

5. Broken wire or loose terminals. 5. Contact dealer or service center.

7. Broken wire in cord set. 7. Contact dealer or service center.

6. Circuit breaker tripped. 6. Reset circuit breaker (B116) and if breaker

trips, call dealer or service center.

9. Motor failed 9. Call dealer or service center.

I. Slicer will not start.

10. No current flow through line

filter on 230-volt slicer. 10. Replace filter (F088) or call dealer/service

center.

1. Blade assembly not on guide

rails. 1. Call dealer or service center.

2. Bent or damaged pusher fingers

(old style P144) or ( new style

PI368, PI014 plastic inserts)

2. Straighten or replace pusher fingers. For new

style replace proper plastic pusher insert and

align to blades before use. See page “New Style

Pusher Assembly” for procedure.

3. Pusher mounting flange of motor

mount is bent. 3. Straighten flange or replace frame assembly

(A650/A651).

4. Loose rivet (R048). 4. Check rivets and bushings and replace as

required.

II. Pusher fingers contact

blades or pusher fingers

not centralized between

blades.

5. Pusher head misaligned 5. See page “New Style Pusher Alignment” for

procedure.

1. Worn drive link guide support. 1. Replace support ((S210).III. Blade assembly will

not stay on rails. 2. Motor mounting plate bent down. 2. Remove cover and motor and straighten

plates to be parallel to rails within (0.015) total

indicated reading.

1. Blade holder retaining screws

(S049) not tightened to correct

torque.

1. Consult assembly procedure for proper

torque of screws.

2. Holes in blades are elongated. 2. Check blades and replace as required and

torque according to assembly procedure.

IV. Blades loose on blade

carrier.

3. Some of blades on blade carrier

may have been replaced with new

blades.

3. Tighten blade holder retaining screws (S049)

to correct torque. Turn blade carrier over and

check tightness of each blade by "strumming"

back of blades. If blade or blades have dull

sound, replace and retighten to torque outlined

in assembly procedure.

Please read thoroughly before operation and keep for future reference

13

M092 REV. C

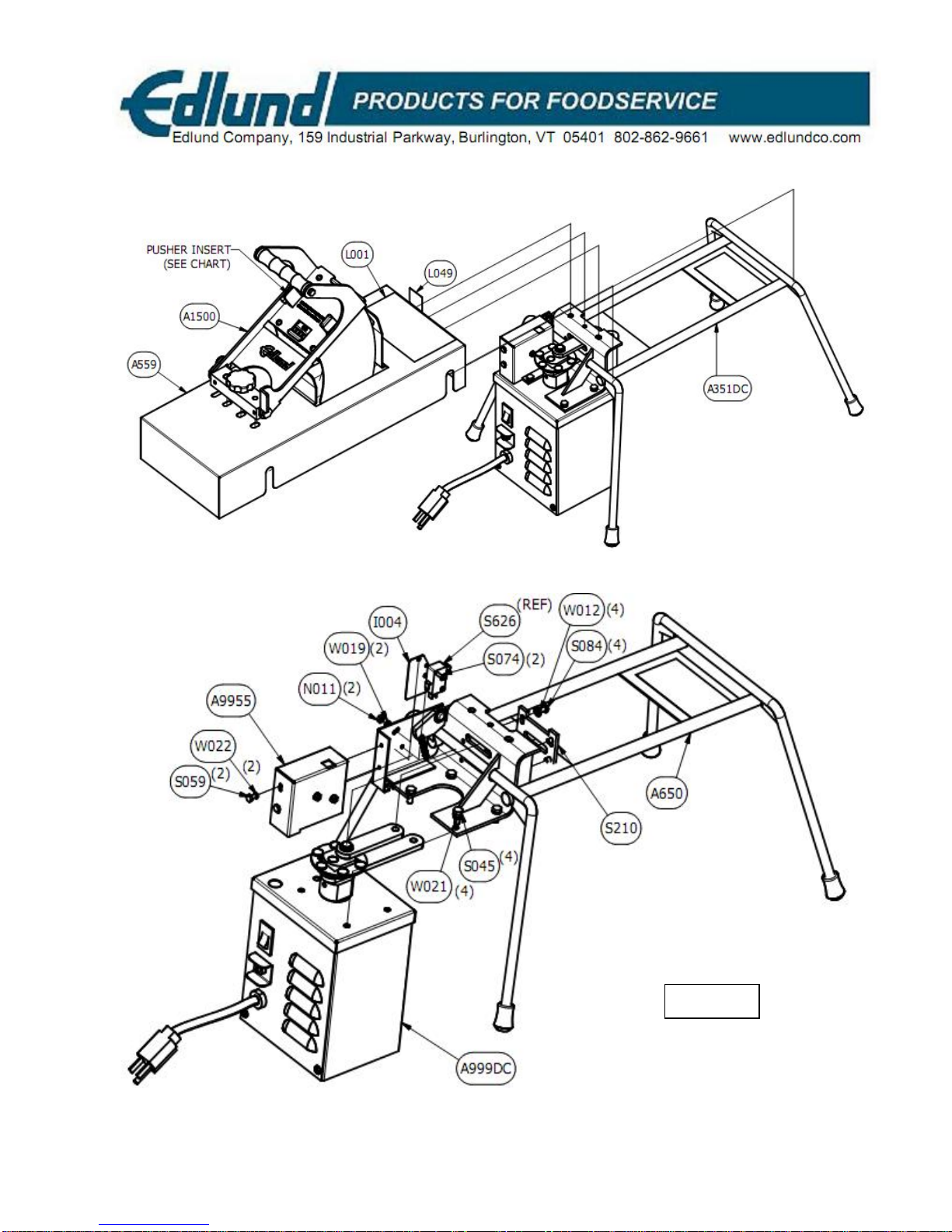

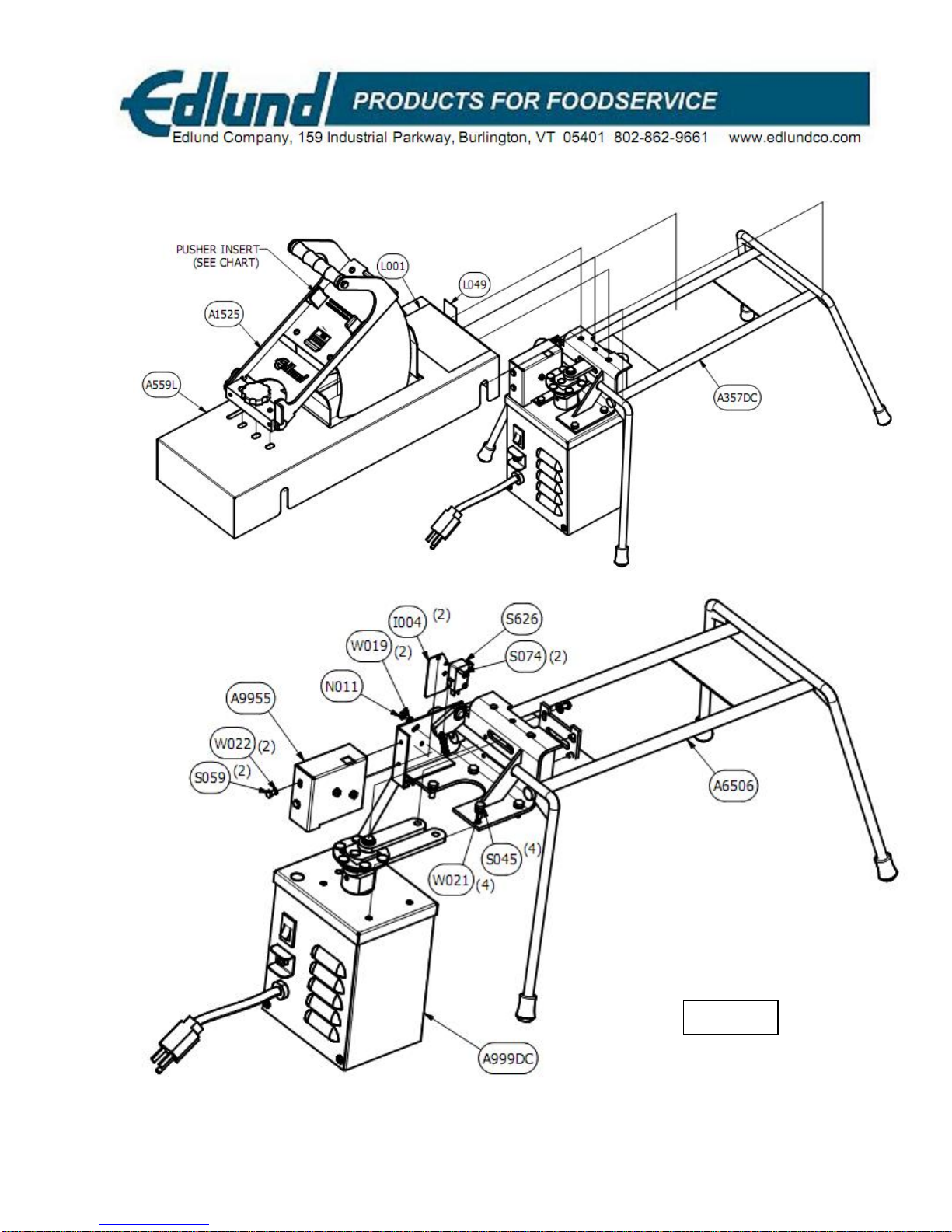

350 SLICER—115V

A351DC

Please read thoroughly before operation and keep for future reference

14

M092 REV. C

350 SLICER ASSEMBLY AND PARTS LIST—115V

QTY PART

NUMBER DESCRIPTION

1A1500 ASSEMBLY, PUSHER HEAD W/ REMOVABLE INSERT

1A351DC ASSEMBLY, 350 MOTOR & FRAME

1A559 WELDMENT, COVER 350

1L001 LABEL, WARNING

1L049 LABEL, NSF MARK

350 FRAME ASSEMBLY (A351DC)—115V

QTY PART

NUMBER DESCRIPTION

1A650 ASSEMBLY, 350 FRAME

1A9955 ASSEMBLY, LEAF MICRO SWITCH AND COVER

1A999DC ASSEMBLY, HOUSING, MOTOR & GEARBOX+LINKAGE,

115V

1I004 INSULATOR, SWITCH PAD

2N011 NUT, #4-40 BRASS

4S045 SCREW, #10-32 X 1/2, HEX HD CAP, SS

2S059 SCREW, #6-32 X 1/4 HEX HEAD, SS

2S074 SCREW, #4-40 x 5/8, SLOTTED, BRASS

4S084 SCREW, #8-32 X 5/16 S/S RHM, SLOTTED

1S210 SUPPORT, LINK GUIDANCE

1S626 SWITCH, ROLLER

4W012 WASHER, FLAT, #8 SS

2W019 WASHER, #4 INTRL TOOTH LOCK, SS

4W021 WASHER,#10 LOCK, SS

2 W022 WASHER,#6 LOCK, SS

350 PUSHER/BLADE

ASSEMBLY

BLADE

ASSEMBL

YPUSHER

INSERT SIZE

A553 PI368 3/16

A554 PI014 1/4

A567 PI368 3/8

Please read thoroughly before operation and keep for future reference

15

M092 REV. C

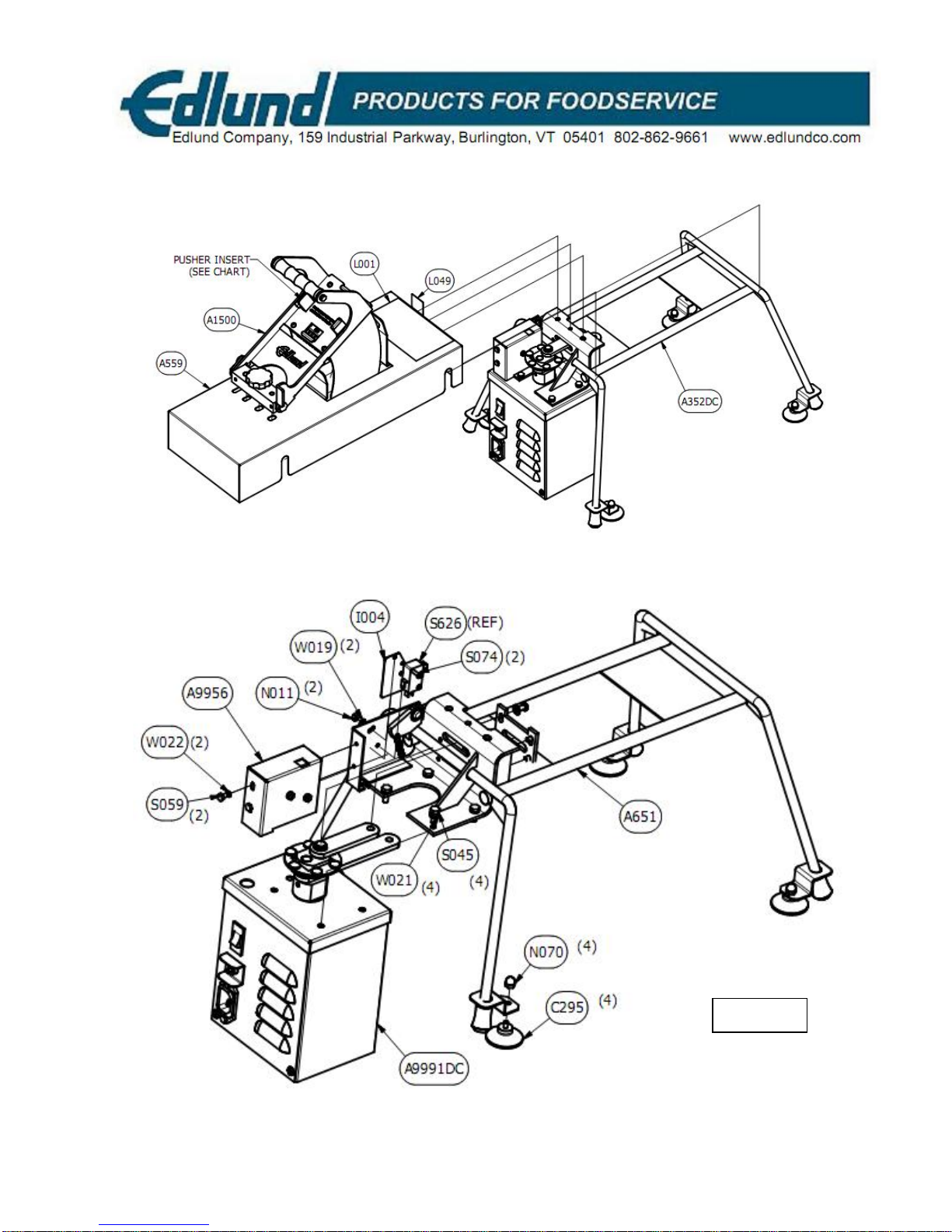

350 SLICER—230V

A352DC

Please read thoroughly before operation and keep for future reference

16

M092 REV. C

350 SLICER ASSEMBLY AND PARTS LIST—230V

QTY PART NUMBER DESCRIPTION

1A1500 ASSEMBLY, PUSHER HEAD W/ REMOVABLE

INSERT

1A352DC ASSEMBLY, 350 W/230V MOTOR

1A559 WELDMENT, COVER 350

1L001 LABEL, WARNING

1L049 LABEL, NSF MARK

350 FRAME ASSEMBLY (A352DC)—230V

QTY PART NUMBER DESCRIPTION

1A651 ASSEMBLY, 350 FRAME W/ SUCTION CUPS

1A9956 ASSEMBLY, MICRO SWITCH AND COVER, 230V

1A9991DC ASSEMBLY, 350 MOTOR/GEARBOX, 230V

4C295 CUP, RUBBER SUCTION

1I004 INSULATOR, SWITCH PAD

2N011 NUT, #4-40 BRASS

4N070 NUT, #8-32 NYLON ACORN HEX

4S045 SCREW, #10-32 X 1/2, HEX HD CAP, SS

2S059 SCREW, #6-32 X 1/4 HEX HEAD,SS

2S074 SCREW, #4-40 x 5/8, SLOTTED, BRASS

4S084 SCREW, #8-32 X 5/16 RHM, SLOTTED, SS

1S210 SUPPORT, LINK GUIDANCE

1S626 SWITCH, ROLLER

4W012 WASHER, FLAT, #8 SS

2W019 WASHER, #4 INTRL TOOTH LOCK, SS

4W021 WASHER,#10 LOCK, SS

2W022 WASHER,#6 LOCK, SS

Please read thoroughly before operation and keep for future reference

17

M092 REV. C

350XL SLICER—115V

A357DC

Please read thoroughly before operation and keep for future reference

18

M092 REV. C

350XL SLICER ASSEMBLY AND PARTS LIST—115V

QTY PART NUMBER DESCRIPTION

1A1525 ASSEMBLY, PUSHER HEAD W/ REMOVABLE INSERT,

350XL

1A357DC ASSEMBLY, 350XL MOTOR/FRAME, 115v

1A559L WELDMENT, COVER, 350XL

1L001 LABEL, WARNING

1L049 LABEL, NSF MARK

350XL FRAME ASSEMBLY (A357DC)—115V

QTY PART NUMBER DESCRIPTION

1A6506 ASSEMBLY, FRAME, 350XL

1A9955 ASSEMBLY, LEAF MICRO SWITCH AND COVER

1A999DC ASSEMBLY, HOUSING, MOTOR & GEARBOX+LINKAGE,

115V

1I004 INSULATOR, SWITCH PAD

2N011 NUT, #4-40 BRASS

4S045 SCREW, #10-32 X 1/2, HEX HD CAP, SS

2S059 SCREW, #6-32 X 1/4 HEX HEAD,SS

2S074 SCREW, #4-40 x 5/8, SLOTTED, BRASS

4S084 SCREW, #8-32 X 5/16 RHM, SLOTTED, SS

1S210 SUPPORT, LINK GUIDANCE

1S626 SWITCH, ROLLER

4W012 WASHER, FLAT, #8 SS

2W019 WASHER, #4 INTRL TOOTH LOCK, SS

4W021 WASHER,#10 LOCK, SS

2W022 WASHER,#6 LOCK, SS

350XL PUSHER/BLADE

ASSEMBLY

BLADE

ASSEMBL

YPUSHER

INSERT SIZE

A553L PI368 3/16

A554L PI014 1/4

A567L PI368 3/8

Please read thoroughly before operation and keep for future reference

19

M092 REV. C

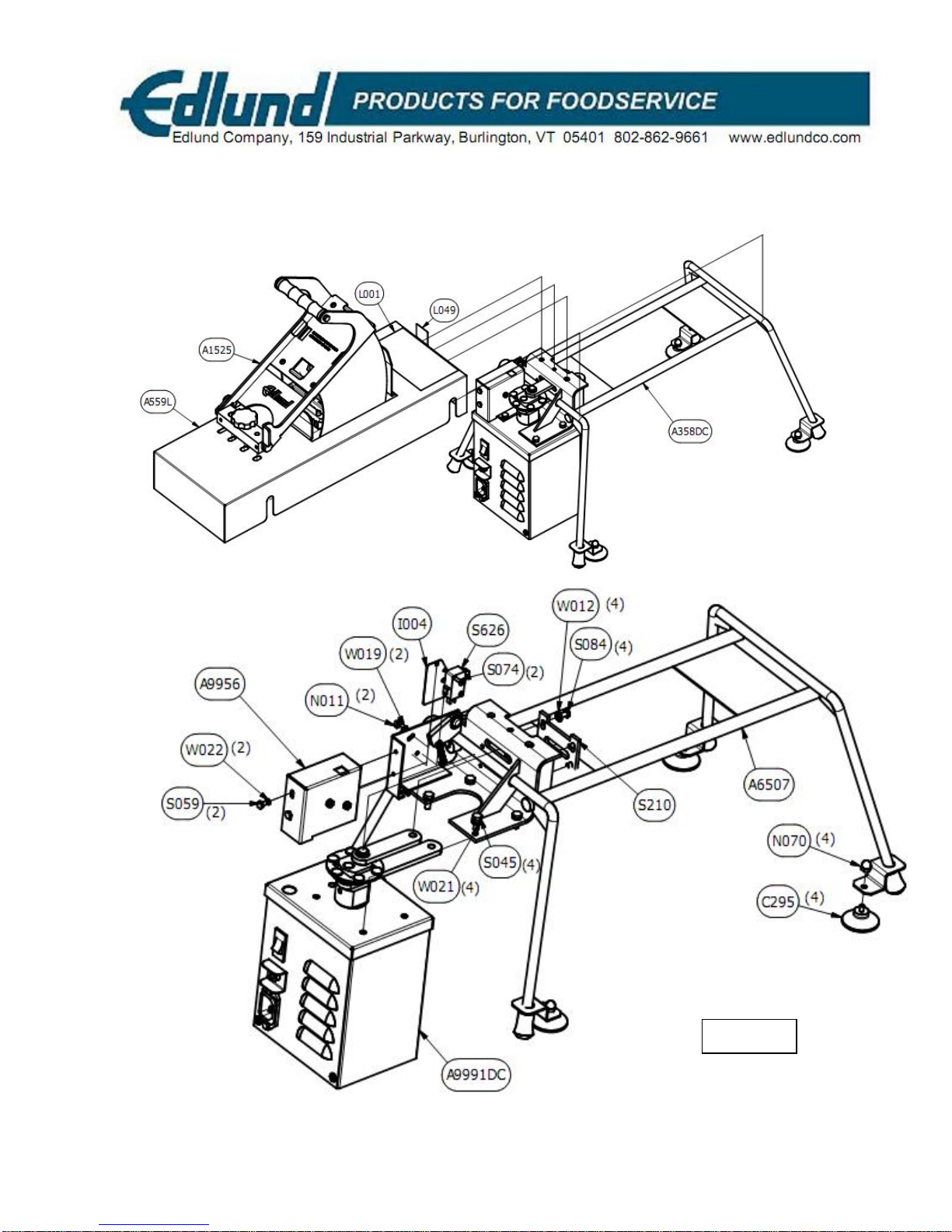

350XL SLICER—230V

A358DC

Please read thoroughly before operation and keep for future reference

20

M092 REV. C

350XL SLICER ASSEMBLY AND PARTS LIST—115V

QTY PART NUMBER DESCRIPTION

1A1525 ASSEMBLY, PUSHER HEAD W/ REMOVABLE INSERT,

350XL

1A358DC ASSEMBLY, 350XL MOTOR/FRAME, 230V MOTOR

1A559L WELDMENT, COVER, 350XL

1L001 LABEL, WARNING

1L049 LABEL, NSF MARK

350XL FRAME ASSEMBLY (A358DC)—230V

QTY PART NUMBER DESCRIPTION

1A6507 ASSEMBLY, 350XL FRAME W/SUCTION CUPS

1A9956 ASSEMBLY, MICRO SWITCH AND COVER, 230V

1A9991DC ASSEMBLY, HOUSING, MOTOR &

GEARBOX+LINKAGE, 230V

4C295 CUP, RUBBER SUCTION

1I004 INSULATOR, SWITCH PAD

2N011 NUT, #4-40 BRASS

4N070 NUT, #8-32 NYLON ACORN HEX

4S045 SCREW, #10-32 X 1/2, HEX HD CAP, SS

2S059 SCREW, #6-32 X 1/4 HEX HEAD,SS

2S074 SCREW, #4-40 x 5/8, SLOTTED, BRASS

4S084 SCREW, #8-32 X 5/16 RHM, SLOTTED, SS

1S210 SUPPORT, LINK GUIDANCE

1S626 SWITCH, ROLLER

4W012 WASHER, FLAT, #8 SS

2W019 WASHER, #4 INTRL TOOTH LOCK, SS

4W021 WASHER,#10 LOCK, SS

2W022 WASHER,#6 LOCK, SS

This manual suits for next models

1

Table of contents